How to finish plasterboard walls. How to sheathe walls with drywall with a profile on a metal frame: do-it-yourself mounting options

Drywall firmly occupies the position of one of the most popular building and finishing materials, and this is easily explained by its many advantages. These can be safely attributed to its environmental friendliness, ease of installation, the ability to use in the most different rooms, relatively small mass and generally available cost.

Plasterboard sheets are used for leveling walls and for, moreover, working with them is available not only to an experienced builder, but also to a novice master. Finishing walls with drywall without a frame and profile is possible on different adhesive compositions and on surfaces built from various materials. The advantages of such fastening in comparison with the frame method are that the reduction in the area of \u200b\u200bthe room is not so noticeable, a decent amount is saved on the elements of the crate, and the installation work pass quickly enough and may well be produced on their own.

The main methods of installing drywall on a wall surface

To appreciate the advantage of frameless installation of drywall, you can briefly consider both existing methods by comparing them.

In fairness, it should be noted that sometimes when installing drywall, it is impossible to do without installing a frame, so this case is also worth mentioning when considering how to install the material.

So, there are two main technologies for fixing drywall sheets to the wall in order to level it:

- Installation of sheets using self-tapping screws on a frame made of a metal profile or wooden beam. This method is chosen in cases where the wall requires additional thermal or sound insulation, and the insulation material is installed precisely in the frame structure, or if the wall has very large distortions that are difficult to level with plaster layers.

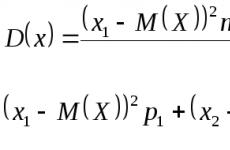

- Fixing sheets on the wall with self-tapping screws and mounting foam or on a gypsum-based adhesive. Self-tapping screws and foam for fixing drywall are used if it is necessary to sheathe not only a wooden wall, but also surfaces derived from other materials that require correction. Adhesive gypsum composition is more often used for leveling concrete or brick wall. However, it should be noted right away that the frameless method of fixing drywall should be used only when the walls have a height not exceeding 3000 mm.

In this publication, the nuances of only frameless drywall fastening will be considered.

Necessary materials and tools

Set of tools

To level the walls with drywall using one of the adhesives, you will need much fewer tools than if a frame was attached to the wall. The list of everything you need consists of the following items:

- A plumb line, a building level and a rule, preferably 1500 mm long - to control the evenness of the original wall and the created vertical plane.

- Electric jigsaw or sharp clerical knife - for cutting drywall.

- Rulers of different lengths, a square, a tape measure and a simple pencil - for marking.

- A wide, medium and narrow spatula, and possibly a trowel (trowel) - for applying and distributing the mortar.

- Construction grater - for processing puttied surfaces.

- Roller and brush - for treating walls with a primer.

- Rubber mallet - for adjusting drywall sheets glued to the wall.

- Electric drill and mixer nozzle - for mixing the solution.

- In some cases, it will be required - for additional fixation with self-tapping screws.

Drywall prices

drywall

Necessary materials

Now it is necessary to consider the materials that will be required to prepare the surface of the walls and for quality installation drywall:

- Priming solution with antiseptic additives.

- Gypsum-based putty mixture, base and finish.

- Dry mortar - drywall adhesive, or mounting foam.

- Serpyanka mesh tape - for sealing joints between sheets.

- Long self-tapping screws may be required to level the wall by adjusting drywall sheets. The size of the fasteners will depend on the evenness of the surface, taking into account the fact that they must be recessed into the wall by 50 ÷ 60 mm.

- One of the alignment technologies will require pieces of foam rubber - this will be discussed in due time.

About some materials - a little more.

Drywall

The Knauf company produces not only a variety of building and finishing mixtures, but also plasterboard sheets for various purposes - this is a simple, moisture-resistant, fire-resistant and moisture-resistant finishing material:

- Ordinary drywall (gypsum plasterboard or, according to Knauf's proprietary classification - GSP-A) is used for rooms with normal humidity.

- Moisture-resistant sheets (GKLV or GSP-N2) can be used to level walls in bathrooms or bathrooms. After processing such a surface, ceramic tiles will perfectly lie on it.

- Fire-resistant sheets (GKLO or GSP-DF) are used for finishing walls around the fireplace, stoves, chimneys.

- Fire and moisture resistant drywall (GKLVO or GSP-DFH2) is well suited for wall decoration in boiler rooms of private houses, in attic and attic rooms.

Here you can also briefly talk about, which does not require much effort, experience and special tools - it is enough to have an ordinary sharp clerical knife on hand. The cutting process takes place in the following order:

- The sheet is laid on a solid base - this can be big table, floor or several stools placed side by side at some distance from each other.

- Then, using a tape measure or ruler, the sheet is marked out, with a simple pencil necessary lines are drawn.

- The next step along the drawn line, also along the ruler, is carried out with a knife, which should cut the top layer of cardboard.

- The sheet is shifted to the edge of a hard surface, and placed on it along the notch line.

- Then, on the edge of the drywall, which extends beyond the base, pressure is applied, which will cause the sheet to break along the cut line.

- The last step is cutting the cardboard on the other side of the sheet.

A modern and reliable material, drywall has firmly entered the top ten most popular building materials. And it is no coincidence, because the decoration of the walls with drywall allows you to re-imagine the already familiar walls and the entire interior of the room, as well as make the room more comfortable and functional. The qualities of this building and finishing material allow you to perform many works with drywall and independently. After all, its ability to take almost any form, plasticity, resistance to many influences ensures the preservation of beauty in the room for a long time.

General scheme of plasterboard wall cladding

Finishing the walls with drywall with your own hands is quite real. However, the basic rule should be observed: strictly observe the sequence of actions. Only in this case the result will be exactly what is expected, and it will last for a long time. Therefore, we will consider what is the algorithm of actions when working with this popular material when doing wall cladding with your own hands.

Conventionally, the entire process of wall cladding with drywall can be depicted in five successive operations:

- Selection and preparation of materials that will be required for wall cladding.

- Marking the surface of the wall, which will be made out with drywall.

- Mounting the frame, on which the material will then be attached.

- Frame sheathing.

- Draft finish with drywall.

These five points are required to obtain the perfect result when decorating a wall with such a versatile material as drywall.

Now let's study in more detail what each step is and how it will be correctly performed.

Competent choice of materials

There are several varieties of drywall. This material can be used in various construction and decoration works. And depending on the type of room in which drywall will be used, the requirements for it will also differ. After all, it can have various characteristics that determine the possibilities for its application.

The most important parameters, according to which one should approach the choice of drywall when deciding to sheathe walls with it, include:

- thickness. There are several varieties of this material for internal works which differ in their thickness. And for wall cladding, a material with a thickness of 12.5 mm will be considered optimal;

- moisture resistance. When upholstering the walls of rooms in which there is high humidity, the only possible use is drywall with the marking "KGLV". Such material is suitable for rooms such as a bathroom and a bathroom, storage rooms, if the humidity index here can increase. For other, "dry" rooms, it will be normal to use ordinary drywall.

Also, other materials will be required to decorate the walls. At the preparation stage, they should also be stocked up in the required quantity. These will be:

- primer;

- elements for arranging the frame. This includes guides, PN and PS profiles, as well as self-tapping screws and direct hangers;

- mesh-serpyanka;

- putty of two types - starting and finishing. Finishing putty will be necessary only if it is planned to paint the wall at the end of the work.

Types of drywall profiles

In addition to the listed materials, certain tools will also be required. They will allow you to perform all the work on plasterboard wall cladding with the highest quality. For this job it is recommended to have:

- masking tape;

- rule;

- a set of spatulas of various sizes;

- electric drill or screwdriver of sufficient power;

- scissors for metal or grinder;

- cuvette;

- roller;

- building level;

- grids (preferably a set) for grinding.

This minimum of tools will allow you to complete the work on decorating the wall with drywall with maximum convenience and quality.

After preparation necessary materials and tools, you can get straight to work.

Making markings on the wall surface

Marking is carried out in order to obtain a perfectly flat surface. It must be performed before starting work on laying drywall.

The execution scheme looks like this:

- A line is applied to the ceiling along which the supporting profile will be attached. Drywall will be fixed to it. The location of the line is at least 40 mm from the wall surface. If the wall to be decorated with this material, will be insulated, then the thickness of the insulation should be added to 40 mm.

- The resulting line on the ceiling should be transferred to the floor surface. For this you can use plumb lines. As well as building level. With its help, vertical lines are drawn on two opposite walls to the floor level. And the resulting points are connected by one line.

- Now markings are applied to the surface of the walls. To do this, the fastening lines of PS profiles are marked, on which drywall will then be fixed. To do this, stepping back from the corners of 10 cm, draw vertical lines. The step of these lines (that is, the distance between them) should be 60 cm.

- Now, along the lines obtained, you should mark the attachment points for the suspensions. For this, an additional horizontal marking is carried out every 50 cm.

The above sequence of steps must be carried out on all walls that are planned to be finished with drywall. This will allow in the best way place the frame and then fix the drywall.

Carcass execution

Aligning the walls with drywall with a frame with your own hands makes it possible to get perfectly even, beautiful walls. Any finish will look great on them: painting, wallpapering. The process of mounting the frame is quite simple. And for its independent implementation, the following detailed step-by-step instruction:

- beforehand, all guides are cut to the length of the wall on which they will be attached;

- further, with the help of dowel-nails, guides are attached to the walls and ceiling. It is these nails that will provide the most reliable fastening and long-term preservation of the material on the surface of the walls and ceiling, which are sheathed with drywall. If the walls that are sheathed are made of foam blocks, then in addition to the dowel-nails, you will need to use special fasteners for foam blocks. So the clutch will be the most durable and durable;

- now the PP profiles are cut to the required dimensions and fixed in the guides. They are fixed in suspensions. It should be remembered that the profiles tend to bend a little. Therefore, it is necessary to align them regularly using the rule;

- now, with the help of fastening the jumpers, the necessary strength of the resulting frame is created. To do this, the transverse jumpers are cut into each other and arranged in a checkerboard pattern.

This method of fastening allows you to get the most durable and flat surface.

Good advice is given by professionals: in order for the resulting surface of the frame to come out even, you should initially install the corner guides, and connect all of them in pairs with a cord. So straight lines will be obtained, along which, like beacons, the remaining profiles can be fixed.

The above sequence of actions is applicable when cladding walls with drywall. In the same way, it is necessary to cover all surfaces that will then be sheathed with this material.

Separately, you should pay attention to the owners of houses made of wood. Because this eco-friendly natural material prone to decay and mold, especially in rooms with a high degree humidity, it is recommended to carefully treat the walls and ceiling with special antiseptic agents before installing the frame. They will perfectly protect the wood, prevent its premature damage. And only after the tree has completely dried out, you can install the frame and sheathe the wall with drywall.

Carrying out the sheathing of the frame

Now we proceed directly to the sheathing of the resulting frame with drywall. Depending on the type and size of the sheathed wall, preliminary cutting of sheets of material is carried out. The process of cutting drywall is quite simple. For this, there is also a simple algorithm of actions that allows you to get individual parts of the required size and shape.

Such an algorithm looks like this:

- several points are applied on the surface of the sheet in accordance with the dimensions required for a separate section of the wall;

- points are connected by straight lines using a rule;

- when using a mounting knife, a part of the sheet of the desired size is cut;

- now the sheet is bent and the cardboard is cut along the fold line.

The resulting sheets are fixed to the required place on the wall using self-tapping screws. This process simple, does not require special skills and abilities. However, you should remember some points that will allow you to get the most even surface of the sheathed wall:

- the edges of the drywall should be exactly on the center line of the profiles. This will make the skin as accurate as possible, since it is the overhanging edges that begin to crack and crumble over time;

- the location of the screws - a step of at least 25 cm;

- caps of self-tapping screws should be carefully "drowned". This will allow further processing of the resulting surface with the highest quality. After all, protruding hats will interfere with further finishing of the walls that were sheathed with drywall.

Lathing for drywall is performed on all types of ceilings. However, when finishing with this material of buildings from the frame, you can do without the crate. In this case, sheets of material are attached directly to the walls of the building. The resulting wall decoration with drywall without a frame and a profile on frame structures keeps perfectly, without violating the geometry of the premises and giving them a more attractive appearance.

We carry out rough finishing

After mounting to the frame of drywall sheets, its rough finish is carried out.

First, a chamfer is cut from the sheets of material. Its width should be about 5 mm. If the corners of the sheets are rounded, then there is no need to chamfer. A sickle is glued to the joints. Using a primer and a paint roller, joints are processed to level the surface.

Puttying plasterboard walls is done in order to eliminate the slightest irregularities, since during the finishing they become noticeable and reduce the value of the final result.

After complete drying of the treated surface, a starting layer of primer should be applied. A paint roller can be used, and in particularly difficult accessible places - paint brush. Particularly carefully should be processed in places where there are depressions from the caps of self-tapping screws.

Plastering of plasterboard walls is carried out as a finishing coating. It is a decorative coating that can have a different texture, different shade. The more even the layer of soil was laid, the more neat and beautiful the decorative plaster will look on such a wall.

December 9, 2016Specialization: facade finishing, interior decoration, construction of dachas, garages. The experience of an amateur gardener and horticulturist. He also has experience repairing cars and motorcycles. Hobbies: playing the guitar and much more, for which there is not enough time :)

You will do the right thing if you make a choice in favor of drywall for interior wall decoration. At the same time, not all home craftsmen understand how to properly mount this material. After reading the article, you will learn how to properly finish the walls with drywall with your own hands.

Finishing technology

Wall cladding with drywall is conditionally divided into five stages:

Stage 1: preparation of materials and tools

Drywall for interior wall decoration of the house exists different types, therefore, it is necessary to approach its choice wisely. The main parameters by which this material differs are as follows:

- thickness- for walls it is necessary to use sheets with a thickness of 12.5 mm;

- moisture resistance- the choice depends on the type of room. If you plan to finish the bathroom or kitchen, you should use moisture-resistant KGLV drywall. For "dry" rooms, ordinary drywall is suitable .

In addition to drywall, you will need some other materials:

- frame elements are PS and PN profiles, as well as direct suspensions and self-tapping screws;

- primer;

- sickle mesh;

- putty - starting and finishing. The latter is only needed if you plan to paint the walls.

As for the tools, the set should be as follows:

- electric drill;

- metal scissors;

- mounting knife;

- screwdriver;

- paint cord;

- building level;

- a set of spatulas;

- rule;

- a set of grids for grinding with a jointer;

- roller with a cuvette.

After preparing all the tools, you can get to work.

Stage 2: marking the wall

Before finishing the walls with drywall, they must be marked out. Otherwise, the surface of the walls may turn out to be uneven.

The markup is applied like this:

- First of all, put on the ceiling the location line of the guide profile along the wall that you will sheathe the GKL. The line must be located at least 40 mm from the wall. If you plan to insulate walls, then the distance must be increased by the thickness of the insulation.

To get a straight line on the ceiling, step back from opposite corners an equal distance and mark the points. Then fix the masking cord between these points, pull it down slightly, and release it. As a result, the cord will hit the ceiling, and leave a trail in the form of a straight line;

- the line obtained on the ceiling must be transferred to the floor so that it is located in the same vertical plane. To do this, you can use a plumb line, with which several points on the floor are indicated. Then these points are connected by a line.

Instead of a plumb line, you can use building level, with the help of which vertical lines are drawn from the line on the ceiling on two opposite adjacent walls. Further, these verticals are connected by a line on the floor;

- now you need to do the markings with your own hands directly on the wall that you will sheathe the GKL, indicating the location of the PS profiles. To do this, step back from the corner of 10 cm and draw vertical lines in 60 cm increments;

- on the resulting vertical lines, mark the location of the suspensions. They must be installed at a distance of 50 cm from each other.

According to this scheme, you need to mark up all the walls that you are going to finish the plasterboard.

Stage 3: frame assembly

The process of assembling the frame is quite simple, besides, the following step-by-step instructions will help you with this:

- first of all, cut the guide profiles along the length of the wall;

- then fasten the profiles according to the markings on the wall and floor with dowel-nails;

- then you need to fix the hangers on the wall using the dowel-nails. If walls from foam blocks are finished with drywall, it is necessary to use special fasteners designed for porous ones, as in the photo below;

- then it is necessary to cut the PP profiles along the height of the walls, then insert them into the guides and fix them in the hangers. Be aware that profiles can sag. Therefore, they must be aligned by applying the rule.

So that all PS profiles are located in the same plane, i.e. to make the wall even, first install the racks that are extreme from the corners, and then pull the cords between them. On them, as on beacons, align the intermediate racks;

- now you need to fix the jumpers between the racks. To do this, the profiles need to be cut, as shown in the photo above.

To give the wall the greatest strength, arrange the jumpers in a checkerboard pattern in 50 cm increments.

AT wooden house before proceeding with the assembly of the frame, it is necessary to treat the walls with antiseptic impregnation. This will protect them from decay and other biological negative effects.

According to this scheme, you need to sheathe all the walls in the room.

Stage 4: frame sheathing

The next step is the cladding of the GKL walls. To do this, you will first have to cut out individual sheets, taking into account the size and characteristics of the walls.

GKL is cut quite simply:

- mark the cut line by marking several points;

- attach a rule to the line;

- cut the cardboard with a mounting knife along the line along the rule;

- break the sheet and cut the cardboard along the fold line.

Finishing walls with drywall is quite simple - the sheets are fixed to the frame with self-tapping screws. However, some nuances must be taken into account:

- the edges of the GKL should fall on the center of the profile. There should be no “hanging” edges, otherwise the finish will crack in these areas over time;

- self-tapping screws should be located in increments of 25 cm;

- the caps of the self-tapping screws must be recessed, otherwise they will interfere with the further finishing of the drywall.

Frame wooden walls can be sheathed with plasterboard without arranging an additional frame made of profiles. In this case, the sheets are fastened with self-tapping screws directly to the supporting structure.

Given these points, it is necessary to sheathe all the walls.

Stage 5: drywall roughing

The final stage is the rough finishing of drywall, which is carried out as follows:

- first of all, cut the chamfers from the joints of the sheets with a width of five millimeters. If the edge of the sheet is rounded, then the chamfer, of course, does not need to be cut off;

- then it is necessary to stick a sickle on all joints;

- then prime the surface with a paint roller. Apply the primer in an even thin film. If necessary, treat hard-to-reach places with primer with a paint brush.

After drying the surface of the walls, apply the primer again;

- now it is necessary to putty the joints of the sheets and caps of the self-tapping screws with a starting putty. For these purposes, you can use a narrow spatula.

Try to apply the putty carefully to get as smooth a surface as possible;

- after the putty has dried, treat it with a brush;

- then the walls must be covered with a starting layer of putty, using a wide spatula. The filling technique is described in detail in other articles on our resource dedicated to this topic.

In the process of applying the starting layer, plaster corners must be glued to all outer corners, which will protect them from chipping;

- after the putty has dried, the surface must be sanded with a P120 mesh stretched over a jointer. Make circular motions with the tool. This will get rid of all significant irregularities;

- sanded walls must be cleaned of dust, and then primed again;

- if you plan to glue wallpaper on the walls or, for example, apply decorative plaster, then work on this can be stopped. If the walls are to be painted, it is also necessary to apply a thin layer of finishing putty.

The principle of puttying in this case remains the same, with the only difference that the “finish” must be applied even more carefully;

- the finish layer must be sanded with a mesh with fine abrasive. The work must be done very carefully so that the surface of the walls is perfectly smooth. Therefore, work must be done in bright light.

To check the quality of grinding, bring a bright lamp to the walls at an acute angle. This will allow you to notice even the smallest flaws on the walls.

Wall sanding is a very dusty job. Therefore, when starting this procedure, be sure to protect your respiratory organs with a bandage or respirator, and also wear safety glasses.

This completes the interior plasterboard finish.

A few words about the frameless installation of drywall

Apart from frame technology installation of gypsum boards, which we reviewed above, there is still a technology that does not require the installation of a frame. Its principle lies in the fact that GKL sheets are simply glued to the walls using special glue or even starting putty.

This technology can be used if the walls are relatively even. As a result, work is carried out much faster, moreover, the space of the room is practically not reduced.

At the same time, the frameless technology for finishing walls with drywall has some disadvantages:

- does not allow to insulate the walls from the inside, as well as to hide communications between the wall and the gypsum plasterboard;

- requires preparation of the surface of the walls. Before making a frame, as we found out, it is not necessary to prepare the walls. Therefore, the frameless mounting method is not always faster than the framed one.

Therefore, when choosing a technology, you should consider all the pros and cons.

The process of installing GKL using this technology is as follows:

- work begins with the preparation of the walls. At this stage, remove the old finish coat. If there are areas with peeling or crumbling plaster on the walls, they must also be removed;

- then the surface of the walls should be cleaned of dust with a vacuum cleaner or brush, and then wiped with a damp cloth;

- Next, the walls need to be primed. If the surface is smooth, such as concrete, an adhesive primer must be used. If the walls are plastered, priming is done with a deep penetration primer;

- while the primer on the walls dries out, apply the primer to the back of the plasterboard;

- after the primer dries, you can start gluing the sheets. To do this, glue or starting putty is applied to their back side in lumps, which are evenly distributed over the entire surface of the sheet.

- after pasting the walls with drywall, a rough surface finish is performed according to the scheme described above.

Conclusion

You learned from the article that the technology for finishing GKL walls is quite simple, although it is not without some subtleties. For more information, I suggest watching the video in this article. If you don’t understand some points or encountered any difficulties in the process of work, write your questions in the comments, and I will definitely answer you.

Starting any repair and finishing work in an apartment or house, you need to choose in advance what material will be used. Many choose plasterboard wall cladding - a fairly simple procedure that you can do yourself. But, if you want to create some kind of decorative element, composition, you will have to try hard. Only then will it turn out exactly what was intended. Therefore, working with GCR boards is not always as easy as it might seem.

Features and benefits of plasterboard walls

Drywall is considered a universal material, it can be mounted on almost any type of surface - brick, concrete, block, wood. For correct installation use different options:

- erection of a metal and wooden frame;

- fixing gypsum boards directly to the wall.

Installation of drywall sheets without crates

Installation of drywall sheets without crates Unlike other materials, drywall sheathing of various surfaces can have many advantages:

- Work with dry plaster (another name for drywall) allows you to finish the walls quickly enough. And also there is no need to use various solutions that require certain conditions.

- The erected structure from GKL fits into any design ideas. You should not think that with the help of this material only flat areas are created - you can successfully make various curvilinear and decorative elements.

- Drywall has excellent specifications. But it is very afraid of high humidity, so it is better to use it in combination with waterproofing materials.

- It is very convenient that the whole structure can be dismantled very quickly. At the same time, the use of a metal frame gives very good rigidity and does not collapse over time.

- It is possible to lay communications without creating various channels. This rule applies to the wireframe method.

- The GKL surface can be processed with almost all finish coatings. Very convenient and what different types finishes can be combined with each other.

Aligning walls with GKL is especially important when used internal insulation at home

Aligning walls with GKL is especially important when used internal insulation at home When creating decorative elements using drywall, you need to take into account that it will be necessary to create additional sections of the frame, which must first be correctly calculated.

Preparing for wall cladding

Do-it-yourself wall cladding with drywall begins with pre-training. Often this process takes much longer than the work itself. It is better to take care of the miscalculation of the necessary costs, material and drawing up a detailed plan (scheme) of work in advance.

First of all, you should measure the room. This must be done with particular care, any errors will lead to problems during the installation process.

Measurement of the premises is an important stage of preparatory work

Measurement of the premises is an important stage of preparatory work On a note! There are various options for drywall sheets on the market, so you can choose the material even for non-standard objects.

Also pay attention to the thickness of the plate, it can be from 6 to 12.5 mm. Width starts from 60 cm to 120 cm.

When choosing, you can focus on the color of the sheet, it gives an idea of its characteristics:

- the most common option is for simple rooms, its color is gray;

- for wet rooms - moisture-resistant drywall, green in color;

- fire-resistant sheets are red.

Green color drywall "speaks" about its moisture-resistant properties

Green color drywall "speaks" about its moisture-resistant properties Immediately determined with the method of fixing the plate, the choice will depend on this additional materials. If a frameless method is used, then it is necessary to choose the right glue and its quantity. When creating a crate, the number of metal profiles and fittings is calculated. Do not forget about the need to prepare the required tool.

What should be considered when installing GKL

So, it has already been noted that a lot depends on the installation method that will be selected in advance. Take into account the following:

- For rooms with a large area, the frame method is suitable. But we must remember that the erected crate takes up part of the area.

- Accordingly, it is better to sheathe small rooms by gluing GCR boards. This is the only way to keep the size of the object. If you use a frame, the room will become noticeably cramped and uncomfortable.

- The use of a metal profile requires compliance with certain rules. Among the main ones is strict adherence to the installation of level guides.

Wall cladding with drywall using battens

The use of this method does not require specific skills. All work is quite simple, but requires care. You should not rush, it is better to do everything measuredly, as a result of which you will get a high-quality design that will please the eye.

On a note! By itself, the technology of wall cladding with drywall has some difficulty precisely in terms of creating a crate. The procedure for facing with GKL slabs is not the main stage of such an event.

The work to create the crate is as follows:

- Everything superfluous is removed from the walls. You should get a clean surface.

- Produce markup. Immediately draw the location of the vertical racks (step 55-60 cm). This makes it possible to pre-drill for the dowel.

- Install the guide profile. This is done along the perimeter of the wall of the room. It is in it that the installation of vertical elements begins. They are attached using U-shaped brackets.

- Attach horizontal braces.

Photo of the frame installation process:

Each stage of work is carried out using a level. Only having achieved perfect evenness - each element is fixed.

Installation of drywall sheets

Plasterboard wall sheathing is done according to the following principle:

- measured right size sheet. Excess is removed with a construction knife.

- The edges of the sheets that will be located next to each other are trimmed. Do it at a slight angle.

- The very installation of the GKL plate consists in screwing it to the profile. Keep a step of 20-25 cm.

- Consider that you need to make a gap between the floor and the ceiling, it should be at least 5 mm.

- Now it remains only to seal the joints between the sheets and proceed to further finishing.

A few tips:

- Self-tapping screws are recessed literally flush with the surface. You can not twist or twist them too much.

- Between the sheets make a gap - 3-5 mm.

- If it is planned to fasten heavy elements, then mortgages are made. They must be securely attached to the wall.

Thus, a drywall room is obtained, which will serve long years. In principle, if you follow the rules for further finishing, then even when replacing the decorative layer, it will not be necessary to change the wall cladding of the GKL.

Sheathing with glue

Installation of drywall on glue is best done when there is at least a little experience in carrying out such work. The fact is that it will be almost impossible to correct the defect with such work.

Guided by the following rules:

It becomes extremely clear how to sheathe the walls of a room with gypsum boards. This procedure allows you to quickly and most importantly reliably create a surface that will serve for any further finishing.

Some Features

Regardless of which option is chosen, there are certain features that should be observed in any case.

- Before starting wall cladding with drywall, they make a preliminary marking of the plates. What is it? Imagine that you want to install various lighting, but how to do it? Indeed, after installing the GKL, you will have to spend extra time searching for a place where the electrical wiring passes. Therefore, everything is done in advance.

- Direct drank holes for built-in lights can be postponed. But then take into account the possibility of getting on a metal (wooden) profile.

- Sheathing around window openings requires the greatest care. Often, radiators are located under the windowsill. So, they immediately calculate the location of removable screens. To do this, make additional mortgages and false panels.

- It is better not to take risks and take care of pre-finishing the surface that will be under the drywall. What it includes is the application of compounds that will protect against the effects of various fungi and mold. They also provide thermal and waterproofing.

- A wooden frame is best used in houses that are made of the same material.

Undoubtedly, wall cladding with drywall will allow you to create a surface that will allow you to show all your imagination for further decoration.

- Material

- Basic cladding methods

- GKL on the frame

- Without frame

- GKL decor?

- Suspension on GKL

- Video: suspension on plasterboard walls

Sheathing walls with drywall for leveling and preparing for finishing is increasingly replacing traditional starting plaster. Drywall was invented for this: a synonym for it, as you know, is dry plaster. Leveling walls with drywall, firstly, is much easier and cheaper than plastering in the old fashioned way. Especially - wooden walls: in order to plaster a tree in the Old Testament way, you must first put glassine on the wall, then felt soaked in liquid clay mortar and a 2-level crate of shreds. Secondly, the most experienced plasterer, working with a falcon and a trowel, will not remove the plaster layer more evenly than 3 mm / m. The plaster itself, drying out, will give more unevenness, because. applied in spots. Meanwhile, for many modern ways decorative wall decoration 3 mm / m is the limit.

Sheathing with drywall allows you to bring the wall to a total, between the corners diagonally, unevenness of 2 mm. Besides, plasterboard sheathing has a trace in front of solid plaster. Benefits:

- Hygienic and hypoallergenic - does not dust, does not get dirty.

- Improves heat and sound insulation of housing.

- "Breathes", i.e. absorbs excess water vapor from the air and releases it when there is a shortage; this is especially important in an apartment house made of reinforced concrete or silicate brick. The breath of drywall is not as deep and even as wood, but still - not a stone.

The disadvantages of leveling walls with drywall are only 2, but quite serious.

The first is fragility. If the wall plastered in the usual way has a furniture corner, a pothole is possible, which is easy to repair. If a stumbled or slipped person leans against such a wall, nothing will happen to her at all. Drywall in both cases is threatened with a break and cracks.

The second is the poor availability of hidden communications. If a pipe leaks in a regular wall or the wiring burns out, the case will be managed with a strobe, which is subsequently sealed. If the accident is behind drywall, you will have to remove at least one slab, spoiling the fine finish until it needs to be completely replaced.

Taking into account all these circumstances, the question needs to be resolved: the usual starting plaster or drywall. In modern budget and mid-level housing, the result is most often in favor of the latter due to low cost and ease of work. Therefore, the purpose of this article is to give the reader the most complete idea of how to sheathe and level the walls with drywall with your own hands, because. lining them room approx. 12 sq. m by hired craftsmen costs somewhere from 30 thousand rubles, the popularity of the material affects pricing.

Material

Drywall is a pressed mass of cellulose filler with a gypsum binder, covered with a protective paper layer. It is produced in sheets (GKL), up to 16 mm thick, and in plates (GKP) up to 32 mm thick. For wall and ceiling cladding, GKL are used ordinary, moisture-resistant GKLV green, fire-resistant GKLO red or orange and fire-resistant GKLVO green with a red stripe.

GKLO and GKLVO are used for finishing wooden buildings, because in the event of a fire, they delay the spread of the flame for a time sufficient to evacuate people. All types of GKL and GKP are intended for internal use only, tk. long-term exposure to external conditions can not withstand. GKV racks in rooms with high humidity and occasional splashing (bathroom / WC, hallway, basement, garage), but not under windy rain.

The parameters of the most commonly used gypsum plasterboard sizes are given in the table, but in trade practice they are often divided more simply: into arched ones up to 6.5 mm thick, ceiling 9.5 mm thick and wall 12.5 mm thick (all including paper coating). Arched drywall is intended for the manufacture of three-dimensional decorative structures, but can also be used for auxiliary wall cladding, see below. Ceiling plasterboards of lesser weight, as the name implies, sheathe ceilings.

Basic cladding methods

Further, starting from the corner along the plumb line, vertical lines are beaten off in increments of 600 mm so that they fall exactly at the joints of the sheets. It should also be taken into account that the GKL sheets should be 20-30 mm from adjacent walls, floors and ceilings. That is, the first line is beaten off at 620-630 m from the corner, the next at 1220-1230 mm, etc. The last line should be the same 20-30 mm from the final corner, plus half of the mounting width of the profile, i.e. by 80-90 mm.

The next step - on the vertical lines make a mark of 80-90 mm from the floor and the following in increments of 600 mm, until less than 600 mm is left to the ceiling. Then the last vertical marks are also made 80-90 mm from the ceiling. A direct suspension is applied to the vertical marks in turn and the places for drilling holes for self-tapping screws into the wall are marked in place. If a standard sheets in height in this room is not enough, in a similar way, but now in terms of level, they mark the wall for mounting the crossbars. Do not forget that the longitudinal axis of the cross member profile must also fall at the junction of the plates of the sheathing belts! That's all for now, you can be distracted by marking and cutting the GKL.

GKL preparation

At this stage of work, you first need to cut incomplete sheets to size. It is simple to cut the GKL: an incision with a mounting knife, a break in weight, a cut from the inside, see fig. below. “From the inside out” is conditional, both layers of the GKL are the same. Next, chamfers are removed from the edges of the sheets for grouting. To do this, you need an edge planer for drywall, see fig. on right. If you have a one-time job for yourself, then it is better to rent it, because. for something else this tool is unsuitable. You need to take a planer at 2 angles - at 45 and 22.5 degrees; why - see below, about grouting.

Note: cut to size in width the last sheet along the row (belt) should be approx. 10 mm narrower than measured. The fact is that for thermal deformations of the sheets themselves, a gap of 1-2 mm must be given between them. On a wall of normal length, somewhere so much will come running. You can take this value into account when marking the wall under the frame, but there will be a lot of fuss, and a profile width of 60 mm on a regular wall is enough to compensate for the discrepancy.

The next moment is marking and drilling / cutting holes and openings for sockets, lamps, pipes, ventilation, etc. To do this, it is convenient to use a sheet of ordinary packaging cardboard 600 mm wide: it is applied to the wall, pressed over the recesses with the palm of your hand, outlined with a pencil, cut out and transferred to the plasterboard. In drywall, holes are cut with a pen or circular drill, and rectangular openings with a drywall knife. It looks like a mounting blade, only its blade is thicker and stronger.

Frame assembly

The installation of the frame for the cladding of the GKL begins with the installation of guide profiles on the floor and ceiling. If adjacent walls are not sheathed, PN profiles are also placed on them to make a solid frame, see fig. on right; the connection of its corners - for each on both sides with a TN9 self-tapping screw (so that the head does not protrude). First fixing points to the floor/ceiling 60 mm from the edge; the rest - with a step of approx. 300 mm so that the latter also falls 60 mm from the other edge.

Next, direct suspensions are attached to the wall, PS / PP profiles are inserted into the PN / PPN (first at the bottom, then at the top), shifted to the place and checked for their evenness horizontally and vertically with a rule and a plumb line or a level in which there is a tube for plumbness. If before. the work was done neatly, then additional alignment is not required. Then the "whiskers" of direct suspensions are bent to the rack profiles and the profiles are attached.

The next stage is the installation of the crossbars. How it is done is described above, but sometimes, say, when tracing pipes running along the wall, a second level needs to be added to the frame. This is done using 2-level crabs, see fig. left. It may also be necessary to assemble the cross members from pieces, because. they will be cut off. It is permissible to assemble rack and guide profiles from pieces only in the most extreme case!

Sections of the profile are connected end-to-end with straight connectors, pos. 1 and 2 in Fig.:

In critical places, for example, in the stroke of doorways, windows and mortgages for hanging furniture and equipment, it is highly desirable to connect crossbars with racks not in a simple way, and with the help of special crosses, the so-called. single-level crabs, pos. 3 and 4.

In the end, you should end up with something like the one in Fig. on right.

corners

In the case when GKL sheathed all the walls, special attention should be paid to the stroke of the corners. FROM internal problems usually not; schemes for tracing the inner corners for sheathing on the frame and combined on glue (see below) are given in pos. 1 and 2 next. rice. By the way, over the past year and a half, the Knauf GKL has been messed up to a complete disgrace: everything is in bubbles, soft, like foam, you can pierce it with your finger. Not counterfeit, original.

Outer corners are more difficult. It is impossible to put on their faces along the rack, at once 2 sheets will have hanging edges, which is unacceptable. The rack must be placed on one side of the corner, a hanging profile of the same type must be attached to it, and the edges of the plasterboard, pos. 3. Then, a PU profile is applied to the joint of the sheets with Fugenfüller glue or similar, pos. 4. PU is better to take with a reinforcing mesh, pos. 5.

PU protrudes above the GKL by 2-2.5 mm. This protrusion must be reduced to the general level of the skin at a width of 400-500 mm, then it will not be noticeable and will not interfere with any finishing. Smooth out the protrusion of PU with gypsum starting putty and a spatula, respectively. width.

Insulation under the lining

Generally speaking, it is bad to insulate from the inside: there is a high probability that the dew point will get inside the room. It is strongly recommended to lay insulation under the plasterboard sheathing only if the wall is already insulated from the outside. In this case, the insulation under the plasterboard sheathing concrete wall done according to the diagram in Fig. on right. If the wall is brick or wooden, before mounting the frame, a semi-permeable waterproofing membrane is applied to it, the same as that used for thermal insulation of roofs: it does not let water through, but releases its vapors. Best of all - microperforated membrane.

Instead of penofol, you can use foilizol or a similar vapor barrier. It is superimposed on the frame before installing the skin with a continuous layer of foil inside. The overlap of the edges of the vapor barrier tapes - from 15 cm; joints are glued with construction tape. The lapels of the edges on the floor, ceiling and walls are the same; the excess is cut off after installing the skirting boards. If there is no external insulation yet, then it is necessary:

- Sheathing is made of GKLV.

- Take not mineral wool as a heater, but cellulose insulation (ecowool), it does not fall off and retains its insulating properties when wet. True, ecowool will cost approx. 25% more expensive.

- Apply a microperforated membrane to any wall before mounting the frame.

sheathing

To mark the holes for attaching the GKL to the frame, pioneer holes are drilled in the sheets, approx. 2 mm in diameter, I apply the sheets in place and mark the places of the cuts on the profiles with a bench scriber. The indentation of the sheet from the floor in 20-30 mm is provided by scraps of a wooden lath. Mark them and do not lose, otherwise the holes will not converge later!

The number of attachment points is 45-70 per sheet 2000-3000 mm long, respectively. 5 points are on the short sides (3 on the racks and 1 between them); the rest are evenly distributed along the long sides and along the center line. The extreme points should be 9-12 mm from the edge of the sheet.

An important point when attaching the GKL to the frame is the screwing of the self-tapping screws. The screwdriver must be set at minimum speed so that the head of the self-tapping screw is only pressed into the cover paper without tearing it, as in pos. 2 fig. In other cases, the fastening will turn out to be weakened by 1.5-1.8 times, and if it is underscrewed (pos. 1), then the protruding heads of the fasteners will also weaken the skin. At the end of the fastening, the heads of the self-tapping screws are rubbed with gypsum putty.

Note: if there are 2-3 belts of vertical sheets on the skin on the frame, then there is no point in running it apart - the strength of the skin will not be added, only the frame will become excessively complicated. At the joints of the belts, you need to put the crossbars (see above), so that the horizontal joints fall exactly on their middles, and fasten the plasterboard as usual.

woodwork

Fasten the frame of the plasterboard sheathing directly to the wooden wall, as in fig. - gross mistake. You can see the building people have already taken a sip of grief on this and broke firewood: many schemes of a floating crate under the GKL in a wooden house roam the Runet. In fact, an effective damper between the "walking" wooden wall and ordinary direct suspensions can be GKL sheathing, you just need to put them correctly.

Sheathing of wooden walls of the GKL is carried out using a vertical counter-lattice of bars from 60x75; wider (60x100, 60x150) - it won’t be worse, only more space will be taken away from the room. Frame scheme - typical, from PN / PS profiles. As for attaching direct hangers to the bars, there are 2 options.

The first is in a house made of glued laminated timber and with central heating. The mounting legs of the suspensions are bent back and attached to the beam from the sides, so the entire skin will be tougher. The second - in other cases: the suspensions are attached to the beams with pairs of wood screws 6x60 through an oval hole in the suspension shelf (see again the figure with fasteners). Self-tapping screws are taken with faceplates and screwed into the wood, stepping back from the edges of the hole by 6-10 mm. In this case, it is desirable to make the sheathing 2-layer from sheets of 9 mm (arched plasterboard).

seams

The methods of grouting joints between sheets / gypsum boards are different depending on the type of decorative wall decoration. Under elastic finishing requiring an absolutely even base, but not afraid of microcracks under it (non-woven or foam wallpaper, PVC-based photo murals, plastic tiles) the edges are chamfered at 22.5 degrees so that the top angle of the V-shaped groove between the plates is 45 degrees. The groove is rubbed with a starting gypsum putty with a plasticizer flush with the common surface.

For other types of finishes, the edge planer is set at 45 degrees, and the top angle of the groove will be 90 degrees. In this case, the groove is filled with putty (preferably adhesive) in some excess, then rubbed into a strip. Further, until the putty has begun to set, a sickle tape is applied (on the left in the figure) and pressed with a polished steel spatula (on the right in the figure) or rolled with a slightly damp smooth roller. When the grout hardens, they rub it with putty and sickle with a smooth transition to the general plane, as on the outer corner, see above.

Note: at the crosshairs of the seams, they are first applied and pressed in a pair of L-shaped segments of a sickle with wings along the seams from 15 cm. Then a tape is laid along the seam with the same overlap on the wings.

Skirting boards

Skirting boards along the contour of the skin are attached to the floor or ceiling. If adjacent walls are sheathed, then a PU profile with a reinforcing tape is placed in the inner corner, as on the outer one, and a plinth is already attached to it with mounting glue.

Without frame

GKL sheathing on glue without a frame, as mentioned at the beginning, is quite possible. But, contrary to popular belief, its technology is determined mainly by the unevenness of the wall, and not by its material. Options for gluing GKL on the walls are given in the figure:

Method for pos. c - combined; first, a crate of strips of the same GKL is glued to the wall. According to the method used lumps of glue approx. 10 cm in diameter are applied in a checkerboard pattern with a step of 250 mm. The height of the lumps is the largest unevenness of the wall + 20 mm, because optimum thickness adhesive layer 12-20 mm. The wall for gluing GKL must be thoroughly cleaned of dust and dirt.

Note: prepare the glue exactly according to the instructions. It is unacceptable to close dry glue with water; you need to stir only with a drill with a mixer. In general, the strength and reliability of glued sheathing depends very much on the quality of water for the preparation of glue.

GKL is glued to the wall with continuous control of evenness horizontally (rule) and vertically (level with a bubble on a plumb line). Here the stumbling block for beginners is a crushed slab. It is unacceptable to pull it away from the wall, you can only press it down. In this case, pre-gluing beacons on the wall from scraps of the working GKL or any other can help out, see fig. on right. Firms involved in drywall will willingly give away small waste of arched GKL, they are just garbage to them. The transferred beacon can be torn off and glued again, in this case, the beacons are just a support.

Beacons are glued to the wall so that they fit between the cakes or strips of glue on the working plate. On a GCR sheet / slab, 4 beacons are needed at a certain distance from the corners. The lighthouses are first glued to the bottom row, leveling with the rule, then from the beacons of the bottom row they lead the rows up, pressing down with the rule and leveling. Plates / sheets of GKL are glued when the glue under the beacons gains strength, i.e. after 3-4 days.

Note: in recent times"People's builders" have even more reduced the cost and simplified the gluing of gypsum boards on the wall, replacing the glue with ... mounting foam. Technically, this looks very doubtful, but there is no more or less long experience in operating such a skin, so everything is possible in the future. Watch the video if you want https://www.youtube.com/watch?v=QEu7IJdnqVA and then decide if it's worth trying. In damp, cold (but not to minus!) utility rooms, it’s probably worth it. If it lasts there, it will fit everywhere. And the method is ridiculously simple and cheap.

GKL decor?

The fact that voluminous decorative interior details are made of plasterboard (on the left in the figure): arches, niches, shelves, dropped ceilings, even wardrobes, notoriously. However, a flat multilevel decorative trim drywall, in the center in fig. To do this, the blanks are glued to the wall, applying a thin (approx. 2 mm) layer of drywall adhesive to them with a notched trowel. If the room is sheathed close, where there will be no joints of plates on the walls, for example. balcony, then the sheathing can simply be painted, and PVC skirting boards or corners can be glued to the corners, on the right in fig. An option for sheathing with joints - do not chamfer the edges, leave gaps between the plates 2-3 mm, and roll a T-shaped furniture PVC edge into them with a smooth roller.

Suspension on GKL

For hanging furniture items and household appliances it is necessary to provide in advance in the frame embedded parts made of wooden beams or OSB. If the suspension point accounts for up to 20-30 kg, mortgages can simply be attached to the profiles, as in the figure:

If, however, there is more gravity at the suspension point or expensive equipment (TV, microwave oven) is suspended, then the mortgages must be framed with crossbars from the profile of the racks. Well, if that suspension point is less than 15-20 kg, then the suspensions can be fixed through the skin, see for example. video clip.