Logging technologies - from Canadian felling to Post and Beam houses. Russian felling technology

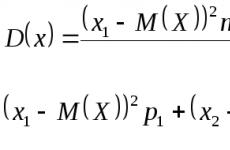

Corner cuts are the basis of the construction of the walls of wooden houses. Corner joints are of two types - without residue (in the paw) and with the remainder (in the bowl, in the oblo).

Types of angle chopped joints

Corner cuts are the basis of the construction of the walls of wooden houses. Corner joints are of two types - without residue (in the paw) and with the remainder (in the bowl, in the oblo). Each of the mentioned types of cabins, in turn, has different design options, which differ in manufacturing complexity, details and efficiency.

Corner chopped joints with the remainder (output) are distinguished by the protruding ends of the logs at the corners of the log house. With this method of construction, the size of the room will be slightly smaller than the length of the logs, but such a corner design is the most durable and well protected from precipitation and wind, and has a more beautiful aesthetic appearance. The integrity and strength of the entire structure depends on the quality of the felling. wooden house, thermal qualities and aesthetics.

Cuttings with residual or with release

Oblo felling

The cutting method leading in simplicity with the remainder and considered one of the oldest in Russian wooden architecture. Another such way of cutting is called cutting into a bowl. An interventional longitudinal groove (lunar groove) and a special bowl are created in the lower log - a semicircular cavity into which a transverse log is placed on top. This method is the least laborious, since the log does not have to be turned over - all the necessary operations are performed in the upper part of the log. But, it is worth considering that such a connection cannot boast of high performance properties. Firstly, the design, decided by the bowl up, is poorly protected from atmospheric influences - moisture easily gets into the bowl, due to which the insulation gets wet, and rots over the years. The same situation is observed with the groove between the logs. Secondly, the flat inner plane of the bowl is easily blown by the wind due to the absence of locking or transverse elements. Especially the situation worsens after the logs dry out and shrink, so regular caulking will be necessary.

chopping

The felling into the okhlupen is also known as the Siberian bowl or okhlupen. It is an inverted version of the connection in the bowl. His design feature in that the interventional groove and bowl are now in the lower part of the upper log. This type of corner connection is more resistant to precipitation. The felling into a flake requires more labor and skill in execution, in comparison with the above-mentioned felling into a flail, since the log has to be turned over several times in the process of fitting. As practice shows, cutting into a flail can be called a cutting into a flail, therefore it is advisable to clarify everything in detail and discuss in detail with the performers all aspects of the connection - the location of the grooves, bowls and other subtleties.

Cutting into a fat tail

The felling in a fat tail differs in an improved bowl. In the design of the bowl, a special additional spike is created, called a fat tail. On the other side of the log, a groove is created into which the spike of the next log is inserted. This cutting method is remarkable in that it provides excellent strength and additional sealing of the corners, since in this case direct blowing is nullified.

When cutting into a fat tail, the bowl can be oriented both up and down. This type of connection is technically much more complicated than conventional bowls. However, due to its excellent performance, fat tail felling is widespread. This type of felling is often referred to as a felling with a cut or with a spike. In camom, however, this is a completely different kind of connection, which is described below.

Hook cutting

Talking about this type of chopped connection into a hook, it is worth noting that in practice and in specialized literature, cutting into a hook can be called two absolutely various designs corner cut. Based on this, we will pay attention to both.

The first option is notable for the fact that the bowl is chosen only up to the middle of the log (from the axis of the log on one side). A semicircular groove is created from the top side of the log to the unselected rest of the bowl. Unlike many other cuts, thanks to this method of connection, the corner is completely protected from through blowing. The method of cutting into a hook is considered very durable and warm. However, it is worth considering that hooking into a hook is a very laborious process and requires great skill.

The second option differs in that it provides for sifting inside logs and achievement c smooth interior walls right angle. To some extent, the configuration of the joint of this cut resembles the bowl with a notch mentioned above. The only difference is that from the inside the log is crimped by a quarter of its diameter, and the spike-cut is created equal in length to the value of the heel.

Canadian felling

Canadian felling, despite the presence of common features with fat-tail felling, differs significantly from it in form. Unlike the round Russian bowl, the Canadian felling is trapezoidal in shape. The Canadian bowl is selected in the log in its lower part. Just like when connecting to a fat tail, a spike is left inside the bowl in the Canadian felling. On the log from the upper side, inclined notches are created, repeating the outlines of the bowl of the log lying on top and the groove for the tenon. The Canadian bowl is famous for its strength, tightness, and, consequently, warmth. The most basic advantage of the Canadian lock in comparison with a round bowl is its shrinkage behavior.

In a log house with round bowls, the following situation is observed - as the logs shrink and shrink, their diameter decreases, while the parameters of the bowl remain practically unchanged. This leads to the appearance of cracks in the corners that need to be caulked. On the other hand, the “cunning” design of the Canadian lock, on the contrary, becomes wedged even more under the influence of shrinkage. All this guarantees excellent tightness and the absence of cracks.

It is worth noting that the Canadian felling consists not only in the non-standard form of the lock, but also includes a whole range of technological nuances, which, only in the case of impeccable execution, provide excellent tightness of the structure for many years.

One of the advantages of Canadian logging is complete absence gaps between logs. This salient feature observed not only in newly erected log cabins, but after their shrinkage and shrinkage. Thanks to this, it is enough to lay the insulation in the crowns only once and no longer remember about the caulk.

felling into the saddle

Cutting into the saddle - is a simplified way of Canadian felling with a spike. The only difference between this option is that a spike is not made in the bowl and a corresponding groove is not created in the upper part of the log. The rest of the design is similar to a Canadian castle.

norwegian felling

Norwegian cabin - almost identical to the Canadian cabin. The only difference between the Canadian and Norwegian felling is the gun carriage. The Canadian felling is made from a log, and the Norwegian from a gun carriage. Norwegian felling is made from a gun carriage, this is the so-called oval log. At the log, two parallel layers are cut or cut down from two sides, which makes the log oval along the entire length. The corner of the lock with serrations and a spike is similar to the Canadian lock. Walls, thanks flat surfaces carriages are smooth, and the volume of the room increases. The appearance of a Norwegian log house made of a large carriage is very impressive, the unique pattern of each carriage, the power and color of the house.

Cuttings without residue

Paw connection

This type of connection has a number of advantages over cuttings with residue. Firstly, material consumption is significantly reduced, which means that construction costs are reduced. Secondly, the rooms are more spacious. Thirdly, from the outside, the corners look perfectly straight. However, this connection method also has significant drawbacks. The main disadvantages of felling in the paw are the lower strength of the structure, increased windage, exposure to the negative effects of precipitation. To eliminate these shortcomings, the corners of the log cabins in the paw must be additionally veneered from the outside.

There are two options for felling into a paw - an oblique paw (dovetail) and a straight paw.

straight paw

With this type of felling, a small distance recedes from the corner and the log begins to be hewn from the sides first. Next, a “paw” is made at the end of the log - they create an even rectangle, which must necessarily fit perfectly with identical neighbors. The main secret that needs to be taken into account at the very beginning of cutting is that to create the first “paw”, you need to choose a thinner log and start from its narrow edge. Otherwise, if you start the procedure with a large diameter log, you won’t be able to make a rectangle on thin logs. The resulting width and length on all logs will be the same, but the height will be different, since it is determined by the diameter of the log.

As a rule, they try to supplement a straight paw from its inner corner with a rectangular root spike. This is done in order to achieve the best operational properties, since in pure form a straight leg is a rather weak connection. A spike is created on the upper face of the paw, and a groove for it is selected from the bottom side.

Koca paw

Cutting into an oblique paw is a more complex way of connecting. In this case, the shape of the paw is significantly modified, now it represents a trapezoid, the two planes of which are sloped. Features of the form formed the basis of the name "dovetail" (Fig. 2). This joint configuration provides greater corner strength than the "straight leg". However, this type of connection is very laborious and only highly skilled craftsmen can do it.

The skew paw can have an even more advanced configuration option - with a spike, which significantly improves its strength. During construction using the “oblique paw” connection, a template is removed from the first paw, for example, from plywood, and the remaining ends are marked on it.

When cutting into a slanting paw, you can use GOST 30974-2002 to select the correct connection options. In GOST, geometric dimensions are established for the paw, due to the diameter of the log. This will be especially advisable if the logs have almost the same diameter or a rounded (calibrated) log is used.

DESIGN FEATURES OF LOG WALLS

Despite the fact that wooden architecture has a long history, traditional technologies gradually undergo changes over time, acquiring more and more modern features. This also applies to wooden log cabins. The traditional structural units used for the construction of log walls since ancient times are gradually supplemented with various technical details that improve the performance of log walls. Next, we will touch on various design techniques that can be used to compensate for a number of shortcomings that arise due to the shrinkage of logs.

Connecting logs along the length

When constructing large wooden log cabins, developers usually face a situation where the length of the wall exceeds the length of the log. Standard length logs is 6 meters. In this case, the logs must be butted with each other. So that the joints are not visible from the outside, the end connection of the logs is made exclusively inside the cuts. It is important to take into account that it is impossible to lay only all joined crowns in a row in height. At least through three rows of joined crowns, a solid log must necessarily go. However, dressing with a solid log is ideally best done through each row. In cases where the house has a long blank wall that does not intersect with other internal walls, an additional cut is made from short pieces of logs in this wall, into which all joints are removed.

To connect logs along the length, the dovetail configuration with a spike is traditionally used. This type of connection is quite simple in execution, but due to the shrinkage of logs, its strength may decrease over time.

Another method is often used for joining logs in the cut. With this method of joining, the logs are attached to the dowels. For each joined log, a distance of approximately 1/4 of the log diameter is set aside from the end and a hole is created for the dowels. In the adjacent perpendicular log, this hole is continued. Joined logs after installation of dowels are carefully connected with perpendicular cut logs.

Another very common way of joining logs is a screed with threaded studs. In this way, grooves are created at the joined logs from above at a small distance from the ends, and a cut is laid from them to the end. Then a stud with nuts and washers at the ends is placed in it, then the nuts are tightened, pulling the logs together. For the durability of the connection, the grooves (ideally logs) should be antiseptic with special wood preservatives.

Undercut

One of the most important components of the structure of log walls is the design of the interventional groove, also called the moon. To achieve a flawless connection of logs, the interventional groove should have a slightly smaller radius than the log itself. Then the log adjoins its neighbor with two ribs very tightly, and interventional insulation is placed in a small gap in the center of the groove. In this case, the edges of the groove protect the seal from getting wet. This design has one more significant advantage. Logs due to the shrinkage of wood are covered with cracks from the bottom side. The log literally "sets" when the edges of the seam slightly diverge. As a result, the logs, after shrinking the log house, fit even more tightly to each other. But if in the design the groove of the upper and the radius of the lower logs are identical in size, then after the occurrence of a crack, the edges of the groove will move apart, which will lead to the appearance of gaps between the logs, which will need to be caulked.

One of the most important components of the structure of log walls is the design of the interventional groove, also called the moon. To achieve a flawless connection of logs, the interventional groove should have a slightly smaller radius than the log itself. Then the log adjoins its neighbor with two ribs very tightly, and interventional insulation is placed in a small gap in the center of the groove. In this case, the edges of the groove protect the seal from getting wet. This design has one more significant advantage. Logs due to the shrinkage of wood are covered with cracks from the bottom side. The log literally "sets" when the edges of the seam slightly diverge. As a result, the logs, after shrinking the log house, fit even more tightly to each other. But if in the design the groove of the upper and the radius of the lower logs are identical in size, then after the occurrence of a crack, the edges of the groove will move apart, which will lead to the appearance of gaps between the logs, which will need to be caulked.

In this specific design of the lunar groove lies the main difference between traditional and modern cutting technologies. In the old days, tow or moss was traditionally used to insulate interventional joints, the log joints were repeatedly caulked. Nowadays, special rolls made of natural materials, for example tape jute, serve as interventional heaters, the width of the materials is selected depending on the width of the groove.

Compensation cut

The use of a compensatory relief cut at the top of the log is another modern refinement of centuries-old technology. The name itself already eloquently makes it clear that the cut is created in order to remove excess internal stresses in the log. The location of the cut was chosen for a reason, because the cut is securely closed by the next log, which eliminates the penetration of moisture into it. The cut in the process of shrinkage expands, but the number of cracks throughout the log, and most importantly, their depth and size decrease.

A cut is made along the axis of the logs, but does not protrude at their ends and does not pass through the locks. The absence of cuts at the ends is a very important point. After all, the indents from the ends and cuts are not created for decoration, but to avoid the penetration of cold air from the street into the wall through the outer ends. This is especially important if the building has walls, the inner end of which goes into the house, and the outer end onto the street. In this case, the creation of a cut along the entire length of the log will lead to a through blowing of the wall, which will lead to the need for its additional sealing.

Hanging corners

This technology applies to all compounds with a residue. The technology of curtaining the outer corners can significantly reduce the appearance of intervent cracks after shrinkage of the log house. The essence of the technology lies in the fact that the interventional grooves on the protruding ends of the logs are selected a little more, so as to achieve a gap of 5-8 mm between the logs. As a result, the releases of logs freely stick out in the air, without leaning on each other.

The dignity of this constructive solution in that, being in the air, the outer ends of the logs dry out much less than the rest of the log. As the log shrinks, the gaps gradually decrease, and the ends, in turn, fit more tightly. While the absence of gaps would lead to hanging logs on the outer outlets. In this case, cracks would form on the inner parts of the corner, since the inner diameter of the logs would slightly exceed the diameter of the outlets in size.

CONSTRUCTION OF THE LOG

Under the first crown, during the construction of the log house, horizontal waterproofing is laid. It does not allow the wood to come into contact with the plane of the foundation, preventing the penetration of moisture and preventing the appearance of mold and rotting of the log house.

The laying of the first crown begins with half-logs, on top of which full-fledged round logs are then laid. Laying the first crown is given special attention, all operations must be carried out with the utmost accuracy. It is placed in a horizontal plane on the foundation, maintaining right angles. Be sure to carry out antiseptic first crown.

Between the rows of logs, an interventional sealant is laid. So that the sealing material does not move during the assembly of the crowns, it is recommended to fix it with a furniture stapler.

For joining logs, pins (dowels) are used, placing them from each other at a distance of 1.5-2 m. Nagels used in wooden housing construction are round rods (shank) made of wood of more durable species (oak, birch) than a log house, their diameter is 25-30 mm. For them, installations simultaneously drill a through hole in three logs. The length of the dowel must be 20% less than the hole prepared for it. Nagel's macce walls are placed in a checkerboard pattern.

After installing the entire log house, logs and beams, rafters are cut, then the draft floor and roof are mounted. The roof is made temporarily, covered under roofing felt or film. The log house is treated with an antiseptic, and the construction site is mothballed for a year, because. the log house should shrink within a year.

After shrinkage of the log house, the final installation of the truss system and subfloors is carried out. In the process of shrinking the log house at home, gaps appear after the wood dries out, so it is necessary to re-caulk the log house, then sand it and cover it with finishing impregnation (oil, varnish, paint, stain, etc.) of which today there is a huge amount. The truss system is re-tightened and the roof is mounted, and then all the necessary internal finishing work. Windows, doors, finished floors and ceilings, electrical and plumbing are inserted.

Articles on construction

Finishing materials from wood

Decoration Materials wood is the best for life. With the complex stages of planning and building your home behind you, you are on the cusp of perhaps the most creative stage of the job—furnishing your home. And if in the exterior wooden house, as a rule, does not need, then the internal, even the most minimal, is necessary.

Russian felling of log cabins is the easiest and most reliable way of building from round logs. "KINGR KEDR" is a team of professionals that successfully works with round timber different diameter since 2002.

Company advantages

First class timber. We harvest wood on our own plots, which are located in rare places for Siberian forests - on the edges and in non-boggy regions. This location provides many benefits:

- We have the possibility of logging at any time of the year. All units of our equipment are equipped with special grips for transporting long lengths and exclusive specimens with embossed butt parts.

- Our forest is characterized by high environmental performance. The Siberian region has not suffered from anthropogenic degradation of air and soil, so wood exudes only useful phytoncides - it is not impregnated with carbon monoxide and sulfur dioxide.

Our cedar trunks are 15% smoother than the average for the region, and their resistance to pathogenic bacteria increases by 10%;

professional projects. The design section includes cutting charts and a scheme for laying crowns. These documents are a guarantee of the identity of the sketches and the finished log house, the ability to rationally cut valuable rock and minimize waste. Detailed scheme laying crowns along the axes speeds up the process of assembling a house. It takes 2 months to cut a large log house on our site, which is 20% faster than when assembling without schemes.

Full guarantee for all types of work. We build turnkey houses and baths and give a guarantee for all types of work and for the log house as a whole. We have a well-organized work process, we took care of the motivation of our employees. High salary, high quality material, good technical equipment attract the best carpenters and finishers to our company.

High-quality complete set of log houses manual felling. For our log cabins, we choose the best! We are dealers of Remmers, Borma and Osmo. Our Customers buy the entire line of these products at a privileged price. We are partners of factories - manufacturers of elite roofing "Metrotile Europe", "RUUKKI" and "BRAAS". We cooperate with leading manufacturers of window and door structures"Rehau" and "Veka".

Connection "with a remainder" and "without a remainder"

There are two ways to connect the crowns - "in the oblo" and "in the paw". The method "in the paw" is the connection of logs in the corners without residue. This method is not used in our company because it has many disadvantages:

- Corner ventilation, large log house heat losses.

- Unaesthetic appearance. Over time, the connections are revealed, which negatively affects the exterior.

- The fragility of buildings. A decrease in the service life is associated with a violation of the structure of the wood during the felling of the house and the insecurity of the corners.

The only advantage such a method is a saving of five to ten percent of wall timber. In our company, we achieve a similar result when choosing a traditional felling with a residue: the use of cutting charts from project documentation reduces lumber waste.

Russian felling: technology features

- Logs are connected in corner bowls. There are two options for the location of the bowls - “in the oblo” (the bowl in the lower log) and “in the okhlop” (the bowl in the upper crown). We practice chopping, which is also called the "Siberian bowl" or "okhlupen".

- In the top log a semicircular bowl is made, which covers the lower log. We chose the "Siberian bowl" because in this position, moisture does not get inside. This increases the strength of the walls and reduces wear and tear over time. Such a log cabin of a hand-cut house is more durable.

- Log releases go beyond the walls. The dimensions of the extensions depend on the diameter of the log. A longitudinal groove is made in the upper crown, which repeats the profile of the upper part of the adjacent log.

- After shrinkage of the log house, the ends are cut off. Possible different variants trimming: straight, "running", under the wedge or with a relief outline of the butt parts.

- For structural rigidity the crowns are interconnected with the help of wooden "nails" - dowels. The ROYAL KEDR company uses dry birch pins that comply with GOST. "Nails" are hammered at a distance of 1.5 - 2 meters from each other in each crown.

- The depth of the groove is equal to the radius of the log, after installation, the upper logs rise above the lower ones by half the diameter. The selection of grooves and bowls in the company "KINGR KEDR" is carried out manually using an adze. Tesla leaves the sapwood intact. The wood is cut along the fibers, in the process they are crushed, the pores and resin channels are clogged. This protects the wood from moisture and makes it durable.

- The boundaries of the grooves and bowls are drawn with a squiber. This is a modern version of the carpenter's tool "dash". The squiber allows you to make marks when felling and provides visual control over the horizontal and vertical positions of the crowns. Exact dimensions bowls and grooves - this is a guarantee of a snug fit of the logs and the tightness of the corners.

- When assembling the frame all hidden places, including the surfaces of bowls and grooves, are treated with REMMERS complex protective compounds, which have a long service life due to deep penetration into the wood.

- An environmentally friendly insulation "Klimalan" is laid between the crowns. This is a material based on sheep's wool without synthetic fillers. It has high plasticity, does not rot and is not saturated with moisture. After shrinkage, when the interventional gaps increase, the insulation straightens and fills the voids.

Russian cabin with a "castle" ("in a fat tail")

Perhaps a stronger connection - "in the fat tail". In this case, a special spike is made, which is located in the corner joints. A groove is made in the upper log, and a spike is cut out in the lower log. When mounting the crowns, the groove is connected to the spike and provides a snug fit. The bowl can be oriented either up or down. This is a labor-intensive technology, but it is characterized by high performance.

Russian cabin "in the hook"

There are two methods of cutting into a "hook" that are similar to each other.

- In the first case, the bowl is selected up to the middle of the log along the axis on one side. A semicircular groove is made in the upper log, deep to the unselected section of the bowl. Such an angle is completely sealed and reliably protected from blowing.

- The difference of the second one is the need to trim the inner side of the log until an angle of 90 degrees is obtained with the inner straight walls. This is reminiscent of a bowl "with a prisek." The difference is that inside the log is cut off by a quarter of the diameter, and the spike is made equal along the entire length of the notch.

The ROYAL KEDR company offers Customers three design options:

- finished projects from our catalog;

- individual design according to amateur sketches, pictures from a magazine or based on a detailed story about the future concept of the house;

- adjustment finished project in accordance with the requirements of the Customer: minor changes in layout, selection of a different diameter.

Before developing a project or before adapting finished sketches for implementation at the Customer's site, it is necessary to conduct geological surveys and make a topographic survey. It is not recommended to start an individual design of a bath or a house until the land allotment has been fully studied.

Our company employs experienced architects, which have in their arsenal their own methods of minimizing material consumption. Rational design of houses reduces the cost of construction and allows you to spend unspent funds on finishing the log house or on its technical equipment. If you wish, you can take a walk around the future house or bathhouse using interactive 3D modeling.

The composition of the house kit

- Wall logs;

- Lumber of natural moisture for:

- floors;

- truss system;

- crates;

- floor or ceiling;

- Mezhventsovy heater "Klimalan";

- Nagel from dry birch;

- Ruberoid;

- Protective compounds "Remmers";

- Shrinkage jacks;

- Hardware.

Construction time

The construction time depends on the complexity of the project, the diameter of the log and the workload of the production site.

Construction stages:

- Individual design: 2 to 3 weeks;

- Foundation pouring: 1 month. It is done simultaneously with cutting;

- Logging and creation of a wall kit: 2-3 months;

- Assembling a log house on the site: 1 month;

- Shrinkage: 9-12 months;

- Finishing, installation engineering systems A: 4-6 months.

In Russia and other countries, the construction of wooden structures is gaining popularity again. There are many reasons, among them - strength, usefulness and beauty. One of best options- Russian felling. What is a Russian felling, what are its features and types of locks?

This technology has been popular since Ancient Russia: most of the buildings were log cabins - from huts to temples and towers of the Kremlin. The company "site" is engaged in the manufacture of high-quality wooden log cabins self made using traditional, time-tested technologies.

The newfound relevance of log cabins is due to their reliability and practicality, because wooden houses are really environmentally friendly and incredibly durable.

What are the reasons for the names of the felling? You can find three main types of felling: Russian, Canadian and Norwegian. They differ mainly in  locks used.

locks used.

You might think that the name is given in accordance with the country where the castle was invented. In fact, they got their name from the countries in which they took root. For example, the "Canadian bowl" castle can be compared with the Russian "saddle cabin", but because of its distribution in Canada, it is called that way. But the main thing in the castle is not the name: whatever it is, it must meet several important requirements.

The lock should provide a strong connection of the logs of the log house. There should be no gaps between the logs of the log house: they should fit snugly against each other. The lock must be made in such a way that water from the external environment does not enter the connection. This is especially true for log cabins, where moisture is a natural phenomenon.

In total there are four types of Russian felling:

Sometimes during the construction of a log house, different types of locks are combined. In the "Our Works" section, you can see photographs of the log cabin of a church in Chuvashia, where three types of connections were used, "flap", "in the paw" and a combined "dovetail" with a Russian bowl on octagonal domes. As a result of this combination, we got the usual “dovetail” on the outside of the octagon, and “into the bowl” inside.

Logging technologies - from Canadian felling to Post and Beam houses.

In wooden housing construction, there are two main technologies for cutting a log house - this is cutting into a bowl, it is divided into Canadian and Russian cutting, as well as frame-log technology - the so-called Post and Beam, from English words Post and Beam (post and beam).

Thanks to manual cutting achieved highest quality, which cannot be obtained when processing logs in other ways. It is during manual processing that the log ideally retains its qualities - warmth, durability, natural beauty and resistance to impact. environment. The technology of manual felling affects not only the style and appearance, but also the thermal conductivity and manufacturability of the chopped log. Possibility to use various materials for home decoration and construction. We will try to explain to you what the differences are.

Cutting a log house into a bowl

Cutting a log house into a bowl is the most common type of felling. The walls in this case consist of logs arranged horizontally. At the junction or intersection of walls (cuts), bowls are cut in the log during cutting. The cutting technology can be performed according to the Russian technology with a round bowl or the Canadian felling can be used, which is also divided into two types - traditional Canadian or diamond bowl.

|

Cutting a log house into a Russian bowl has long been the most common type of felling in Russia. In the cut, all logs and bowls are round. Disadvantages of the technology of felling a log house into a Russian bowl.In the process of drying, the logs decrease in size and at the corner joints of the logs, gaps are formed, which are larger, the thicker the diameter of the log. For example, if you used logs with a diameter of 30 cm in your log house, then gaps of about 7 mm may form, and if the log is 40 cm, then gaps can be up to 10 mm. Advantages of felling a log house into a Russian bowl.This type of felling has taken root in cold Russia for a reason. Typically, the width of the groove in the log (thermal lock) is about half the diameter of the log. |

Canadian felling

Canadian felling is the most logical technology in wooden housing construction using logs with a diameter of 36 cm or more.

The main advantage in the Canadian bowl during the cutting of the corner joint on top of the log is the notches, which give the log at the place of the cut not a round, but a saddle shape. Due to this, the top log during the drying process does not form a gap in the cut, but slides down along the made notches and prevents the appearance of gaps between the logs.

Cutting a log house into a Canadian bowl

|

In the cut in the log, upper notches are formed to improve shrinkage processes. Advantages of log cutting technology in Canadian bowl.The processes of shrinkage of a wooden house for residents are more imperceptible. Cons of felling a log house into a Canadian bowl.When forming the notches, due to which the drying process in the Canadian bowl is more favorable, the width of the thermal groove between the logs decreases. When cutting a log house into a Canadian bowl from a log with a diameter of 30 cm, the width of the groove will be about 10 cm, and from a log with a diameter of 40 cm, about 15 cm. |

Logging into a Canadian diamond bowl

|

A wooden house or bath house cut into a diamond Canadian bowl is considered aerobatics. A chic appearance is achieved not only by the upper notches in the cut, but also by the lower ones. Thanks to the repeated intersection of the edges (notches) in the cut, this type of felling got its name - diamond. Advantages of the technology of felling log cabins into a diamond Canadian bowl.The same as the traditional Canadian bowl - favorable processes for felling during the period of log shrinkage. Disadvantages of felling a log house into a diamond Canadian bowl.Small width of the thermal groove. It can be even narrower than a house cut into a traditional Canadian bowl, as the log has notches at the top and bottom of the log. We recommend building houses in a diamond Canadian bowl from a log with a diameter of at least 46 cm. |

Log cabin in hybrid style.

|

Benefits of logging in a hybrid styleIf you have a complex (not double-pitched roof), then it is not possible to use chopped gables. truss system rigidly fastened with a sheathing, counter-sheathing, roofing will not allow gables located perpendicular to each other during the drying process to naturally change the angle of the roof slope using traditional sliding supports for rafters. On the gables between the logs, gaps are necessarily formed equal to the size of the logs. Disadvantages of logging in a hybrid stylemissing |

Logging using Post and Beam technology

|

Post & Beam felling technology, when the frame - the basis of the house consists of beams and pillars made of logs, allows you to use a variety of materials to fill the walls - horizontal logs without cuts, stone, glass. As a rule, frame walls are made with cladding of various types of sheathing boards - log siding, shingles, imitation of timber or unedged boards. Also on frame wall you can easily lay tiles or stick wallpaper. Frame-log houses allow the use of completely different finishing and building materials in the design Benefits of post and beam fellingThe frame-log construction is very stable and practically does not shrink. Disadvantages of felling a log house using Post & Beam technologyThe disadvantage of the frame-beam construction may be the filling of the walls with chopped logs. The height of the pillars and beams in Post & Beam houses remains unchanged over time, while the chopped walls are subject to shrinkage. More information about Post and Beam technology on the page building a house Post and Beam |

The rich experience and knowledge of the carpenters of the Medvezhy log company allow the construction of a wooden log house by any known method of beam felling

One of the main activities of our company is felling log cabins in the classic Russian style. This technology involves the use of manually debarked logs and one of three types of corner joints. We offer you to briefly get acquainted with the features of the implementation of projects of cottages in the classical Russian style.

Features and main differences of technology

The houses realized in the Russian style are distinguished by the following main features:

- as wall material for the Russian felling of a log house, a round log is used;

- logs are prepared mainly by hand (details are described below);

- in the conditions of production according to the project of the cottage, a preliminary felling of the house is carried out;

- Russian felling of log cabins involves the use of one of three popular types of connection (described briefly below);

- after preliminary adjustment of the logs and assembly of the house at the production site, the log house is disassembled and transported to the customer's site;

- the final assembly of the house on the site is being carried out.

Home in classical style from logs debarked by hand differ not only appearance, but also a number of positive performance characteristics proven for centuries. In particular, they have minimal heat loss. Hand debarked logs are not prone to large cracks and crevices.

Prices for log cabins

3 types of connection

The classic cutting of the Russian bowl can be done in several ways. The following three types are especially popular:

- In oblo - a semicircular bowl is cut out in the log of the lower crown and adjusted to the size of the upper crown. Today it is not common for technological reasons.

- In an okhlop - a semicircular bowl is cut out at the bottom of the upper crown and adjusted to an already laid log.

- A bowl with a ledge (or a “tail fat” thermal lock) is an improved version of the clasp connection, when a ledge is additionally cut out in the bowl under the groove of the transverse crown. We use this, the most complex and high-quality type of felling.

There are other ways of cutting the Russian bowl, the advantages and disadvantages of which will be told to you by our experts.

Harvesting and processing logs

Logs for the construction of houses in the Russian style are harvested and processed mainly by hand. best material for these purposes is the northern forest of winter harvesting.

The processing of logs for the construction of a future house is carried out in several ways. Including, debarking is carried out with a scraper, planer or with the help of an apparatus high pressure. You can read more about this on our website.

In the finished log house, the logs are additionally polished and painted in the desired color, tinted or protected with colorless compounds.

The advantages of building in the Russian bowl from the Sokolnikov Brothers

Houses in the classical Russian style of our execution are:

- high-quality timber from the northern regions of the Kirov, Vologda and Arkhangelsk regions, as well as the Komi Republic;

- careful manual processing logs;

- the use of any type of felling;

- work with individual and standard projects;

- felling and final assembly of the log house by the same team of experienced carpenters;

- a gift for each new log house - authentic chopped furniture to match the Russian style.

Houses in the Russian classical style from the Sokolnikov Brothers

To order the construction of a house according to classical Russian technology in our performance, call the specified phone number. We also invite you to visit our office and our own production, which can be easily found at the addresses provided in the "Contacts" section.

Everything is very simple and clear! The first floor is chopped

Everything is very simple and clear! The first floor is chopped