Solar collector for pool heating. Pool heating - do-it-yourself solar collector

The idea of such a collector belongs to a resident from the Moscow region, who, after building an inexpensive pool, wondered how to heat it. So the idea came up, how you can make a collector with your own hands, with which you can heat 10 cubic meters of water to an acceptable temperature.

The collector connection scheme is simplified, water is pumped from the bottom of the pool and then enters the collector. Well, from the collector water outlet, the water then enters the pool. The pump was used Dzhilek Drainage 170/9 with a capacity of 10200 l / h, and the lifting height was 9 meters.

As for the heat exchanger, it was decided to make it from plastic pipes with a diameter of 1/2 inch. In this case, not a solid pipe twisted into a spiral is used, but a kind of “snake”. It is thanks to the laying of pipes with a “snake” that when cold weather sets in, it is very easy to drain the water from the pipes.

In order to withstand a radius of about 5 cm when bending a metal-plastic pipe and ensure a good pipe laying density, metal corners were used. With this approach, the distance between the pipes was reduced by half. Of course, copper pipes would work more efficiently, but such a home-made product would be costly, and difficult, which is not very good for the frame, and besides, it would be problematic to assemble such a structure.

Assembly materials and tools:

- two plywood with dimensions of 1.52x1.52 m and a thickness of 10 mm;

- wooden beam 50x50 mm and 6 meters long (10 pieces);

- plastic clips for pipes 1/2 inch (160 pieces);

- galvanized steel corner for the manufacture of the frame 50x50 mm (60 pcs.);

- sanitary corners mother-mother and father-mother (120 pieces);

- fitting (male) for a metal-plastic pipe (120 pcs.);

- metal-plastic pipe 1/2 inch diameter and 110 m long;

- two cans of paint for painting pipes;

- black antiseptic - 5 l;

- aluminum corner 10x10 mm in size and 225 cm long (4 pcs.);

- ordinary glass with a size of 113x93 cm and a thickness of 4 mm (4 pcs.);

- 2.5 m lining (4 pcs.).

Collector manufacturing process:

Step one. Assembly of corners and fittings

You need to take the corners and fittings and connect them. For these purposes, fum tape is used.

Step two. Organization of the site for the installation of the collector

To install the collector, a special platform was made. For its manufacture, crushed stone, sand and paving slabs. The site is located to the south.

Step three. Assembly and installation of the collector housing

To make the collector housing, you will need plywood and bars. The bars are connected using galvanized steel corners. Due to the fact that the collector is intended for use only in summer, the author did not insulate the back wall, although it would not be superfluous to do this to increase efficiency. Insulation, if desired, can be installed from the back, and then sewn up with plywood from above.

To protect the case and not to paint it once again, it was coated with a black antiseptic.

The total weight of the hull was about 30-35 kg, in connection with this, the structure must have a powerful support, since with a gust of wind the structure may fall and the entire pipe will go down the drain. For the manufacture of supports, bars measuring 50x50 mm are used, and they are connected using metal corners.

The collector is attached to the support using steel angles 100 mm long and 50 mm wide.

Step four. Pipe installation

Clips must be installed on the collector body, with the help of which pipes will be attached. Due to the fact that when heated, the pipes will become elastic and sag, the distance between the clips should be about 50-70 cm. After installation, the clips will be painted black.

Now you need to take the pipes and cut them to size. After that, the pipes can be installed. After installation, the pipes are painted black so that they can heat up as much as possible when exposed to sunlight.

Step five. How to glaze the collector

In order for the collector to work effectively, it must be glazed. To install glass around the perimeter of the collector, you need to nail the lining, it has a side, and glass will be installed into it.

Due to the fact that the collector turned out to be quite large, it will be problematic to find glass of this size. But this is not a problem, it can be assembled from several fragments. In addition, such a large and thin glass will sag and will not last long. It is advisable to divide it into 4 parts. An aluminum corner is used to join the glass. In the center, the corner is attached to the beam, and the glass is fixed with washers.

Now solar collector for heating the pool is ready for operation. Now it needs to be connected to the pump. For 3-4 hours of operation of the device, the water in the pool (which is 10 cubic meters) heated up to a temperature of 27 degrees, which is quite good. When the collector worked for 7 hours, the temperature rose to 32 degrees. During operation, the outlet water is very hot, therefore, when bathing, it is better to turn off the pump so as not to get burned.

To maintain a pool of 20 m²: heating water for bathing and showering, about 19,000 kWh of thermal energy is required. Reducing costs even by 30% will increase the profitability of using an artificial reservoir.

Solar collectors for swimming pools, with proper calculations and configuration, can compensate up to 13,000 kW / h. The solar system, despite the need for initial costs, is economically beneficial. The full return on investment comes after 3-5 years of active use.

Types of collectors for heating pools

Solar systems for domestic and commercial artificial reservoirs are divided into several classes according to the type of construction and internal structure. The choice of a solar collector is influenced by its performance, the ability to accumulate and release heat, as well as the payback of the equipment.Several types of solar water heaters are used to heat water:

- According to the features of the accumulating element- solar systems are divided into:

- tubular (vacuum);

- panel;

- pyramidal;

- and flexible manifolds.

- According to design differences- there are open and closed solar systems. Each type has its own advantages. In open collectors, the absorber, made of plastic and rubber, does not fit under the glass. As a rule, open-type solar systems are designed for domestic heating of water in the pool in the summer.

Closed collectors, tubular and panel work regardless of the season (season). The absorber is covered with glass, which significantly reduces heat loss and increases the efficiency of water heating.

Tubular solar collectors

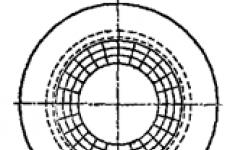

The main difference between solar systems is which storage element is used in the internal device. Tubular solar collectors for swimming pools use vacuum glass flasks, consisting of several elements:- hollow glass tube- flasks, depending on the design, are produced with one or two wall flasks. During production, oxygen is pumped out of the cavity. The vacuum serves as a natural and effective thermal insulator.

- Copper rod - plays the role of a heat exchanger. A liquid or gaseous coolant circulates inside.

- prefabricated distributor- a number of tubes are connected to the node. The module redistributes the heated coolant, directing it to the storage tank (pool bowl).

Read also: Vacuum solar collectors for home heating and domestic hot water

Vacuum collectors remain effective even in winter and cloudy weather, which makes it possible to extend the swimming season for open water for several months (from April to October). After the onset of late autumn, the tubular water heater will compensate for about 20% of the heat energy.

Panel solar collectors

Another type of solar systems used for commercial and domestic applications. Panel collectors, although they have a similar principle of operation with other solar water heaters, differ from them internal device, consisting of:- aluminum box;

- the top transparent panel from thick-walled glass;

- absorber - a metal plate coated with a selective layer;

- heat exchanger made of copper or aluminum tubes.

Read also: Flat solar collector - device and principle of operation of a panel solar system

The absorber is in close contact with the tubes through which the coolant circulates. After heating, the water is fed into an artificial reservoir. Flat solar collectors for swimming pools are especially effective in clear sunny weather. After the onset of autumn and winter time years, the heat output of the solar panel system decreases. Flat water heaters It is recommended to use in regions with a temperate and hot climate.

Pyramidal collectors

Used for domestic purposes. In the summer, a pyramidal solar plant will provide enough thermal energy to heat the water to a comfortable 23-25°C. Pool heating with pyramidal solar water heaters is rarely used due to low thermal efficiency.The principle of operation of the heliopyramid is as follows:

- the unit is connected to the pumping station;

- the role of the absorber is played by hoses with a diameter of 25-40 mm;

- the whole structure is placed on the reflector;

- water is heated and forced into the pool;

- The solar heater is in continuous operation.

Flexible manifolds

Visually resemble a rubber mat. They are of the open collector type. The rubber solar water heater has channels for circulation of the coolant.Solar collectors work effectively in sunny weather, quickly heating and maintaining the required temperature of the water in the pool. The coolant is circulated pumping station operating in continuous mode.

Flexible solar collectors for swimming pools are easy to transport. If necessary, they are simply rolled up like a rug. The sizes of a rubber collector are selected individually according to the area of the pool.

How is the pool heated by a solar collector

In spite of existing differences in the internal structure, the principle of operation of all solar systems is identical. Solar collector for heating water in the pool works as follows:- heat is absorbed;

- with the help of accumulated thermal energy, water is heated, which plays the role of a heat carrier;

- hot liquid is not discharged into a storage tank, but enters the bowl of an artificial reservoir (pool);

- the circulation of the coolant for greater efficiency is carried out by a forced method (pump).

Installation of panel water heaters is justified if it is planned to heat water only during the bathing season. It will not work to heat the pool with solar panels, since when the winter season sets in, the thermal efficiency of the system sharply decreases.

For a small outdoor pool, it is better to use pyramidal and flexible collectors.

Reviews show that heat loss during heating of the water of an artificial reservoir is reduced by approximately 2 times if a special coating is used at night or during the period when the pool is not in use.

Collectors for pools of factory production

The range includes solar systems designed for domestic and industrial use. The following manufacturers are the most popular:- Intex is a company that produces accessories for swimming in the pool and open water, and water heating. In particular, the production of flexible solar collectors has been launched.

- Azuro is a Czech company that manufactures swimming pools and everything necessary for their operation. In the product range, there are two lines of water heaters:

- Azuro Spiral - pyramidal collectors, with a total absorbing area of 0.96 m²;

- Azuro Shelter - flexible solar collectors, with the ability to install both a straight unfolded leaf and an arch. Absorbable area 1.84 m².

- Kokido Keops is a dome collector designed for heating water in frame and prefabricated pools. It is allowed to connect 4 separate modules into a single system. The solar system copes with the heating of 40 m³ of water.

- Sunheater is a brand of the American company SmartPool Inc. The flexible solar heater can be installed on the roof or mounted on a frame near the pool. Absorbent sheet length 6 m, width 0.6 m.

- Speck BADU BK is another popular flexible solar collector model. The solar system increases the heating of the water in the pool by 10-15°C, after which it automatically maintains the temperature. Products are different good quality assemblies.

How to make a collector for the pool with your own hands

A solar heater of a pyramidal or flexible type costs starting from 20 thousand rubles. A home-made water heater, taking into account the purchase of all the necessary components, will cost 5-6 thousand rubles. For the pool, it is easiest to make a pyramidal solar collector. The water heater has a simple internal structure. Easy to assemble.First you need to calculate the length and diameter of the solar collector pipes for the pool. Calculations are performed in the following way:

- the recommended value of the coolant velocity in the solar system is 0.4-0.7 m/s;

- the length is calculated taking into account the fact that 1 m of hose (25 mm in diameter) on a sunny day will heat about 3.5 liters of hot water in 1 hour. The table shows the number of hours of sunshine for temperate regions:

Pyramidal solar water heater for swimming pool is manufactured:

- from a polyethylene black pipe;

- from HDPE pipes.

- the pipe is wound in a spiral onto the frame and fixed with clamps;

- between the turns leave a gap of 1-1.5 cm;

- the hose at the point of entry into the solar water heater for the pool is thermally insulated.

Installation and connection of the solar collector to the pool

Solar systems of tubular and panel type must be mounted by specialized teams. Connection to the pool of solar water heaters of pyramidal type and flexible collectors is carried out independently. The assembly is carried out according to the following scheme:- the location of the solar collector is determined;

- the pyramid is installed on a reflective mat;

- a flexible collector is spread directly on the surface of the soil, or mounted on the roof;

- a pumping station is installed to supply cold water from the pool;

- The return line is connected directly to the bowl of an artificial reservoir.

It will not work to heat the water in the pool in winter with the help of solar collectors alone. If you plan to operate the reservoir throughout the year, you need to install the main source of heat: gas, solid fuel or electric boiler. The solar system in the winter season will compensate for the cost of heat in the range of 10-20%.

The solar collector for the pool is a special solar thermal system, with which you can simply, fairly cheaply provide acceptable-comfortable temperature indicators of water in the pool of any kind, size. The solar collector "absorbs" solar energy and converts it into heat, which is used to heat water.

The efficiency of the entire heating system depends on the quality of the solar collector. The design of this heating system should provide maximum “absorption” of solar energy and minimize heat loss.

Why heat water with a solar collector in swimming pools

The water in the pools is heated mainly in the off-season (end of spring, beginning of autumn), sometimes even in summer, when the air temperature is not systematically and does not warm up well enough. Low temperature water can lead to colds, both adults who bathe in it, and children.

Home (private) pools are mainly characterized by small size, the optimal water temperature for swimming in this type of reservoir is from + 25ºС to + 30ºС. To prevent the feeling of extreme coolness, chilliness, the temperature difference between water and air should be within 2-3 degrees.

The use of a solar collector will help maintain these optimal water temperature indicators. This design eliminates large financial and labor costs.

When using a solar collector, the indoor type of pool can be used all year round.

Features of homemade solar collectors

When mounting a solar collector for heating water in a pool with your own hands, you must first understand the features of these structures. They differ in cost, those materials, technologies that are used in the assembly.

If it is correct, carefully approach the assembly of a solar collector for heating water in the pool with your own hands, then it will not yield in terms of quality, technical specifications its professional, industrial counterparts and in some cases exceed these characteristics.

Despite the difference in materials for mounting solar collectors, the principle and features of these structures are similar.

Solar Distributor Assembly Steps

Stage 1 . The model of a solar power distributor with a power of up to 2000 W is one of the highest quality and most expensive. To mount it, you need materials:

- Pipes made of metal-plastic;

- Wooden box;

- plastic mounts;

- self-tapping screws;

- A special frame (frame) for fixing the wooden box in the correct, necessary plane;

- Black paint;

- The surface that will perform the function of protection (preferably glass);

- Small pump.

Stage 2. After the procedure for the selection of materials, it is necessary to determine the place where the solar collector will be located to heat the pool. To avoid heat loss during water transportation, experts recommend choosing an open, well-lit place near the pool for installing solar collectors. The collector must be placed at a certain angle, which depends on the terrain.

Before mounting the frame of the structure, a place is prepared on which a compacting “cushion” based on crushed stone is built, concrete screed(or platforms from paving slabs).

Next, a special coil is mounted: a beam is cut, which is connected with self-tapping screws and clamps, sheathed with plywood. This platform is characterized by a rather large weight of up to 35 kg, in connection with this, the supporting frame must combine strength and reliability. It is also worth considering that the frame will be affected by the weight of snow, bushings, and glass. After the construction of the platform, it is painted with black paint.

Next, the collector frame (bearing frame) is mounted. Special anchors are installed to which the transverse bars are fixed. Given the lower angle, reduced wooden frame on individual plan, the platform is mounted on the frame in compliance with the lower angle.

Attention ! The places where the pipes will be located are preliminarily marked. Plastic fasteners are installed, which are purchased with pipes. Fasteners are painted black.

Stage 3. Direct assembly of the solar battery. The cut tubes and assembled fittings are attached to the coil. The design with the help of a spray gun (can) is painted black.

Stage 4. To assembled structure the pump is connected. Pipes are mounted in the pool, taking into account the fact that they must be located and exit from the bottom of the pool.

Attention ! Since the water must flow slowly, heat up well enough, it is recommended to use a medium power deposit for a solar thermal system.

Stage 6 The assembled structure is being tested. If testing gave positive result, then the solar collector for heating the pool is ready for continuous operation.

How to save money when building a solar collector

For savings Money when building solar batteries for heating the pool with your own hands, you can replace expensive materials with cheaper ones that are slightly inferior in terms of quality characteristics. In this regard, experts recommend:

- To save the family budget, metal-plastic pipes can be replaced with their PVC counterpart. This analogue is much cheaper and they are connected with a special adhesive solution, which has an affordable price.

- If you use a special "lattice" (its corners are previously replaced with tees) instead of a "snake", then you need a pumping system that is characterized by less power and, accordingly, is cheaper.

- In order to prevent heat loss, increase the efficiency of the solar battery, it is recommended to insulate the back wall with foam plastic, special mineral wool. The gaps between the collector and the side are sealed with silicone.

- To prevent heat loss, a special rubber sealant is placed between the glass and the structure along the entire perimeter.

- To automate the process of heating water, it is recommended to install a thermal relay, thanks to which the system will automatically turn off after heating the water to the required temperature, and also turn on when the water in the pool cools down.

Attention ! If it is necessary to further simplify the design of the solar collector for heating water in the pool, conventional polyethylene pipes or hoses can be used.

It is mounted on a board in a spiral shape. The optimal length of the pipe is from 50 m. It is connected directly to the pool. A circulation pump is used to pump cold water.

Advantages of a solar collector

The use of a solar collector for heating water in the pool has its advantages:

- Most effective method, which allows you to maintain comfortable temperature indicators of water in the pool.

- This type of pool heating is one of the most economical financially, since the costs spent on the purchase of all necessary materials and installation of the structure as a whole pay off in a short time.

- With possible power outages, solar energy remains the only affordable, uninterrupted source of electricity.

- Solar collectors are easy to use, easy to care for (in order to maintain excellent performance systematically clean the filters from the resulting contamination).

What to consider when using solar collectors

When using metal pipes when mounting the structure of a solar water heater for pool water, it is recommended to pay attention to the fact that given material will be affected by high humidity, temperature fluctuations.

Attention ! Before frost, collectors that have metal pipes in their design must be disconnected from the water supply. Residual water is drained from the system. If these measures are not carried out and even a little water remains in the pipes, this will lead to their destruction in frost.

When mounting a solar collector, a special filtration system is installed. It is recommended to cover the pool with an awning to prevent the water temperature from dropping at night.

Thus, a solar collector for pool heating is a necessary design to maintain optimal water temperature indicators. It is quite easy to assemble with your own hands. It is necessary to follow certain steps in the construction of a solar collector. This type of water heating is characterized by a huge number of advantages from material savings when purchasing all materials to ease of operation and maintenance.

For more information on how to install a solar collector to heat water in the pool, see the video

A solar collector is an alternative source of thermal energy through the use of solar. Now this convenient device is no longer an innovation, but not everyone can afford to install it. If you calculate, buying and installing a collector that will satisfy the domestic needs of an average family can cost five thousand US dollars. Of course, the payback of such a source will have to wait quite a long time. But why not make a solar collector with your own hands and install it?

The standard device has the form of a metal plate, which is placed in a plastic or glass case. The surface of this plate accumulates solar energy, retains heat and transfers it for various household needs: heating, water heating, etc. There are several types of integrated collectors.

Cumulative

Storage collectors are also called thermosyphon. Such a do-it-yourself solar collector without a pump is the most profitable. Its capabilities allow not only to heat water, but also to maintain the temperature at the required level for some time.

Such a solar collector for heating consists of several tanks filled with water, which are located in a heat-insulating box. The tanks are covered with a glass lid, through which the sun's rays break through and heat the water. This option is the most economical, easy to operate and maintain, but its efficiency in winter is almost zero.

flat

P represents a large metal plate - an absorber, which is located inside an aluminum case with a glass lid. A do-it-yourself flat solar collector will be more efficient when using a glass cover. Absorbs solar energy through hail-resistant glass, which transmits light well and practically does not reflect it.

Inside the box there is thermal insulation, which can significantly reduce heat loss. The plate itself has a low efficiency, so it is coated with an amorphous semiconductor, which significantly increases the thermal energy accumulation rate.

When making a solar collector for a pool with your own hands, a flat integrated device is often preferred. However, it does not worse cope with other tasks, such as: heating water for domestic needs and space heating. Flat is the most widely used option. It is preferable to make a do-it-yourself absorber for a solar collector from copper.

liquid

From the name it is clear that the main coolant in them is the liquid. A do-it-yourself water solar collector is made according to the following scheme. Through a metal plate absorbing solar energy, heat is transferred through pipes attached to it into a tank with water or non-freezing liquid or directly to the consumer.

There are two pipes attached to the plate. Through one of them cold water from the tank, and through the second, the already heated liquid enters the tank. Pipes must have inlet and outlet openings. Such a heating scheme is called closed.

When heated water is directly supplied to meet the needs of the user, such a system is called open-loop.

Unglazed ones are more often used to heat water in the pool, so assembling such thermal solar collectors with your own hands does not require the purchase of expensive materials - rubber and plastic will do. Glazed ones have higher efficiency, so they are able to heat the house and provide the consumer with hot water.

Air

Air devices are more economical than the above analogues that use water as a coolant. The air does not freeze, does not leak, and does not boil like water. If a leak occurs in such a system, it does not bring so many problems, but it is quite difficult to determine where it happened.

Do-it-yourself production is not expensive for the consumer. The solar panel, which is covered with glass, heats the air that is between it and the heat-insulating plate. Roughly speaking, this is a flat collector with space for air inside. Cold air enters inside and, under the influence of solar energy, warm air is supplied to the consumer.

The fan, which is attached to the air duct or directly to the plate, improves circulation and improves air exchange in the device. The fan requires the use of electricity, which is not very economical.

Such options are durable and reliable and easier to maintain than devices that use liquid as a coolant. To maintain the desired air temperature in the cellar or to heat the greenhouse with a solar collector, just such an option is suitable.

How it works

The collector collects energy using a light accumulator or, in other words, a solar panel, which transmits light to an accumulating metal plate, where the solar energy is converted into heat. The plate transfers heat to the coolant, which can be both liquid and air. Water is sent through pipes to the consumer. With the help of such a collector, you can heat your home, heat water for various household purposes or a pool.

Air collectors are used mainly for space heating or heating the air inside it. Savings when using such devices are obvious. Firstly, there is no need to use any fuel, and secondly, the consumption of electricity is reduced.

In order to get the maximum effect from the use of the collector and to heat the water for free for seven months a year, it must have a large surface and additional heat exchangers.

Engineer Stanislav Stanilov introduced the world to the most versatile solar collector design. The main idea of using the device he developed is to obtain thermal energy by creating a greenhouse effect inside the collector.

Collector design

The design of this collector is very simple. In fact, this is a solar collector made of steel pipes welded into a radiator, which is placed in a wooden container, protected by thermal insulation. As thermal insulation material may speak mineral wool, polyfoam, polystyrene.

At the bottom of the box is placed galvanized a metal sheet on which the radiator is mounted. Both the sheet and the radiator are painted black, and the box itself is covered with white paint. Of course, the container is covered with a glass lid, which seals well.

Materials and parts for manufacturing

To build such a homemade solar collector for heating a house, you will need:

- glass to serve as a lid. Its size will depend on the dimensions of the box. For good efficiency, it is better to select glass with a size of 1700 mm by 700 mm;

- frame under glass - it can be welded independently from the corners or put together from wooden planks;

- box board. Here you can use any boards, even from disassembly old furniture or plank floor;

- rolling corner;

- coupling;

- pipes for assembling a radiator;

- clamps for mounting the radiator;

- sheet of galvanized iron;

- radiator intake and exhaust pipe;

- tank with a volume of 200-300 liters;

- aquacamera;

- thermal insulation (foam sheets, expanded polystyrene, mineral wool, ecowool).

Stages of work

Do-it-yourself Stanilov manifold manufacturing steps:

- A container is knocked together from the boards, the bottom of which is reinforced with bars.

- A heat insulator is laid at the bottom. The base must be especially carefully insulated to avoid heat leakage from the heat exchanger.

- After that, a galvanized plate is arranged at the bottom of the box and a radiator is installed, which is welded from pipes, and fixed with steel clamps.

- The radiator and the sheet below it are painted black, and the box is white or silver.

- The water tank must be installed under the collector in a warm room. Thermal insulation must be arranged between the water tank and the collector so that the pipes are warm. The tank can be placed in a large barrel, into which expanded clay, sand, sawdust, etc. can be poured. and thus insulate.

- An aqua chamber must be installed above the tank in order to create pressure in the network.

- Do-it-yourself solar collector installation must be carried out on the south side of the roof.

- After all the elements of the system are ready and installed, you need to connect them to the network with half-inch pipes, which must be well insulated in order to reduce heat loss.

- It would be nice to build a controller for a solar collector with your own hands, since factory devices are not used for long.

Size calculation

The calculation of dimensions in order to make a solar collector for heating with your own hands is primarily aimed at determining the load of the heat supply system, the coverage of which is assumed by this device. It goes without saying that the use of several energy sources in the complex is implied, and not just solar energy. In this case, it is important to arrange the system in such a way that it interacts with others - then this will give the maximum effect.

To determine the collector area, you need to know for what purposes it will be used: heating, hot water, or both. After analyzing the water meter data, heating needs and insolation data of the area in which the installation is planned, it is possible to calculate the area of \u200b\u200bthe collector. In addition, it is necessary to take into account the needs for hot water of all consumers that are planned to be connected to the network: washing machine, dishwasher etc.

Selective coating performs perhaps the most basic function in the operation of the reservoir. A coated plate or radiator attracts many times more solar energy, turning it into heat. You can purchase a special chemical as a selective coating, or you can simply paint the heat storage tank black.

To make a selective coating for solar collectors with your own hands, you can apply:

- special ready-made chemical;

- oxides of various metals;

- thin thermal insulation material;

- black chrome;

- selective paint for the collector;

- black paint or film.

Collectors from improvised materials

It is cheaper and more interesting to assemble a solar collector for heating a house with your own hands, because it can be made from various improvised materials.

From metal pipes

This assembly option is similar to the Stanilov collector. When assembling a solar collector from copper pipes with your own hands, a radiator is cooked from the pipes and placed in a wooden box, laid with thermal insulation from the inside.

Copper pipes will be the most effective, aluminum pipes can also be used, but they are difficult to cook, but steel pipes are the most successful option.

Such a homemade collector should not be too large to be easy to assemble and mount. The diameter of the pipes for solar collectors for welding the radiator must be smaller than the pipes for the inlet and outlet of the coolant.

From plastic and metal-plastic pipes

How to make a solar collector with your own hands, having in your home arsenal plastic pipes? They are less effective as a heat accumulator, but they are many times cheaper than copper and do not corrode like steel.

Pipes are laid out in a box in a spiral and fixed with clamps. They can be coated with black or selective paint for greater effectiveness.

You can experiment with pipe laying. Since the pipes do not bend well, they can be laid not only in a spiral, but also in a zigzag. Among the advantages, plastic pipes are easy and quick to solder.

From a hose

To make a solar collector for the shower with your own hands, you will need a rubber hose. The water in it heats up very quickly, so it can also be used as a heat exchanger. This is the most economical option when making a collector with your own hands. hose or polyethylene pipe fit into the box and attached with clamps.

Since the hose is twisted in a spiral, there will be no natural circulation of water in it. To use a water storage tank in this system, it is necessary to equip it with circulation pump. If this country cottage area and a little hot water leaves, then the amount that will flow into the pipe may be enough.

From cans

The coolant of the solar collector from aluminum cans is air. Banks are interconnected, forming a pipe. To make a solar collector from beer cans, you need to cut off the bottom and top of each can, dock them together and glue them with sealant. Finished pipes are placed in a wooden box and covered with glass.

Basically, an air solar collector made from beer cans is used to eliminate dampness in the basement or to heat the greenhouse. As a heat accumulator, you can use not only beer cans, but also plastic bottles.

From the fridge

Do-it-yourself solar hot water panels can be built from an unusable refrigerator or an old car radiator. The condenser removed from the refrigerator must be thoroughly rinsed. hot water obtained in this way, it is better to use only for technical purposes.

Foil and a rubber mat are spread at the bottom of the box, then a capacitor is laid on them and fixed. To do this, you can use belts, clamps, or the mount with which it was attached in the refrigerator. To create pressure in the system, it does not hurt to install a pump or an aqua chamber above the tank.

Video

You will learn how to make a solar collector with your own hands from the following video.