Techniques for lengthening rafters from boards 50x150. What is a rafter? Calculation of the section of boards for rafters

Making the roof of the house is an important and responsible task. The integrity of the structure and the peace of the residents will directly depend on the quality of the upper structure. Before starting work, it is necessary to choose the right boards for rafters and other roof details, perform their high-quality pre-treatment and correctly connect them, preparing them for the roofing material.

Roof types

Currently, about ten are used for residential buildings and outbuildings. various kinds roofs Some of them are more familiar to us, others are very rare. The main designs are.

Pitched roofs made using direct truss systems:

- lean-to;

- gable;

- four-slope - hip and half-hip (with a ridge) and tent (without a ridge);

- multi-forceps:

- conical.

Pitched roofs with curved rafters:

- semicircular;

- hemispherical.

Almost all types of roofs are based on special parts that provide the roof with the necessary strength and give it the desired shape. It's about rafters.

Requirements for the quality of rafters

For the manufacture of rafters, edged boards of various sections are used. The most common parts with a section of 50x150 or 50x200. A bar of square or rectangular section is not used, since it cannot provide the necessary strength to the structure or will significantly make it heavier. Do-it-yourself rafters are always installed on edge. In this direction, the parts are stronger and not subject to bending.

Mounting truss system outbuildings

For work it is better to choose softwood boards. This is due to several of their features:

- the presence of resin prevents the formation of rot in the material;

- such parts have a relatively low weight, unlike, for example, boards of the same section made of birch;

- coniferous material is more affordable, and it is much easier to find it at sawmills.

In addition, be sure to pay attention to such elements in the wood as knots. The presence of rotten drop-down elements, which can lead to a decrease in the strength of the rafter leg in the future, is not allowed.

Preparing rafter system parts for installation

Before proceeding with the installation of the roof truss system with our own hands, we recommend that you carefully treat the surface of all wood parts used in the work.

Pre-inspect the purchased lumber, select the highest quality. Boards with falling knots can be used in pieces, for example, when lengthening or for making racks (headstocks), struts, crossbars and other roofing details. After selecting a sufficient amount of lumber, it is treated with special protective compounds that prevent rotting and burning.

You can apply flame retardants and antiseptics with your own hands in the following ways:

- immersion;

- brush or paint roller;

- spraying.

Each method is good for one purpose or another. After one layer of impregnation has dried, it is recommended to re-treat. It is advisable not to mix the compositions for various purposes in one container.

Choosing the best truss system

Having selected high-quality boards 50x150, and having completed their processing with our own hands, we proceed to the installation of the truss system. Before starting work on the perimeter of walls made of bricks or blocks, it is necessary to lay a mauerlat - a beam that will serve as a support for the lower parts of the rafter legs.

It is fastened with threaded studs recessed into the wall or steel wire laid in the seam of the masonry. In buildings made of timber or logs, the role of the Mauerlat is played by the upper crowns of the log house.

Depending on the size of the span between the walls of the house, we choose the option of installing rafters. There are systems with hanging rafters or layered, based on an intermediate load-bearing wall.

Roof options: 1) With hanging rafters. 2) With layered rafters

The first type of construction has a horizontal transverse beam - puff. In the second given element missing. For support, the ridge beam rests in several places on the intermediate wall of the house. This is not very convenient in the case of manufacturing an exploited under-roof space - an attic, but it is optimal for large flights between walls.

Determine the number of roof trusses

To determine the amount of lumber needed for the manufacture of rafters, for example, 50x150 boards, it is necessary to calculate the required number of truss trusses - pairs of rafters connected at the required angle. On average, the span between them is 0.9-1.2 meters or slightly less. The determining criterion is the intended use roofing material.

So, for ondulin, the manufacturer recommends a rafter installation step of 0.6-0.9 meters, for metal tiles - one of the most common materials in last years- 0.65-0.95 meters. Of great importance when choosing the inter-rafter distance is the slope angle of the slopes, which depends on the snow and wind load in each particular area.

Having determined the step size, we divide the length of the walls by this indicator and add a unit, taking into account the installation of gable trusses. We get the number of rafter pairs. Multiplying this number by two, we determine the required number of rafters. We calculate the length of the boards according to the Pythagorean theorem, knowing the same slope angle of the slope and the span of the walls.

We mount the truss system - we collect trusses

Having decided on the number and size of the rafters, you can begin to assemble the roof truss system with your own hands. As a rule, they try to install pre-assembled farms. You can make them as attic floor at home and on the ground and lift ready.

In any case, a few templates will greatly facilitate the work.

The first of them is a rafter of the required length with ends sawn at the required angle. If necessary, the edges can be cut not in a straight line, but with ledges that facilitate the installation of parts. For example, if the rafters rest on a beam, fastening can be done with steel angles, perforated steel tape, or nails. In all cases, a figured cut will increase the quality of the installation.

The second template is a sheet of plywood with stops nailed at the required angle, into which the upper ends of the rafters are inserted and connected by crossbars - transverse boards with a section of 50x150, providing the necessary rigidity of the rafter pairs. If free space allows, you can use one self-assembled farm as a template.

Installing farms

Do-it-yourself farms are lifted up. Installation is convenient to start with the extreme pairs, called gables. They are installed vertically, controlling the position along a plumb line or a board nailed to the wall of the house, and fix the position with the help of additional slopes. The lower ends of the truss rest on the mauerlat beam or on the log crowns. They are nailed to them with nails No. 100.

Methods for attaching the rafter leg to the Mauerlat

Having fixed the extreme farm, the rest are fixed, observing the span between them. To control this value, you can first cut spacers from a 50x150 board with your own hands and do not measure the distance for each pair. The corners of the roof trusses after their installation are additionally connected with a ridge beam or board. In addition, the crate will help fix the rafters.

The quality and durability of the roof largely depend on the correct calculation of the pitch of the rafters. It affects the laying of insulation, the fastening of roofing material and the installation of additional parts. Pay attention only to the requirements for the distance under the roofing sheets, then there may be problems with the insulation boards. And vice versa, adjusting the size of the insulation can make the frame too weak, and in winter there will be a threat of collapse. How to correctly calculate the distance between the roof rafters? We will talk about this in our article.

As a rule, the pitch between the rafters depends on several factors. But usually the distance fluctuates between 0.6 and 1.2 meters. These figures are rounded, in practice the distance may differ by several centimeters downwards. For an accurate determination, the following calculations must be performed:

- Determine the length of the slope by measuring along the eaves of the house. Suppose that it turned out 17.8 meters.

- Divide the figure obtained by the planned step of the rafters. If it was decided that the distance between the beams would be 0.8 meters, then 17.8 / 0.8 = 22.25.

- Further, we round the result up and add one: 23 + 1 = 24. At this stage, the number of rafters required is determined.

- Now we calculate the distance between the axes of the beams. To do this, the length of the slope must be divided by the number of rafters: 17.8 / 24 \u003d 0.74 m.

So, you will determine the actual distance at which the rafters for a roof made of metal or some other material should stand.

Often, when planning a roof frame, specialized calculators are used. They enter basic data and get the finished result. Nevertheless, you should not completely trust the program, since only a person can take into account some conditions. When calculating, you can understand how the system works, what loads are acting. If necessary, adjustments are made to strengthen or facilitate the design. Self-calculation will help to more accurately determine the required step of the rafters of the gable and pitched roof.

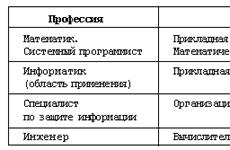

Step calculation depending on the roofing material

For each coating, its own standards and dimensions are developed for the truss system. The main factors are the strength of the material, its weight and resistance to external loads. Consider the main types of coatings.

Decking

The step of the rafters under the corrugated board can vary from 0.6 to 0.9 m. The final result depends on additional conditions, which we will discuss below. If for some reason the step should be larger, a transverse board with a large section is added. In this case, usually the rafters themselves are chosen with dimensions of 50x100 or 50x150 mm.

In addition to the rafters, a crate of 30x100 millimeters is used. The gap between the boards should be about 0.5 meters. It can be more, it all depends on the type of corrugated board and the height of the wave. Sheathing boards protruding beyond the boundaries of the eaves should have a thickness of 1.5 cm more than usual. This is done based on the need to mount ventilation, a chimney or a drain.

Ceramic tiles

The main difficulty in designing a roof frame for ceramic tiles is the large weight of the material for the roof. It is 10 times heavier than corrugated board and accounts for 40 to 60 kg per square meter.

Under such a coating, dry beams are used, with a moisture content of only 15%. Their cross section should be either 50x150 or 60x180 mm. With such indicators, the maximum allowable distance between the rafters can be 1.3 meters. The minimum allowable step through which rafters can be placed is 0.8 m. The roof slope affects the final decision: at 15 °, the step is 0.8 m, at 75 ° - 1.3 m.

The length of the rafter leg is also taken into account, the shorter it is, the larger the gap, and vice versa. In addition, if the slope is less than 45 °, and movement is planned on the surface, the beams are placed in increments of no more than 0.85 m.

The distance between the boards of the crate is selected so that each intersection of the tiles has its own base. The standard length of the material is 400 mm, and the amount of overlap during installation varies between 55 and 90 mm. It turns out that the distance between the central axes of the crate can be either 310 or 345 millimeters.

metal tile

In recent years, the question has been particularly acute: how to determine the distance between the rafters under the metal tile? It imitates more expensive ceramic material, but at the same time it has the positive properties of corrugated board. Installation of such a coating is simple and does not require large financial costs. All this makes the material attractive for the roofs of private houses.

The mass of metal tiles is less than ceramic, so a simpler frame is required. The section of the beams is reduced to 50x150 mm and the step between the crate is increased. The step of the rafters under the metal tile varies between 0.6 and 0.95 m.

Ondulin

The allowable step for covering from ondulin is 0.6-0.9 meters. The standard section of the rafters is 50x200 millimeters. Such dimensions will allow to withstand the load of the roofing pie on the gable roof.

On top of the counter-lattice, a crate of bars measuring 40x50 millimeters is attached. The pitch between the central axis is 600 mm.

Additional factors

When calculating the pitch of the rafters, attention is paid not only to the type of roofing. Many other points are taken into account, data on which can be found in reference books and SNiPs. Here are some of the factors:

- Snow and wind loads. The more snow falls in winter and the stronger the winds blow, the smaller the distance between the beams should be. But, if you increase the angle of the roof slope over 45 °, then it is allowed to increase the step.

- Choice of heater. To reduce the cost of insulation boards, it is recommended to take them into account standard sizes. They produce mats with a width of 600, 800 and 1200 mm. If this condition is neglected, then a large number of undercuts will appear, cold bridges and construction will be delayed.

- lumber quality. It takes into account the type of wood, grade and section. As mentioned above, strength is affected by how well the beam was dried. When buying wood, pay attention to evenness and the presence of defects in the form of knots and traces of pests.

- Floor beams and puffs. If you equip under a gable roof attic floor, then the maximum distance between the rafters should be 0.75 meters.

The calculation of the distance between the beams for a gable and single-pitched roof is different. Even if he makes several slopes, for each it is necessary to make a calculation individually. This is especially true for buildings with different lengths of cornices.

Taking into account all these factors, it is possible to determine how far the rafters should be installed. Although all calculations can be done independently, since reference data is freely available, it is better to turn to professionals. They have experience in designing, they will quickly determine the required distance between the rafters. Yes, you will avoid possible errors and you will be safe.

Building a strong and reliable truss system is not an easy task. In the construction of the frame of the future roof, every little thing is important, because it is only in hot countries that you can put an armful of hay on a simple structure, and it will serve faithfully. But in the conditions of the Russian climate, where a strong wind can tear off the roof from an entire plant, and snow accumulates up to several tons, completely different requirements are imposed on the roof and its “skeleton”. And therefore, even at the design stage, the focus is on the rafter board with all its parameters, such as length, thickness and material of manufacture.

Therefore, if you want to be calm about a new roof and its durability, study the basic principles for selecting its structural elements: which board is designed to carry and distribute the main load, what timber is needed between the rafters, and what material to purchase for arranging the ridge run and internal puff farms. And our article will help you understand all these subtleties.

So, let's start with where exactly you will buy the rafters - it depends on how meticulously it will be necessary to calculate the parameters of each board in the structure.

So, ideally, if you can entrust the purchase of boards and beams to an experienced specialist, because. he is even able to assess the quality of the material by eye and understand whether the purchased quantity will be enough. Although, guided by our advice, you yourself will completely cope with this task.

This short video will help you understand which boards are suitable for the rafter system:

In total, you have three options for purchasing rafter boards, and we will analyze the advantages and disadvantages of each of them.

Method number 1. Cubic meters of lumber

So, pay attention to such important points. If you are offered wood in cubic meters - this is quite an acceptable way, you simply indicate the number of cubic meters of boards and timber in a specialized company. And already on the spot, you will process all this with protective impregnations and build a roof.

The only point is that there will be a lot of work, as well as waste. Therefore, you will need to purchase boards 10% more than you originally planned according to your calculations, so that there is a margin for trimming, waste and unexpected defects that were not detected before.

Method number 2. Custom cut boards

Another option is to purchase ready-made rafters after cutting. Many companies custom-cut wood to the desired parameters and provide already ready-made version, it remains only to assemble the structure itself on the roof. There will already be a minimum of waste here, work will go faster, it is only important to first guess with the size of the rafters. But there is one minus: in the general set, one or two boards may be missing. After all, especially attentive people do not always work at such enterprises, and it is not a fact that the same workers will not hide a bar from each order. And you will have to roll up your sleeves and make additional templates for the missing elements.

How to order ready-made cut boards for rafters? You simply make a paper version of the roof project or a special program, show it to the designer, and then to the company representative. Pretty simple!

Method number 3. Finished roof trusses

The third option is to purchase ready-made roof trusses. They are easier to install on the walls directly on the roof than to assemble separately, and the whole structure is assembled in 1-3 days. And for this you no longer need a carpenter! Such truss trusses are assembled at the factory and turn out to be quite high quality. You just have to install them and connect them in the skate.

You won’t have any waste here at all, but, of course, ready-made roof trusses will cost more than just rafter boards. In addition, usually a measurer is even sent from the manufacturer’s company to the site so that he personally checks the distance between the walls of the house and corrects something in project documentation. And this is already something of a safety net for you, especially if the calculations of the truss system seem complicated for you (they are not easy for professionals, believe me).

Self-made rafters from boards

So, if you don’t like the idea of ordering the processing and cutting of boards, then get ready to be a designer, an architect, and a carpenter at the same time. In fact, all you need to know about your rafters is their angle of inclination, section, distance, and method of attachment.

If you have ever watched the work of professionals, then you must have admired how masterfully and effortlessly they measure the desired length of the rafters and make them into complex cutouts. At the same time, all they need to know is the parameters of the roof. And at the same time, they use the most elementary tools: a carpenter's square, their own recorded calculations, or a "smart" book. But, in a good way (and by all the rules), you should initially calculate everything using special construction calculators. By the way, special applications for smartphones are also popular today. Although you can easily do the most basic calculations yourself.

So, since if you took up the manufacture of rafters from boards on your own, then you already know for sure the width of the building and the thickness of the ridge board. And here it is important not to make a mistake when calculating the future length of the rafter: be sure to subtract the thickness of the ridge board from the full width of the building. Believe me, many people forget about it for some reason. Now divide the result by two and you will get the run of each rafter leg.

The angle of inclination of the roof can be determined using geometric formulas, and the type of formula depends on what shape of roof you are going to build: a classic gable, or a more complex four-slope. After all, their structural units are different, and the requirements for the ability to withstand certain loads are also different.

Rafters for a gable roof: a simple calculation

Rafter for gable roof it is easiest to make, because, in fact, they are standard triangles, which are only important to arrange in a row strictly vertically, with a certain step, and fix the tops with a ridge run:

Rafters for a pitched roof: triangles + rectangles

Make rafters for standard hipped roof(tent, hip) it will be a little more difficult for you, because more needs to be done here accurate calculations:

The rafter system of a hipped roof is distinguished by the fact that rafters are installed here, which are directed to the corners of the walls - diagonal. And even more: other rafters of the slopes rest on such boards. Because of this, slanting (another name is “diagonal”) rafters carry a load one and a half times more than ordinary ones, and their length also exceeds the standard length of the boards.

Most often, such rafters are made paired:

Rafters for unusual roof shapes: complex design

At pitched and flat roofs- standard rules for the manufacture of rafters, calculation of loads and structures. But a completely different approach in the construction of outbuildings, gazebos and other household facilities. Here, the roof does not always have to be something like a miniature copy of a large and real one. On the contrary, it is important to think over everything in order to invest in the budget and correctly combine a small design with a large one.

For example, as an option, special elongated rafters are made for the roof of an extension to the house:

The demonstrated rafters do not create point loads on the edge of the roof (as is often the case, unfortunately, in the practice of private construction), and as a result, the roof does not tilt to one side over the years. Here, the load, due to the unusual length of the rafters, is distributed evenly, with less pressure and over all slopes. Yes, and this design looks more competent and professional.

But such rafters are made for round roofs small houses, outbuildings and gazebos:

And, finally, in some cases, part of the rafters does not play any functional role at all in the entire structure - only decorative. Making them takes a lot of time, but you don’t need to calculate strength at all. And see how just one additional board in the truss system completely changes the whole look of the roof:

Bent boards for gabled roof rafters

And finally, if you like unusual and fashionable lancet roofs, then you should know that all this is also possible to bring to life. Such boards are really made: they are steamed up to 100 degrees in the factory, and, at high humidity, giving elasticity, they bend according to a special pattern. Only after that they are glued together and dried in special chambers.

Also, in addition, special cuts are made along the fold line of such bars, which also causes its own difficulties, and therefore such a rafter system will cost more. And if we talk about private construction, it will be difficult for you to complete this entire technological stage. But there is such a possibility.

And we figured out the design and parameters of the rafters, and now let's move on to the most difficult step - calculating the sum of all loads that affect such roofs. Thanks to the answer to such questions, you can calculate not only the length of the rafters, but also their cross section, which will be reliable.

How to calculate the load on the truss system?

So, you will need to build on what kind of area you live in. After all, the rafter board depends on this: the dimensions are selected so that the roof maintains maximum integrity and at the same time successfully resists both static and dynamic loads.

Here is the whole set of loads that you will have to consider when designing the truss system and its parameters:

What are roof limit states?

And now - in more detail. In order to accurately determine which section of the rafters is necessary for the roof device, you first need to calculate the sum of all-all possible loads. This calculation is done according to the so-called "limit states" method, when the roof structure loses its ability to resist the external influence of the wind, a large number snow or receives significant deformation.

When does it happen? When the roof structure has already exhausted its bearing capacity, stability and endurance. Those. this is the very moment when there is so much snow on the roof that the truss system cannot withstand it and breaks, or the structure of the roof is such that a strong wind can eventually tear it off. And here it is necessary to take into account both the data of both static and dynamic loads:

- when snow, insulation and roofing put pressure on the roof, this is a static load;

- wind and other influences that cause the opening of the roof nodes or the deflection of the rafters are dynamic loads.

If the roof does not cope with all this individually or in combination, then this will lead to negative consequences. In addition, it is dangerous in itself when the rafters have cracks, deflections and other initially invisible problems that adversely affect the bearing capacity of the structure. It is very important to prevent all this.

In order to meticulously calculate the pressure on the roof, we have a separate article. You will just need to look at the map of your area for the average wind and snow loads, use them to determine the minimum thickness of the rafter section and their minimum spacing along the slope:

You have two ways to work with all this data:

- Method number 1. Calculate everything down to the millimeter using special formulas, an online calculator or the mind of a hired roof specialist.

- Method number 2. Focus on the traditions of construction in a particular region and make the simplest calculations with a margin.

The fact is that it is not without reason that in every country the houses are similar to each other. For example, in the snowiest regions of Russia, high sharp roofs have long been built, and in especially windy regions, they are more gentle. If a standard height snow cover in your area is higher than the national average, then either you better build a roof with steep slopes, or make the rafters twice as thick and strong so that they can withstand all the necessary load. Therefore, if you want to purchase rafter boards with standard values, organize the same roof slope as your neighbors - that's the whole trick.

So, if you know what the load on the roof will be approximately during its service, then you will also find out the one that will affect each individual rafter. How? Just divide the load by their number, and here it is important to know whether the rafters themselves will cope with the responsibility assigned to them. And this, in turn, can also be found out.

How to calculate bending and tensile strength?

Absolutely every rafter is affected by a variety of physical forces. And the more rafters at each gap, the easier it is for each of them individually, and vice versa. But after all, it makes no sense to put continuous rows, and therefore it is more rational to calculate and insure everything.

Stress conditions at rafters made of different wood

How exactly the rafter will work for bending and stretching during operation depends not only on its thickness, but also on what material it is made of. Namely - from what grade, breed and moisture content of wood. The following data tables will help you understand this:

Here are some features of wood species suitable for rafters:

- Hardwood trees are less flexible than pine trees, and their properties are different in all directions. Therefore, boards from this wood are less often used specifically for rafters. On the other hand, larch has such good performance that it can be compared with oak in terms of durability.

- Pine is relatively inexpensive, but has a large number of knots. On the other hand, resinous wood will always provide high resistance to decay, and pine timber is excellent for arranging a truss system due to its lightness and strength.

- Spruce is ideal for floor beams and rafters. Moreover, dry spruce is as strong as pine. This wood is perfect for those areas that are all the load.

- Oak wood is stronger and more durable, and therefore more expensive, because in order to be used in construction, its age must be about 120 years! Whereas pine has only 30.

- All other types of wood should be used for the manufacture of rafters carefully, carefully studying their properties.

So, to summarize: the main property of wood as a material is its deflection strength. But, if this is not enough, the boards simply increase in length. In addition, according to SNiPs “Loads and Impacts”, the load on all rafters is uneven, the rafter on the left can be loaded much more than the rafter on the right, and therefore you always need to play it safe and take such values with a margin.

The choice of the length and section of the truss elements

All rafter legs are made of the same thickness and length, depending on the pitch of the rafters and the load that will act on them:

In different forms of roofs, trusses are attached in their own way, and two main designs are most popular today: with hanging and inclined rafters.

- Rafters rigidly interconnected, lie in the same plane and have only two points of support - these are the outer walls. And the rafters at the same time rely on the Mauerlat or the upper crown of the log house.

- hanging trusses, on the contrary, consist of rafter legs that work on compression and bending, and under the weight of the structure they expand, which is transferred to the wall. To compensate for these forces, the rafter legs must be tightened with puffs - these are horizontal beams that will need to be fixed at the base of the rafters or higher. They are also important to calculate correctly.

And the length of the rafters of both variants of the truss system depends directly on the angle of the roof:

And even more: knowing the height of the future roof and the width of the end of the house, you will immediately determine the length of the rafters, using the most common formulas from the school geometry course.

Combination of wood and metal

If you have to make the truss elements thinner than necessary, then they need to be strengthened with struts, crossbars and racks. But, sometimes it is necessary to stiffen the entire truss system in view of the design of the building itself. For example, the spans will be large, or the house is located in an area with disadvantaged climatic conditions. For this purpose, a combined rafter system made of wood and metal is used, where the metal takes over the most critical areas.

In this case, the natural deformation of the wood of the rafter boards will no longer play its negative role, and you can safely refer to the choice of parameters. Metal elements in such a system are installed as independent rafters, and as reinforcement elements for rafter legs. As a result, metal inserts significantly increase the rigidity of the entire truss system, although they complicate its operation.

The thing is that the condensate likes to settle just on the metal, and upon contact with the wooden parts, it causes their gradual decay. That is why, in the combined system, boards for rafters must first be treated with moisture-proofing agents, and even if necessary, film insulation of the contact between wood and metal is used. In addition, under such a roof, competent ventilation of the under-roof space and constant monitoring of the condition of wooden rafters are necessary.

Of course, the simpler the roof truss system, the more clear and understandable the requirements for the parameters of all its elements, while even an experienced specialist does not always feel confident with a complex roof. But the main task for both a beginner in this business and a professional is to achieve the final quality of the entire structure!

All photos from the article

The integrity and stability of the roof ensures the safety of the entire house and normal living conditions for people. The strength of the roof frame depends primarily on the quality of the lumber, its moisture content and the necessary pre-treatment. Generally wooden structure must withstand the load of the roofing cake and be resistant to any bad weather.

Wood in the construction of the roof frame

Traditionally, rafter boards are made from spruce, pine, fir, cedar and larch. The supporting elements of the frame - ridge timber, rafters and racks that carry the lion's share of the load, can be made of dry aspen boards, in this state they are much superior in strength to coniferous ones.

For the manufacture of rafter legs can be used different types lumber:

- logs, which are inconvenient due to their weight, and cutting at the junctions takes a lot of time;

- bars, the only drawback of which is the high cost;

- boards - they are convenient for the manufacture of side and side rafters.

Protection of wooden surfaces

Although coniferous resin is a natural protection against decay, wooden parts must be additionally treated with moisture protective agents against microorganisms (GOST 20022.0) and flame retardants (SNiP 2.01.02). This must be done before splicing and assembling the structure, otherwise it will be impossible to get to the joints and areas covered with fasteners.

It is possible to order wood already industrially treated under pressure, immersion or dispersed. The supplier is obliged to provide documents indicating the type of impregnate and the method. AT independent work The instructions on the preparation will help you, indicating the number of treatments and drying time.

Note!

Processing takes place in two stages with the final drying of the previous layer.

Dry and warm weather will promote good absorption.

The quality of the impregnation is clearly visible on the cut - the layer of absorbed substance is clearly visible.

Rafter extension

Simple types of connection allow you to splice rafters from boards to the required length:

- overlap - the boards overlap each other, the combined part must be at least 1 m, the degree of cut of the ends does not matter, they are fastened with nails / studs;

- end-to-end - the ends cut at a right angle are joined and connected with metal fasteners or an overlay from the board, connecting with nails / bolts;

Note!

In the first and second cases, the nails/bolts are staggered for added strength.

- oblique cut - the ends are cut at an angle of 45 °, connected and fastened in the middle with a bolt with a diameter of 12–14 mm.

Rafter board parameters

The longer the rafter, the wider the board should be, for example, for a regular 6-meter opening, a width of 150 mm is suitable, over this length - from 180 mm. The necessary strength of the rafter legs will be provided by 50 mm.

The cross section of the rafters is determined by several parameters:

- the weight of the structure as a whole;

- opening length;

- the width of the house;

- the angle of inclination of the roof slopes;

- the strength of the winds;

- snow cover thickness.

Note!

A professional calculation of all kinds of nuances will help determine which board to use for the rafters (section).

This will help save on the purchase of material if you are determined to buy "for the future" thicker and wider.

Specifications

The following requirements are imposed on the rafter board of the 1st grade in accordance with GOST 2695-83, 11047-90 and 2140-71:

- the moisture content of sawn boards should be no more than 22%, milled - 18%;

Note!

The nominal parameters of lumber (thickness * width) are determined at its 20% moisture content.

With a smaller / larger% indicator, the dimensions are set in accordance with GOST 6782.2.

Permissible deviations in thickness will be ± 2.0 mm and width ± 3.0 mm.

- on 1 meter, 2 fused healthy knots are allowed on a face up to 40 mm in size and 2 - 1/3 of the thickness on the edge;

- normative bending resistance 24 MPa (SNiP II-25).

Among others, the following vices are considered unacceptable:

- humidity exceeding the permissible parameters;

- falling knots;

- internal sapwood;

- sap fungus stains and rot;

- foreign inclusions (pebbles, metal fragments);

- acute wane;

In building your dream home, are you already at the finish line, and it's time to deal with the intricacies of the truss system? Let's put it this way: pleasant worries await you: calculating the angle, weight and safety margin of the rafters, an agreement with a familiar craftsman or company, or preparing all the necessary tools for independent carpentry work.

And so that tomorrow all these worries do not become a headache and you do not worry about whether this or that knot is done correctly, we have prepared this article for you. So, let's figure out how to make high-quality rafters for a gable roof with your own hands so that it is no worse than purchased ones.

- Short production time.

- Technological precision of all details.

- The same, already fitted dimensions of all structural elements.

But then be prepared for such cons:

- High cost (at least twice as high as if you planed the rafters yourself).

- Delay in delivery (especially in season).

- The use of low-quality or under-dried wood (and then the roof will “lead”).

So convenience or quality? If this is not the first time for you to cut or plan something out of wood, feel free to take on the manufacture of rafters! Here's what it all looks like in real life:

Rafters in the construction world on plain language it is customary to divide the main ones, i.e. carriers, on which the roof rests, and on auxiliary ones, which are located inside the roof and serve as a support for hemming the ceiling and walls of the attic (if one is planned). The strength and reliability of the future roof depends on how accurately and correctly you calculate the truss system in advance.

The truss system of any gable roof itself consists of the following basic elements that you need to make:

- Mauerlat.

- Vertical racks.

- Crossbars.

- Rafter legs.

- Struts.

- Skate ride.

Complex roof structures with multiple elements, it is better to entrust the calculation to a professional, but you can handle the small roof of a private house. For this you will need these simple formulas, which will help you find out how thick the rafters should turn out, with what slope and what span:

How to draft a future roof?

Active in roof construction Golden Rule- measure seven times, and cut only once. And first of all, it is important for you to understand that each rafter leg has its own individual location. Therefore, first, be sure to draw up a detailed project, and preferably in a special program. Only after that, according to your 3D model of the future roof, mark exactly where and what exactly the connections of the rafters with the Mauerlat and among themselves will be.

It is important to determine the angle of inclination of the rafters as accurately as possible and at what angle they need to make cuts. And don’t worry about how to make all these rafters for a gable roof yourself: you just need a regular machine.

Determine the angle of the roof: calculate the load

The angle of inclination of a gable roof is made from 5 ° to 90 °. But the most proven and standard option is 35 ° -40 °, where loads are most rationally distributed and building materials are consumed.

Straight slopes are built when only a non-residential attic will be under the roof in the future, main function which - ventilation and heat exchange control. But when the under-roof space is planned to be residential, attic, they initially plan the so-called broken gable roof. Its difference is that the slopes in the middle have, as it were, a kink that changes their angle to a steeper one. And for arranging the attic, and for protecting the whole house from the weather, this design is quite suitable.

Please note that most roofing materials are suitable only for slopes greater than 45°.

Fixed and variable roof loads

From the same loads depends on what step the rafters need to do for your gable roof. This table will help you choose the desired section of the rafter legs:

Indicators of rafters for deflection

Even strong-looking rafters may not be suitable for building the roof of a residential building due to the fact that they do not have enough deflection indicators. There are separate items in the section of SNiPs, which are called "Loads and Impacts".

And the easiest way to increase the strength of the rafters for deflection is to make the section larger. A little more difficult - to strengthen it with a beam, bringing its edge to the strut.

Reinforcing elements for rafters

The more racks, struts and fights - the more stability and stability the entire truss system has.

If you have suspicions or even an accurate count that simple design the roof will not withstand future loads, make additional reinforcement elements for it. Such prevention will never hurt, but it will save you from many problems. Note that it is especially disappointing when the roof of the garage falls through - right on the car. And for a residential building, such problems are not a joy.

Strengthen the rigidity of the truss structure struts, additional runs and support posts. Struts are designed to reduce the span of the rafter legs. The angle of their inclination to the horizontal is usually at least 45°.

A run is a horizontal beam, which is parallel to the ridge and is fixed on vertical posts. More on video:

Determine the type of roof: cold or warm?

And now about the concept of the attic. If you are building the roof of a bathhouse or a small master's room, it can be done using the most simplified technology - they put rafters, connected them in a ridge and covered them with sheets of roofing material. But for the roof of a residential building, where ventilation is important, this principle is indispensable. There will already be at least three levels:

- The upper or first level of the rafters is about 200 mm.

- The average is always equal to the height of the auxiliary rafters.

- The third is already on the edge of the wall.

It is so convenient to lay insulation, because the roof of a residential building is distinguished by the fact that heat rises up and, in the absence of thermal insulation, the roofing is constantly heated.

Bottom line: in winter, the snow melts and slides down, freezing and accumulating even more near the cold eaves. There are a lot of problems from this: both long dangerous icicles and clogged drainage system, and the gradual destruction of the entire roof. Decide for yourself!

We determine the type of truss system: layered or hanging?

So, now is the time to think over the supporting bases for future rafters, which also need to be prepared in advance and on which many parameters of the roof itself will depend. So, the rafters are divided into layered, hanging and hybrid.

Hanging rafters are usually the lot of small and light roofs, the distance between the supports of which does not exceed 6 meters. But in buildings with a load-bearing middle wall or additional supports for the roof fortress, layered rafters are arranged. Or a combination like this:

Another difference is that the hanging truss system makes the Mauerlat work in compression, and the layered one in shear. But the main task of both layered and hanging rafters- transfer the loads of the entire roof to the walls and foundation as evenly as possible.

We select material for rafters

So, if you have decided on future loads, it's time to pick up suitable material. As it is usually used for the manufacture of rafters:

- Wood. Solid wood, boards or glued beams.

- Lightweight metallic profile. These are galvanized steel profiles.

- Black metal. These are I-beams and steel channels.

- Heavy reinforced concrete structures for industrial construction.

Dry board: an economical option

If heavy loads are not expected on the rafter system, then make the rafters from a dry planed board with a small section. But if knee-deep snow is not uncommon in your area and the roofing material will not be easy - then some of constituent elements you will have to make glued. That's the whole difference.

It is most convenient to make elongated side rafters and diagonal rafter legs from the board. So, a board 40 mm thick, which is often used for outbuildings, is not suitable for a roof. Not less than 50 mm! Moreover, the longer the rafter leg is planned, the wider the board itself should be. So, rafters 6 meters long will have to be made from a board 150 mm wide, and even longer - from a board 180 mm.

for the roof frame house it really is one of the most the best options!

And also the rafters from the board are the most economical, and at the same time they are almost not inferior in strength to the timber ones. It is only important to choose the right section and use quality material. Therefore, when buying material, be sure to take a special device for measuring wood moisture and use it. There is nothing worse than damp rafters. And it's not just about future mold: such a roof will lead and warp, because this material changes its shape when it dries. At the rafters, fasteners will fly and even the cover of your gable roof will bounce in places. In short, no problems!

But from regular board it is most convenient to splice the rafters along the length:

Durable metal: resistance to dampness

And, you will be interested to know that rafters can be made not only from wood! So, iron truss systems, which were once used exclusively for industrial construction, are returning to their former popularity today. And, note, this material for the roof has many advantages, the most valuable of which is complete absence damp fungus. The under-roof space, after all, most often “pleases” with accidental leaks.

And the work itself with such rafters during installation is no more difficult than with wooden ones - see for yourself:

Beams: the benefits of quality wood

The beam is more durable, but it is bad because it has a lot of weight and cuts have to be made at the attachment points. For a log, this is not only a problem, but also some loss. bearing capacity such a rafter leg. But so far this material is the most popular for the manufacture of rafters.

Most of all, lumber is suitable for the manufacture of rafters, which meets the requirements of GOST 8486-86 or 2695-83. And this:

- Humidity is not more than 18%, measured with a moisture meter.

- Cracks that are not through and do not exceed half the length of the board.

- For each linear meter - no more than three knots, and each of them - no more than 30 mm in diameter.

Therefore, when buying wood for rafters, be sure to check the documents from the seller that speak of product quality.

The type of wood is also important. The fewer knots and cracks on the beams, the better. Some varieties also please with good moisture resistance and resistance to decay and pests. For the roof, this is what you need. Therefore, we recommend making rafters from coniferous wood, which is rich in resin, and resin is a natural barrier against decay. But special processing is still needed.

And take into account also this fact: in the manufacture of the rafter system, the material needs to be purchased 5-7% more than necessary, because it will not always be possible to make an ideal cut of the rafter or cut of the required depth. There will still be an overrun, and therefore stock up on it in advance so that you have a tree of the same moisture content and properties for the entire rafter system.

Otherwise, if any individual elements roofs you had to purchase separately, they may take longer to dry (wood always dries), or vice versa. Distortions can turn out to be considerable, i.e. the entire roof frame will be constantly affected by various physical tensile and pressure forces. Any experienced roofer will tell you how bad it is and what it is fraught with. And therefore - take more material for the manufacture of rafters than you plan. If everything goes smoothly, there will be plenty to make the first bench in front of the new house.

Treatment with antiseptics and propylene

And at this stage it is already important to protect the future truss system from biological destruction. You do not want the roof to collapse after a couple of years of operation, do you? Therefore, be sure to treat the wood for the rafters with fire and bioprotection.

The rafters are usually impregnated with an antiseptic, and treated with a flame retardant on top. It is also possible to alternate such processing several times. If you use universal impregnation, be aware that it usually includes products with different periods services. For example, fire protection will end earlier than bio.

But the choice of means for processing today is huge. These are universal protective equipment, and a variety of flame retardants, and antiseptics. It's easy to decide: if you are building in a fairly hot and dry area, first of all use fire-retardant impregnations that deprive the wood of natural flammability. And if your house will stand where the humidity is high, almost all year round- protect from decay.

You can, of course, use both drugs - but only without mixing, otherwise the whole material will deteriorate. You just need to choose one agent as an impregnation, and the second as a protective surface layer. Just try to dilute everything in the concentration indicated by the manufacturer. But do not treat frozen or damp wood with anything: its fibers simply will not absorb anything.

Video hint on the topic of rafter processing:

Note that a brush or a spray when processing rafters give little result - complete immersion and subsequent drying are much better. Just use a regular container, cover it with a film from the inside and make a “bathroom” for future rafters. Moreover, it is desirable to turn all this on the ground, as soon as you bring the material to the place, because. in the finished rafter system it will be difficult to get to the internal elements of the connections. And they are the most defenseless in terms of moisture. Dry after processing the part so that all sides are ventilated, and for at least 24 hours.

Do not forget also that wood, like any natural material subject to biological degradation. Therefore, in addition to fire-bio-protection, it is important to consider waterproofing in all places where the rafter system adjoins brick walls home, if any.

We make the right cuts on the rafters

Now let's move on to practice. First of all, you definitely need to make a convenient template, according to which you will make even, identical rafters:

And follow these instructions:

You will have to tinker with a rigid mount:

If we are talking about moving nodes, then follow this principle:

In practice, everything is really simple:

As you can see, the eyes are afraid, but the hands are doing!

How to assemble a truss system?

Finally, the rafters are ready, and you can proceed with their installation.

Build on the ground or on the roof?

So, in fact, everything is quite simple and somewhat similar to the children's designer. The easiest and most convenient way is to make farms right on the ground, and only then raise them. It is a little more difficult to assemble the rafters directly on the roof, but it is easier to lift them there. Start from this: if you have the opportunity (a crane, for example) to drag 200 kg of one truss onto the roof, drag it, if not, lift each individual rafter 50 kg using improvised means and do the assembly on the spot.

So, first of all, for convenience, make a template according to which you will assemble the trusses, and another template for mounting cuts on the rafters (use plywood). You just have to cut the mounting cuts on the rafters, attaching a template, and connect them together at a certain angle. This triangle is called the truss truss.

Attention to strength - rules for increasing the length

If the thickness or length of the board is not enough to make a normal rafter leg, build up the rafters. And there are several ways:

- Bring the boards together, folding them with wide sides and stitching them with nails.

- Lay the boards in half the length, resulting in a particularly strong rafter leg that can withstand considerable loads.

- By making an oblique cut at the ends to create a vertical anti-slip stop, and connect with a bolt.

- Lay two boards with an overlap of a meter in length, connecting the rafters with studs or nails.

Also consider when calculating that the roof ridge accounts for about 50% of the load from the entire truss system. Therefore, always make the beam for the ridge so that it has a safety margin of at least 25% more than it was originally calculated.

And the most vulnerable parts of the truss structures are the lower ones, those that rely on the Mauerlat.

Cooking truss trusses

You need to fix the rafter knots with the help of:

- External straight brace.

- Metal corner plate.

- Internal metal rod.

You can also connect such rafters with studs - it will even be stronger. To do this, instead of a cut, we now make a cut in half a tree and connect the rafters with a ledge. Next, we drill a hole for the stud 12-14 mm and fix it with nuts with wide washers.

Let's start with an overview of proven grandfather methods:

Here's how they work:

Here's how they work:

When assembling a hanging type truss truss, you need to connect the upper ends of the rafter legs. To do this, cut the end of each at exactly the same angle at which you make the roof, connect the beams with cut planes and fix with two nails. Close the joint with a wooden lining or a metal plate.

Another useful tutorial:

Lifting and installation of finished trusses

Already on the roof, first of all, you need to start by installing those rafters that form the two extreme gable roof trusses (they are also called gable). To further secure them, put temporary struts. Next, stretch a strong cord between the extreme tops of the trusses, which will become the level for the intermediate rafters.

Now we raise and place all the other roof trusses at a distance of at least 0.6 meters from each other. Again, if some of the structures turned out to be quite bulky, prop them up with the same temporary supports.

The rest is a matter of technique: