Make a brick oven for your home with your own hands. Cooking oven for the summer kitchen: an overview of factory models and a brick slab laying scheme

There are a large number of different stoves that can serve both for heating and for heating the house and cooking. Some are quite voluminous and massive, others are compact, and for a particular room, the desired option is selected that will be most effective for a given area. In addition, any of the furnaces must be installed with the obligatory consideration of the requirements developed by specialists in accordance with SNiP 41-01-2003.

In the conditions of the modern information space, brick ovens for the home, drawings with orders can always be found on the Internet. However, it must be remembered that building this structure on your own is quite difficult, since each stove-maker has his own experience and professional secrets, which are acquired only with work experience.

Criteria for choosing a brick oven

If it is nevertheless decided to similar work independently, then it is necessary to decide on the model - with knowledge of the matter, paying attention not only to appearance and the design of the stove, but also on its heating capacity in relation to the room that it will have to heat.

When choosing a furnace by size, it must be taken into account that its side walls give off more heat than the front and back. This factor must be taken into account when planning the installation of the stove in one place or another.

Furnaces are divided not only by functionality, but also by its form. They can be rectangular, T-shaped, with a ledge in the form of a stove bench or stove, and others.

Stoves can only be used for heating living rooms and can be installed, for example, between the living room and bedroom, perform several functions and serve as a dividing wall between the living rooms and the kitchen.

For rooms with a small area, you should not choose too massive buildings. Although many of them are multifunctional, they will take too much useful place which can be used for other purposes.

Naturally, the location of the heated room in the house, as well as the degree of insulation of the entire building, also plays a big role.

Stove selection table depending on the heated area and the location of the rooms:

| Room area, m² | Furnace surface, m² | |||

|---|---|---|---|---|

| Not a corner room, inside the house | Room with one outside corner | Room with two outside corners | Hallway | |

| 8 | 1.25 | 1.95 | 2.1 | 3.4 |

| 10 | 1.5 | 2.4 | 2.6 | 4.5 |

| 15 | 2.3 | 3.4 | 3.9 | 6 |

| 20 | 3.2 | 4.2 | 4.6 | - |

| 25 | 4.6 | 6.9 | 7.8 | - |

All these criteria must be predetermined, and based on them, a choice should be made in favor of one or the other model.

Types of brick ovens

As mentioned above, the design of furnaces can be different - both very difficult to build, and quite simple. The most famous of the models are "Dutch", "Swede", "Russian". Modifications named after their designers are widely popular. So, the furnaces of Bykov, Podgorodnikov, Kuznetsov and other masters are very common.

- There are heating stoves that do not have a hob and other elements, but consist only of walls in which flue ducts, furnaces, blowers and cleaning chambers pass.

- Heating and cooking stoves have in their design a stove for cooking, sometimes an oven, a hot water tank and a drying chamber.

- Another type of heating structure is a fireplace stove, which has two fireboxes in its design - a fireplace and a stove. This model can be used by heating only one of the fireboxes or both at the same time.

- There are also stoves that include the entire complex necessary for human life both in summer and in winter. Often they are equipped with a heated bed, which may well serve as the basis for the bed.

You may be interested in information about what is

Prices for finished heating stoves

heating furnaces

Choosing a place to install the oven

It is also important to provide for the correct installation location of the furnace. The best place is the crosshairs of the walls of the house. If it does not have a large area, then such a stove can heat all rooms at the same time. It is desirable that the structure is located near the entrance to the building, since the heat emanating from it will create a barrier to the cold air coming from front door. In addition, if the firebox door opens into the hallway, it is easier to deliver fuel to it without carrying it through the whole house.

When choosing a place, you need to take into account several more factors that are important for the operation of the furnace:

- The building must be installed in such a way that there is free access to any of its walls - this must be taken into account for unhindered control of the integrity of the walls and for cleaning the chambers.

- When erecting a furnace, it is necessary to provide for a separate foundation for it, not connected to the base of the house.

- The chimney must pass between the attic floor beams and not stumble upon them when it is raised - this is provided for when building a house, and if the stove is being built in a finished building, then before laying the foundation for it.

- For fire safety purposes, a heat-resistant flooring made of metal sheet or ceramic tiles must be placed on the floor in front of the furnace door.

Basic design of a brick oven

To know how each of the elements of the furnace works, and what it is intended for, you need to consider the basic design of the heating structure:

- The fuel chamber is designed for laying and burning fuel. It is separated from the blower chamber by a grate and connected to internal channels, through which smoke and hot gases follow through the entire furnace, redirecting to the chimney pipe.

- The blower chamber provides an adjustable air supply to the furnace and is a collector of ash from burnt fuel, therefore it requires periodic cleaning.

- An oven, a hob and a tank for heating water - these elements are built into heating and cooking stoves.

- Cleaning chambers are necessary, as soot collects in them, which crumbles from the walls of the chimney channels passing inside the furnace. With the help of them, periodic cleaning of the furnace is carried out to maintain normal traction.

- The chimney ducts passing inside the furnace can have a different configuration depending on different models. Hot gaseous products of combustion, passing through them, heat the walls of the furnace, which give off heat to the room.

- Channels direct smoke with combustion products into a chimney located at the very top of the furnace and then going outside the building.

One of the most important conditions for the efficient operation of the furnace is good traction, which is achieved by high-quality masonry in compliance with the ordering scheme and periodic cleaning of the structure during operation. In addition, it is necessary to observe the required height of the chimney and its correct location on the roof.

You might be interested in why

Materials for building a furnace

An important issue for the long-term functioning of the furnace is the choice quality materials for its masonry, so you should not save on them. To build a building you will need:

- Red refractory brick, the quantity of which is determined by the selected model. It must be remembered that this material is quite fragile, so its transportation and unloading must be carried out very carefully.

- Fireclay bricks are used for laying a combustion chamber in direct contact with fire. It will take from 40 to 200 pieces, but the exact amount can be found in the diagram of the selected model. This type of brick is able to withstand temperatures of 1450-1500 °, it keeps heat for a long time, gradually giving it to the walls of the furnace.

- You can’t do without raising the oven without mortar for laying bricks, which is made on the basis of clay. The stove-makers are advised to use the Borovichevsky composition of the solution - it is quite plastic during the laying process and refractory during operation.

- Cast iron elements are doors for the firebox, blower and cleaning chambers, valves and a grate. If the heating and cooking stove is raised, then one or more two-burner stove, oven and water heating tank provided by the design.

- Steel wire for fixing cast iron elements in masonry.

- Asbestos cord or sheet - for laying between brick and metal parts.

You might be interested in information on how to make a cast iron stove out of it

Now, having become acquainted with some of the nuances of building a furnace, we can consider several models that should be available for masonry even for beginners.

Heating stove by V. Bykov

This oven is for heating purposes only as it does not include a stovetop or oven. However, despite this, it is quite popular for houses with a small area, as it is compact - it takes up little space, but at the same time it is able to heat even three rooms.

The size of the building is 510 × 1400 mm, while its height without a chimney is 2150 mm. If we take the size in bricks, then it is 2 × 5½ bricks.

The stove is quite simple in laying, as it does not have complex internal configurations. In appearance, it generally resembles a thick wall, so the designer himself called it a "thick warm wall." Heat transfer from the entire structure is 2400 kcal/h, but at the same time, 920 kcal/h fall on the side walls, and only 280 kcal/h on its front and back parts. The cross section of the flue duct is 130 × 260 mm.

Thanks to its small width, the stove fits perfectly between two rooms, opening into a third room, for example, into a hallway, and is not only a separator for two rooms, but also a source of heat for them.

The whole design of this model is conditionally divided into two compartments - this is the upper gas outlet and the lower one is the furnace. In the lower part there are two channels - ascending and descending. They help heat the furnace part of the furnace and equalize the temperature throughout the building, preventing it from overheating.

The upper part of the furnace is made in the form of a cap, divided into five vertical, descending and ascending channels, which are overlapped by ⅔ of bricks laid horizontally in the masonry. They create a kind of sieve that delays the release of heat directly into the pipe. The walls of the channels not only direct the heated air in the right direction, but also significantly increase the internal surface area of the furnace. These factors increase the efficiency of the heating structure, which leads to greater heat transfer. It is also facilitated by a valve installed in the upper part of the building, which regulates the exit of warm air into the pipe.

For this oven model you will need the following materials:

- Red refractory brick - 407 pcs.

- White fireclay brick SHA-8 — 197 pcs.

- Furnace door 210×250 mm - 1 pc.

- Cleaning doors 140×140 mm - 2 pcs.

- Grate 250×252 mm -1 pc.

- Chimney damper 130×250 mm -1 pc.

- Metal sheet for flooring in front of the firebox, size 500 × 700 mm - 1 piece, instead of a sheet, it can be laid ceramic tile.

Prices for ready-made furnaces for brick ovens

Firebox for brick ovens

Bykov furnace ordering

The laying of the furnace takes place on the foundation prepared for it, which should have a size larger than the base of the furnace by 100 ÷ 120 mm in each direction. The height of the foundation must be two rows of masonry below the finished floor. Before laying, it is laid with a layer of waterproofing - roofing material.

| ordering | Description of works |

|---|---|

| According to this scheme, two zero rows are presented, which are below the level of the finished floor. Each row will require 22 red bricks. |

| Masonry, located on the same level with the finishing floor, and also mounted in front of the firebox a metal sheet. The floor surface around the stove is lined with heat-resistant ceramic tiles. |

| 1 row - a blower chamber is formed. At the entrance to it, a hewn brick is installed, which facilitates the selection of combustion waste. For laying this row, 21 bricks are needed. |

| 2nd row - when laying it, the blower door is installed and the chamber itself continues to form. For laying this row, 20 bricks are required. |

| 3rd row - the blower chamber continues to form. The wire attached to the ears of the door is embedded in the seams of the masonry. For a row, you will need 19 whole bricks and 2 ⅓ bricks, which are stacked near the installed door. |

| 4 row - the front part of the blower chamber is blocked with bricks together with the installed door. At the rear of the structure, the base of the swivel well begins to form. This row will take 12 whole, 6 in ¾ and 2 in ½ bricks. |

| 5th row - the base of the fuel chamber is formed from fireclay bricks above the blower chamber. Hewn bricks are laid in the front and rear parts of the base, along which the combustion waste will slide into the ash-blowing chamber through the grate installed on the same row. A gap of 5 mm must be left between it and the bricks. The fuel chamber door is mounted on the same row. It will take 17 whole and two ⅓ bricks. |

| 6 row - the walls of the fuel chamber begin to form, the chimney well continues to lay out. 11 pieces of fireclay bricks are used. |

| 7 row - the chimney well is divided in two by two bricks. The bricks above the well must be hewn. As a result of masonry, the base of two vertical channels is formed - ascending and descending. In this row, 11 whole, 2 in ½ and 4 fireclay bricks cut obliquely across the entire width were used. |

| 8 row is laid according to the scheme, repeating the previous one, the only difference is the direction of the brick. A row will take 15 bricks. |

| 9th row - the door of the fuel chamber is blocked with two bricks. This row will require 16 fireclay bricks. The back of the oven is placed according to the scheme. |

| 10 row - bricks are laid according to the scheme in compliance with their direction. This row needs 16 bricks. |

| 11 row - a brick on the back wall of the furnace and at the entrance to the drop-down channel must be hewn from above, otherwise the work is carried out according to the scheme. A row will require 12 whole, 2 in ½ and 4 in ¾ fireclay bricks. |

| 12 row - there is a combination of a falling chimney channel and a fuel chamber. For a row, you need 13 whole and 2 in ½ fireclay bricks. |

| The 13th row is laid, according to the presented scheme, and it uses 10 whole, 2 in ½ and 4 in ¾ fireclay bricks. |

| The 14th row also fits according to the scheme, it will take 10 whole and 6 in ¾ bricks. |

| 15 row - using prepared bricks, ¾ in size, a narrowing of the fuel chamber, combined with a descending channel, is arranged. The total number of bricks used is 7 whole and 14 pieces in ¾. |

| 16 row - the combined descending channel and the fuel chamber are completely blocked with bricks. This and the next row divide the structure into two parts - the upper gas-air and the lower fuel. For a row, 17 whole, 4 in ¾ and 2 in ½ bricks are used. |

| 17th row is laid out of red brick. An opening of the ascending channel is left in it, along its edges hewn obliquely bricks are mounted. Used 14 whole, 6 in ¾ and 2 in ½ bricks. |

| 18 row - a horizontal channel of the furnace is formed, it is the basis for mounting five channels that will go vertically. The cleaning chamber door is installed on the same row. For a row, you need 8 whole, 2 - ½, 2 - ¼ and 4 in ¾ bricks. |

| 19 row - the formation of the first vertical channel, the upper part of the building, is underway. It will be a continuation of the ascending channel of the lower furnace part of the furnace. The bricks that form this channel must be cut obliquely from below. Used 11 whole and 4 in ¾ bricks. |

| 20 row - the second vertical channel begins to form in the same way as the first. Half a brick is mounted between the first and second channels. This part in this series and in subsequent ones has a dual purpose - it is the basis for next row and forms windows in the masonry for heat exchange with the walls and maintaining normal traction. In a row, 7 whole, 3 in ½ and 8 in ¾ bricks are used. |

| 21 row - the third, fourth and fifth channels are formed in it. Bricks placed at the base of the walls dividing the channels are pressed together from below, as in previous cases. For a row, you need 11 whole, 5 in ½ and 4 in ¾ bricks. |

| The 22nd row is placed according to the scheme in compliance with the formation of channels. For a row, you need 11 whole and 4 pieces of ½ and ¾ bricks, for a total of 17 pieces. |

| The 23rd row is also laid according to the scheme and for it you need to prepare 12 whole, 4 in ½ and 4 in ¾ bricks. |

| 24 row - on this row, the laying of the wall between the second and first vertical channels is completed. The upper brick in the wall is hemmed from the two upper sides obliquely. For a row, you need 9 whole, 3 in ½ and 8 in ¾ bricks. A total of 18 bricks need to be used, some of which split in two. |

| 25th row - it completes the laying of the walls between the second and third vertical channels. The upper brick in the wall from above is pressed together on both sides. For masonry, you need 10 whole, 4 in ¾ and 5 in ½ bricks. |

| 26th row - completion of the wall masonry between the third and fourth vertical channels. The upper brick of the wall is also pressed on both sides. You need to prepare 10 whole, 4 in ¾ and 4 in ½ bricks. |

| 27th row - work is proceeding according to the scheme, and it requires 9 whole, 4 in ¾ and 4 in ½ bricks. |

| 28 row - it uses bricks made in ¾ of a solid brick - they form a horizontal channel for flue gases, which is called the cap. For a row, 4 whole ones are used, 14 pieces - ¾, 4 hewn obliquely over the entire thickness. |

| 29 row - in it, the channel formed in the previous row is completely blocked, with the exception of the opening left for the chimney pipe. For its masonry, 17 whole, 4 - ¾ and 2- ½ bricks will be required. |

| 30 row is also laid out solid, according to the scheme, except for the opening for the chimney. It uses 6 whole and 20 in ¾ bricks. |

| 31 rows are laid out according to the scheme and 17 whole, 4 in ¾ and 2 in ½ bricks are prepared for it. |

| 32 row - the first row of the chimney begins to be laid out, for it you will need 5 whole bricks. |

Stove-fireplace "Swede" A. Ryazankin

Quite popular, due to its efficiency, the heating and cooking stove of the "Swede" type. Its design contributes to the rapid heating of the premises and allows not only to heat the house, but also to cook dinner.

The appearance of the "Swede" Ryazankin

Such a stove is usually installed between the kitchen and the living area of the house, positioning it so that the hob and oven are turned towards the kitchen. In some Swede designs, a fireplace is provided on the side intended for heating the living room or bedroom. It is this option that is worth considering, since it is perfect for both a spacious and a small building, and, as you know, many owners of private houses dream of a fireplace in one of their living rooms.

This stove model is heated with wood, has a size of 1020 × 890 mm around the perimeter and 2170 mm in height, excluding the pipe. At the same time, it is necessary to provide for the fact that the fireplace portal will protrude 130 mm beyond the building. The foundation must be larger than the size of the base of the furnace and be 1040 × 1020. The power of the Swede reaches 3000 kcal / h.

For the construction of this model of the furnace, the following materials will be required:

- Red brick, excluding pipe laying - 714 pcs.

- Blower door 140×140 mm - 1 pc.

- Door for combustion chamber 210×250 mm — 1 pc.

- Door for cleaning chambers 140×140 mm — 8 pcs.

- Oven 450×360×300 mm - 1 pc.

- Two-burner cast-iron stove 410 × 710 mm - 1 pc.

- Grate 200×300 mm - 1 pc.

- Chimney damper 130×250 mm - 3 pcs.

- Steel corner 50×50×5×1020 mm - 2 pcs.

- Steel strip 50×5×920 mm - 3 pcs.

- Steel strip 50×5×530 mm - 2 pcs.

- Steel strip 50×5×480 mm - 2 pcs.

- Fireplace grate, you can make it yourself from reinforcing bars.

- Metal sheet for flooring in front of the firebox 500 × 700 mm - 1 pc.

- Asbestos sheet or cord for laying between metal elements and masonry bricks.

Furnace masonry

The presented diagrams show in detail the location of all the cast-iron elements of the fireplace stove, and the description of the masonry will help to avoid mistakes at some rather complex stages of work.

Experienced master masons recommend laying the entire oven dry to begin with, that is, without mortar, adhering to the scheme and understanding the configuration of each of the rows. This process is especially important for beginners who are barely familiar with the work of the stove.

Another trick of experienced craftsmen is the preliminary adjustment and laying of each of the rows without mortar during work. Any row is first laid out, and, if necessary, individual bricks are cut or hemmed, and then they are laid on the mortar.

This approach will slow down the work somewhat, but will allow it to be done much better, without errors that could negatively affect the creation of normal traction.

When performing masonry, you need to keep at hand not only the diagram of each of the rows, but also a sectional drawing of the furnace. It will also help - it will allow you to present all the channels passing inside and the design of the furnaces.

So, the laying is done as follows:

Ordering - from 1 to 6 row

- The first, continuous row of the furnace, is laid on onlaid on ready ruberoid foundation. It is very important to lay out the row perfectly evenly and correctly, since the quality of the masonry of the entire structure will depend on it. Therefore, first it is worth marking the roofing material with a ruler, square and chalk, drawing on it the shape of the base of the furnace, observing the dimensions. Then, relying on the scheme and observing the brick laying configuration, the first row is assembled dry, and then - laying on the mortar.

- 2 row. Metal elements are laid in it, consisting of pieces of reinforcement, on which a fireplace grate will later be fixed by welding, or this decorative element vm is completely leveled. The rest of the laying is carried out according to the scheme.

- 3 row. At this stage, the doors of the first cleaning and blowing chamber are mounted, previously wrapped with asbestos rope or lined with pieces of asbestos. To fix the doors in place, a wire is used, which is threaded into special eyelets of a cast-iron frame. Further, the wire is placed in the seams of the masonry, where it is fixed with mortar and pressed against the top row of bricks. Temporarily, until the final fixing, the doors are supported on both sides with bricks.

- 4 row. The work is proceeding according to the scheme, but the series is notable for the fact that the doors on both sides are fixed with masonry, which must be brought out perfectly evenly. The seams in this area can be two to three millimeters wider due to the wire embedded in them.

- It is recommended to lay out the 5th row using fireclay fire-resistant bricks, as well as all the walls of the combustion chamber. On the same row, a grate and an oven box are mounted, which are wrapped or lined with asbestos, in order to avoid its premature burnout.

- 6 row. On this row, a furnace door is installed, wrapped with an asbestos cord, and with pieces of wire fixed in it.

- 7 row. The masonry is carried out according to the scheme, a steel strip is mounted above the laid out walls of the fireplace, which will serve as a support for the next row of masonry. It is laid flat or in the form of a semi-arch, giving it the desired shape in advance.

- 8 and 9 rows are laid out according to the presented scheme.

- 10 row. The front wall of the furnace is being strengthened, since a cast-iron hob will be mounted in this part of the building. A steel corner is fixed to the wall with the help of two wire hooks, then pieces of asbestos sheet are laid on the place of installation of the plate, and the plate itself is installed. In the same row, the door of another cleaning chamber is fixed.

- 11 and 12 rows are laid out according to the scheme without installing metal elements. On the twelfth row there is an overlap of the cleaning chamber door.

Ordering - from 13 to 24 row

- From 13 to 15 rows are laid according to the developed scheme, strictly adhering to the brick laying configuration.

- 16 row. The device of the walls of the chamber is being completed, located above the hob, which is covered with metal strips. They will serve as the basis for laying bricks for the next row.

- 17 and 18 rows are stacked according to the scheme.

- 19 row. At this stage, two more cleaning chambers are mounted, which are fixed in the same way as the previous ones.

- 20, as well as 21 rows are placed according to the scheme.

- 22 row. Two more doors of the cleaning chambers are being installed.

- 23 row. The laying goes according to the scheme.

- 24 row. A chimney valve is being installed, the frame of which is installed on the mortar.

- 25 row. Next to the first, on the adjacent chimney channel, a second chimney valve is mounted.

- 26 row. The cleaning chamber door is being installed.

- From 27 to 30 rows are laid out according to the scheme.

- 31 row. At this stage, the third, last chimney valve is installed.

- 32-33 rows. In this area of \u200b\u200bthe design, there is a transition to laying out a pipe that rises to the ceiling.

When passing a pipe through attic floor, it is necessary to isolate combustible materials of construction from it. To do this, a metal box is arranged around the chimney with sides 100 ÷ 120 mm higher than the thickness of the ceiling. This "difference" remains in the attic.

If the oven walls are not covered decorative material, then when laying bricks, the still wet mortar in the seams is embroidered with a special tool, that is, it is given a neat convex or concave shape.

The oven - "Swede" can be supplemented with a warm stove bench. This interesting project is presented in the video.

Video: brick "Swede" with a stove bench

And at the end of the article - one more good advice. Before deciding on an independent construction of the furnace, without having sufficient experience in this work, it is recommended that you first practice in the usual laying of bricks on the mortar. Believe me, this process is not as simple as it seems at first glance.

Evgeny AfanasievChief Editor

Publication author 27.08.2015

Despite the development of new technologies in the field of heating, a conventional wood-burning brick oven remains the main source of heat in many private and country houses, garages and various outbuildings. But the construction of even a simple heating stove costs money - the homeowner needs to buy materials and pay for the services of a stove master. To save on construction, we suggest laying down a brick oven with your own hands. Below we will tell you how to build it correctly, we will provide drawings and masonry ordering schemes.

Furnace project selection

There are countless designs for wood-burning brick ovens, and experienced craftsmen are constantly coming up with new designs. It will not be easy for the owner of the house, who decides to build a brick stove, to choose a suitable heater. Therefore, first give clear answers to the following questions:

- What tasks should a brick oven solve in your house, will it only be a heating one, or will it need to be used to cook food and heat water?

- How much space are you willing to allocate for the construction of the stove when building a new house?

- If a cottage or a house has already been built, then you need to think about the location of the heater and the passage of the ceilings with a chimney. In this case, it is necessary to take into account the device of a separate foundation.

- Decide in advance on the design, you may wish to build a fireplace stove with panoramic glass.

Advice. At first, a beginner should not take on the laying of a serious brick oven in the house, but to begin with, lay down something simple and small in the yard - a barbecue or barbecue, since there are quite a lot of such projects published. Having trained and stuffed your hand, you will understand the nuances of this work and start building a home heater more confidently.

Scheme of laying a street barbecue with lockers

Scheme of laying a street barbecue with lockers Of course, it is unlikely that an ignorant person will be able to build a beautiful stove with built-in panoramic glass with their own hands. But after all, to perform these works and consultations, you can always invite a stove-maker. As a rule, these people are friendly, because the construction hearth must always be approached with a soul. As for choosing a project, you are offered 3 simple options:

- conventional hob for 2 burners with a tank for heating water;

- channel heating furnace - Dutch;

- heating and cooking stove of classical design.

The technology for building the original rocket stove is presented in ours.

Cooker with water boiler

This stove has dimensions of 890 x 510 mm and is designed for cooking with simultaneous heating of water in a tank located on the path of flue gases leaving the furnace. The total heat transfer of the stove is 1.2 kW when laying firewood twice a day. This furnace is shown below in sectional drawings:

The stove is provided with a tank-boiler connected to the water heating system of the house

The stove is provided with a tank-boiler connected to the water heating system of the house Such a small-sized do-it-yourself brick oven is quite simple in execution and will take up little space in the kitchen. Subsequently, a heating shield can be attached to it in order to take more heat from the flue gases. The laying diagram below shows the order of the furnace:

To fold the hob yourself, you must first purchase the following materials and oven fittings:

- full-bodied ceramic brick - 185 pcs.;

- cast iron stove for 2 burners measuring 530 x 180;

- firebox door 250 x 210, ash pan 130 x 140, revision door 130 x 140;

- equal-shelf corner 30 x 4 - 3.6 m;

- oven 320 x 270 x 400;

- water tank 150 x 350 x 450.

Also, roofing steel and sheet asbestos with dimensions of 115 x 64 cm are required for lining under the stove, and a sheet of metal 50 x 70 cm is needed for laying on the floor in front of the stove.

Dutch channel stove

This classic duct-type heating stove really comes from Holland. Its advantages are simplicity and undemanding to the quality of materials, and the body of the stove can also be increased arbitrarily in height and thus heat rooms on two floors. In addition, the Dutch woman can be safely considered a mini-oven, since it occupies a small area.

Making the simplest Dutch stove for 3 channels, shown below in the drawing, for an experienced craftsman will not be very difficult. A beginner will have to work hard to make high-quality masonry with dimensions in terms of 1010 x 510 mm, extending to a height of more than 2 m plus a chimney. But first, it is proposed to familiarize yourself with the masonry scheme of this brick oven and the orders:

From the drawing it is easy to understand the principle of operation of the Dutch woman - combustion products heat the walls of the heater, moving along the internal vertical channels

From the drawing it is easy to understand the principle of operation of the Dutch woman - combustion products heat the walls of the heater, moving along the internal vertical channels

For construction, the following materials will be required:

- full-bodied ceramic brick - 390 pcs.;

- grates 250 x 250 (cast iron or steel grate);

- firebox door 250 x 210, ash pan 140 x 140, revision door 140 x 140;

- metal gate valve 130 x 130;

- asbestos sheet 1000 x 500;

- the same sheet of roofing steel.

Heating and cooking oven

The design of this heat source is already more complex, although outwardly the stove resembles the same Dutch stove. Its dimensions are 650 x 510 mm, and the developed thermal power is about 1.5 kW. By the name of a brick oven - heating and cooking - it is easy to understand that it is designed both for heating rooms in the house and for cooking. The construction scheme is shown in the figure:

Scheme of a combined stove for heating and cooking

Scheme of a combined stove for heating and cooking An important point. If you carefully study the diagram, you can understand that the summer mode of operation in this simple design is not provided.

This means that cooking in the summer on the stove will be hot if it is located in the house. You will have to cook in a different way or choose a more suitable heat source design. Homeowners who are not embarrassed by this fact are offered a list of materials and procedures in order to successfully fold a brick oven:

- full-bodied ceramic brick - 211 pcs.;

- cast iron stove for 1 burner measuring 360 x 410;

- grate 250 x 250;

- firebox door 250 x 210, ash pan 130 x 140, inspection door 130 x 140, ventilation door 130 x 75;

- equal-shelf corner 32 x 4 - 300 mm;

- valve 140 x 140;

- knitting wire with a diameter of 1.5 - 5 m.

The grates are installed on the bricks of the 5th row, the cast-iron hob - on the 10th

The grates are installed on the bricks of the 5th row, the cast-iron hob - on the 10th What kind of brick to lay the oven

Main building material for the construction of the furnace is a red ceramic brick of brand 150, made from baked clay. Its dimensions are standard - 250 x 120 x 65 mm, although in the past other stones were also produced for the furnace business. But now all the dimensions are unified, so that the fireclay (refractory) brick, from which the furnace firebox is often laid out, is the same size as the usual one.

In construction, a stone 88 mm high is still used, but it is not suitable for laying furnaces, since it has cavities. Here, only a full-bodied stone is required, without voids and cracks, good quality. True, there is 1 exception - the Dutch oven, it can be laid from used bricks. But it’s not worth bringing to the point of absurdity, a heat source made of cobblestones will definitely not heat.

The fact is that a heating and cooking stove built with your own hands from low-quality red brick can crack even at the stage of drying the masonry mortar. It should be noted that the clay mortar dries up, and does not harden, like cement. Therefore, beginners are not recommended to experiment with bad or used bricks, otherwise the newly built oven will immediately require repair.

A firebox for a wood-burning stove is formed from fireclay stone (if required by the project)

A firebox for a wood-burning stove is formed from fireclay stone (if required by the project) A separate recommendation concerns masonry mortar. At first, you should not go to the nearest ravine for clay, because it still needs to be brought to the correct condition. It is better to buy a ready-made mortar for laying stoves, clay or fireclay.

How to build an oven

In the vast majority of cases, construction begins with the construction of a foundation for a future heat source. An exception may be outdoor mini-ovens, which, due to their low weight, are sometimes placed directly on concrete screed yard. All others, regardless of location, must be built on a solid foundation. Moreover, it is not allowed that the foundation of the furnace is connected with the base of the house or arranged close to it, it is necessary to leave a gap of at least 5 cm, and preferably 10.

Important. Failure to comply with this requirement may lead to the fact that after a year or two the oven may crack and even deviate from the vertical.

If the house has a good foundation in the form cement screed, and the total weight of the furnace does not exceed 750 kg, then the foundation is not required, the laying can be started directly from the screed, having previously laid sheets of asbestos and roofing steel. The structures given in the previous section have a weight of over 750 kg, and therefore it is necessary to arrange a reliable foundation for them. The foundations for the furnace are of 2 types: rubble and reinforced concrete.

Regardless of the type of base, you first need to dig a hole whose dimensions exceed the area of \u200b\u200bthe furnace by 10 cm in each direction. The depth depends on the thickness of the upper layer of black earth or other subsiding soil, while the base of the foundation must rest on a denser layer. In the first case, the pit is laid with rubble stone with dressing, using a solution of the following components:

- sand - 6 parts;

- cement - 1 part;

- lime mixed with water - 1 part.

All voids between the stones are also filled with this solution, and the upper part, located at a depth of 80 mm from the floor, is leveled with it. Reinforced concrete base is poured with formwork and reinforcing mesh, having previously poured a pillow of crushed stone 10 cm thick onto the bottom of the pit.

Important. After the mortar or concrete has hardened, a waterproofing barrier made of roofing felt in 2 layers must be laid on top of the foundation.

The laying of the furnace is carried out in accordance with the orders in compliance with the thickness of the seams within 3 ... 5 mm. A few recommendations:

How to fold a small oven at home is described in detail in the video:

It is clear that the first time a newly-made master will not be able to lay down a beautiful stove due to lack of experience. But this is fixable, because outside you can make a cladding brick wall using staining. Previously, they were plastered and covered with two layers of whitewash of chalk or lime, but now there are simpler and more convenient means. In addition, lime is easily transferred to clothing when accidentally touched and constantly needs to be updated.

If we talk about how you can paint a brick oven, then there are such options:

- organosilicon heat-resistant enamel grade KO, designed for high temperatures;

- silicate or acrylic paints;

- heat-resistant varnish (for example, PF-238) mixed with dye.

The most preferred option is transparent enamel KO-85, KO-174 and KO-813. It is suitable both for the furnace itself and for painting metal parts, as it can withstand temperatures up to 600 ° C. Silicate and acrylic paints will not last as long, but they are cheaper. Also, the stove can be painted with transparent varnish PF-238 or mixed with gouache of the desired color, as shown above in the photo.

In any case, the coating is applied for 2 times, the second layer is applied after the first has dried. The tool used is a brush and a roller. It is desirable to pre-treat the surface with a special primer composition designed specifically for such purposes.

Conclusion

Of course, it is unrealistic to deeply reveal all the nuances of a complex furnace business within the framework of one article, we have described only the main points. To successfully build your first brick oven, a beginner home master it is worth studying the relevant literature, practicing masonry. The preparatory stage is no less important - you should choose the right materials, prepare tools and fixtures.

This article contains an understandable, very detailed photo instruction for laying a brick oven with your own hands, tips on how not to make a mistake when choosing the necessary materials and how to properly place the stove in a private house for optimal heating of a larger area.

Options for installing a stove in the house

The placement of the stove depends entirely on what exactly the owners expect from it. If it is installed in a house of a small area and will be used as a fireplace for friendly gatherings, you can use the first scheme. Such a stove is a good option for barbecue on the grill or shish kebabs.

Options for placing a brick oven

The second scheme is for a solid quadrature house. In this case, the front side of the fireplace stove opens into the living room, the stove walls heat both bedrooms, and the heat in the remaining rooms is maintained by heat exchange.

The third scheme with a stove for heating and cooking is a budget housing option for a bachelor or a small family. Pluses - a warm couch and the possibility of placing a dryer in the hallway.

Important: it is worth taking care of the external insulation of the house in advance, because it greatly increases the efficiency of stove heating.

Selection of bricks, sand, mortar

In order for the oven to serve for a long time, you need to correctly select all the materials. Bricks are of three types:

- Ceramic - can be used to build a furnace.

- Silicate - not suitable at all in this case, even double M150.

- Refractory - ideal, but they are more often covered only with a firebox and fireplaces, varieties: fireclay, refractory bricks, etc.

Tip: when choosing a brick for the stove, you need to completely abandon its hollow types.

The solution is made from clay. Red clay is suitable if the stove is made of red brick; when using fireclay, special fireclay clay is required. Some stove-setters still make their own solution from river sand with a grain of 1-1.5 mm, clay (in a ratio of 2.5: 1) and water in the old fashioned way. It is advisable to use angular quarry sand without foreign inclusions and the so-called greasy clay. However, it is easier and more reliable to buy ready-made oven mixture in the store, having prepared it according to the instructions.

From the fittings, you need to purchase grates, blower and furnace doors, soot cleaners, valves or dampers.

Preparation, list of tools

Before starting work, you need to determine and mark out the place that the new stove will take.

The chimney pipe must be no closer than 15 cm from the roof rafters.

If you are laying for the first time, professional stove-makers advise you to practice in advance by making a model of the future furnace from the prepared brick. Naturally, without solution. This minimizes the possible risks in real laying, allowing you to learn from your mistakes, which can still be corrected in the layout.

The furnace foundation requires preliminary waterproofing, in area it must exceed the area of \u200b\u200bthe stove.

During the laying of a new row, it is necessary to control the absolute verticality of the walls.

For the construction of a brick oven, the following tools are needed:

- plumb;

- trowel;

- roulette;

- putty knife;

- Bulgarian;

- knitting wire;

- building level;

- metal strips, corners;

- containers for cement and clay mortar.

Step-by-step instructions with a photo for laying the stove

Different stove-makers have their own masonry technologies and their own secrets that have come with years of experience. Here is information about enough easy way creating a fireplace stove for heating two-story house, the process will not seem extremely difficult even for beginner stove-makers.

Foundation masonry

Base row brickwork will serve as the foundation. It is carried out with any brick, some stove-makers even fill this level with rubble.

When laying the base row, cement mortar is used.

The foundation is completely filled with mortar, the layer is leveled.

The erection of the furnace body

The first oven row is marked. The horizontal, from which they repel when marking, is the wall of the room.

Where the fireplace is planned to be placed, a grate is placed. From this row, the bricks are already laid on the furnace mortar.

An important stage of work is the scrupulous alignment of each new row by level.

Second row laying. The stove wall closest to the wall of the room is reinforced with an additional brick to increase fire safety.

The place where it will be located in the 2nd row remains empty, the rest of the furnace is completely laid. A door is mounted through which the owners will clean out the ashes.

The door is installed on the solution, leveled. For a more reliable fixation, it is fixed with a wire that must be laid between the bricks.

The grate is laid not on a simple, but on a refractory brick. In order for it to lie on the same level as the bricks, holes are cut out in fireclay bricks.

The size of the brick is easily adjusted - the excess is measured and carefully cut off.

The large door is mounted next to the installed grate.

The large oven door is similarly fixed with wire fasteners.

The first firebox row is placed exactly above the fireplace, it is reinforced with metal corners and a strip or thick tin. So that the masonry can lie on them, it is cut with a grinder, then the slots are brought manually to the desired size.

The next brick row is laid.

A fireplace grate is laid on a refractory brick along with a brick row.

The door is fixed, the brick is strictly adjusted to it.

The firebox of the new stove with a fireplace is ready.

Fire-resistant fireclay bricks are placed over the furnace furnace.

The body of the stove is built.

Creating a chimney

The place left under the chimney is divided into wells. The design requires reinforcement with metal plates.

Brick chimney wells are being laid.

Soot cleaners are mounted above the furnace roof.

The wells are again divided, the first rows of walls should be reinforced with strips of metal.

After strengthening, the ceiling of the furnace body is erected. The space related to the chimney remains empty.

The cornice of the body is laid out, then the chimneys are laid.

The final stage of work on the first floor. The stove is located at the bottom left, the smoke inside the chimneys moves in a spiral and exits at the top left. The final separation of the wells is closed with a tin sheet. In order to compensate for the pressure inside the fireplace stove, 2 brick rows are laid on the tin.

Two chimneys stretch to the second floor of the house - from the fireplace and the stove itself, they are separated from each other. Each chimney requires a separate damper.

Floor level of the second floor. Waterproofing is mounted here, the chimney is again reinforced with metal corners. In order to save money and not build a heating stove on the second floor, the chimney of the stove under construction is again divided. The smoke will go through it like a snake, having time to warm up the room. In order for the chimney to warm up much faster, it is laid in the area of \u200b\u200bthe second floor with a thickness of 1/4 or 1/2 bricks.

A hole for the stove chimney is carefully sawn out in the roof.

Before bringing the chimney to the roof, it is reinforced with metal corners.

If the chimney is located in close proximity to the roof ridge, it must be laid out above the ridge by at least 0.5 meters. If further, then the height of the chimney is allowed, equal to the height of the ridge, but not lower. In this case, the wind increases the stove draft, lifting the smoke up.

Even a small oven in the house is a cosiness and comfort. Larger stoves require increased skill and additional materials, but the principle of their construction is similar to the above method.

Not a single village house can do without a stove, as it will feed and warm. Today, gas pipelines have been laid in many villages, and it would seem that it is possible to switch to more convenient way heating. However, many homeowners are in no hurry to give up brick stoves, which give a completely different, special warmth. In addition, in regions rich in forests, where there are no problems with firewood, it is possible to save on gas by having a brick oven in the house.

To find out how to fold, you need to study in detail the layout and masonry technology. Before proceeding to the study of a specific option, several models should be considered, as there are compact and massive structures. You need to choose a stove that will occupy a smaller area in the house, but will have all the functions that are in demand in the household.

There are a lot of models of brick ovens. Experienced stove-makers can make their own changes to finished projects, since they already know by heart where and how the internal channels through which smoke is removed should pass. Thanks to the correct scheme of their placement in the design of the furnace, it will evenly warm up and give off most of the heat to the room. It is better for novice masters to strictly follow the already drawn up ordering schemes, without deviating a single step from them, since even one incorrectly placed brick can ruin all this rather laborious work.

Types of brick kilns

Furnaces are divided into three main types according to their functionality - cooking, heating and. By choosing the right design, first of all you need to decide what exactly will be required from it.

The cooking oven has a cast iron hob for cooking and heating water. Typically, these ovens are small size and are popular for installation in small private houses and in the country. Of course, the cooking stove is capable, in addition to cooking, also to warm a small room.

The heating and cooking stove is a multifunctional massive structure

The heating and cooking stove is a multifunctional massive structure A heating and cooking stove can warm a house or a country house with a large area, and sometimes a stove bench is included in its design, and in addition to the stove, an oven, a tank for heating water and a niche for drying vegetables and fruits are built in.

Always compact. It does not include hob and serves only for space heating. Such a structure is able to warm two rooms, if it is placed between them, built into the wall.

Choosing the best place to place the oven

Having chosen the desired model of the furnace, you need to look for a suitable place for it. The building can be installed against a wall, in the middle of a room, or built into a wall. The choice of location will depend on the size of the furnace structure and on the desire of the owner of the house.

- The stove, standing in the middle of a large room, can divide it into two different zones, for example, a kitchen and a dining room or living room. The hob will go into the kitchen, and flat wall with well-made masonry, it will become a designer decoration of the living room. Perhaps, immediately or over time, there will be a desire to build a wall to the furnace, and completely separate the two rooms - in this case, the partition must be isolated from the furnace with non-combustible material. You can use asbestos sheets for this or install brickwork.

- It is undesirable to build a furnace against an external wall, as it will quickly cool down there.

- When installing a stove between two rooms, it must also be separated from the walls with heat-resistant materials.

- The proposed place of construction must be well measured and it must be taken into account that the foundation must be 100 ÷ 120 mm larger than the base of the furnace. In addition to the base area, you need to calculate the height of the building so that it fits well into the room in all respects.

- In order to make it easier to work, it is necessary to find an ordering scheme for the selected model.

Having decided on the model and installation site, you can purchase materials for construction and prepare tools.

Tools, building materials for laying a brick oven

Depending on the size of the oven, it requires a different amount of materials and additional cast iron and steel parts, but the tools for masonry are the same.

Tools

Of the tools and fixtures for the construction of any furnace you will need:

"Goat" is a scaffolding that will facilitate work at height when the stove is raised above human height. They are convenient in that the master stove-maker can not only climb on them, but also put a container with a solution next to him and even put the tools and building materials necessary for this stage of work.

"Goats" will be needed when laying the upper rows

"Goats" will be needed when laying the upper rows Another version of the stand, more compact, is the “tragus”. You need to have two such devices, because if you put them at a certain distance from each other and lay thick boards on top, you get the same platform. Can also be used separately, as stairs.

You can get by with a couple of more compact "traguses", making temporary boardwalks on them

You can get by with a couple of more compact "traguses", making temporary boardwalks on them From the tools you will need to prepare the following set:

1. A pick will be needed to separate and hew bricks.

2. Panicle, made of bast, for removing dried sand and pieces of mortar from the finished laid rows of masonry and mopping inside the masonry.

3. Corner - will help bring the corners inside and outside the oven exactly 90 degrees.

4. A plumb line is needed to verify the vertical of the walls.

5. An oven hammer is also required to separate the brick into pieces and chip off small protrusions of the hardened mortar.

6. Pliers will be needed to cut, bend and straighten the wire.

7. A rubber mallet is necessary for tapping bricks in the masonry if they are difficult to fit.

8. A chisel will also be needed for splitting bricks, as well as parsing old masonry.

9. Trowel (trowel) of different sizes - for applying the solution and removing the protruding excess.

10. A rule will be needed to level the surface of the foundation.

11. Lead scriber is used for marking, especially in cases where it is planned to finish the stove with tiles.

12. Stukaltse is a piece of pipe, which is also used for trimming tiles; instead of a hammer, they hit a knife.

13. Wooden spatula - for kneading and grinding the solution.

14. Metal scriber for marking.

15. The level is needed to check the horizontal rows and vertical walls.

16. A rasp is used to remove sagging and lapping lumps.

17. Jointing is necessary for the accuracy of the design of the seams if the stove is not plastered or trimmed with decorative tiles.

18. Container for mixing the solution.

19. A sieve that will help make the masonry mortar thin.

building materials

The number of materials will depend on the stove chosen, and their list is almost always the same. For a purely heating type, you do not need a hob, oven, water tank. But usually a standard set of cast iron and steel elements consists of the following items:

1. Door for blower.

2. Door for furnaces.

3. Doors for cleaning ovens.

4. Valve for the chimney.

5. Burner of several rings.

6. Cooktop.

7. Grate grate.

From other metal elements you may need:

1. Oven.

2. Tank for water.

3. Metal corner 50 × 50 mm.

4. Metal strips 3 ÷ 4 mm thick.

5. Steel wire.

Directly for masonry you will need to purchase:

1. Brick hardened red.

2. Fireclay brick.

3. Ingredients for clay mortar or ready-made dry heat-resistant mixture for laying stoves.

4. The foundation will require cement, crushed stone, sand, formwork material and a sheet of roofing material for waterproofing.

5. You will also need a heat-resistant material for the protective lining of the walls of the house and a metal sheet or ceramic floor tile.

Refractory brick prices

Refractory brick

Preparing a site for the construction of the stove

Usually the foundation for the furnace is poured simultaneously with the general foundation of the house, although it is not rigidly connected to it. However, it often happens that the furnace is being built already in the finished building.

Further actions depend on which floor is arranged in the room.

- If the foundation is concrete and completely filled, according to the slab principle, and the structure of the furnace is not conceived as too massive, then you can start laying the furnace directly on the concrete floor, after laying a sheet of roofing material under the masonry.

- If the foundation is tape or the floor is wooden, then you will have to build the foundation from scratch.

Foundation

The foundation must be deepened into the ground. To do this, a place is marked on the floor for the oven, and then the boards or thin concrete floor are removed.

- A pit is dug in the opened ground, 400-500 mm deep.

- At the bottom of the pit, a “cushion” of 100 mm is made of sand, and then of the same thickness - of crushed stone, the layers are well compacted.

- Further, along the perimeter of the pit, a formwork for pouring concrete is arranged - it should rise above the main floor by 100 ÷ 120 mm

- The bottom layer of the foundation, up to about half the height, may consist of crushed stone, sand and cement. It is poured, distributed evenly over the entire area, and left to harden.

- After the bottom layer has set well, you can pour the top layer, which will consist of a thinner solution. The space is filled with fully prepared concrete mortar and leveled with a rule, and the upper formwork boards will serve as beacons for this. The foundation must dry well and gain the required strength. To do this, it is necessary, starting from the second day, to moisten with water, which will improve the uniformity of ripening. cement mortar and prevent cracks from forming.

- A completely finished foundation (after 3 ÷ 4 weeks) is covered with roofing material to create a waterproofing layer. Then markings are made on this surface - the shape of the base of the furnace is drawn, along which the first row will be laid out.

Dry masonry

- For a novice stove-maker, experienced craftsmen recommend not to rush to lay bricks on the mortar, so as not to make mistakes. Especially in the event that this work will be carried out for the first time, it is best to bring the entire furnace structure dry.

- Carrying out this process carefully, with a constant eye on the existing scheme, you can understand the internal design of the chimney channels and the arrangement of the furnace and blower.

- For dry laying, it is necessary to prepare auxiliary slats having a thickness of 5 mm, which will determine the distance between the bricks - it will be filled with mortar during the main laying, forming seams.

- After the entire model of the furnace up to the chimney is laid out, it is again dismantled, while the bricks of each of the rows can be stacked separately, if there is enough space in the room for this, and numbered, indicating the row and the specific part in it. This is especially important if, when laying dry, the bricks were adjusted to the required size.

- It should be immediately noted that during the final laying, each of the rows is also better to first, for control, lay out dry again, and then immediately fix it to the mortar.

- In addition, you need to know that when laying bricks on the mortar, it is applied with a thickness of about 7 mm, then the brick is pressed and, if necessary, tapped with a rubber mallet. Excess mortar is immediately picked up with a trowel.

- After laying two or three rows, until the mortar has set, the seams are decorated with embroidery. If suddenly the solution was not moist enough, it can be sprinkled with a little water from the spray bottle.

- We must not forget that during laying, constant monitoring of the vertical and horizontal rows is necessary.

Knowing these nuances, you can go directly to the masonry.

The presented video shows a diagram of the construction of a compact heating stove, which is suitable even for a very small room. True, other additional functions are not included in it:

Video: heating stove for small spaces

Compact "Swede"

Convenient, versatile and fairly compact Swedish stove

Convenient, versatile and fairly compact Swedish stove It can be called the most accurate and compact oven, suitable for small spaces. This stove can be called a heating and cooking stove, since it has a high body with chimney channels located inside, which means that when it is fired, the walls will warm up well, giving off heat to the room. At the same time, there is also a hob in the design.

The first picture shows a “Swede”, which has a wider gable part than in the second photo, as it is supplemented with an oven, and instead of cleaning windows above the stove, a drying niche is made. This version of the furnace is twice as wide as the second model.

This is also a "Swede", but of a slightly different design.

This is also a "Swede", but of a slightly different design. The ordering scheme shown below almost completely corresponds to the stove in the presented photo, with some exceptions: instead of two windows for cleaning, a niche is arranged above the hob, a slightly different pipe location is on the other side of the structure, and consistent roundness of the corners. When laying in this order, the oven will look something like this.

The design is laid out, based on the ordering scheme:

Scheme-ordering for laying a compact heating and cooking "Swede"

Scheme-ordering for laying a compact heating and cooking "Swede" Although this diagram shows that from the first row they begin to lay out the blower chamber, after all it is worth laying it out as a solid plane, and only from the second row you can start working on the blower chamber. But, in order not to create confusion, the description will go exactly according to the scheme, and the first solid row can be called “zero”.

- So, from the first row, the formation of the blower chamber begins.

- On the second row, a blower door is installed. The door is fixed to the wire and temporarily supported by bricks until it is lined with masonry on all sides.

- From the fourth row, two chambers for cleaning begin to be brought out and doors are also installed on them.

- On the fifth row, a grate is laid.

- The firebox door is also fixed with wire on the sixth row, and is also supported for a while by bricks mounted on the grate, and also if necessary, a support is also placed on the front side of the door.

- On the seventh row lay the beginning of the vertical chimney channels.

- On the ninth row, the firebox door is blocked with a brick, the wire of which it is fixed, removed into the seams between the rows.

- On the eleventh row, a hob is laid on the left opening, strips of asbestos are laid under its edges. The front lower edge of the cooking chamber is framed with a steel corner.

- From the twelfth to the sixteenth row, the cooking chamber is displayed.

- On the seventeenth row, metal strips are laid, and its upper edge is formed into a corner.

- The next two rows are laid solid, leaving only three chimney channels.

- On the twentieth row, another door is installed, and a cleaning chamber and a niche for drying begin to form.

- At 22- ohm in a row, the chamber door is covered with masonry.

- On the 23rd row, the chamber is completely blocked, and a hole is left at its end, which will continue the chimney channel.

- At 24- ohm a row of metal strips cover the drying niche.

- At 25- ohm install the cleaning chamber door.

- At 27- ohm the door is covered with masonry.

- At 28- ohm covers the entire chamber.

- At 30- ohm in a row, two valves are installed on the chimney channels. First, the frame of this part is laid on the solution, and then the valve is inserted into it.

- From the 31st to the 35th th row is laid out segment .

- From the 35th to the 38th, the construction of the pipe fluff begins.

- Next, comes the laying of the pipe, which already has his own numbering. From the first to the 26th row, the shape of the pipe does not change, only it is necessary to carefully monitor the evenness and internal cleanliness (from mortar residues) of the chimney channels. This part of the pipe is called the riser.

- On the third row, they put another door on the cleaning chamber.

- At 27- ohm a row put another chimney valve.

- At 29- ohm make the expansion of the pipe by one row, and by 30 ohm it is returned to its original form.

- Starting from the 31st row, the narrowest part of the pipe is laid out, which is led out through the roof.

When the chimney passes through the attic floor, it must be isolated from it with combustible materials - it can be asbestos, mineral wool or expanded clay, poured into a box located around the entire perimeter of the pipe.

The hole in the roof through which the pipe passes, after construction, must be closed with waterproofing material, which is applied both to the pipe and to the roof.

Installation of other oven elements

As mentioned above, other elements can be built into the oven, so it is worth considering how some of them are installed.

Oven

If the design provides for an oven, then it is most often installed on the same level as the firebox or hob. This is important for its rapid and uniform heating.

- In the place where it will be installed, metal corners are first mounted - they will become reliable supports for the cabinet.

- Further, the oven is wrapped with asbestos cord - this material is heat-resistant and will help the thin metal of the cabinet last longer.

Video: laying technology for an efficient oven with an oven

Prices for masonry mixtures and adhesives for special purposes

Masonry mixes and adhesives for special purposes

hot water tank

The hot water tank can be installed in different ways. Sometimes it is built into the design of the furnace, in other cases it is placed on top. The main thing is that it is located next to the chimney channel, from which the water will receive the necessary thermal energy. In this case, it is necessary to provide a hole for filling the tank with water and a tap from which it can be taken. It is desirable to make a water tank from a stainless alloy, otherwise very soon yellow water will come out of it, which is of little use for water procedures.

Another option for installing this water heating element is to install it on the same level with the hob, above the firebox, when it will heat up only from below. In this case, it is best to lay a cast-iron or thick steel plate under the tank, otherwise its bottom will burn out very quickly. The container in this installation option is not embedded in the walls of the furnace.

The disadvantage of this setup is that less space remains for the hob, or the firebox will have to be made deeper, which means that the overall dimensions of the stove will increase, which is not always possible in cramped spaces.

When choosing a stove model for your home, you need to think through everything in advance - what functions should be implemented in it, its size and design. Based on this, it is worth choosing a building design with an ordering scheme.

It should be noted that laying a stove is a real art, and not even every experienced craftsman always succeeds perfectly. Therefore, if there are no skills in this work, then it is better to invite a specialist who will help to do everything right.

Stove heating country houses Today it is gaining a second youth. And this is not surprising, given the special atmosphere and homely warmth that a simple brick stove can create, even made by your own hands. Often it is installed even in the presence of more technologically advanced heating systems, trying to get a stylish, original element of the interior. Today we will talk about the most popular models of brick ovens and share the secrets of the oven craft.

Features and secrets of the popularity of brick ovens

A brick oven is not only a functional heating device, but also a stylish interior element.

Probably, there is no such person who would not like a living hearth with crackling firewood and especially comfortable warmth. But the good old brick oven will be able to please not only with this, but also with the ability to create the most favorable atmosphere for health. It's all about the material from which this amazing unit is built. Being the closest relative of ceramics, brick emits water vapor into the air when heated, and absorbs it back when it cools. The stove, as it were, “breathes”, due to which the optimum humidity is established in the room. It is also important that the heat becomes already at a temperature of 18–19 ° C, while when using other types of heating, the comfort level starts from 20–21 ° C. In addition, being made of clay, brick is an environmentally friendly material, which means that during the operation of the heater, you can not worry about the release of compounds harmful to health.

Despite the fact that each type of brick heat generators has its own functional and design features, all of them are similar in terms of arrangement of the furnace and heat exchange parts. So, any stationary furnace of this type has:

- foundation, which serves as the base of the heater and evenly distributes its weight over the entire area;

- a furnace that simultaneously acts as a firebox and a combustion chamber;

- a grate that allows for the lower air supply to the combustion zone. Due to this, the performance of the heating unit increases and it becomes possible to adjust the intensity of fuel combustion;

- ash chamber, which facilitates the cleaning of the furnace;

- a chimney that creates the necessary draft and emits exhaust gases into the atmosphere.

Construction of a channel-type brick kiln

In addition to their main purpose, wood-burning heat generators are also used for cooking, as well as arranging an additional place of rest. The structure itself can be installed both indoors and in the yard, for example, in a recreation area with a barbecue, barbecue or cauldron. If we talk about fireplace stoves, then their heat-generating function is completely relegated to the background, giving way to a visual and image component.

The advantages of brick ovens include:

- rapid heating of the surface;

- the possibility of using several types of fuel;

- low operating costs;

- the risk of burns when touching the walls of the heater is eliminated;

- especially soft, comfortable warmth;

- the air in the room is not dehydrated;

- ample opportunities in terms of interior decoration.

The units under consideration also have disadvantages. The most significant of these is the potential danger of carbon monoxide poisoning, which appears during improper operation. Another - large dimensions and weight. That, perhaps, is all. As you can see, equipment of this type has solid advantages and practically complete absence negative aspects, which, however, determines its high popularity.

Classification of heating devices. Criteria for choosing the optimal design

All existing models of brick ovens can be divided into several types:

- heating devices;

- cooking units;

- combined ovens;

Having decided on the required functionality, you need to choose the option that you can fold yourself. In order not to consider the whole variety of stationary units, let's focus on the most popular options:

- Dutch stoves. Thanks to the channel design, they have good heat dissipation and take up little space. Such heat generators operate in the mode of slow burning or smoldering, which significantly reduces the requirements for the quality of building materials. And although the efficiency of the "Dutch" rarely exceeds 40%, they have found many fans, partly because of the low cost and ease of construction.

The classic "Dutch" is an extremely compact structure

- Swedish wood stoves have a chamber-channel layout, which allows you to increase the efficiency up to 50%. Just like the "Dutch", the "Swedes" take up little space, but require a more careful approach when choosing materials and are a little more difficult to manufacture. Nevertheless, the labor and financial costs are fully justified by the increased productivity and expanded functionality of this type of heat generators.

The Swedish stove will please its owner with high efficiency and functionality.

- have a unique layout, due to which they carry an indescribable flavor and originality. Their efficiency exceeds 60%, but not everyone will like the features of operation. In addition, not every beginner will be able to fold the oven. Most likely, you will have to hire a professional stove-maker, and this will entail additional costs that increase the cost of an already not the cheapest design.

The Russian stove can completely transform the interior, but it will require a lot of space for installation.

- Kuznetsov's bell-type furnaces, famous for their thermal efficiency, have an efficiency of up to 90%. The secret of their success lies in a special device that contributes to the most complete combustion of fuel and maximum heat transfer. A feature of the "blacksmiths" is an extremely clean "exhaust" and the absence of soot, which minimizes the time spent on caring for the heater. As for the minuses, they include the complexity of the design and high requirements for materials. However, the latter disadvantage is compensated by the fact that much less brick is required for the construction of a “cap” than for any other furnace.

Unlike canonical bell-type stoves, modified units can have a hob and oven

Step-by-step instructions for laying the Kuznetsov stove with orders can be found in our next article:.

Having considered everything possible options, we have come to the most crucial moment - the choice of a heater that can meet all the requirements for it. The main criteria in this case are functionality and installation location. And if the first is not difficult, since it completely depends on the preferences and requirements of the owner, then the second paragraph requires the very close attention. We will tell you more about how to choose a stove in accordance with the type of building.

- House intended for permanent residence. If a stove heating will be used as the main the best option than "Swede" or "cap" can not be found. In addition to the fact that these units have excellent performance and do not take up much space, they are also easily complemented by other elements - hob, water circuit, oven, drying niches or stove bench. If the functionality is relegated to the background, and the main requirement is compactness, then a “Dutch woman” that heats several adjacent rooms is a good option.

- Country house "weekend" or cottage. Since these buildings involve irregular residence, it will be enough to install a small heater equipped with a hob. Fireplace stoves with an open hearth are ideal, as they can be used to heat the room in the shortest possible time. Such an advantage cannot be overestimated in winter, when the air temperature in the room drops to sub-zero temperatures.

- oven in country house with water or other type of heating. In this case, the heater serves to create a special atmosphere. If the area of \u200b\u200bthe room allows, then you can install a full-fledged Russian stove or a unit with a firebox, a fireplace and a stove bench.

- Bath heater. For this case, the simplest stove-heater is suitable, in which a container is built in to obtain hot water. If the bath is attached to the house, then instead of the tank, you can install a full-fledged boiler designed for a liquid heating system.

- Furnaces for open areas. Most often, such heaters are installed on open verandas, in summer kitchens or gazebos and are used for cooking. For these purposes, the structure is additionally equipped with a hob, barbecue, barbecue, cauldron, etc.

The barbecue oven will decorate the site and fill the resting place with functionality

Having decided on the type and filling of the furnace, do not rush to start construction. In order for the heater to meet all expectations, it is necessary to thoroughly understand the principles of its operation.

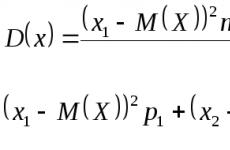

Calculation of the main parameters

Before choosing a working project of a heating device, it is necessary to make a preliminary calculation according to the parameters of a particular room. Most exact method is the determination of dimensions based on the heat output of the furnace. In order not to go into complex calculations, for well-insulated houses they use a simplified calculation scheme proposed by I. V. Kuznetsov. This method uses the average thermal power taken from one square meter of the surface of the unit (TMEP). For a conventional firebox, take a value of 0.5 kW / sq. m, and if necessary, intensive heating, which occurs during severe cooling - up to 0.76 kW / sq. m.

When determining the thermal power of the furnace, only those of its surfaces that participate in heat exchange processes are taken into account. For example, in the "Dutch" sections of the walls located near the floor, below the horizontal sections of the flue, are not excluded from the calculations.

In principle, already these values are enough to select a suitable project from those that can be found in the public domain. If the available options are not suitable for any reason, then you will need to calculate the parameters of the main elements of the furnace and design your own design.

Drawings and diagrams of brick ovens

Sauna stove  Fireplace stove Classic "Dutch" Bell stove

Fireplace stove Classic "Dutch" Bell stove

Firebox