How is the sealing of the seams of a wooden house performed? Reliable protection of the house from drafts and heat loss Do-it-yourself warm seam technology.

Terma-Chink- professional acrylic sealant "warm seam" for wooden house with excellent adhesion to wood, brick, plaster, natural stone, concrete, polymer concrete, foam concrete, PVC, metal (tin, zinc), etc.

Application area

"Warm seam" for wood is used for long-term sealing of log joints wooden houses , rounded logs and timber, as well as for sealing end and side cracks in wood and sealing seams and joints various designs from a tree inside and outside of rooms of all types of buildings and constructions. The sealant is a material that is completely ready for use. After curing, it forms an elastic rubber-like material.

Properties and features

- has no smell;

- has high elasticity;

- provides effective thermal insulation of the house;

- weather resistant, incl. to ultraviolet radiation;

- has high vapor permeability;

- surface coloring, as well as tinting of the material is possible;

- can be applied to damp, but not wet, surfaces;

- sealant "Warm joint" can be applied to horizontal, vertical, inclined surfaces with positive and negative angles of inclination;

- long-term sealing of joints in building structures with a deformability of 25%.

You can buy a "warm seam" for a wooden house in Moscow from the OLIVA manufacturing plant by placing an order on the website or by contacting by phone 8-495-651-6574.

Consumption

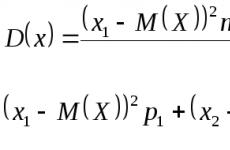

Estimated mass consumption is calculated by the formula:

Mp=btV (kg/r.m), where: b- joint width (m), t- sealant layer thickness (m), V - specific gravity(1350 kg / m 3)

Specifications

| Consistency | Thixotropic paste (non-flowing) |

| Compound | Aqueous polymer dispersion, modifying additives, pigment, filler. |

| Drying time, h | Surface film formation time - 1 hour |

| Hardening time, h | No more than 24 hours at a thickness of 2 mm |

| Elongation at break at 20°C, % | Not less than 700% |

| Density, kg/l | 1.35 kg/l |

| Tensile strength at uniform separation, kg/cm² | At least 10 |

| Projected service life | At least 30 years old |

| Recommended application temperature, °С | from +5°С to +35°С |

| Vapor resistance | 0.25-0.3 m2 h.Pa/mg |

| Dry residue, % | Not less than 72% |

| Operating temperature, °C | from -40°С to +80°С |

| Specifications (TU) | 2257-001-13344853-14 |

| tinting | Standard colors: white, gray, larch, pine, golden pine, oak, walnut, rosewood, honey, teak. Tinting in other colors is possible. |

| Warranty period of storage, months | 24 months |

Surface preparation

Clean surfaces from dirt, dust, grease, loose particles, residues cement mortar, residues of previously applied sealing materials, impregnations, varnishes and glazing compounds, etc.

When working in winter time clean the surface of ice and frost. It is possible to apply the sealant on both dry and wet surfaces. The presence of dripping moisture on the surface is unacceptable!

DO NOT apply sealant during rain or snow! In hot weather with low air humidity, surfaces can absorb moisture strongly, in which case it is recommended to pre-moisten the surface with water using a sprayer.

Application method

The sealant is applied to the prepared surface with a spatula or special hand or pneumatic guns. Voids and leaks are unacceptable. The recommended thickness of the sealant layer is from 2 to 3.5 mm. The surfaces of the applied sealant are given the necessary shape using special templates. Soapy water is used to prevent the sealant from sticking to the tool. To improve the appearance of the seam, it is recommended to limit the edges of the seam with masking tape before applying the sealant, after applying the sealant (after 30-40 minutes), remove the tape.

Drying time

The time of formation of the surface film is 1 hour (at + 23ºС and 60% humidity). Curing time at a layer thickness of 5 mm 24 hours (at + 23ºС and 60% humidity)

Tool cleaning

Rinses off in the uncured state warm water. In the vulcanized state, it is removed mechanically.

Storage

In a tightly closed container at a temperature of +4°С to +40°С. Can be transported and stored low temperatures. For frost-resistant sealant, up to 7 cycles of freezing and thawing (cycle - no more than 1 day) at temperatures up to -18ºС, or a single freezing up to -18ºС, but for a period of not more than 7 days, are allowed. Defrosting is carried out without additional heating at temperatures up to +22ºС. Keep out of the reach of children. Shelf life 24 months from the date of manufacture.

A warm seam for a wooden house is one of the most modern and convenient ways sealing, which allows you to quickly, efficiently and permanently isolate the cracks in the wood, formed during the shrinkage of the house.

The use of a sealant eliminates the traditional, not the most reliable and durable caulking of tow, especially in homes with a natural drying method. Since the standing houses, a lot of cracks are formed, poor-quality sealing of which can lead to a lot of unpleasant moments.

Disadvantages of traditional insulation methods:

- Pulling tow by birds.

- Rope, tow and other natural materials allow moisture and insects to penetrate between the logs.

- decline thermal insulation properties at home, the appearance of drafts.

- Regular content updates.

There are many on the market various kinds sealant, but for such specific work as sealing joints in wooden house, not for everyone. Sealants based on acrylic and butyl rubber are widely used.

Acrylic type sealant is the most used material in European countries and America.

Advantages of acrylic sealant:

- Within half an hour, a protective film against dust begins to form on the surface of the sealant. The time for complete polymerization depends on the manufacturer, usually from one to four days. In humid rooms, the film formation time increases.

- Allows you to seal seams of different thicknesses.

- Eco-friendly, does not emit odor and is used for interior and exterior decoration.

- Working with the material does not require special protective equipment, it is enough to use gloves and special clothing.

- Temperature range from -10 to +35С°

- There are different color solutions, which will allow you to decorate the sealant to match the color of the house painting.

- It is possible to partially finish the facade of the house, the interior and rooms with high humidity.

- The sealant has good adhesion and adheres well to wood. In the frozen state, it is plastic and does not crack when "walking" the walls of the house.

- Quick and easy to apply. Extra parts are easily removed. The tool is washed with plain water.

- The material is vapor-permeable, allows air to circulate, but prevents the penetration of moisture through the seam. Acrylic is resistant to sunlight, does not fade and is not subject to destruction, durable. If necessary, the seam can be easily dismantled.

- Good protection against insect penetration.

- At a price no more expensive than a traditional correctly executed caulk.

- The performed seam can be of various shapes, concave or convex.

Lack of material - in the process of performing work and until the final moment of polymerization, the weather must be dry.

Domestic manufacturers suggest using a sealant based on butyl rubber, a material that belongs to the type of non-curable and does an excellent job of insulating, easy to apply.

Types of packaging

Types of sealant packaging depend on the manufacturer:

- In file-packs, for use in pistols.

- Packing in the form of a bucket, it is convenient to work with a spatula. The box can have a classic, or hermetically sealing lid with a hole inside, for the possibility of loading the sealant into the gun.

- In the form of a cord in a polyethylene protective film. After removing the film, the cord is placed in the seam and leveled with a chisel. This type allows you to insulate the house, people who do not have enough experience in performing work on sealing joints, and allows you to save on the purchase of an expensive automatic gun.

Warm seam technology

The "warm seam" technology for wooden houses involves several stages of work.

Used materials, tools:

- Putty knife.

- Special construction pistol. Lubricant may be required during work to better job gun mechanism.

Important! The cut size of the nozzle allows you to adjust the amount of sealant released and the size of the seam.

- Primer, for impregnation of the most absorbent parts of wood.

- Special insulation cord made of foamed polyethylene, for laying in wide gaps from 1 cm, to save the amount of sealant and better finish the seams.

- An industrial stapler with an elongated spout, or a hammer and small furniture nails, for possible fixing of the insulation in the crevices.

- Soap solution that moistens the surface of the spatula when leveling the seam.

- Construction tape may be needed for homeowners who do not have experience with sealant.

Preparatory work:

- Cleaning the surface of wood from dirt and the top peeling layer.

Note! Sealing should be done before the wood is coated with antiseptic, as the solution may interfere with the adhesion of the material.

- Surface drying.

Basic Operations:

- To simplify the work, stick a special industrial adhesive tape on the logs, which will protect the wood of the seam from contamination with sealants, outside the application area.

- The sealant is applied to all the seams between the logs and the gaps formed. If the gap is larger than 10mm, it is recommended to lay a special cord.

- The cord can be installed with a chisel, in some cases it may be necessary to additionally fix the cord along the entire length with small nails or a stapler. The size of the seam should be within 4÷12 mm.

- Apply the composition with a gun or chisel. In the case of using sealant in the form of a cord, remove the film and install the sealant in the gap.

- Level the surface and remove excess elements from the seam with a chisel or sponge soaked in water. It is also allowed to work with only one spatula.

- Removing tape.

- After completion of the polymerization process, the seam can be treated with acrylic-based paints and varnishes.

Doing the “warm seam” technology for wooden houses with your own hands, using a gun, or a spatula is a simple task, but it requires some skill and patience. Since it will be problematic for a beginner to apply a professional even seam from the start, all the more so to do it quickly.

Using a sealant in the form of a cord will speed up the procedure, but this technology requires the subsequent coating of the surface of the seam with an alkyd-based varnish.

In more detail about how a "warm seam" is performed for wooden houses on the video.

Conclusion

In order for a wooden house to please with its warmth and comfort for a long time, it is necessary to take care of the quality of the materials used and the observance of technologies. Works performed using the “warm seam” technology are done once and for a long time, which allows the owner to avoid spending money on regular caulking of house facades.

Buildings from natural wood exposed to the negative effects of precipitation and temperature. The material shrinks, which leads to cracks. To prevent the formation of gaps and improve the thermal insulation of the room, a warm seam wood sealant is used. It helps to eliminate defects in natural wood and protect the building from the cold.

Insulation of joints in a wooden frame has a number of features and differs from sealing joints on concrete, brick, metal bases. The use of familiar materials is not always appropriate, since it requires periodic replacement. Thermal insulation cannot 100% protect joints. The use of a warm seam for a wooden house creates an effective barrier against cold and moisture.

The essence of the method:

- The space between the wooden elements is caulked with any heat-insulating material laid flush.

- A special Vilaterm cord is laid over the insulation, which protects the inter-seam sealant from contact with the thermal insulation.

- A warm seam is applied to the laying cord - a sealant based on acrylic, silicone or polyurethane.

The sealant is easily and accurately smoothed, forming even and uniform seams in width. They can be painted with colored or transparent paints and varnishes. Reliable protection using warm seam technology well prevents blowing through the house.

Attention! A warm seam does not replace heat-insulating materials for caulking, but complements them. You can not apply a warm seam if insulation and cord are not laid between the logs. Otherwise, the sealant will crack, crumble and begin to fall out.

Materials and tools

Before applying a warm seam for wooden structure, you need to prepare for work and calculate the consumption of sealant. If the log house is not yet caulked, you need to seal all the joints with heat-insulating material - tow, foam, foamed polyurethane, jute, and other insulation.

To seal joints using the warm seam technology, you need:

- Composition for wood, produced in cartridges.

- Construction gun for sealed tubes.

- Foamed polyethylene Vilaterm without holes.

- Spatulas with different width working surface.

- Paint brushes up to 30 mm wide for painting.

- Adhesive tape for gluing areas along the length of the joints.

- Clean water, rags to remove excess weight.

The use of a pneumatic gun speeds up and simplifies the work. The tube with sealant is firmly fixed in the installation tool. The mixture is easily squeezed out in dosed portions. To evenly fill the seams, you can use guns various types and designs.

Sealant selection

Compositions for sealing joints in wooden structures presented in a wide range. The most popular brands are mixtures produced by Eurotex, Neomid, Remmers. The compositions can be used for interventional seams, truss system, window frames, door frames, wooden stairs and implementation interior decoration interior. To make a warm seam, you need to choose sealants that are resistant to deformation, temperature changes. Mixtures should have good adhesion and a long service life.

Varieties of interventional sealants for wood:

- Silicone products on a neutral or acid basis. Suitable for wooden surfaces, have an impressive operational resource (20-25 years). Paint silicone sealant you can’t, there are ready-made color mixtures on sale. A suitable product is BARTON'S Interventional Sealant " Warm house».

- Polyurethane compounds have optimal strength and good adhesion, but are more expensive. Mixtures withstand mechanical stress, are not "afraid" of moisture and chemicals. After complete drying, the mixtures do not shrink, can be stained, but do not have sufficient resistance to ultraviolet rays.

- Acrylic sealants for wood are most often used. Non-toxic environmentally friendly products adhere perfectly to porous fibrous wood. The composition of sealants does not include solvents. After polymerization, acrylic sealant warm seam is painted "under the tree".

When choosing a means for sealing the joints of wooden structures, preference should be given to proven compositions of well-known brands. In table. 1 shows the most popular formulations and their main advantages.

Table 1. Sealants for wood warm seam

| Name | Compound | Main advantages | Peculiarities |

| BARTON'S "Warm House" | Silicone | Elastic, does not shrink | Additives for rotting pests |

| PU-25 | Polyurethane | Good adhesion, waterproof | Large temperature range |

| Neomid Warm House Wood Professional Plus | Acrylic | Elasticity and elasticity of seams, tear resistance | Low fluidity, rich color gamut |

| PERMA CHINK | Acrylic | Fast setting, convenient packaging | small consumption |

| Energy Seal | Acrylic | Resists deformation well after curing | Treatment of narrow seams up to 2.5 cm |

| Remmers Acryl 100 | Acrylic | Resistant to compression, stretching, UV | Long service life of 20-25 years |

| EUROTEX | Acrylic | Processing of all types of wooden structures | 3 wood shades |

| Neomid Wood Professional | Acrylic | Elasticity up to 300%, sealing the joints of log cabins | Holds heat well |

| Zobel | Acrylic | Accelerated curing, interventional joints | 3 composition warm seam |

| EurAcryl | Acrylic | Resistant to water, UV rays | Extensive area of use |

| Ramsauer Acryl 160 | Acrylic | Adhesion with different bases | A protective film forms quickly |

Note: C inside it is recommended to process logs with an acrylic sealant warm seam. Environmentally friendly product does not emit harmful substances, is non-toxic.

Price

Sealant prices vary widely. The cost of products is influenced by the popularity of the brand, the place of production (domestic or foreign companies). To perform large-scale work, it is recommended to buy sealant in a capacious container. It's cheaper than buying several compact tubes. The average consumption of 600 ml of the composition in the cartridge is 4-6 m. The cost of the popular German Remmers product is 430-450 rubles.

Eurotex sealant is supplied to plastic buckets 25 kg each, at a price of 7000 rubles. But with such a quantity of the mixture, 250 m3 can be processed. seams.

To process a wooden frame in a new way modern technology warm seam, you need to follow certain rules and recommendations from the masters.

The process of sealing joints can be divided into several stages:

- Cleaning the gaps from dust and debris, sealing the seams along the length with masking tape.

2. Laying of heat-insulating material to fill the interventional space.

3. Laying a special Vilaterm cord, which limits the contact of the sealant with the insulation.

4. Applying a warm seam to the joints using a construction gun according to the principle of processing seams with mounting foam.

5. Removal of excess mass at the seams of a log house of a wooden structure with a damp rag or spatula.

After sealing the seams with an interventional sealant, you need to form perfectly even and smooth seams. To do this, with a small brush dipped in clean water, gently smooth out the warm seam. To finally align the joints, they are passed over them with a damp cloth or foam rubber sponge.

On video: How to make a "warm seam" with interventional sealant.,

Corners and cuts

The most difficult thing to do with your own hands is sealing using the warm seam technology at the junctions of wooden walls. To carry out the processing of corners and cuts, a cord of the required length is laid in the joints, pushing the material into the middle with a narrow spatula. After that, a warm seam sealant is applied and the mass is leveled. The work is painstaking and time-consuming, but the tightness of the entire wooden structure depends on the quality of sealing the corners.

Attention: wooden walls treated with impregnations and flame retardants with solvents and oily inclusions, on which the sealant does not adhere well. Masters recommend pre-cleaning the top layer of wood with a grinder, hand grater or sandpaper. Surfaces coated with water-soluble impregnations do not need to be sanded.

For owners of wooden houses, the problem of insulation using warm seam technology is always relevant.

Therefore, users often ask questions related to this topic:

- Will there be any benefit from applying sealant to caulked joints? - Subject to the technology of a warm seam, the effectiveness of the method is very high.

- When to remove the excess hermetic mass that has fallen on the surface of the logs? - It is desirable to remove the remains of the mixture immediately, until the composition begins to dry out.

- Which warm seam is better to use - internal or external? The best option- double-sided processing of a wooden structure to improve waterproofing characteristics.

Another common question is whether it is allowed to perform work in the cold season at negative air temperatures? - Outdoor work in frost can only be carried out with some compositions, for example, Accent-136.

Reviews

According to the owners of wooden houses, the warm seam technology works one hundred percent. Heat is better retained in the rooms, and the building itself takes on a more attractive appearance. The process of applying a warm seam takes a lot of time. It takes at least two weeks to close up the external joints in a house of 100 m2. Full processing at a cost of 10,000-15,000 rubles. Users are advised not to apply the product in a thin layer so that the sealant does not come off the wood. According to reviews, doing the work yourself costs two times cheaper than using the services of professionals.

The technology of using sealant warm seam (2 videos)

Types of sealant warm seam (25 photos)

CREATOR: gd-jpeg v1.0 (using IJG JPEG v62), quality = 100

CREATOR: gd-jpeg v1.0 (using IJG JPEG v62), quality = 100

WARM SEAM - FOREVER!

Advantages of a warm seam from RIKEDOM

- We carry out TAMMERED and CONCAVE warm seam. This is more difficult and longer than a convex, but ONLY a concave seam provides the best water drainage, does not crack and looks more aesthetically pleasing.

- Our warm seam is even and very beautiful. The optimal width of the seam directly affects its longevity, so application experience is especially important here. And he's huge!

- We use sealants that have proven themselves for decades. We will tell you which colors will look most advantageous with one or another color of the coating.

- The RIKEDOM painting technology provides reliable wood protection. And it is not just words. You will no longer need to regrind the log house NEVER.

The cost of a warm seam

The quality of the warm seam directly depends on the selected sealant for a wooden house. From our experience, the best in terms of PRICE-QUALITY ratio is the German company REMMERS (REMMERS - Acryl-100), made in Germany. The first house we sealed with REMMERS has been in operation for 15 years and the sealant has held up perfectly!

REMMERS Acryl-100 sealant will not crack or flake off over time. It has excellent adhesion properties. It is environmentally friendly and has all the necessary certificates. Therefore, we use it and recommend it to everyone!

In our company, you can also order professional painting using proprietary technology, which has earned rave reviews from our customers!

Carefully cover objects

Scheme of work with you:

Appointment for a consultation in our office by phone

2 hours

Consultation at the RIKEDOM office

Departure of the foreman to the facility to determine the exact measurements

Signing of the main contract. Departure of the brigade for a trial square meter of grinding

Payment. Carrying out work at the facility

Delivery of works. Issuance of a PASSPORT for maintenance

Answers to your most common questions:

Coming to our office, you get a detailed consultation on how we work and make a decision whether you need it or not. And also we decide on the possibility of performing work at your facility. It is in the office, when communicating with managers, that a preliminary decision is made on the implementation of certain works. You can also find out estimated price. For measurements of geometry and humidity, our foreman visits you only after consultation in the office.

Why don't we just send a measurer? Because it's not serious, and we are a serious company. Just taking measurements so that you get a price is meaningless until you understand the principle of our work. Not a single "measurer" has the vast practical experience that the head of the company has. For your convenience, packages have been developed, where the price is determined per square meter of a log house. You yourself can "roughly estimate" how many square meters make up the walls of your house.

In other firms - a different technology of work, and therefore a different price. Our technology - from sanding to finishing painting - is aimed precisely at protecting the tree, that is, at the durability of the applied coating. And this means that in the future you will not have to again spend money on regrinding and painting again. This is the fundamental difference - not to pay again and again in the future, as 90% of the owners of wooden houses with ordinary painting do. And, of course, the work of RIKEDOM always stands out against the backdrop of hundreds of painted houses.

For each house painted by us - a warranty service PASSPORT is issued. That is, you need to understand that everything will be fine with the coating if you provide it with timely care.

During the production process, a special Journal is filled out, which indicates which tools and materials were used, a sketch of the structure, indicating problem areas and other technical characteristics.

The VIP package was created for clients who want only the best and are accustomed to maximum comfort. In addition to everything that is included in the FIRM PACKAGE, the VIP PACKAGE has additional privileges:

*4-layer painting. That is, in addition to priming and two mandatory layers of impregnation on the facade or oil / azure inside, another layer of composition is added, with another thorough interlayer grinding. This procedure is invaluable for the facade, for its greater protection and durability! For interiors - the quality of the tactile sensations of a magnificent wood finish is significantly increased!

*Restoration: chips, protruding wood chips, nail holes, etc. - we will restore everything, impeccability will please the eye.

* Creating a closed perimeter: put around scaffolding, we close it with canopies - the dust from grinding will not scatter, the neighbors (if the houses are closely located), the landscape and so on will not “suffer”. And what is important - the "closed perimeter" helps to improve the quality of work, because when painting and installing a warm seam, precipitation and direct sunlight are unacceptable. And in the autumn-winter period, this shelter at home allows you to heat the space inside the canopies and thereby comply with the technology.

* We remove and put back platbands, ebbs, drainage system and anything else you need to get the job done.

*Individual color selection, free shipping test paints, as well as the paint itself and sealant.

*The most pleasant: PERSONAL control over the object from the company's management, as well as the solution of all issues on the object with the company's leaders.

Because we do not look at the cans where the paint consumption is written. Our task is to power the tree, and not just paint it. But the absorbency of a tree depends both on the type of product, breed, and also on where the forest comes from. On different objects - different absorbency. On different logs - also different absorbency. We do not drip a couple of drops and stretch them out over ten squares in order to save you paint. We will power it until the most important thing is provided - the protection of the tree.

Therefore, the paint leaves on the objects - in different ways. That is - the paint goes after the fact. So does the sealant. The thickness of the warm joint depends solely on the diameter and fit of your log, as well as the size of the discrepancies in the interventional space. Therefore, the seam is selected based on these parameters. Make it too narrow - just simply tear the seam, make it too wide - not beautiful and useless. The size of the seam is determined only by the master, and the consumption of the sealant directly depends on this.

At our consultation, you will receive only INDICATIVE calculations for paint and sealant, based on our experience.

People with extensive experience in working with wood, with golden hands and a developed sense of responsibility. The backbone of craftsmen and foremen has not changed, we have been with them for more than 12 years. Of course, there are also beginners who are trained by the masters, so the staff is expanding. Judging by the number positive feedback what we receive from clients, we can proudly say that we have the best professional staff!

Technology warm seam for timber / logs:

If you want the warm joint sealant not to stand out against the general background of the painted log house, then the warm joint is applied to pre-sanded and primed wood, and then covered with two layers of azure / oil.

If you are planning a warm seam contrasting with the color of the log house, for example, a log house in the color of dark walnut, sealant-white, then it is applied to the finishing layer of azure / oil. REMMERS sealant has excellent adhesive properties, so it can even be applied to oil!

Also, a warm seam can be made between laser/oil layers. As you can see, if there are several ways to apply a warm seam, which one you will have, we will decide based on your log house, type of coating and wishes.

The price of a warm seam consists of the cost of installing a warm seam for a wooden house and the cost of a sealant for a warm seam. Everything else - scaffolding, polyethylene lace and others expendable materials- included in the cost of work.

The price of a warm seam for wooden houses in our company is due to the fact that we carry out a concave and rammed warm seam - as the highest quality of all types.

Before the device of a warm seam, it is NOT necessary to carry out caulking. In general, konpatka for a wooden house is a temporary procedure, it lasts for 3-4 years (it gets wet, birds pull it out, etc.). And the cost of high-quality caulking is the same as the cost of a warm seam. Therefore, you can spend money and time once every 3 years, or you can perform the warm seam technology once and for all.

Advantages and properties of a warm seam:

- The device of a warm seam on the outside gives 100% absence of blowing in the joints of logs / beams

- The sealant of the warm seam outside and inside, in addition to the absence of blowing, gives the heat capacity to the house. That is, a warm seam works best when sealing outside and inside the house.

- Beautiful, neat view of the walls of the house

- Reducing energy costs during the heating season

- The seam can be made invisible against the general background of the walls, or it can be beautifully emphasized along with the ends of the logs. In any case, a beautiful, high-quality warm seam has not yet spoiled any building, but, on the contrary, decorates it.

- Using quality material sealant, for example, if you buy a warm seam from Remmers in Moscow, you can be sure that the seam will not crack and retain its properties for many years.

- The price of work on sealing a wooden house is comparable to the price of a high-quality caulking device, BUT, caulking for three years, and a warm seam for at least 20 years!

Sealing cracks in a log house:

- Sealing of cracks in the log house is performed ONLY after the end of the full shrinkage period, which is three to four years. That is, when the log house finally sits down, the log / beam will crack. The moisture content of the log in this case is 15-14%. If the cracks are sealed with sealant up to this point, there is a risk of the sealant being squeezed out of the cracks, which significantly spoils appearance at home and leads to the dismantling of the sealant (and this procedure is oh so not simple!).

- When painting a log house, after a year or a year and a half, only large cracks can be sealed, especially on the facade of the log house, from water getting there.

Warming of a wooden house

Living in a wooden house, especially for log cabins and timber, people often face the problem of blowing and freezing in the walls, and therefore they ask about the insulation of a wooden house. But do not sheathe the walls with mineral wool, clapboard, or even worse, with plastic! The simplest and most reliable thing that can be done is a warm seam (sealing).

Warming of a wooden house in log cabins and timber

The fact is that in the process of shrinkage of the log house, significant gaps are formed between the crowns of the log house, cracks through which cold from outside enters the house. No matter how large the diameter of the log is, no matter how high-quality it is folded, 4-5 years after the installation of the log house, you will still come to the question of insulating the walls of a wooden house.

There are a lot of problematic places: this is the junction of the roof to the walls, the junction of the lower crown to the lining board, cuts (log releases), interventional seams. Previously, the insulation of a wooden house was solved with the help of caulking, in fact, a high-quality caulking of a log house is a very expensive thing and must be done good professionals. But, alas, very short-lived. Because caulking is "stealed" by birds, so you have to caulk every 3-4 years. Modern solution warming of a wooden house is a "warm seam" technology. It is carried out using special sealants for wood, based on acrylic and silicone. A warm seam reliably protects your log house from blowing, and if it is also made inside, it significantly increases the heat capacity of the house. You can even apply a warm seam to already painted houses, having previously prepared the junction.

A warm seam and sealing cracks perfectly solve the problem of warming a wooden house. 100% of those who performed this procedure noted a significant increase in the heat capacity of the house and, as a result, a decrease in heating costs.

Before taking measures to insulate a wooden house, it is necessary to shoot with a thermal imager in order to understand exactly what problem areas exist on the log house. This is especially true for houses made of profiled timber. Because, often, the client applies for the insulation of everything log house, that is, he wants to perform a warm seam along all interventional joints, and thermal imaging, as a result, shows that blowing and freezing occurs only in cuts. And there is no reason to perform a warm seam everywhere, it will be enough to carry out warming measures in places of overcuts.

Therefore, in order to carry out the insulation of a wooden house, you should not rush to sew up the walls, it is easier to perform restoration (resurfacing, beautiful and reliable painting), as well as sealing. All these services are provided by our company. In the end, it all looks very aesthetically pleasing and your wooden house will not lose its chic.

Ecologically clean wood has long been considered an excellent material for building a house. Huts or log cabins built of wood are good because they breathe easily. In summer, such buildings do not get very hot, like brick or stone houses, and it is comfortable to stay in them even in the heat, and in frosty winters, wooden walls keep heat well, not letting cold into the room. For these reasons, many people prefer to build their summer cottages and country houses just from wood.

However, along with the above advantages, the tree also has many disadvantages. So, under the influence of natural factors, it undergoes deformation and deterioration. Moisture contributes to the swelling of wood logs, in dry weather they dry out. All this leads to the fact that gaps begin to appear between the crowns of the log house, through which wind and cold can enter the house, and rain and dampness are the causes of wood decay and its gradual destruction. But these processes can be prevented if the log house is insulated and the log joints are sealed in time. The salvation of the dwelling is the high-quality sealing of the seams between the crowns. What materials are better to use for sealing walls and how is seaming done in a wooden house correctly?

Is it worth caulking a wooden house?

The most famous interventional heaters are moss, hemp and tow. The virtues of these natural materials are resistance to temperature fluctuations, bactericidal and mold fungi, low thermal conductivity, good moisture absorption. But fewer and fewer people building log cabins use these materials to seal the seams in a wooden house. Why did the demand for moss, tow and hemp decrease so much?

The process of caulking the cracks and gaps between the crowns is quite laborious and time consuming, because it is necessary to carefully and evenly plug them natural materials with the help of a chisel. The walls cannot be caulked immediately after the construction of the log house, since it will take at least a year to shrink, and during this time the moisture can already begin its destructive work. The disadvantage of caulking tow and moss is the fact that this process will need to be repeated more than once. The thing is that birds love to “steal” materials from people to build nests. Pulling moss and tow out of cracks and joints, they violate the integrity of the seal and give wooden frame messy messy look. Winds also worsen the appearance of the walls. As for material such as hemp, it is subject to attacks by moths, which, through their activities, harm the seal.

Knowing these shortcomings of natural heaters, manufacturers building materials produce more advanced sealants to improve the quality of insulation of all cracks, seams of a wooden house. What are the advantages of modern wall insulation?

Back to index

How to insulate walls with tape tow and linen rope?

One of the improved sealants is natural tow in rolls. It is made from flax, which is first well combed on carding machines, then the fibers are polarized and turned into a tape 15 cm wide. Next, the fibers are cleaned of various impurities. The result is an excellent sound and heat insulating material with good waterproof properties.

Unlike ordinary tow, tape is easier and denser to fit between the joints, it is not so brittle due to its softness.

Due to the naturalness of the material, the log walls breathe well and do not rot. Tape tow seams are more durable, and it is not easy for birds to pull it out of the slots. The rolled material is laid, like the usual one, along the crowns and along their edges with the help of a chisel or a special caulking spatula, carefully tucking the edges of the tape into each seam and slot. The result is a reliable seal between the logs, and the appearance of the log house is quite attractive.

A house insulated with linen rope looks even more beautiful. Such sealing of seams is called rope. As a heater, a three-strand linen rope is used, which is fixed to the seam with staples or nails. To work on the following materials and tools are needed:

- tape measure or ruler;

- scissors;

- linen rope;

- a hammer;

- short nails;

- metal staples;

- tassel;

- wood impregnation.

The acquired linen rope is placed along the line of the inter-beam seam and every 15 cm, pulling it well, a bracket or a nail with a small hat is hammered into the timber. At the corners of a wooden house, the distance between the fasteners may be smaller. In order for the rope sealing to look aesthetically pleasing, when driving in nails or staples, the following action is performed: first, a strand of rope is slightly opened, then fasteners are hammered in, the rope itself is tucked against the wall of the log house and pulled. The strand is closed, and the staple or nail head is hidden under it from prying eyes.

When the sealing of the seams with a natural linen cord is completed, care should be taken to preserve it for a long time. To do this, you need to take a protective impregnation for wood and carefully process all the rope edges with it. You can perform this procedure, impregnating at the same time the log walls themselves. Despite the fact that the process of sealing all the seams of a wooden house is quite long, it is not difficult, and you can do it without resorting to the help of other people. Rope insulation of seams in a wooden house is highly reliable, perfectly protects the log house from moisture and gives the structure an unusual but attractive look.