Gate accordion for the garage. Installation of folding gates: an accordion for a garage and a summer residence

Many have learned to make folding gates in the form of an accordion with their own hands. This convenient design has found application in small summer cottages, where space is limited, as well as for closing the openings of garages and hangars. Accordion doors do not load the ceiling walls, perfectly preserve the microclimate in the room, and in terms of service life are not inferior to horizontal roller shutter structures.

Principle of operation

The design of folding gates is quite simple. Understanding the principle of operation, installing them in a garage or in the country is not difficult. The composition of such a sash includes panels, between which there is a flexible gasket made of rubber or other soft material that allows you to fold and unfold. In addition to laying, the elements of the web are interconnected by canopies.

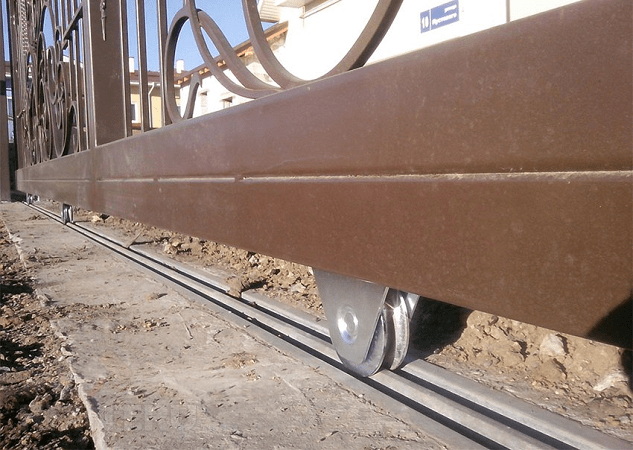

The mechanical movement of the panel occurs along the guides, which are installed from below, but the design can be additionally equipped with an upper guide. The movement of the web is carried out by a roller built into the guide.

Materials and tools

In order for the work on the manufacture of accordion gates to be carried out quickly and in an orderly manner, you should immediately stock up on all materials and tools so that at the most inopportune moment it does not turn out that something is missing.

- For the installation of racks, two metal U-shaped metal beams (channel) are required.

- To ensure the movement of the sash along the guide corner, metal rollers with bearings are needed.

- The width of the corner or channel in size must be matched by the roller, since one of these blanks will need to be made into a guide.

- For cladding, corrugated board or iron is used, preferably galvanized.

- Mineral wool or polystyrene is used as a heater.

- A metal pipe that will be used to make the frame. The optimal diameter is 25 mm.

Tools that will be needed in the production process:

- Level or plumb, as well as tape measure. Needed for measurement and control.

- Welding work can be carried out welding machine at 220V.

- Drill and screwdriver. Necessary for fasteners in the process of work.

- Bulgarian. You will need to cut the metal and clean the welding seams.

All tools and materials are available, and most of them will be available to every owner.

Load-bearing structure of the gate

Regardless of the design of the gate, supporting pillars are indispensable. In addition, the newly built garage does not yet have any extensions in the opening, so you should start work by installing the support:

- Measure the height of the opening and subtract the thickness of the guide from it. On the channels for the supports, a mark is made according to this size and the required length is cut off with a grinder.

- A metal corner is installed on the lower ends of the channel by welding.

- Channel bars are welded to the side walls of the opening and to its lower part.

- Next, the cross beams are installed. At the bottom, the beam is welded to the corners, previously installed on the channels, and is attached to the upper part of the opening with the help of anchors.

- The corner where the rollers will be installed is welded to the upper cross beam above the gate.

Thus, the basis for further assembly gates is almost ready.

Panel manufacturing and frame assembly

The main condition for the performance of accordion gates is that the elements of the canvas are absolutely the same size. Therefore, it is necessary to correctly calculate their dimensions. To do this, you can divide the width of the opening into several equal parts, while making the panel width less than 10 centimeters is not recommended.

When the number and width of the panels are determined, it's time to get to work:

- The metal tube is cut with a grinder into parts that correspond to the width and length of the panel.

- On the flat surface the gate frame is welded using transverse lintels to stiffen it.

- In order for the gate to close tightly, a special pin should be welded to the pipe of the last lower panel, which, when closed, will cling to a hole in the floor, and brackets should be welded to the outermost upper pipe of the panel and to the support table so that a lock can be hung during operation.

- The elements of the canvas are fastened together by canopies of 2 pieces on each side.

- A roller is installed on the sash panel. To do this, a metal plate is welded to the frame of the web elements with a metal pin pre-attached by welding, bent at a right angle. The diameter of the pin must match the diameter of the hole in the roller. The bent end of the pin is inserted into the hole of the roller and fastened with a washer.

Next, you need to sew up the sliding gate panels with corrugated board or galvanized iron. The gaps that form between the elements of the canvas, where the canopies are fastened, are closed with soft rubber or dense tarpaulin material. If the gate is installed in a garage or for a summer residence, then they must be insulated with polystyrene foam or mineral wool, sewing the insulation on top with a facing material, for example, plywood or chipboard.

rusolymp.ru

How to make an accordion sliding gate with your own hands

When choosing a gate, one should take into account not only the design, but also its design features. If the site has a limited area, you will need a compact entrance group that takes up a minimum of space when opened, while being functional and easy to use. Accordion gates fall under these criteria, which can be purchased ready-made or made by hand.

Characteristics and principle of operation of the device

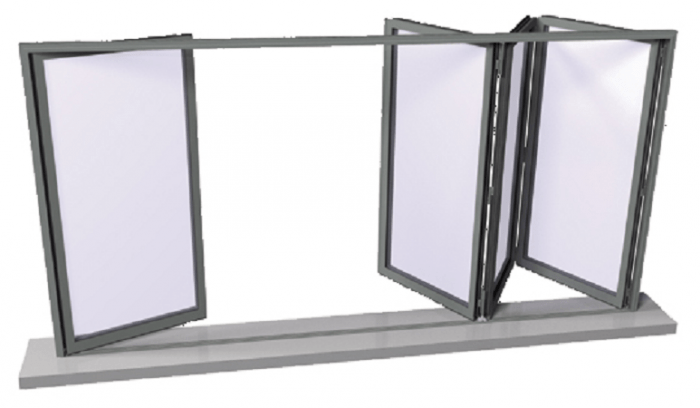

This entrance design consists of several separate panels connected by a dense flexible material (synthetic fabric, rubber), which, when opened, fold into an accordion. When closing, the canvas stretches, filling the entire opening.

Folding gates consist of a frame, in the upper part of which a crossbar is installed. It contains a guide that ensures the movement of sections. The sashes move along it on rollers like wardrobe doors.

The fabrics of the construction are solid. The material for their manufacture is sandwich panels with high sound and thermal insulation properties, low cost. Between themselves, they are fastened with loops, which are fixed on the supporting frame. They provide opening of shutters at an angle of 90˚, and closing - at an angle of 180˚.

Additional option: a wicket can be installed in the plane of the gate, and the structure can also be equipped with automation.

Automation installation

To make it more convenient to use the sliding entrance system will allow the installation of automation. For this, a top or bottom drive system is used. The first one is installed in the upper part of the wings and does not require laying the foundation, but has height restrictions - no more than 4.5 m.

Benefits of folding doors:

- occupy a minimum of free space due to its compactness;

- can be installed from outside or inside opening;

- unpretentious in operation, serve for a long time;

- strong. Additionally, the supporting frame of the structure is reinforced with a metal profile, stiffeners, which makes the gate reliable, burglar-resistant;

- are not difficult to manufacture. You can build folding gates with your own hands, which will not only save money, but also make a design that perfectly matches the surrounding space.

Note: accordion gates are used for garages, cottages, hangars, pavilions, where there is not enough space to install an entrance structure with swing or sliding doors. During their installation, the load does not fall only on the ceiling, it is evenly distributed on the walls.

Varieties of folding structures

Folding doors can be made in two types:

- hinged construction. It consists of two canvases, which are stretched from the supporting pillars to the middle of the opening, where they are connected. When closed, swing gates fold like an accordion against the walls;

- rollback system. It is a single section that fills the entire opening, and when opened, folds compactly along one side of it.

Manufacturing sequence

To make an accordion gate with your own hands, you will need:

- 2 channels to be used as supports;

- corrugated pipe for the manufacture of the base with a section of 25x25 mm;

- corner guide;

- sandwich panels or other sheet sheathing material;

- fittings (rollers on bearings, hinges);

- I-beam - a profile for fixing the structure to bearing walls;

- primer composition.

Of the tools you will need:

- welding + set of electrodes;

- angle grinder;

- screwdriver;

- drill;

- Bulgarian;

- devices for checking the evenness of the structure.

Preparatory work

Before you make a folding gate, you should draw up their drawing. Given the width of the opening and the features of the selected type of gate, determine the number and dimensions of the sections. For a sliding design, they must be the same size.

Attention: the diagram must show all technological features accordion gates - opening markings, height, width of racks, dimensions of panels and gaps between them, attachment points for fixing elements.

Installation of supports

If a Garage Doors installed for the first time, it is necessary to strengthen the opening. For this, a channel is used. It should not occupy the entire width of the opening, but only the part where the rollers will not be placed. A paw made of metal is welded to their lower part. Then, with the help of channel anchors, they are attached to the opening.

Frame assembly

According to the dimensions of the panels are cut metal pipes required sizes. They are laid out on a flat surface to avoid distortion, and the frame is welded.

Tip: to strengthen the structure will allow transverse and diagonal lintels, which are located along the entire plane of the gate.

Installation of canopies

The panels of the entrance gate-accordion are connected with the help of canopies. For this, loops on bearings are used (for each section, 2 pcs.). They are fastened so that the structure develops according to the principle of an accordion.

Fastening the guide and rollers

After that, a transverse beam is laid on the pillars, into which the guide for the rollers is mounted / welded. To attach the roller to the edge of the folding section, a plate must be welded. A pin is attached to it, which is pre-hardened. Its free end is bent at an angle of 90˚, inserted into the roller and secured with nuts.

Structural sheathing

The frame of the accordion gate is sheathed with sheet material. It is fastened with rivets, screws, welding. The gaps formed between the panels are covered with a tarpaulin.

Please note: when sheathing sections, it is necessary to provide a place for installing a hinged / mortise lock.

Additional processing

To maintain a favorable microclimate in the garage, the structure must be insulated. For this, foam or mineral wool is used. After inserting the insulation, the inner sides of the panels are sheathed with plywood / fiberboard.

To avoid restrictions on dimensions, the installation of a drive with a lower stop will allow. But this system has a drawback - it is necessary to lay the foundation for it.

Installation of sliding gates, working on the principle of an accordion, is an ideal option for decorating the entrance to a summer house or garage, where there is a lack of free space. This design is not only compact and practical, it can be made even more functional with the help of automation.

zaborstroj.ru

Folding gates "accordion"

In life, situations are not uncommon when ordinary entrance garage doors no longer fit into the space of the garage or space saving is required. In such cases, an excellent alternative to traditional gates will be accordion folding gates, the design of which allows you to get a functional detail with little use of space. Among the undoubted advantages of such a design, the following points can be noted:

- due to folding according to the accordion principle, the design does not require additional space inside or outside the room;

- installation of swing gates is possible from any side of the opening;

- in installed structures, the weight is distributed in such a way that the main load falls on the walls, without affecting the roof;

- sliding systems are easy to operate and very easy to open with a lot of snow, without requiring cleaning the area.

Garage doors, acting on the principle of an accordion, are not only an aesthetically beautiful element, but also carry a functional load, which allows them to be used in industrial buildings

Garage doors, acting on the principle of an accordion, are not only an aesthetically beautiful element, but also carry a functional load, which allows them to be used in industrial buildings

Gate accordion: the principle of the device

A design feature of sliding gates, functioning like accordion bellows, is the presence of several separate panels that are connected by means of a flexible but dense material, which can be thick rubber or dense fabric. The sashes are driven by rollers located at the vertical ends, which move along special guides. A similar scheme is applied in hinged doors cabinets.

The modern construction market offers a large number of ready-made solutions or there is the option of manufacturing swing garage doors on an individual order. Most often, the manufacturing material is ordinary sandwich panels, since this material is distinguished by low cost and excellent sound and heat insulation qualities.

Also, the advantages that sliding entrance and garage swing gates have include the ease of making such a design with your own hands, which allows you not only to save money, but also to end up with a design that fits perfectly into the space.

Making entrance swing gates with your own hands

For the manufacture of garage sliding gates, which can be an excellent solution for a summer cottage garage, you will need:

- welding machine and a set of electrodes;

- angle grinder;

- screwdriver and a set of different screws;

- drill;

- brush for priming metal parts.

As materials for the manufacture of garage doors such as "accordion" do-it-yourself are used:

- metal corners;

- square pipe;

- metallic profile;

- primer;

- hinges, rollers;

- I-beam, which will be used to fasten the gate to the bearing walls.

Sequence of installation of swing garage doors

The first step in the installation of swing gates is the installation of the channel, since the finished structure will be attached to it. At the same time, during the installation process, it should be borne in mind that the channel will not need to be installed to the entire height of the doorway, but to subtract the dimensions of the carrier flight, which serves to accommodate the roller wheels.

The second step is counting and section preparation. The number of individual sections should be determined in advance, depending on the width of the room and on the type of garage door chosen. Most the best option will make a schematic sketch of the future design with his own hands, which will greatly facilitate the installation process in the future. The main condition for swing doors is the same size of each panel.

An important detail of the sliding gates will be rollers that will ensure the normal movement of the leaves.

An important detail of the sliding gates will be rollers that will ensure the normal movement of the leaves.

The next step in the manufacture of a gate for a summer residence with your own hands will be to assemble the frame. At this stage, pre-prepared metal pipes are used, which are cut in accordance with the dimensions of the panels. When welding the frame, it is better to choose a smooth and even surface in order to avoid distortions, which will negatively affect the finished gate.

To give the entire structure the required rigidity, when welding the frame, it is recommended to weld transverse or diagonal sections along the entire perimeter of the door. If the gate is supposed to be locked during operation, then it is necessary to provide for the presence in the leaves of a place for installing a rod that acts as a locking element. Also, on the last panel, you will need to provide a place to place a mortise lock or lugs for a conventional padlock.

The best option may be bearing canopies, which should be mounted at the place where the wings are articulated with each other in order to ensure compliance with the opening of the doors with an "accordion".

The last stage of installation will be the installation of movable rollers. In the form of a guide, when installing gate rollers for a summer residence, a corner is most often used, which needs to be welded to the cross beam.

After the installation of the entire structure, finishing work takes place, which includes sheathing and insulation of the garage door for summer cottages. The choice of material for sheathing depends on the preferences of the owner. To fix the sheathing material, you will need self-tapping screws and a drill. It is also possible to fasten with metal rivets that need to be welded. All the gaps that may be between the gate leaves for giving must be closed with dense material, such as thick rubber or tarpaulin, which will allow you to withstand Negative influence weather factors.

The issue of garage door insulation should be approached very carefully, since maintaining the required microclimate inside the room is important. As a heater, mineral wool, polystyrene or any modern material. After the insulation layer is located on the inside of the sashes, it must be closed from above with a fiberboard sheet or any available facing material.

Sliding gate systems "accordion" have found their application in summer cottages, where the lack of free space is especially relevant

Sliding gate systems "accordion" have found their application in summer cottages, where the lack of free space is especially relevant

It should be noted that with a competent approach and due preliminary preparation the process of creating a gate for a summer residence with your own hands does not take away a large number time and can be performed alone without the involvement of partners.

Automatic garage and entrance gates

A more expensive, but also more convenient option for sliding garage doors are automatic models that can be easily opened with a remote control. Similar Models must be equipped with electromechanical drives. Manufacturers currently offer two drive options:

- Drive with top suspension. In this embodiment, the mechanism is mounted at the top of the sashes. When installing this option, it is not necessary to create a special foundation for the drive. But the downside is the limited height of the gate, which should not exceed 4.5 meters.

- Drive with bottom stop. In this case, it is possible to avoid restrictions on overall dimensions. But when installing this option it will be necessary to create a foundation to accommodate the drive across the entire width, which will affect the cost of the entire structure.

Installation of sliding gates built according to the "accordion" principle is an ideal solution when there is not enough free space. A installation automatic gate will be not only a practical option, but also a very convenient solution, since it will allow you to open the garage door with the easy touch of just one button.

ozabore.com

Types of folding gates and their characteristics

Folding gates are a good alternative if the design of swing gates is no longer to your satisfaction. The main reason for replacing them turns out to be mainly that the sashes require a lot of space to open.

The main advantage of any folding gate is space saving both outside and inside the building. In addition, the main part of the folding structures is suitable for use in places where a lot of snow falls. Everyone knows how difficult it can be to open swing gates after heavy snowfalls.

Folding products are of the following types:

- Sectional.

- Roller blinds.

- Harmonic.

Let's consider them in order.

Sectional doors are a set of movably interconnected horizontal sections. Sections in gates intended for domestic use, such as a garage door in a private house, usually measure 40-60 cm in height and 1.9-9.4 meters in length. Of these, gates are typed, with a height of 1.35 to 4 meters. Usually this is enough to satisfy the needs of the average resident of a private house.

The principle of operation of such gates is that the guide rails of the gate, installed on the sides of the opening, continue on the ceiling. Thus, when opening, the gate, sliding along the guides, is located horizontally on the ceiling above the entrance.

This design has its pros and cons:

- These gates do not occupy the usable area in front of the opening or inside, on the sides of it. The mechanism for opening them is also located at the top, on the ceiling, and modern garage owners have not yet come up with ways to store useful things there.

- Of the types of folding products we have listed, sectional ones can be recognized as the most sound and heat insulating. The panels are large enough. For them, sandwich panels are usually used, which are connected using hinges. In addition, many manufacturers of such products make the edges of the panels curly in the form of a tongue-and-groove lock to prevent blowing through and even cover these edges with a sealant. So when the gate is closed, neither cold air nor dust enters the room.

- This is a strong and durable design, resistant to mechanical stress. Having installed such a product once, you will use it for a long time.

- To protect against unauthorized entry, such products are usually equipped with a valve - a spring bolt. It is suitable if the gate is always locked only from the inside or in a room, for example, a garage has another additional entrance. To close the gate from the outside, a bolt-type lock with handles is installed on them, by pulling which you can close or open the gate. On the inside, a cable is attached to the handle, which, when turned, pulls the crossbar out of the groove. Such structures are opened both by means of an automatic electric drive and manually.

- Depending on the needs of the garage owner, windows can be made in the sections, and there can also be a built-in wicket door right in the door leaf so that you can enter the room without opening the entire gate. Although this increases the cost of construction.

- Safety measures for automatic structures are that they are usually equipped with photocells: the canvas stops moving if something is between the floor and the edge of the gate. Also, some manufacturers equip sandwich panels with special devices that prevent pinching fingers between the gate panels.

The main disadvantage of such a device can be considered that the room should be spacious. Its length must exceed the height of the opening by at least one and a half times, otherwise the gate simply will not fit. Also they are quite expensive.

Roller blinds or roll constructions consist of plastic or metal narrow lamellas flexibly fastened together. The principle of their operation is that the flexible door leaf, sliding along the guide profiles, rises and is wound on a special drum located at the top of the opening inside a special box, just as it happens with roller blinds.

Roller shutters have the following advantages:

- They are very easy to operate and install: some non-professional craftsmen assemble them themselves from suitable strips of metal and plastic, which can also be transparent.

- Roller shutters are very compact both in closed and in open form, they do not take up space either in the garage or outside it.

- Rolling gates are quite cheap compared to all other types of gates. In addition, they are very maintainable, both individual lamellas and the entire curtain can be replaced, while the drum and the drive do not need to be changed.

- They look neat and beautiful and cover the room well from dust.

However, the list of negative aspects of roller shutters is also impressive, and their most important unpleasant property can be considered the fact that, due to their compactness, they cannot resist mechanical damage well, which means that they can be hacked relatively easily, even if they locked or padlocked.

Also, the lamellas of such gates have a limitation in thickness and width, there are many of them, cracks may occur in the places of fastenings, because of this, their thermal insulation is very doubtful. At temperatures below zero, the surface of the gate can become covered with ice, and this makes it difficult to open them. Thus, the use of roller shutters is limited, for example, to guarded garage complexes and premises, for which the vulnerability of such a design will not be critical.

"Accordion" is quite popular today. The canvas of such gates consists of vertically arranged panels, interconnected by hinges and sealed with some kind of flexible material - rubber or fabric. A sealing tape or, for example, a nylon brush is also mounted at the bottom and top. At the moment of opening and closing, the rollers mounted on the vertical ends slide along the guide rail, which can be located both in the upper part of the opening and in its foundation.

In case of installation of a guide rail (guide beam - for industrial models) at the top of the opening, its height should be limited to 4.5 meters. Thus, open structures can be located both outside and inside the room, depending on which corners of the panels interact with the guides. The width of the opening, in this case, mainly affects the number of panels, although it narrows somewhat when the gate is folded.

In everyday life, in residential premises, the design of doors in the form of a folding accordion has been used for a long time precisely in order to save space and eliminate the "dead zone" in the room needed to open and close the door. In turn, accordion doors have been successfully used for a long time in large garages, workshops of enterprises, in rooms intended for storing large-sized equipment and machinery - train depots, aircraft hangars, industrial enterprises; but they are very slowly and reluctantly penetrating into private use as entrance doors or garage doors.

Although the design has undeniable advantages, and craftsmen successfully master their manufacture with my own hands. AT recent times the number of firms that make such gates to order on a turn-key basis is growing.

Accordingly, the advantages of the design can be called:

- Such tilt-and-fold gates can be used to cover an opening of any width: the folded structure will eventually take up not so much of the opening.

- These structures can be folded both inward and outward from the opening. The minimum space required to open the structure will be equal to the width of one sash-panel. Accordingly, the resistance of the "accordion" to wind loads is much higher than that of swing gates of the same size.

- Accordion doors are perfect in cases where it is undesirable to load the upper part of the opening: the weight is distributed so that all the load falls on the walls only.

- Being made from suitable materials, accordion doors can provide good sound and heat insulation.

Among the disadvantages of this design can be called the difficulty of installing systems against penetration: not every lock is suitable for a folding structure. In addition, during intensive use, the seal between the panels is damaged: the door design provides for a much stronger tension on the folds than, for example, for the seal between the panels of sectional doors.

Insulated products for summer cottages can be folded and folding. Their chain mechanism is very convenient and the adjustment takes place in several movements.

And in conclusion of the article, we will give a comparison of gates of different types using the example of a specific task. So, to close an opening 12 meters wide and 6 meters high, you can use any type of gate.

At the same time, swing or sliding type gates will require at least 6 meters on each side of the opening. For sectional doors, as we remember, above the door it is required to allocate an area the size of the opening itself for the installation of guide rails and the drive.

Roller shutters of this size will require a powerful drive and a fairly large box for the drum. At the same time, the accordion-type gates will occupy, depending on the material, approximately one square meter to the left and right of the opening. It is important that such gates can be manually opened, if necessary, by one person sequentially one panel-sash, while it is simply impossible to open similar sectional or roll structures alone.

Many have learned to make folding gates in the form of an accordion with their own hands. This convenient design has found application in small summer cottages, where space is limited, as well as for closing garages and hangars. Accordion doors do not load the ceiling walls, perfectly preserve the microclimate in the room, and in terms of service life are not inferior to horizontal roller shutter structures.

Principle of operation

The design of folding gates is quite simple. Understanding the principle of operation, installing them in a garage or in the country is not difficult. The composition of such a sash includes panels, between which there is a flexible gasket made of rubber or other soft material that allows you to fold and unfold. In addition to laying, the elements of the web are interconnected by canopies.

The mechanical movement of the panel occurs along the guides, which are installed from below, but the design can be additionally equipped with an upper guide. The movement of the web is carried out by a roller built into the guide.

Principle of operation.

Materials and tools

In order for the work on the manufacture of accordion gates to be carried out quickly and in an orderly manner, you should immediately stock up on all materials and tools so that at the most inopportune moment it does not turn out that something is missing.

- For the installation of racks, two metal U-shaped metal beams (channel) are required.

- To ensure the movement of the sash along the guide corner, metal rollers with bearings are needed.

- The width of the corner or channel in size must be matched by the roller, since one of these blanks will need to be made into a guide.

- For cladding, corrugated board or iron is used, preferably galvanized.

- Mineral wool or polystyrene is used as a heater.

- A metal pipe that will be used to make the frame. The optimal diameter is 25 mm.

Tools that will be needed in the production process:

- Level or plumb, as well as tape measure. Needed for measurement and control.

- Welding work can be carried out with a 220V welding machine.

- Drill and screwdriver. Necessary for fasteners in the process of work.

- Bulgarian. You will need to cut the metal and clean the welding seams.

All tools and materials are available, and most of them will be available to every owner.

Load-bearing structure of the gate

Support pillars.

Regardless of the design of the gate, supporting pillars are indispensable. In addition, the newly built garage does not yet have any extensions in the opening, so you should start work by installing the support:

- Measure the height of the opening and subtract the thickness of the guide from it. On the channels for the supports, a mark is made according to this size and the required length is cut off with a grinder.

- A metal corner is installed on the lower ends of the channel by welding.

- Channel bars are welded to the side walls of the opening and to its lower part.

- Next, the cross beams are installed. At the bottom, the beam is welded to the corners, previously installed on the channels, and is attached to the upper part of the opening with the help of anchors.

- The corner where the rollers will be installed is welded to the upper cross beam above the gate.

Thus, the basis for further assembly gates is almost ready.

Panel manufacturing and frame assembly

The main condition for the performance of accordion gates is that the elements of the canvas are absolutely the same size. Therefore, it is necessary to correctly calculate their dimensions. To do this, you can divide the width of the opening into several equal parts, while making the panel width less than 10 centimeters is not recommended.

When the number and width of the panels are determined, it's time to get to work:

- The metal tube is cut with a grinder into parts that correspond to the width and length of the panel.

- On a flat surface, the gate frame is welded using transverse jumpers to stiffen it.

- In order for the gate to close tightly, a special pin should be welded to the pipe of the last lower panel, which, when closed, will cling to a hole in the floor, and brackets should be welded to the outermost upper pipe of the panel and to the support table so that a lock can be hung during operation.

- The elements of the canvas are fastened together by canopies of 2 pieces on each side.

- A roller is installed on the sash panel. To do this, a metal plate is welded to the frame of the web elements with a metal pin pre-attached by welding, bent at a right angle. The diameter of the pin must match the diameter of the hole in the roller. The bent end of the pin is inserted into the hole of the roller and fastened with a washer.

Next, you need to sew up the sliding gate panels with corrugated board or galvanized iron. The gaps that form between the elements of the canvas, where the canopies are fastened, are closed with soft rubber or dense tarpaulin material. If the gate is installed in a garage or for a summer residence, then they must be insulated with polystyrene foam or mineral wool, sewing the insulation on top with a facing material, for example, plywood or chipboard.

rusolymp.ru

Folding gate "Accordion": making your own hands

In life, situations are not uncommon when ordinary entrance garage doors no longer fit into the space of the garage or space saving is required. In such cases, an excellent alternative to traditional gates will be accordion folding gates, the design of which allows you to get a functional detail with little use of space. Among the undoubted advantages of such a design, the following points can be noted:

- due to folding according to the accordion principle, the design does not require additional space inside or outside the room;

- installation of swing gates is possible from any side of the opening;

- in installed structures, the weight is distributed in such a way that the main load falls on the walls, without affecting the roof;

- sliding systems are easy to operate and very easy to open with a lot of snow, without requiring cleaning the area.

Garage doors, acting on the principle of an accordion, are not only an aesthetically beautiful element, but also carry a functional load, which allows them to be used in industrial buildings

Garage doors, acting on the principle of an accordion, are not only an aesthetically beautiful element, but also carry a functional load, which allows them to be used in industrial buildings

Gate accordion: the principle of the device

A design feature of sliding gates, functioning like accordion bellows, is the presence of several separate panels that are connected by means of a flexible but dense material, which can be thick rubber or dense fabric. The sashes are driven by rollers located at the vertical ends, which move along special guides. A similar scheme is used in the swing doors of cabinets.

The modern construction market offers a large number of ready-made solutions, or there is the option of manufacturing swing garage doors to order. Most often, the manufacturing material is ordinary sandwich panels, since this material is distinguished by low cost and excellent sound and heat insulation qualities.

Also, the advantages that sliding entrance and garage swing gates have include the ease of making such a design with your own hands, which allows you not only to save money, but also to end up with a design that fits perfectly into the space.

Making entrance swing gates with your own hands

For the manufacture of garage sliding gates, which can be an excellent solution for a summer cottage garage, you will need:

- welding machine and a set of electrodes;

- angle grinder;

- screwdriver and a set of different screws;

- drill;

- brush for priming metal parts.

As materials for the manufacture of garage doors such as "accordion" do-it-yourself are used:

- metal corners;

- square pipe;

- metallic profile;

- primer;

- hinges, rollers;

- I-beam, which will be used to fasten the gate to the bearing walls.

Sequence of installation of swing garage doors

The first step in the installation of swing gates is the installation of the channel, since the finished structure will be attached to it. At the same time, during the installation process, it should be borne in mind that the channel will not need to be installed to the entire height of the doorway, but to subtract the dimensions of the carrier flight, which serves to accommodate the roller wheels.

The second step is counting and section preparation. The number of individual sections should be determined in advance, depending on the width of the room and on the type of garage door chosen. The best option would be to make a schematic sketch of the future design with your own hands, which will greatly facilitate the installation process in the future. The main condition for swing doors is the same size of each panel.

An important detail of the sliding gates will be rollers that will ensure the normal movement of the leaves.

An important detail of the sliding gates will be rollers that will ensure the normal movement of the leaves.

The next step in the manufacture of a gate for a summer residence with your own hands will be to assemble the frame. At this stage, pre-prepared metal pipes are used, which are cut in accordance with the dimensions of the panels. When welding the frame, it is better to choose a smooth and even surface in order to avoid distortions, which will negatively affect the finished gate.

To give the entire structure the required rigidity, when welding the frame, it is recommended to weld transverse or diagonal sections along the entire perimeter of the door. If the gate is supposed to be locked during operation, then it is necessary to provide for the presence in the leaves of a place for installing a rod that acts as a locking element. Also, on the last panel, you will need to provide a place to place a mortise lock or lugs for a conventional padlock.

The best option may be bearing canopies, which should be mounted at the place where the wings are articulated with each other in order to ensure compliance with the opening of the doors with an "accordion".

The last stage of installation will be the installation of movable rollers. In the form of a guide, when installing gate rollers for a summer residence, a corner is most often used, which needs to be welded to the cross beam.

After the installation of the entire structure, finishing work takes place, which includes sheathing and insulation of the garage door for summer cottages. The choice of material for sheathing depends on the preferences of the owner. To fix the sheathing material, you will need self-tapping screws and a drill. It is also possible to fasten with metal rivets that need to be welded. All the gaps that may be between the gate leaves for the cottage must be closed with dense material, such as thick rubber or tarpaulin, which will withstand the negative effects of weather factors.

The issue of garage door insulation should be approached very carefully, since maintaining the required microclimate inside the room is important. Mineral wool, polystyrene foam or any modern material can be used as a heater. After the insulation layer is located on the inside of the sashes, it must be closed from above with a fiberboard sheet or any available facing material.

Sliding gate systems "accordion" have found their application in summer cottages, where the lack of free space is especially relevant

Sliding gate systems "accordion" have found their application in summer cottages, where the lack of free space is especially relevant

It should be noted that with a competent approach and proper preliminary preparation, the process of creating a gate for a summer residence with your own hands does not take a lot of time and can be done alone without involving companions.

Automatic garage and entrance gates

A more expensive, but also more convenient option for sliding garage doors are automatic models that can be easily opened with a remote control. Such models must be equipped with electromechanical drives. Manufacturers currently offer two drive options:

- Drive with top suspension. In this embodiment, the mechanism is mounted at the top of the sashes. When installing this option, it is not necessary to create a special foundation for the drive. But the downside is the limited height of the gate, which should not exceed 4.5 meters.

- Drive with bottom stop. In this case, it is possible to avoid restrictions on overall dimensions. But when installing this option, it will be necessary to create a foundation to accommodate the drive across the entire width, which will affect the cost of the entire structure.

Installation of sliding gates built according to the "accordion" principle is an ideal solution when there is not enough free space. And installing an automatic gate will not only be a practical option, but also a very convenient solution, since it will allow you to open the garage door with a light touch of just one button.

ozabore.com

Folding gates for a garage and a summer house with your own hands

When installing a gate with your own hands on the site, it is always difficult to choose the right design. To a greater extent, it depends on the existing or planned fence. If it is low and made of lightweight materials, then there is no point in making the gate massive.

Folding gates "accordion"

Their type is also affected by the size of the site: if it is small and you need to save every meter, then you need to choose a design that, when opened, does not take up much space, but at the same time will not restrict transport at the entrance.

The best option for such conditions are folding gates "accordion". They are quite simple and reliable in operation, they can be made from any comfortable material with your own hands.

Folding doors "accordion" are often installed in garages, hangars, pavilions with large openings. This design does not load the floors, and the walls bear the entire load. They keep the room temperature well and have a long service life.

Device principle

Folding gates, working on the principle of "accordion", consist of several panels. They are fastened together by a flexible dense material (rubber, dense fabric, etc.) and canopies. The panels move along the opening along one or two guides with the help of a roller.

There are many companies involved in the production of folding gates "accordion" for individual orders. They usually produce them from sandwich panels. Such material has good sound and heat insulation.

Described below detailed instructions how to make folding garage doors with your own hands.

Necessary material for the garage door

- Two channels. They will be used as racks.

- Two metal rollers on bearings for the movement of the valves along the guide.

- Channel or corner to be used as a guide. The size depends on the chosen roller.

- Profiled sheet or sheets of galvanized iron for cladding.

- Styrofoam or mineral wool for insulation.

- A metal tube, round, rectangular or a suitable size for the frame of the gate panels (diameter 25 mm for the tube).

Necessary tools for the job

- Roulette, level and corner for marking.

- The welding machine is semi-automatic with a power of 220 W.

- Screwdriver and drill for fasteners.

- Bulgarian for cutting metal and cleaning seams after welding.

Installation of load-bearing posts for gates

If the garage has just been built, then, as a rule, the opening for the gate in the area of \u200b\u200bthe walls is not reinforced with anything. Therefore, we take two channels with a length equal to the height of the opening, minus the thickness of the transverse beam for the roller. A metal "paw" is welded to the lower edge of the channel. Further, with the help of anchors, the channel is attached to the bottom of the opening and to the wall.

If there is no channel, then it is possible to weld a frame from the corners and metal jumpers along the width of the garage wall and attach it with anchors.

The cross beam, to which the roller corner will be attached in the future, is laid on the pillars and welded to them. The beam is welded to the upper part of the opening or fastened with bolts.

Calculate the number of panels for the gate

The number of panels and their size depend on the length of the opening and on the type of folding garage door. If you have a poor idea of them, then it is better to make a schematic sketch before starting work. It is necessary to clearly mark the opening, take into account the size of the racks, the gap between the panels and their width.

The desire to make a door in the garage also needs to be taken into account in advance. In this case, it is most convenient to make one leaf of the gate hinged. The main condition for a sliding sash is that all panels are the same size.

welding table

Building a garage door frame

When you have decided on the size of the wings, you can start making folding gates with your own hands. To do this, we take metal tubes and cut them to the size of the panels.

It is advisable to cook the frame with your own hands on a previously prepared flat surface so that there are no distortions. To give additional structural rigidity to the finished frame, we weld additional transverse or diagonal jumpers.

The frame for garage doors is made in a similar way from the same metal profile.

To lock the sliding sash, you can make special fasteners for the locking pin in each panel, which will hold the garage door, clinging to the holes in the garage floor. Or weld lugs for a barn lock onto the edge panel of the sash and the support post.

Installation of canopies on gate leaves

We select canopies that can withstand the weight of the wings. For this, bearing canopies are better suited. Sliding sash panels are also connected with canopies, two canopies for each panel. These canopies should allow the folding sash to fold completely like an accordion.

For a swing sash, bearing canopies are also suitable, only for convenience, you need to take into account in advance that the sash opens outward.

Installing a roller on a folding sash

The guide for the roller will serve as a corner. We weld it to the beam above the gate. To fix the roller to the folding sash, it is necessary to weld a plate to its frame from the edge, where it is not attached to the rack by a canopy. A hardened metal pin is welded to it.

At one end, it should be bent under a ninety degree tail, its diameter should correspond to the diameter of the hole in the roller. The bent end is inserted into the roller and secured on both sides with washers and cotter pins or ordinary nuts. Cotter pins are inserted into pre-prepared holes in the pin.

Before finally welding the plate with the pin, the folding gate must be set so that there are no gaps at the bottom and top of the opening.

gate trim

You can choose any material that is convenient for you to cover the sashes. Sheathing can be fastened with self-tapping screws using a drill, screwdriver and rivets or welded. The gaps between the folding panels are covered with a dense fabric like tarpaulin or rubber, which will withstand the influence of weather factors.

Warming

Insulation of folding garage doors is an important point. To preserve the microclimate, you can insulate the garage door with your own hands with foam plastic or mineral wool.

After that, the insulation is sewn up with sheets of plywood, fiberboard or any other decorative facing material.

svoivorota.ru

Do-it-yourself folding garage doors + drawings

Most experienced motorists prefer the old hinged or casement gate options, considering them the most secure and reliable due to the heavy weight and thickness of the metal. But, as practice shows, casement systems have a worthy competitor, namely, folding garage doors. Such is the popularity of the hinged design that today it accounts for approximately three-quarters of garage doors sold. It's worth looking into the reasons.

Advantages and disadvantages of garage doors

To understand the difference between using lift-and-tilt systems and the old hinged design, you need to try them at least a couple of times in practice, for a knowledgeable person the difference is visible to the naked eye:

- The folding gate system allows you to avoid the formation of a "blind" zone when leaving the garage. In lifting systems there are no shutters that block the view, which is why garage cooperatives dozens of cars are beaten every year;

- The absence of hinged doors when opening the doors increases the room for maneuver in front of the gate, there is no need to park the car a couple of meters from the doorway in order to be able to open and close the garage.

Folding gates are cheaper to manufacture, they are more convenient to use, a simple device allows you to build on your own. But it is not possible to install such a system in every garage, at least you need free space in the ceiling above the entrance to the garage.

We build folding gates for the garage with our own hands

The device and the principle of operation of the gate are clear from the above diagram and drawing:

- Structurally, the gate consists of two frames - the shield itself, or a panel that closes the doorway, and a supporting support frame with guide elements;

- When opening, the upper part of the folding gate deviates and moves on rollers or bearings along two guides until the panel is completely on two horizontal beams;

- The lower edge of the panel rises and is fixed in this position.

The plane of the folding gate makes a movement resembling the rolling of a conditional cylindrical surface of a large radius. To facilitate the lifting of steel or wood panel folding gates, the design uses compensating springs or counterweights in the form of a load suspended on cables.

Important! Unlike hinged systems, there are no external hinges in folding gates, which are easy to cut with a grinder. At the same time, the panel covering the doorway is adjacent to the supporting frame from the inside, respectively, it is much more difficult for intruders to pull out the garage door with a cable hooked to the towbar of a pickup truck or tractor.

Manufacturing of hinged gates

The easiest way is to make a folding gate design from a steel corner and a channel. Initially, you will need to measure the dimensions of the doorway, cut it out of the channel and weld the frame of the garage doorway.

In the upper part of the frame, two horizontal corners are welded with a shelf width of at least 40-50 mm. The length of each corner is more than two meters, so it is necessary to carry out welding work and assemble the entire structure "on the ground", before installing the folding gate system in the doorway.

The angle of attachment of the corner to the frame must be adjusted according to building level. After welding with the frame, each corner is reinforced with a temporary brace made of a board or a wooden batten to avoid deformation of the structure at the time of its installation in the garage doorway.

If a lift in the form of weights suspended on cables is used in the folding gate system, one stud with a grooved roller with a diameter of 30-50 mm must be welded to the upper part of the frame.

Particular attention should be paid to the manufacture of the main panel of the folding gate. Structurally, the folding panel is a frame made of a pipe or a metal tubular profile with outriggers welded in the lower and upper parts - brackets.

The tubular frame of the panel must be marked and welded exactly to the dimensions of the stationary frame. The main condition is to perform welding in three stages so that the frame of the folding panel does not turn out with a “propeller” due to overheating.

First, the cut pieces of the profile are laid out on a flat area and fixed together by spot welding. At the second stage, the joints are welded on one side of the folding frame, after 30 minutes they are turned over and welded on the reverse side. If the panel frame turned out to be strictly in one plane, sheet metal can be fixed, otherwise neat straightening will be required using blowtorch and sledgehammers.

Assembly and installation of folding gates

Before installing the swing gate system, you will need to pre-assemble the structure. To do this, a stationary frame with welded corner guides is laid out on a flat horizontal platform. A freshly welded movable panel is laid on top of the frame, its position is leveled as it will stand in the closed position in doorway garage.

To connect the two parts of the gate, it will be necessary to weld oblique brackets with roller or bearing rollers to the upper profile of the panel.

The reliability and smooth operation of the lifting mechanism depends on how accurately the supports are installed. Groove rollers are put on the studs welded to the stationary frame. Additional L-shaped brackets are welded to the bottom beam of the panel, to which the lift-lift cable of the supporting gate will be attached.

It remains to install the stationary frame in the garage doorway and fix it with anchor bolts to the side walls of the garage. Subsequently, the attachment points will need to be carefully poured with concrete mortar and plastered. Before the stationary frame is finally fixed, it will be necessary to align its position with the building level. Next, you need to make a U-shaped fixture, with which the ends of the corner guides are fixed to the ceiling.

At the final stage, after installing the movable panel into the frame, it is necessary to pull the cables from its lower brackets through the grooved rollers on the sides of the stationary frame, to which the load is suspended. In this case, the height of the suspension must be selected so that in the open state the loads do not fall to the floor.

Conclusion

The device of folding gates allows you to make them from almost any material and any thickness. After adjusting the operation of the lifting mechanism, a soft sponge rubber seal is glued around the perimeter of the panel and insulation is laid. At the bottom of the panel, brackets are welded for the installation of a padlock. The service life of such a design depends on the accuracy of manufacturing and can be at least 10-12 years without repair.

bouw.ru

Folding gates with your own hands - ready-made options and different types

Folding gates - perfect solution when choosing for a garage, because not always ordinary swing garage doors can fully function due to small area rooms and spaces in front of it. In these cases, many people have the question of how to make an “accordion” gate with your own hands.

This design is a worthy alternative to ordinary garage doors. You can also use folding gates - "accordion" for giving or own house.

The design saves significant space due to its functionality. Usually note several of its main advantages:

- Compactness. Folding gates do not require additional space at all, both inside and outside the garage.

- Convenient installation. It can be made from any side of the opening.

- Thoughtful design. The system is designed so that the load is mainly on the walls, while the roof is practically not loaded.

- Easy to operate. This advantage is especially evident in winter time: the sliding system will open without much difficulty even with large amounts of snow, because they are completely undemanding to cleaning the area.

- Ergonomics. Folding gates are aesthetically appealing and highly functional. This makes it possible to use them in industrial buildings.

The principle of operation of the structure

The main feature of the design is the presence in the design of special panels, the connection of which occurs with the help of a flexible material, such as rubber or dense fabric.

The shutters move with the help of rollers that are at the vertical ends and move along the guides.

The current market offers a wide range of prefabricated structures, and possibly also the production of custom-made gates. The most popular material used in the manufacture is a sandwich panel. The design with their use will turn out to be the cheapest, and also has such advantages as good sound and heat insulation.

An important advantage panels in front of others is ease of installation, so you can make a gate with your own hands. This allows you to significantly reduce costs and make a design that fits your requirements perfectly, because it will be made by you personally.

Tools that you will need in order to make the entrance gate with your own hands:

- welding machine;

- screwdriver;

- drill;

- brush (for priming metal parts).

In order to make such a gate with your own hands, you need materials:

- corners;

- square pipe;

- metal profile;

- primer;

- loops;

- rollers;

- I-beam (required for fastening the gate to the walls).

Work order

It is necessary to start mounting folded gates with the installation of a channel, which will be the basis of the entire structure, because it will be attached to it. During installation, it is worth considering that the channel is not installed to the entire height of the opening.

It is necessary to take away the dimensions of the carrier rail, which serves as space for the rollers.

Next, sections are counted and prepared. Their exact number must be known in advance, and it will depend directly on the type of gate chosen. The best option would be to sketch the entire structure of the mechanism on paper. You shouldn’t bother yourself too much, a schematic sketch is enough, but then it will greatly facilitate the installation process for you.

Rollers are one of the most important parts of the gate. They provide smooth movement of the valves.

After that, you need to assemble the frame. To do this, you need to use the pipes that you prepare in advance. They should be cut to exactly the dimensions of the panels. It is advisable to weld the frame by laying it on horizontal, even surfaces, because then there is less risk of getting skewed. You don't want to get crooked gates.

In order to give the structure the necessary rigidity, it is necessary in the process welding work weld diagonally and across the segment.

It is worth considering that on the last panel you need a place for a mortise lock or ears for a padlock.

After completing all of the above work, we select canopies for sashes, and the main criterion for selection will be the weight that they can withstand. The best option would be a bearing canopy. It is attached at the junction of the valves.

The folding gate is almost ready. The last stage of installation is the installation of rollers. As a guide, a corner is most often used.

It must be welded to the cross beam.

All major work on the installation of the sliding system is completed. Now you need finishing work - sheathing and insulation. Numerous catalogs and personal preferences will help you choose the material for sheathing. Sheathing is fastened with self-tapping screws. It is important not to leave any gaps, because you do not want weather factors to gradually render your folded gate unusable.

Separately, it is worth highlighting the insulation of folding gates. This issue cannot be treated negligently, because it is important to maintain the correct microclimate in the room. For insulation, you can take mineral wool or foam. In general, the choice is not limited to these two materials - the market is full of the latest materials. The selected material is located on the inside and closed with a fiberboard sheet.

But it is not necessary to opt for fiberboard, you can take any facing material to your taste.

It will not be difficult for a competent worker who has previously prepared to perform such work. Plus, such work does not take much time and effort, and they can be done alone.

Gate automation

Last but not least is the gate automation. It's more expensive, but convenient option, because the gate will fold like a book automatically, after a command from the control panel. Such models are equipped with electromechanical drives. To date, manufacturers offer 2 main types of drives:

- Drive with top suspension. This option must be mounted at the top of the sashes. A definite plus is that no additional foundation is required to install this drive. But the minus of this choice is the limitation of the gate in height. The height of such gates cannot be more than 4.5 meters.

- A drive that has a bottom stop. With this, you can not worry about the dimensions - it is not limited to them. But for the installation of such a drive, it is necessary to carry out additional work, because the installation requires an additional foundation across the entire width, and this increases the cost of the entire structure.

The accordion-folding design is considered the ideal solution in cramped circumstances. And automating the system will be a very practical solution, since one press of a button is enough to open the garage.

Also, one cannot ignore the fact that this is the most suitable option for summer cottages.

Such gates for summer cottages often do not do without a gate, because this greatly facilitates the process of opening a garage - you will not need to open the entire structure, although the gates fold easily, but you should not bother yourself once again.

ovorotah.com

DIY gate

With the development of construction and production technologies for private households, new ideas and designs come, devices appear that were previously used only in the industrial sector and objects of national importance. We are talking about a very interesting retractable gate system that saves the owners from having to open and plow inconvenient swing doors of classic designs.

We choose how to make a gate only with our own hands

In addition to inconvenience in handling, bulky sashes of hinged gate structures “eat up” a decent piece of the local area or space in front of the gate. If there is not enough free space in the yard, it makes sense to build a gate with your own hands according to one of the most compact and easy-to-use schemes:

- Entrance gate in the form of a retractable design. At proper planning schemes and devices of the sliding panel, such a system will occupy a minimum of usable space of the site;

- Folding or sectional systems. According to the device, such structures resemble a screen or horizontal blinds.

The installation of retractable systems requires a high assembly culture and careful fitting and adjustment of all components, but the benefits obtained more than cover the time and effort spent.

Retractable structures are divided into cantilever schemes and roller gates on wheels. Despite the external similarity, the systems have design differences in the method of supporting the leading edge of the movable panel.

In console versions, the leaf hangs "in the air" during the entire time of movement of the moving part of the gate structure, from the moment of contact with the roller catch of the lock on the pole. As a rule, low and light cantilever gates with a small overhang of the movable panel are built according to this scheme.

Roller options are made according to the scheme with a supporting wheel mounted on the lower beam of the moving part of the gate. The use of a wheel makes it possible to make the blocking panel arbitrarily massive and high, but at the same time it will be necessary to regularly clean the guide support bar laid in concrete base. Most often, sliding roller wheel schemes are used for passage with a width of more than four meters, for example, the territory of an industrial facility or a car park, where trucks and construction equipment constantly run.

For home version sliding gates are more suitable for cantilever structures, which are easy to manufacture and reliable to use.

We build cantilever gates with our own hands

The design of cantilever gates is based on the standard principle of "latches". In fact, the whole structure consists of four nodes:

- Movable panel mounted on a guide bar;

- Brick or metal pillars and a fixed gate or fence panel, forming a "pocket" into which the movable panel and drive are removed;

- System of clamps and guides along which the door panel moves;

- An electric motor with sensors for the position of the movable sash and locking mechanisms.

Important! The device of cantilever gate structures is no more complicated than any other types of gates, but before assembling it with your own hands, you should understand the structure of console systems industrial production.

Features of the gate device

The most important part of the cantilever gate design is an electromechanical drive, consisting of an electric motor with a planetary gear and a drive gear, and a toothed rack mounted on the bottom carrier beam movable panel. The entire drive structure is mounted on a massive concrete base reinforced with a steel bar. Often, the design of the drive with a concrete "cushion" is brought closer to the "pocket" of the gate, so as not to interfere with the movement of the car.

The movable part of the structure is made in the form of a panel or frame mounted on rollers. When a signal to close is given, the electric motor drives the toothed bar through the gearbox, and the panel smoothly leaves the gate “pocket” along the roller bearings until it comes into contact with the traps-clamps located on the opposite side.

We build the base and supports for cantilever gates

The design of the base of the cantilever gate is somewhat different from the usual swing or folding schemes. The whole device is divided into two main parts: the control and the receiving. The design of the first half includes a fixed part of the gate or fence, which forms the so-called “pocket” with an electric drive, columnar support and guide rails - the place where the movable panel enters when the passage is opened. The second part is a pole with stops-clamps. Its function is to capture and fix the panel in a fixed state.

The specifics of the operation of the gate structure requires the manufacture of a powerful concrete base under the first half, compensating for the overturning moment that occurs when the wings are opened. For this, a concrete pad is made, reinforced with a steel bar, at least one and a half meters deep and about two meters long, as shown in the diagram and photo.

When pouring the mortar into the concrete base of the pillow, it is necessary to lay the embedded element made of channel No. 20 with reinforcing posts. After that, vertical bearing pillars can be laid out of brick or cast from concrete to the height of the future gate structure. During the construction of the pillars, reinforcing metal plates are laid on the inside.

Installation of wiring and welding of the cantilever gate frame

For normal functioning the gate structure will need to be supplemented with a signal system and a circuit of two photocells that control the position of the movable gate leaf in the closed and open state. The wiring must be laid according to the diagram shown in the photo.

A little more complicated than laying the wiring is the manufacture of a movable frame with a balancer. The frame drawing is shown below. The frame of the movable panel is welded from a profiled pipe 60x40 mm according to the specified dimensions. To increase the rigidity of the frame, a tubular profile of a smaller section of 30x20 mm is first welded inside along the perimeter of the pipe, and diagonal struts are installed. How to make a roller support can be found in the video:

In some cases, experts recommend making a movable panel on the gate from a corner with your own hands, and then scalding it with a thick profile of 60x40 mm. In this case, a ready-made mating plane is obtained on the frame from the shelves of the corner, on which it is easy to fix the cladding made of corrugated board or sheet iron.

After welding, the frame is subjected to sandblasting or emery, treated with an anti-corrosion compound and painted with automotive enamel to match the color of the gate and fence. In the lower and upper parts of the pillar, you will need to install locks on the gate with your own hands, on which the shackles for padlocks are attached. At the same time, experts recommend equipping the upper lock with a latch, and hanging the lock on the lower stopper. The upper lock is relatively easy to open with your hands, but it is almost impossible to reach the lower lock from behind the fence.

Do-it-yourself accordion gate

If there is not enough space on the site to install conventional swing or modern sliding gate systems, you can use original design folding or sliding gates. Both options allow you to save as much space as possible inside the site and the territory in front of the passage, which is especially important if the carriageway passes almost close to the gate.

The design works on the principle of an accordion - interconnected door hinges separate panels.

Each panel is a welded frame made of a profiled pipe measuring 60x20 mm or a corner with a shelf width of at least 50 mm. On the upper and lower end surfaces of the frames, guide pins or axles are welded, with the help of which the panels are installed in two guide rails of the gate opening.

Panel frames are made by welding on a conductor box knocked down from boards. Thus, it is possible to achieve the maximum match of all panels in size and shape. It remains to connect the panels with door canopies and install on the guide rails.

One of the panels, most often the extreme left or right, is made in the form of a double frame. This is done to hang the doors of the gate, as in the photo. To do this, first, on the inner surface of the profiled pipe of the frame, weld door canopies, after which a wicket frame welded in advance is installed and the location of the mating halves is fixed on the door frame.

The frames of sections or panels are most often lined with corrugated board or polycarbonate, the material does not fundamentally affect the operation of the gate. It remains to paint and install constipation.

Conclusion

Like all complex drive mechanisms, sliding gates require constant care and maintenance. If the jammed drive of swing gate structures is easy enough to turn off and manually open the leaves, then for retractable, especially heavy wheel-roller systems, it is rather difficult to make manual opening without additional mechanisms.

Cantilever gate structures of industrial production, in addition to obstacle and load sensors, have a built-in additional manual drive mechanism. In the event of a power outage or failure automatic system control, a manual gate is simply inserted into the mechanism, and the gate is opened by turning the working gear. Therefore, when designing a drive with your own hands, it makes sense to provide for such an option for opening doors in winter.

bouw.ru

Do-it-yourself folding garage doors drawings: step-by-step production

Technologies today are developing at an incredible pace, and it is far from always possible to keep track of new products. All these changes apply to any area, they did not bypass the garage door. A few decades ago, swing models were considered the most popular, but gradually they were replaced by retractable ones, and then by lifting ones. If you dwell on the latter option in more detail, you can say for sure that they are today considered one of the most reliable. Thieves consider them impregnable.

Folding gates for the garage, each person can make their own

Folding gates for the garage, each person can make their own

One of the most important features of swing gates is that they do not require additional space to open. This solution allows the owner vehicle have a huge opportunity for various maneuvers when you need to put the car in the garage. Despite the fact that most companies offer a huge range of models, many residents of the country are trying to make tilt-and-turn gates with their own hands. First of all, you need to understand the manufacturing process, prepare the entire tool and invite an assistant. But what types lifting gate exist?

Varieties of models with a lifting mechanism

All gates of the lifting type can be divided into 2 groups:

- rotary;

- sectional.

Installing a gate of this type will be an excellent solution in garages, where:

- the lintel of the garage doorway is too low or absent altogether;

- the owner just wants to protect the garage from intruders as best as possible;

- you need to make your garage modern and as comfortable as possible.

It is very convenient to think about installing sectional models when there is enough space for a car in the room to be able to move the gate from one position to another. According to the installation technology, they are very similar to the rotary options already loved by many: the interior space under the ceiling acts as a place for their location. The basis of this design is created by sections that maintain mobility relative to one another. If you use this version of the gate, then access to the garage is opened by moving the sections along the guides upwards, which are installed on the surface of the walls and ceiling. Do-it-yourself folding gates have a number of advantages.

You can make folding models from any material: metal profile, metal and others.

You can make folding models from any material: metal profile, metal and others.

Pros of folding garage doors

There are many advantages to this type of gate, but it is especially necessary to highlight the following:

- the shutters are strong and rigid, which allows you to protect the room from the penetration of intruders;

- the features of these gates make it possible to maintain an optimal microclimate in the garage, it is well warm and waterproof, and this is very important for protecting the car from corrosion;

- this design has an attractive appearance, which makes any garage attractive;

- in the open position, the door takes up minimal space (under the ceiling), and it takes very little time to open it.

Today, you can buy tilt-and-turn gate models to decorate and make your garage securely protected at any hardware store, but they are easy to make on your own.

Before you start solving the important question of how to make folding garage doors with your own hands, the drawings must be made in accordance with your dimensions. Before you start solving the important question of how to make a sliding garage door with your own hands, the drawings must be made in accordance with your dimensions.

Before proceeding with production, you need to create a drawing according to individual dimensions.

Before proceeding with production, you need to create a drawing according to individual dimensions.

How to create a sliding garage door with your own hands: drawings

It is necessary to start work on creating a folding gate for a garage with your own hands by building a drawing. On a piece of paper, you need to indicate your individual dimensions of the doorway, or rather, take the following measurements:

- measure the doorway;

- determine the height of the lintel, measure the distance from the top of the opening to the one where the ceiling is adjacent to the wall;

- determine the distance from the opening to the garage wall;

- measure the depth of the room.

When the scheme of the future product is ready, you can begin to make a frame, the basis of which may well be the frame from the old gate. You can also make a new frame using wooden blocks.

Hinged gates can be equipped with automation, thanks to which you can easily open and close them

Hinged gates can be equipped with automation, thanks to which you can easily open and close them

Frame manufacturing

There is nothing difficult in making a frame; everyone can easily cope with this work, even without certain skills and experience. For work you will need:

- guide element;

- rack for the manufactured box;

- a wooden beam to help assemble the box;

- bracket to help fix the spring;

- hinge corner;

- beam for the guide element;

- gate leaf frame;

- good quality strong spring;

- bracket for lever;

- the lever necessary for convenient lifting of the mechanism.

Channel No. 8, 70 cm long, is perfect for making a support mechanism for a spring.

To assemble the box, you need to purchase 2 pieces of timber, the length of which should be two meters and 30 cm, and the section 120x80 mm, you will also need one more of the same timber, but the length is slightly more than two meters and 75 cm.