The height of the fence on the roof snip. Roof fencing: GOST and installation features of barrier structures Roof fencing in accordance with fire safety standards

The construction of new buildings is a rather laborious process, as a result of which apartments, offices, industrial premises. Regardless of the purpose of housing, it must comply with safety requirements. One of the elements that allows you to safely operate the building is a metal roof railing.

The main function that the roof fencing performs - its height is determined based on the characteristics of the roof and the building itself, comes down to preventing accidental falls of people, as well as fencing a dangerous area.

What you need to know about roofing security system

The existing classification of roof fencing is based on the design of the materials used for the production, as well as the size and shape of the elements. All of the above, one way or another, is regulated by the type of roofs and specially created standards.

Installation in accordance with GOST standards

Qualified builders when performing construction works refer to officially registered standards, in this case it is GOST, in which a list of requirements is compiled taking into account fire safety and labor protection.

Consider the basic rules for the arrangement of enclosing elements, depending on the characteristics of the building:

Features of the design of the fence

What material are the barriers made from?

Long before the necessary design is acquired and the roof railing is fastened, it is necessary to pay attention to the features of the materials from which it can be made. Roofing plays an important role. In this case, we are talking about a possible incompatibility different materials, which, when exposed to the atmosphere, will lead to a negative reaction.

The installation of a universal fence will greatly simplify the task of developers, since the level of its interaction with the environment and the roof is minimal, so rust will not appear on it at the bends, which is typical for a reliable and practical material. The high cost of such structures, along with long-term operation, in general, will make the acquisition more economical than other options.

Compliance with safety regulations when working at heights

Any roofing work, including installation roof railing, provides for compliance with safety rules:

Careless attitude to safety is fraught with injury.

Performing the installation

According to the basic technology, the fastening of the fence on the roof is carried out in the absence of precipitation and wind. This requirement significantly reduces the risk of roof falls.

The installation of roof barriers on the roofs of buildings is one of the most important stages in finishing the structure. Roof railings are designed to insure people during their stay on the roof: installers who regularly repair the roof, install new equipment or replace old equipment, building residents who can relax or do household chores on the roofs in use, firefighters who come to the call or perform a scheduled inspection of the roof .

It follows from this that the main function of roof fences is to prevent a person from falling off the roof of a building when performing repair, fire-fighting or maintenance work. When combining roof fences with snow holders, another important element of ensuring safety is achieved - preventing the massive descent of snow masses down, where there may be people, plantings, power lines or cars.

Pitched roof and materials that are used in its equipment

This type of roofing of buildings received the name "pitched" because of the peculiar design - the pitched roof consists of slopes - planes located at a certain angle of inclination (from 10 degrees or more). There are two main types constructive solutions when equipping a pitched roof:

- split roof with attic;

- combined roof without attic.

Life time pitched roof directly depends not only on the quality of the materials used, but also on their performance properties.

Wooden pitched roof

Most often, wooden pitched roofs are equipped by developers of low-rise residential buildings, using a structure consisting of trusses with various types of rafters. Often such a roof can be observed on houses that were built using Canadian technology. The truss system of wooden roofs includes:

- Mauerlat;

- racks;

- rafter legs;

- coupler;

- crate.

Such structures are used in buildings with two bearing walls, where there is no middle carrier.

A wooden roof has many advantages: wood is a relatively inexpensive material, environmentally friendly and has a long service life (with proper care).

However, it is not without drawbacks: wooden roofs are sensitive to fires and have low fire resistance, are practically unstable to damage by microorganisms and insects, decay and dampness, and are very sensitive to the corrosive influence of the external environment.

Coating "wood-metal"

Pitched roofs of this type are constructed from metal and wooden structures when their upper part is wooden, and the lower part consists of reinforcement. Arches, trusses and frames are usually made of wood. This type of solution makes it possible to work both in compression and in tension.

However, in practice, in private construction, such roofs are equipped much less frequently than wooden ones: they cost much more. But most often, wood-metal roofing is used in the construction of industrial buildings.

Wooden-metal roofing allows you to cover spans up to 20 meters long, it looks good and lasts a long time, but it is quite expensive.

Reinforced concrete roof structure

In this case, the truss structure is constructed from reinforced concrete: the rafters are manufactured at the factory and delivered to the installation site. The rafters have rectangular sections, and connect them to each other with embedded parts. Often, reinforced concrete structures are used in the construction of large-scale industrial and economic structures: barns or warehouses.

This type of roof is characterized by excellent performance, it has a long service life and does not require complex technological maintenance during use, it has increased strength indicators.

But reinforced concrete gives a significant load to the foundation of buildings (due to the large weight of the structures), and it is impossible to install the roof on your own (without the use of special construction equipment).

Features of fences of different types of pitched roofs

For rolled roofs, it is desirable to use only industrially reinforced roof railings.

For gable roofs the same standards and rules apply as for all other types of non-exploited roofing. The code of building requirements states that when arranging roof fences for such roofs, it is possible to do without installing a rigid base under the roof fence, based on the fact that there will be no constant crowds of people on the roof.

But for those situations when repairs, installation of equipment or firefighting work are being carried out, and a person will have to spend some time on the roof, it is necessary to mount special fences in the format of a ladder or bridge. Such barriers on the roof will be able to evenly distribute the weight of a person over the entire roof area and reduce the risk of a person falling to the ground.

The state standard informs that on non-operated roofs of administrative, industrial and other non-residential buildings, a system of roof fences with a height of at least 60 cm must be equipped, regardless of the height of the structure, the number of floors in it or the angle of the roof.

For residential buildings, the height of the fence should be doubled - up to 120 cm. Indicates GOST and the distance between any two elements of the barrier structure - up to 30 cm.

The Code of Construction Rules and Regulations, issued 01/21/1997, requires non-operated roofs to be equipped with a safe exit and roof railings along the entire roof perimeter line. If the gable roof is partially exploited (sections of the pitched roof alternate with flat exploited ones), when arranging the roof, be sure to consider the following requirements:

- in without fail roof railings are installed on roofs whose height exceeds 10 meters, and the roof is tilted by no more than 12 degrees; on roofs whose height is more than 7 meters from the ground level, and the roof is inclined by more than 12 degrees;

- if the height of the structure is less than 30 meters from the ground, a roofing barrier with a height of at least 110 cm is mounted along the entire perimeter of its roof; at a height of a structure of more than 30 meters from the ground, a roof barrier with a height of at least 120 cm is mounted along the entire perimeter of its roof;

- if there is a parapet on the roof of the structure, the height of the roof fence can be reduced by the height of the parapet;

- the distance between two transverse elements of the fence structure should always be no more than 30 cm, the distance between two vertically located - up to 1 meter.

Railing for a mansard roof with a large slope

A small roof slope on a mansard roof is a rarity: they almost always slope quite steeply. In such conditions, installing a roof fence is not only difficult, but often almost impossible. However, the Code of Building Regulations requires the installation of a roof barrier on a building if:

- the roof of the building is tilted up to 12 degrees, and the height of the building exceeds 10 meters from ground level;

- the roof of the structure is tilted by more than 12 degrees, and its height exceeds the mark of 7 meters.

This means that you will need to expand the cornices or make fences in such a way that they can be installed in a vertical position.

When installing a fence on a mansard roof, you need to remember that the distance from the cornice must be at least 35 cm. less than 120 cm in height.

When installing a fence on a mansard roof, you need to remember that the distance from the cornice must be at least 35 cm. less than 120 cm in height.

If there is no 30 meters from the roof of the building to the ground, a roof barrier 110 cm high can be installed. Again, the height of the fences can be reduced if the roof is equipped with a parapet. The following requirement must be fulfilled: there must be a distance of up to 120 cm between two vertical elements of the fence structure.

On a pitched roof of any type, the roof fencing should not have “empty” sections, be located along the entire length of the perimeter and withstand static loads of 0.3 kN / meter. This requirement applies to all industrial and residential facilities.

By the way, similar requirements of GOST and SNIP are imposed on multi-gable roofs with a complex relative position of slopes.

Features of installation of roof railings of a pitched roof

Metal roof barriers prepared for installation must include the following elements:

- supports (they are also racks) - pipes, most often having a circular cross section;

- transverse elements - also pipes with a circular cross section;

- brackets that fix the racks on the roof and fix the fence in the desired angle;

- small parts: washers, screws, bolts.

Remember that railings must be installed on the roof of any slope strictly vertically, at an angle of 90 degrees to flat surface earth. The combination node of each section and the transverse elements of the roof must be treated with a sealant. If the length of the fence pipe needs to be reduced, use a non-abrasive tool - a hacksaw.

Remember that railings must be installed on the roof of any slope strictly vertically, at an angle of 90 degrees to flat surface earth. The combination node of each section and the transverse elements of the roof must be treated with a sealant. If the length of the fence pipe needs to be reduced, use a non-abrasive tool - a hacksaw.

The most reliable is the installation of fences on hinged mounts. Start work on installing the fence by determining the place where the support will be fixed - it should be no closer than 35 cm to the inner edge of the eaves.

At the selected point, a rubber lining is placed, and then the bracket is fastened with self-tapping screws to the batten board through the roof covering. To determine the step between two vertical elements, read the requirements of GOST and SNIPs.

Remember that the enclosing supports are fixed using only galvanized screws at the lowest point of the wave (if the roofing material is not even), placing a rubber gasket.

In this way, you need to fix all the brackets around the perimeter of the roof in order to install the racks next and adjust the desired angle at which the support will be tilted. The hinge is fixed in the desired position with the help of washers-gaskets. Then the first crossbar is installed, passing the pipe through the technological holes and fixing it with a bolted connection.

Similarly, you need to install and fix the remaining horizontal crossbars. After the design is ready, it is necessary to install the plugs and seal the places of all joints with a sealant.

Properly installed roof railings ensure the safety of people on the roof and near the building. Do not forget that:

- it is necessary to install roof railings, taking into account the requirements of GOST and SNIPs;

- it may not be possible to install a fence on pitched roofs: expand the eaves or install a fence of a different design;

- seal all joints with sealant;

- order an inspection of the installed fences and save the certificate of its conduct.

An ideal roof includes not only high-quality and expensive material for covering it, the complexity of the configuration or unique design but also a safe fence. In European countries, the constructed building will not be put into operation if a protective system is not installed. It consists of a snow retainer, a ladder, safety hooks, walkways and the fence structure itself.

Fencing the roof with railings will prevent a person from falling during repair work on the roof, installing an antenna, when cleaning ventilation or chimney pipes, and in the winter-spring months it will delay the avalanche of snow or ice. In addition, it will protect people and property from accidental falls of objects during roofing work. The roof railing is a steel grating, which can also be in the form of balusters or parapets that rise above the roof.

There is a huge choice of both materials and colors of fences suitable for any type of roofing material: stainless and galvanized steel, aluminum and copper. This diversity allows them to harmoniously fit into the overall appearance of the building.

Elements of the construction of the roof fencing

Snow guard , prevents the fall of layers of snow. Its installation can be performed along the perimeter of the building or fence only part of the roof of the building, installing it only in problem areas. It is produced both with universal fasteners for any type of coating, and with a fastener designed specifically for seam roofing.

transition bridges are used for safe movement on the roof. With the help of connecting elements, their length increases, while the fastening fragments do not interfere with free movement. If necessary, the angle of inclination is adjustable.

Wall stairs provide safe access to the roof for carrying out various kinds works, and can also serve in emergency situations, providing access to the building.

roof fencing requirements

Roofs are subdivided according to the type of structures: flat and pitched, and according to maintenance - operated and non-operated. Although the latter type of roof does not provide for the presence of people on it, it is still required to be equipped with a fence, the minimum height should be 600 mm, regardless of the height of the building itself.

Mansard roofs often have a rather steep angle of inclination, so roof fencing is rather difficult, and often not at all possible.

In accordance with building regulations, a building with a roof slope of up to 12% inclusive and a height exceeding 10 m, as well as a building with a height of more than 7 m with a roof slope exceeding 12%, are subject to the installation of a fence.

The distance from the edge of the cornice during installation should be 35 cm. The height of the roof fence depends on the height of the structure, if it is up to 30 m, then the structure should be 1100 mm, if more than 30 m, then 1200 mm. On the building, originally equipped with a parapet, the protective system is mounted along its height.

The distance between the risers should not exceed 1200 mm and can be adjusted depending on the roofing material.

Roof railings should be safe and easy to install. The mounted system, as well as the fastening elements on a pitched roof, must undergo a strength test to determine its reliability.

To do this, a horizontal load equal to 54 kgf is applied to points located no more than 10 m apart, after a couple of minutes it is removed. If there is no violation of the integrity of the structure and there is no residual deformation, then the test was successful.

What is roof fencing

As a rule, this is a collapsible design that allows installation in a fairly short time. Its installation can be carried out on absolutely any type of roofing material and even a wavy surface. Below is a drawing of the roof railing.

5-adjusting bracket;

6-universal bracket;

9 - screw with a hexagonal head 8x50 mm;

Rigidity is given to it by brackets and diagonal stops. With the help of hinged fastening, the fence is mounted on the roof with almost any slope.

The profile for metal fencing of the roof comes in various thicknesses and configurations. But in any case, the quality of the material for its manufacture and for all components plays an important role. The most commonly used are galvanized and stainless steel, sorbitol coated with a special powder composition or copper.

Types of materials and their characteristics

Cink Steel thanks to rolling with increased precision, it is used for the manufacture of fasteners and any kind of fences. High corrosion resistance is achieved by applying a zinc coating. Products made from this rolled metal can be used for an average of 50 years. In addition, galvanized steel is resistant to temperature extremes, and is able to withstand from -80°C to + 300°C, while it has a low degree of thermal conductivity and is significantly cheaper than other materials with similar properties.

Galvanized steel with special coated , the composition of which contributes to an increase in the service life, and also with the help of it you can give the product a variety of color shades.

Stainless steel - it contains a variety of alloying components, for example, chromium, titanium, nickel, molybdenum, etc. Where the main element of the alloy is chromium (up to 20%), the higher its content in steel, the higher the degree of corrosion resistance. The resulting film protects the steel from the effects of the surrounding atmosphere.

Copper is a heat and electrically conductive material with excellent anti-corrosion characteristics, its melting point is 1083°C. After about 10-15 years of operation, the products are covered with a dark green patina, which becomes an impenetrable barrier from the effects of atmospheric phenomena.

Protective structure kit

The kit contains support posts with mounting brackets and 3 m of railing pipe. If the height of the racks is 600 mm, then two lines of pipes are required, with a height of racks from 800 mm - three lines or more. Depending on the design, the required number of screws and bolts is included in the package.

For high-quality and convenient installation, the kit includes all the necessary fasteners and other additional elements, such as plugs for racks, which prevent premature development of corrosion on their inner, unpainted surface. As well as rubber gaskets that prevent moisture from entering the holes made during installation.

In some designs, the pipes are connected by a mother-father transitional type, which allows you to increase the length without the use of cutting and welding equipment.

The attachment point is an important place when mounting the rack to the roof surface. Fixing to the folded roof occurs with the help of a clamping device - clamps, this method allows you not to violate the tightness and integrity of the folded picture.

On profiled and flat roofs, installation is carried out using fixing screws, sealing washers-gaskets. The screw being driven deforms the spacer, which fills the space around the mounting hole. To install a fence on a pitched roof, the angle of which is 15-45%, will help the hinge mount without the use of additional tools.

Such a fencing system carries both a functional and a decorative component. If necessary, it can be additionally equipped with a snow retainer.

Installation of roof railing on hinged fasteners

This type of fastening requires continuous crate, it is worth noting that installation can be carried out both before laying the roofing, and after.

Work begins with determining the place where the rack supports will be attached. The required distance from the edge of the eaves should be measured. Having installed the bracket at the desired point, placing a rubber gasket, using self-tapping screws, it is fixed into the crate through the coating material, the step between the supports should be 900 mm. If the roof surface is covered with corrugated material, then fasteners are made to the places of its deflection.

Then it is necessary to adjust the required angle of inclination of the support, and fix the hinged device at the desired point with washers-gaskets. Further, the pipe is passed through the prepared holes and fixed with bolts, the same manipulations should be performed with the second and third crossbars (if any are provided for by the design).

The final stage of work includes the installation of plugs and sealant treatment of the joints.

The principle and course of operation of installing a fence on a seam coating is the same, only the mounting system is different. For this kind of roofs, a special device is used, which is a tightening bracket. It is mounted on the crest of the fold using a special clamp, which fully ensures the integrity of the roofing, thereby eliminating leaks.

Do-it-yourself fencing design

For pitched roofs, it is recommended to use factory-made reinforced railings. A railing-like structure suitable for flat roofs with a flat horizontal surface can also be built with your own hands. The main thing to remember is that quality materials and competently carried out work on the connection of all components depends on the safety of people.

For a frame of one section with a height of 600 mm and a length of 2.5 m, you will need:

- 6.5 m of U-shaped metal profile 40x25 mm;

- 4 m profile 25x25 mm or rods Ø 16 mm;

- screws (anchor bolts) for fastening the section to the roof.

Tools:

- welding machine;

- Bulgarian;

- drill with a drill for metal;

- You may also need a perforator.

From the profile (40x25) with the help of a grinder, it is necessary to prepare the following parts: 2 racks of 600 mm each, 2 horizontal bars of 2.5 m each; from a profile of 25x25 mm or a metal bar with a cross section of 16 mm, 8 horizontal bars 500 mm long and 2 support posts 400 mm each are cut. You will also need 4 metal plates 10 mm thick and 7x10 cm in size.

Stages of work:

- in all 4 plates, mounting holes are pre-drilled for subsequent fastening to the roof base, the diameter of the drill should be slightly larger than the diameter of the screw or anchor bolt;

- support posts are welded to the plate at an angle of 90 °;

- then the retaining elements are welded to the metal plate at an angle equal to at least 30°;

- further, the vertical upper crossbar is also welded to two straight racks;

- 500 mm is measured from it and a second boundary line is being installed;

- the remaining clearance of 100 mm will not allow dust, leaves or snow to linger on the roof;

- between the crossbars, vertical lines from a profile or a rod are mounted, the pitch of which will be approximately 300 mm. You can attach them both from the inside and from the outside of the structure;

- it remains to attach the supports to the finished frame;

- the structure is mounted to the crate using screws. If the roof surface is made of concrete, then it is necessary to make holes with a puncher and use anchor bolts as fastening materials, the length of which should be at least 160 mm.

It should be noted that the length of the structure can be increased almost indefinitely with the help of additional sections. However, each subsequent block is made without the first support post, in which case the horizontal bars are welded to the last post of the previous frame.

Estimate for roof fencing

Above, a detailed list of all necessary materials. The final cost is calculated individually for each roof, and depends on a large number of factors. But in order to roughly navigate its final cost, below is a list of prices for materials for roof fencing.

It is important to observe all precautions when installing any type of roof fencing. Such a system is an indispensable element of any building, ensuring the safety of both people on the roof during repair work, as well as property located in close proximity to the building from falling various construction objects.

Most buildings (10 meters or more high) have or should have roof railings. In some cases, they are mounted and operated with deviations from the requirements of GOST. Let us consider in detail in which cases the installation of fences is required, which technical requirements are presented to them and how they should be operated.

The normative document that establishes the requirements for roof railings is GOST R 53254-2009 "Fire fighting equipment. Fire ladders external stationary. Roof railings. General technical requirements. Test methods".

Building roof railings

There are two types of roof railings - for a roof with a parapet (KP) and for a roof without a parapet (KO).

The need for roof fencing:

According to the requirements of regulatory documents, fencing must be provided for:

- buildings with a roof slope of up to 12% (6.8°) inclusive, up to the eaves or top outer wall(parapet) more than 10 m;

- buildings with a roof slope of more than 12% (6.8 °) and a height of more than 7 m to the eaves;

- operated flat roofs, balconies, loggias, outdoor galleries, open outdoor stairs, flights of stairs and venues

Technical requirements:

Roof railing structures must be manufactured in accordance with the requirements of GOST R 53254-2009, GOST 23118, GOST 23120, GOST 25772 and according to working drawings approved in the prescribed manner. They must be primed and painted in accordance with the requirements of GOST 9.032, the coating class is not lower than the fifth.

Fencing elements must be securely attached to each other, and the structure as a whole is securely attached to the roof of the building. The presence of cracks and breaks in the metal is not allowed.

Roof railings should not cross the exit to the roof from fire escape platforms.

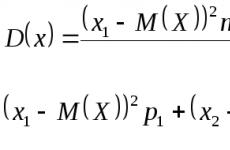

Dimensions of roof railing elements

1. Without parapet.

2. With a parapet.

1- vertical enclosing element; 2- horizontal enclosing element

*not regulated

Operation of roof railings

Guardrails must be kept in good repair and at least once a year it is necessary to conduct a survey of their integrity with the preparation of an act based on the results of the verification.

In case of detection of structural integrity violations, they are restored (repaired) with subsequent strength tests.

Tests and annual inspection should be carried out by organizations having trained personnel, certified test equipment and measuring tools with the results of its verification.

Preparing for fire inspections

Fire safety audit

Profiled film where it is not used. This roofing material for roofs and wall coverings and accessories for various fences.

And all because of the low weight of this building material, it is the original appearance and is able to withstand heavy loads.

Right off the bat, we must determine that corrugated panel is a versatile building material that is not a thick galvanized sheet with an extruded recess (longitudinally).

These grooves can be rectangular, trapezoidal, wavy. Production prof. Floors are made of high quality steel cylinder or galvanized cold rolled steel. The thickness of the steel sheet can be 0.5-0.9 mm and should not be specially coated.

All about roof railing

The most common way to use polymeric substances. Read more...

Pipe Profile

Pipe profiles are often used in various industries due to their reliability, durability and economy.

Therefore, the use steel pipes in world practice is growing every year, and their operation is increasingly focused on buildings and structures of large arrays.

What are the pipe profiles? Pipes with a cross section that is very different from a round pipe. Steel pipes of this type are made up of various shapes cross section what is known: oval pipes and square, ribbed, flat oval or rectangular pipes, as well as segmented, faceted (3, 6, 8 surfaces), tear and others.

The material from which they are made profile pipes, - low-carbon and carbon steel. Read more...

profiled

Profiler is the name of a building material. Its volume cannot be measured at all - this building material is used both in construction and in industrial construction.

Why do many consumers prefer to buy profiled sheet metal over other roofing and wall materials? The answer is simple - a profiled sheet can combine all the advantages and properties of excellent building materials. In addition, its price is much more affordable for the average consumer, and its volume is not limited to zero. Because corrugated sheet has a very cold climate, it is hot, easy to install, and can take a long time.

But at this point, there will be more focus on a topic, such as setting up a fence from a profile. Read more...

fittings

Reinforcement is a complex of parts and devices that are connected together and used in concrete in the production of various reinforced concrete structures. All elements of this assembly are not the main parts of structures or structures, but support their continuous operation.

Basically, these are steel bars that are connected together in reinforced concrete structures. There are several types of element combinations.

The first is a gas pipeline. It is used for gas, water, industrial products.

AT electrical networks ammo, shields and sockets act as reinforcements. The third is the oven. It is a series of various metal furnace parts and is used in metallurgical furnaces. In addition, the fittings are arranged in accordance with the purpose, conditions of use, and the construction of the building. Read more...

The roof of a large building consists not only of a roof, but also has many additional elements. The more complex the roof device, the more counter connections in it with additional structures - nodes. When installing the roof, they must be most carefully equipped and sealed. This will prevent leaks during use.

The fence on the roof will ensure her safety during work and movement.

Roof guard structures

Roof fencing is an important part of the roof structure, which ensures the safe operation of the roof and the possibility of its high-quality maintenance.

The obligatory presence of enclosing devices on the roofs of buildings with a height of more than 10 m is stipulated in the regulatory documents in force in the construction industry.

Roofing installation instructions.

For each type of roof (pitched and flat) there are standards for installing fences.

They are described in SNiPs and taken into account at the design stage. For a metal building envelope, the following approximate dimensions of the fence are recommended:

- support height - 70 cm;

- the distance of the supports from the cornice is at least 35 cm;

- the interval between the supports is 90-120 cm.

Enclosing devices of a standard type have the form of a prefabricated structure.

They consist of vertical supports and horizontal beams rigidly fastened to the roof and to each other. The supports are made from a corner bent in the shape of a triangle. Horizontal crossbars can be made of steel pipes 3 m long. They are installed in supports through special holes and fastened with bolts (upper - M10x35, lower - M8x55).

The holes at the ends of the pipes are closed with polyethylene plugs.

Designs, types and features of roofing fences

Galvanized and stainless steel is used as a material for the manufacture of roof fencing.

On inverted roofs operated in the summer period, deaf reinforced concrete fences - parapets are equipped. On these types of roofs, they are mounted regardless of the number of storeys. The normalized height of the lattice fence in this case is reduced by the height of the parapet.

Roof barriers such as snow retainers are divided into tubular and bent from metal sheets.

Their fastening is carried out according to the same technology as that of the enclosing ones.

Types of roof attachment points with fencing

Roof railing diagram.

The connection of the supports of the enclosing structures with the roof surface requires special attention during installation; the safety of roof operation depends on its strength.

The device of junction points is planned in advance at the stage of roof installation. Special embedded elements are installed under the waterproofing layer or special structures are constructed with then an additional waterproofing layer applied.

The vertical metal post of the triangular support bears the functional load, the horizontal one creates the attachment point of the structure to the roof.

The diagonal bar provides the rigidity of the fence. The support is leveled in accordance with the slope of the roof, fixed with bolts. The assembly is fastened to the roof beam using three galvanized M8x60 self-tapping screws and rubber gaskets.

The attachment points of the safety fence to the roof structures must be as reliable as possible and exclude the possibility of self-relaxation of the fasteners.

The crate under them is solid.

When using universal brackets, the position of the attachment point is adjusted according to the slope of the roof. The interval between the brackets is equal to the pitch of the rafters. Mounting points are covered silicone sealants. Special plugs are applied to the sections of the roof adjacent to the fasteners.

Some companies produce roof railings with fastener sets for various types of roofing: seam, with natural and metal tiles, from corrugated board, bituminous, etc.

e. Fences are also made to order, in harmony with the appearance of the roof and the building as a whole. Protective elements and sealing washers are completed. When screwing in the screw, the spacer washers deform and tightly fill the drilled holes in the material.

On a roof made of metal tiles or seam fasteners are mounted at the bottom of the wave in the support bar.

Guardrails can also be mounted on sandwich panels and profiled sheets H114, H75, H60. Upon completion of installation, all joints must be sealed.

All joints of the roof and fasteners are carefully coated with bituminous cold mastics or compounds with the addition of fibrous fillers.

For mounting the safety structure on the seam roof, a mounting clamp is also used.

At the same time, the integrity and tightness of the folded paintings is not violated.

On asbestos-cement roofs, for reliable fixation of supports on the crests of the waves of the cornice row of sheets, bent steel plates 5 mm thick are installed.

Secure them with screws and nuts through a wooden gasket. Under the run, corners of half a meter in length are welded to the plates and fence posts are already attached to them. Racks are prepared from reinforcing steel Ø16 mm.

Upon completion of the installation of fence structures, special strength tests of the fence attachment points are carried out.

In European countries, without the construction of safety structures on the roofs of buildings and their testing, housing construction cannot be insured.

When often needed Maintenance at home to go up to the roof. To remain more or less safe on it, it is necessary that the height of the roof fence and the fence down in terms of security comply with legal regulations. Dimensions and basic requirements set out in the relevant parts of the current GOST 25772-83, which, in turn, is connected to SNIP 31/06/2009 related to public buildings and SNP 01.31.2003, in relation to high-rise buildings.

Purpose of the fence

The roof fence is metal structure installed continuously around the entire perimeter of the roof or just along the roof.

It consists of:

- supports - hollow pipes or profiles;

- horizontal long elements - rods;

- universal supports that ensure the spatial verticality of the body;

- Fasteners are designed to fasten the poles to the roof or rooftop.

If the height of the house exceeds 10 meters, in any case it is necessary to install a roof fence, SNiP and at the same time mention the tiles.

For them, the height of the ground height is determined not on the upper, longitudinal ridge, but on the breakdown of the shear structure. In some cases, the standards require the installation of a fence for fences with elements of snow 150 mm high.

Roof rails ensure the safe presence of people on the roof, lift it to make repairs and coatings, fire, snow removal, chimney cleaning, install an antenna, etc. Prevents falling from a height and helps people move to the roof and ran the fence.

Due to the ease of walking on sloping roofs, walkways are located along the entire length of the roof railing.

For fenced roofs, fencing is both a protection and a decorative element.

The developed design allows tourists to enjoy a panoramic view of the metropolis or the surrounding natural landscapes without fear of tragic consequences with an accidental loss of balance.

The solutions in this case are more elegant, but no less reliable than conventional unused roof cases. But in any case, the design of the fence must match the entire architecture of the house.

Regulatory requirements

How high is the roof, GOST provides:

- for unused roofs - at least 600 mm;

- for the operation of roofs - depending on the height of the building.

If it does not exceed 30 meters, the upper level of the fence rises above the roof level by 1000 mm or more, and if the structure is higher - at least 1100 mm.

In the first case, it is assumed that the stem of the column is in the range of 1200 mm, and the distance between the horizontal passes is 300 mm. In the second case, the standards require the addition of vertical elements to the fence, which is equipped with a maximum diameter of 110 mm.

Similar requirements apply to balconies.

In the case of roof parapets, the height of the roof protection is reduced by the height of the difference between the roof levels and the top of the concrete or brick barrier.

If the parapet has standard height, the need for its design disappears by itself.

building pavement requirements

But such examples are rare in modern construction, since additional "growth" on the walls, with the exception of increasing the constant load on the foundation, does nothing.

The standard designates guides on the roof:

- KO - without parapets;

- KP - with the presence of a section of parapets along the perimeter of the roof.

When marking products, the length and height of the fence in decimeters, the GOST number and the possibility of filling the frame are also indicated:

- P, only with vertical and horizontal elements;

- E - screen, with sheet materials covering the main frame;

- K - total, with partially covered areas.

An example of the designation of a roof grid without a railing 3 meters long and 0.6 meters high is the following:

However, regardless of the size of the metal barrier, it is superimposed general requirement detection of horizontal forces.

According to SNiP 2.01.07-85 *, under the influence of loads less than 300 N per meter of structure, the fence must remain motionless.

According to statistics, welded metal frames provide the greatest security, but there are fences on the market that consist of connecting crabs and fasteners. In order to attach the railing to the roof elements, we need special fasteners and to install screen inserts that are not included with the roof railing, conventional equipment.

The durability of metal elements is ensured by high-quality paint or anti-corrosion coating is used in the production environment - galvanization, composite, etc.

Without appropriate initial and subsequent routine surface treatment aggressive effects environment can quickly lead to rust.

To avoid problems, the rooftop should be checked every five years. It is necessary to check the integrity of the structure, the stability of the position and the reliability of the fasteners, various defects in protective layer etc.

It is wise to test problematic fences for energy experts who have the appropriate test equipment.

Rules for obtaining finished products

Rooftop metal rails with a height of 600mm or more are tested by the technical control department of the manufacturing company according to the production process.

A batch may contain products of only one mark in an amount not exceeding 200 pieces. For quality control, 5-10 units of products are selected. The review is carried out on several parameters, and if at least one of them is not satisfactory, it determines additional checks and measurements for work in parts.

They are controlled by:

- appearance;

- high-quality protective coating;

- linear dimensions;

- welds;

- deviations from perpendicularity and straightness;

- correct labeling.

Roof rails are designed for safety during transport and storage.

Packaging should protect products from accidental mechanical damage to the protective coating. The weight of one package should not exceed three tons. It contains elements with the same height.

May 31, 2016 at 04:05 pm

Roof- the upper insulating and enclosing part of the building, which serves to protect the building from adverse environmental influences. It consists of a waterproofing layer and a base (battens, solid flooring) laid along the supporting structures of the roof.

The roof consists of bearing and enclosing structures.

The enclosing structures are the roof and gable/gable. The supporting structure is a truss system.

Attic- this is the space between the surface of the coating (roof), the outer walls and the ceiling of the upper floor.

stingray- the edge, the sloping surface of the roof.

bias- the roof slope indicator, is determined in three ways: in degrees of the angle between the roof slope and the ceiling of the upper floor; in percent - the ratio of the height of the roof (H) to the projection of the roof slope on the ceiling of the upper floor (L), multiplied by 100 = (H / L) ⋅ 100; in proportions (H:L).

pitched roof- a roof with a slope of more than 6 ° (10%).

With a lesser bias they call - flat roof.

Mezzanine- a superstructure of a small height above a part, usually the central one, of a low-rise residential building, which has its own roof, towering above the common one.

Dormer windows- openings for lighting and ventilation attic space, as well as access to the roof.

Roof types by geometry

Performance characteristics

According to operational characteristics:

- the roof may have a non-residential attic and residential (mansard);

- exploited roof and not exploited.

Attic(attic floor) - residential attic.

The attic may not be insulated (only the ceiling of the upper floor is insulated) and insulated (the roof slopes are insulated).

Roof operated- flat roof used both for its intended purpose and for other operational purposes: recreation area, sports ground, lawn, etc.

Protective structures of the roof

Roof- the upper fencing (shell) of the roof, directly exposed to atmospheric influences.

Protects the building from the penetration of atmospheric precipitation.

Gable- the end part of the roof, part of the facade of the building, the enclosing structure between the roof slopes. It serves to create a closed room under the roof (attic) and to protect it from adverse environmental influences.

The pediment is separated from the lower part of the wall by cornices and, as a rule, is made of a different material than the wall, for example, a wall of timber or brick, a pediment of boards.

Tong (wimperg)- the top of the end wall of the building, which has an acute-angled shape and is located between two roof slopes, but, unlike the pediment, the gable is not separated from the wall by a cornice and forms a single plane with the facade and is made of the same material.

If we compare the gable with the pediment, then the difference will be, in the absence of a cornice that visually separates the wall and the pediment, and the material of the pediment may differ from the material of the wall.

Visor- a mini roof, which is located above the end walls under the gables and serves to protect the walls from atmospheric moisture.

Eaves- the outer strip of the roof slope, protruding beyond the line of the wall.

It serves to prevent precipitation from falling on the walls and is at least 75-80 cm.

Roof railing height - regulatory requirements, acceptance rules

The overhang of the roof is divided into gable and eaves.

roof eaves- this is a structure consisting of a roof overhang and its closing part from below and from the side. The cornice differs from the overhang in that it completely covers all the elements of the truss structure that extend beyond the line of the walls. The cornice protects not only from atmospheric precipitation, but also prevents the penetration of dampness and various living creatures into the attic and into the under-roof space.

Cornices can be not only completely part of the roof, but also part of the wall. The cornice encircling the entire perimeter of the wall is called - crowning cornice. For example, when the roof cornice passes into a visor that separates the gable from the wall. Soffit- hemming cornice board.

Roof elements

Skate- the uppermost element of the roof in the form of a corner, which serves to close the junction of the roof slopes.

Hip- a triangular slope of a 4-pitched roof, located at the end of the house, covered from above rests with a sharp end.

Half-valma- a hip, the length of which is shortened along the slope from the side of the ridge of the roof or from the side of the end of the building.

Endova (groove)- the inner corner of the roof in the form of a gutter, formed by the connection of two slopes.

Ridge (rib)- the line of intersection of two slopes forming an external corner.

Products — ventilation holes in a pitched roof.

Aerators- vents of flat roofs, mechanical devices for ventilation in the layers of a full pie of flat roofs.

Be sure to use when making a new carpet according to the old one.

fillet- a transitional ledge from the base of a flat roof to an abutment, usually arranged at an angle of 45 ° to smooth the corners of the mates.

razuklonka- screed device on a flat roof with small slopes and the formation of ridges and valleys.

Roofing films- are used to protect thermal insulation and load-bearing structures roofs from moisture.

Basic waterproofing (or roofing) carpet- layers of rolled materials or layers of mastics reinforced with glass or synthetic materials, sequentially performed on the base under the roof.

Ballast system- fastening system soft roof on the flat roofs with high bearing capacity, as well as in exploited roofs.

Affordable, easy to install and does not damage the main waterproofing carpet, and in addition, provides it additional protection from mechanical damage and ultraviolet rays.

Collar- protective edging with roofing iron of the protruding elements of the roof.

dropper- an element of the steel coating of parapets, firewall walls in the form of an edge bent down.

gutter- an element of a pitched roof with an external drain, designed to collect water and forced discharge into drainpipe atmospheric water.

downpipe- a pipe used to drain water.

Roof load-bearing structures

truss system- a structure consisting of rafters and other elements that perceives and resists all types of loads and transfers them to the walls of the building.

Consists of roof trusses.

Farm- a structure of bars or rods fastened together.

Rafter(rafter leg) - an element of a truss truss that perceives all types of loads and transfers them to the walls, and the upper floor of the structure, serve as a support for the roof.

The lower end rests against the wall, and the upper end is connected at an angle to the opposite rafter leg.

Inclined rafters- have an emphasis on the ends and the middle part (at one or more points).

Hanging rafters- resting in the lower part on a puff or Mauerlat and in the upper ridge part rely on each other or on the ridge run (without intermediate supports).

Skate- the upper horizontal edge of the roof connecting the roof trusses.

Skate fight- a piece of board / plywood or a metal lining connecting the rafters in the ridge.

Mauerlat- a beam located along the perimeter of the wall, on which the lower ends of the inclined rafters rest.

Mauelat allows you to distribute the concentrated load from the rafters to the entire section of the wall.

Rack- a piece of board / timber based on a puff and supporting the rafter leg, serves to unload the rafters and to organize the walls of the attic.

grandma- the central pillar, which rests on the ridge.

Strut- Angle stand.

Rigel- a piece of board connecting the rafter legs to each other.

Serves to increase the rigidity of the truss truss and prevents the rafter legs from moving around.

puff- a log / beam / board connects the rafter legs to each other. It differs from the crossbar in that the puff is based on the Mauerlat and the bed.

filly- a piece of board that lengthens the rafter leg to organize the roof overhang.

Sleg- guide for natural tiles.

roof base- the surface on which the roofing is laid.

Usually performed in the form of a crate or solid flooring.

crate- roofing flooring made of boards or bars, attached to the rafters and serving as the basis for roofing.

The lathing perceives the entire weight load from the roof and transfers it to the truss system through the counter-lattice and rough flooring.

counter grating- bars with a minimum section of 30 × 50 mm, located under the crate, perpendicular to it and providing ventilation of the under-roof space and serving to fix the waterproofing film.

Draft flooring- flooring from boards, chipboard, fiberboard or other types of boards that are nailed directly to rafter system and serves as the basis for the waterproofing material and the basis for fastening the counter-lattice.

obreshetina- an element of the crate, which is made of wooden bars, slats or planks of coniferous species (without wane and passing knots) not lower than the second grade, on which the tiles are laid.

The minimum section of the bar is 30 × 50 mm.

Using the ladder, each of us at the subconscious level, we are trying to find a handle that you can rely on and feel more confident. For this reason, it is important that the height of the stairs match optimal parameters and that the grip itself must be properly shaped. Many masters who build stairs leave this shade out of attention and at the same time make a big mistake.

In this article, we will look at all the details of the design of the fence stairs and how to make different types of fences.

When designing a staircase project, it is necessary to take into account not only the problem of design and comfort, but also the existing regulations.

When it comes to stair railings, you should refer to the following groups of rules:

Often in their professional activity builders are guided by other regulations, but it is enough for us to confine ourselves to these two basic documents.

SP 17.13330.2011 Roofing. Updated version of SNiP II-26-76

Of course, this only applies when we are dealing with hosting objects for personal use. In cases where work is carried out to order, there is no need to coordinate all structural elements not only with the customer organization, but also with supervisory authorities.

So let's think about the information from the labeling rules.

The height of the fence plays a very important role.

This parameter must comply with GOST, and not only because this violation can be punishable by fines, but also because it is simply impractical to use a ladder with too high or low probability of lowering and keep growing significantly.

There are also rules for the manufacture of wall levers, which are designed to facilitate the descent and ascent of stairs:

The distance between the gripper and the wall must be at least 4 centimeters.

Usually the standard distance from the center of the stick is 7.5 cm.

Other elements of staircases

In addition to the requirements for fences and fences, there are many standards for the characteristics of other elements in the development stages:

The most appropriate gradient is 1:1.25.

Various options interior stairs allow you to install them at different angles from 20 to 45 degrees.

The size of the steps at the same distance should be the same size.

The maximum deviation from the set value cannot exceed 5 mm in the vertical and horizontal planes.

We must know that this rule does not apply to the first phase, which may be slightly closed in the floors.

- The maximum number of steps in one staircase should not exceed 18 pieces.

Standards regarding stage sizes:

- Step height can vary from 12.5 to 21 cm.

- The step width should be between 21 and 35.5 cm.

- If it is assumed that the stairs will be curved, then the sharpest part of the degrees can be at least 15 cm wide, and in the central part - at least 20 centimeters.

Stairs must be designed in such a way that the doors located on them can be opened and closed.

Methods for making different types of handles.

Stair fences made of wood

It is not easy to know the dimensions of each structural element for the installation of stair railings. To make a staircase with your own hands, you should first consider how to make different materials.

Let's start with the simplest material to work with - wood:

Wooden handles consist of three parts.

This type of structure includes support columns, balusters and handrails.

As a material for their production, both coniferous and deciduous trees are used. Of course the most suitable materials for this are cedar, larch or oak, but the price, pine, alder or birch are more attractive.

Without a special woodworking machine, it will not be possible to produce boxes for wooden rails on our own.

And the process itself can take a very long and hard work.

For this reason, it is not difficult to think about the possibility of buying ready-made components.

By the way, the well-known phraseology "sharpening hair" means only the process of grinding the baluster, which means wasting time.

– Before assembly, the finished workpieces must be treated with a special composition that prevents the growth of microorganisms and varnishes.

Possible examples where varnish treatment is carried out after the structure has been installed.

Direct installation of the frame is carried out after the installation of all other parts of the stairs:

- In the lower and upper parts of the stairs, carriers are placed in the form of supports.

It is best to use anchor bolts as anchors.

- Pull the cord between the brackets to the desired height, which should not be less than 90 centimeters.

“Then there are balusters. They are installed on the stairs so that the distance between them does not exceed 20 centimeters. Exceeding this value can be promised with subsequent problems with the recovery of the lost head of the child.

- Self-tapping screws are suitable for fastening the balusters, which are screwed to the base from the wrong side of the step.

The type of fastening called "at the tip" will be more labor intensive, but also more durable and reliable.

- The focus on the tight lace on the balusters placed the markings at the cutting level.

Additional parts of the columns are cut off and then the attachment is attached to them.

The end of the fence must be attached to support posts or left free. With the second mounting version, the projected part of the handrail should not exceed 30 centimeters.

metal fences

Metal railings are highly durable and reliable.

At the same time, their production costs, as well as the complexity of their operation, often preclude their installation. However, it is possible to install a metal fence yourself.

Pipe profiles can be used as a building material:

- This method of fastening metal rails is most often used when installing outdoor stairs.

- The staircase itself can be made of metal, concrete, brick or stone.

In the case of brick or stone structures, it is important to ensure that pre-assembled plates are installed in the places where the handles are installed.

- Installation begins with the installation of racks. Cut the profiled pipes into 5x5 centimeters and cut them into mortgages.

In case the embeds are at the top of the stage, a special carrier should be used for assembly.

- Using a support rod (pipes or bands of ferrous metal with the required thickness), it is necessary to connect the upper parts of the supports.

- In addition to filling between the bearings, welded pipes 2x2 cm.

You can place them in any position, depending on your desire.

- Profile pipes can be replaced with fake round or square rods, but this significantly increases the cost of stair railing.

Upon completion of welding, the structure must be properly cleaned and coated with paint. A wooden or plastic fence must be installed on top of the cart.

Prefabricated stair railings with glass filling

Currently, glass is used in interior design.

For this reason, a glass fence does not surprise anyone.

To install such a stair fence, special triplets or heat-resistant glass panels should be ordered. If you use ordinary thick glass for these purposes, the design is too fragile, even if you use protective elements.

How to assemble a glass fence?

- Firstly, it is necessary to install support rods on stairs and ladders, the height and step of which between them must comply with accepted standards.

- It supports anchoring with anchor bolts, it is advisable to use at least three pieces.

— Fasteners are attached to the brackets in the form of a spoining with inserts made of polymers.

- Insert damaged glass into fasteners.

— Adhesion with special leads expands through glass.

In such cases, the handrail function is most often performed using a nickel-plated steel tube. The end of the frame is closed with plugs.

Despite the external fragility, a special glass partition is more durable than a wooden fence.

We suspect

When building and installing internal stages, it is necessary to pay special attention to the nuances and build all work on the basis of regulatory documents.

This applies to parameters such as the height of the railing stairs, the size of the stairs and the structural characteristics of the handrails - in addition to the requirements of GOST and SNiP, the safety of the entire structure also depends.

The article was prepared in cooperation with the company "Style of the Century" - the production of stairs.

Website http://www.stil-veka.ru.

When maintaining a house, it is often necessary to climb onto the roof. In order to be more or less safe on it, it is necessary that the height of the roof fencing and the reliability of the fastening of the railing comply with regulatory standards.

Dimensional parameters and basic requirements are defined in the relevant sections of the current GOST 25772-83, which, in turn, is referred to by SNiP 31-06-2009 related to public buildings, and SNiP 31-01-2003 related to multi-storey buildings.

The purpose of the fence

The roof fence is a metal structure that is installed continuously around the entire perimeter of the roof or only along the overhangs. It consists of:

supports - hollow pipes or profiles;

horizontal long elements - crossbeams;

universal brackets that provide the fence with spatial verticality;

fasteners designed to fix the racks to the roofing or roof.

With a house height of more than 10 meters, in any case, a roof fence must be installed, SNiP, at the same time, also mentions mansard roofs. For them, the height from ground level is determined not to the upper, longitudinal ridge, but to the fracture of the truss structure. In certain cases, the regulations require the installation of a fence with snow-retaining elements 150 mm high.

The roof fencing ensures the safe presence of people on the roof who have climbed onto it for the purpose of repairing and painting the coating, extinguishing a fire, removing snow, cleaning the chimney, installing antennas, etc. It prevents falls from a height and helps a person to move along the overhang, holding on to the handrail.

For ease of walking pitched roofs, along the entire length of the roof fencing, transitional bridges are installed.

For operated roofs, the fence is both protection and decorative element. The viewable design allows vacationers to admire the panoramic views of the metropolis or the surrounding natural landscapes, without fear of tragic consequences in the event of an accidental loss of balance. Lattices, in this case, are made more elegant, but no less reliable compared to ordinary fencing of non-exploited roofs. But under any circumstances, the design of the fence must match the overall architecture of the house.

Regulatory requirements

What is the height of the roof fencing, GOST defines as follows:

for unused roofs - at least 600mm;

for operated roofs - depending on the height of the building. If it does not exceed 30 meters, then the upper level of the fence is raised above the roof level by 1000 mm or more, and if the building is higher, at least 1100 mm.

In the first case, the step of the racks is taken within 1200 mm, and the distance between the horizontal crossbars is 300 mm. In the second case, the regulations require adding vertical elements to the fence, installed with a maximum step of 110mm. Similar requirements apply to balcony railings.

If there is a parapet on the roof, the height of the roof fence is reduced by the height of the difference between the levels of the roof covering and the upper cut of the concrete or brick barrier. If the parapet has a standard height, the need for its extension disappears by itself. But such cases are rare in modern construction, since additional "growths" on the walls, in addition to increasing the constant loads on the foundation, do nothing.

The standard establishes the designation of roof railings:

KO - without the presence of a parapet;

KP - with the presence of a parapet part along the perimeter of the roof.

The marking of products also contains the length and height of the fence in decimeters, the GOST number and the option to fill the frame:

R - lattice, only with vertical and horizontal elements;

E - screen, with sheet materials covering the main frame;

K - combined, with partially partitioned sections.

An example of the designation of a roof trellis without a parapet 3 meters long and 0.6 meters high is as follows:

KO - 30.6 R GOST 25772-83.

In the instructions of SNiP 31-01-2003 there is a clause stating that the fence on the roof in places where there are dangerous drops cannot be less than 1.2 meters high. But regardless of the dimensional parameters of the metal barrier, it is subject to a general requirement for the perception of horizontal forces. According to SNiP 2.01.07-85 *, when exposed to loads of less than 300N per meter of construction, the fence must remain immovable.

According to statistics, welded metal frames, but there are fences on the market that are assembled by means of connecting crabs and fasteners. To fix the fence to the load-bearing elements of the roof, special fasteners are required, and for the installation of screen inserts that are not included in the delivery of the roof fence, ordinary hardware is required.

The durability of metal elements is ensured by high-quality painting or an anti-corrosion coating applied under production conditions - galvanizing, composite, etc. Without proper initial and subsequent surface treatment, aggressive environmental exposure can quickly lead to rust.

To avoid trouble, roof fencing needs to be inspected every five years. It is necessary to check the integrity of the structure, the stability of the position and the reliability of the fasteners, to identify various defects in the protective coating, etc. It is recommended to get rid of the detected problems immediately, since the maintenance of the roof fence in order is the key to safety for those who will someday have to work on the roof.

It is recommended to trust the strength testing of problematic fences to specialists who have the appropriate testing equipment.

Rules for acceptance of finished products

The metal roof fencing, the height of which is 600 mm or more, after manufacturing, passes the acceptance procedure by representatives of the technical control department of the manufacturing company. A batch may contain products of only one brand in the amount of not more than 200 pieces. For quality control, 5-10 units of products are selected from them. The check is carried out according to several parameters and, if the result is not satisfactory for at least one of them, additional examinations and measurements are prescribed, up to piece acceptance.

Subject to control:

appearance;

the quality of the protective coating;

linear dimensions;

welds;

deviations from perpendicularity and straightness;

correct labeling.

Roof railings are packaged for safety during transportation and storage. The container should provide protection of products from accidental mechanical damage to the protective coating. The weight of one package should not exceed three tons. It can only contain elements of the same height.