How to repair a slate roof with your own hands. Slate roof repair: a pressing issue with simple solutions How to repair a slate roof

About 20-30 years ago, slate was considered the most reliable and was the most common roofing material. Currently, in many countries the use of such a roof is prohibited due to the presence of carcinogenic substances in it. It is difficult to argue with science, but people have lived and live in such houses for many decades, while they do not feel any harm to their health.

Among the main advantages of slate can be noted durability and relatively low cost. The service life of slate, subject to the rules for arranging the truss system, is at least 50 years.

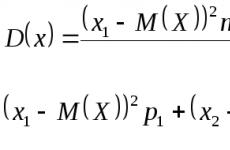

The mass of an eight-wave sheet 40/150 with an area of 1.6 m2 is 26.1 kg, a seven-wave sheet is 23.2 kg

Causes of violation of the tightness of the slate roof

Like any building material, slate roofs lose their original properties over time. They have to be completely replaced or repaired.

Why do slate roofs leak?

| Causes of leakage | Short description |

|---|---|

| Depending on the type, one sheet of slate weighs 23-35 kg, if the roof area is 100 m2, then rafter system must withstand approximately two tons of weight. In addition to the load from the slate, there are also significant forces of the snow cover. Especially in spring, when the snow absorbs a lot of moisture. If the calculations are made incorrectly or mistakes were made during construction, but the load-bearing elements bend, the slate will crack. | |

| Most often, slate is damaged by hail, sometimes undermined by hurricane gusts of wind. There are cases when the slate cracks during the installation of various utilities on the roof - the coating cannot withstand the weight of the installers. | |

| After about 20–30 years, mosses begin to grow on the surface of the slate. Their root system penetrates the material and gradually destroys it. | |

| If slate nails are not driven in correctly, then there is a possibility of cracking. Another mistake - the nails do not fall into the crate, the sheets are not fixed according to the rules, during the wind they rise a little and vibrate. Such movements also cause the formation of cracks. |

Depending on the cause, the nature and size of the crack changes; when choosing materials and repair technologies, these factors must be taken into account.

The faster leaks are fixed, the less negative consequences will have to be eliminated in the future. In the article we will consider some of the simplest and most effective ways to repair slate roof.

Important. Roof repairs are done at high altitude, never violate safety regulations, do not work without insurance and special devices.

If you need to repair a very old slate, then walking on it in shoes with a hard sole is prohibited, the sheets can no longer withstand such loads. It is necessary to prepare a special ladder or platform, otherwise, instead of repairing one leak, several sheets can be ruined. Sometimes they can no longer be repaired, you have to completely change. But here a problem arises. The standards of slate sheets have undergone significant changes over the past decades; it is almost impossible to select a new slate with the same linear dimensions and wave parameters.

Repair of a slate roof with a soft roll coating

This is one of the easiest and most reliable ways to restore the tightness of a slate roof. Modern roofing roll materials are made on the basis of modified bitumen, which is not only afraid of temperature changes from plus to minus, but is also very resistant to harsh ultraviolet radiation. Namely, it is the main enemy of bitumen, under the influence of UV rays it loses plasticity, cracks and leaks. Modified bitumen does not change its original characteristics for twenty years, this time is quite enough for a repaired slate roof.

To carry out the work you need to have a piece soft roof appropriate size, gas spray with a torch and a sharp mounting knife.

Practical advice. Cracks occur in the upper and lower parts of the slate wave. If they are in the upper part, then you can not repair, there are no leaks because of them. On the contrary, during the repair, sheets can be further damaged.

Step 1. Clean the surface of the slate adjacent to the damage from dust and dirt. It is recommended to use a metal brush, it will remove the thin top layer of slate. This thin layer has already begun to lose strength, it is better to remove it, the patch will hold on much stronger.

Step 2 Taking into account the size of the problem area, cut off a piece of soft roofing. The specific brand does not matter, at present, domestic manufacturers of roofing materials use imported bitumen, and this guarantees high quality. The size of the patch should be about five centimeters larger than the parameters of the hole.

Patch. Technoelast material from TechnoNIKOL

Step 3 Heat the slate around the hole with a burner, this will improve the adhesion of materials and remove moisture.

Step 4 Heat up the soft top. It is necessary to heat until the bitumen becomes liquid over the entire surface. It is important not to overheat it, because of the very high temperature it may boil or ignite.

Step 5 Quickly place the patch in place and press firmly. You can press it with your hands, but be sure to wear mittens.

Try it on a tear, if the gluing is weak, then lift the edge and re-heat the patch and slate, press it when ready.

Important. Pay the greatest attention to the junction of the upper part of the patch, it is here that repeated leaks can appear. Do not rush, work very carefully and carefully.

Soft roofing must exactly repeat the relief of the surface of the sheets. They have small grooves, the bitumen must fill them to the full depth. If the heating temperature is correct, then bitumen should be slightly squeezed out along the perimeter of the patch. Such a patch can stand for several years, exact time depends on your professionalism.

Slate roof patch

Prices for various types of gas burners and blowtorches

Gas burners and blowtorches

Repair of a slate roof with mastic

This method does not require heating, which is considered one of the advantages. For repairs, you will need rubber-bitumen mastic, a brush and a polymer mesh.

Step 1. Thoroughly clean the leak, preferably with a wire brush. Slate dust must then be blown off or removed with a clean paint brush.

Step 2 Cut off a piece of plastic mesh, lay it on the crack. Spread with the first layer of mastic. Work carefully, carefully rub the mastic into the surface of the slate. Remember that the reliability and durability of the patch largely depends on the degree of adhesion of the first layer.

Step 3 Allow time for the mastic to polymerize, depending on the weather and the type of material, this will take 3-4 hours.

Step 4 After the first layer is completely dry, the second layer can be applied. The technology of work is no different from the above.

Important. The dimensions of the mastic along the perimeter of the second layer should be 1–2 cm larger than the dimensions of the first, this will increase the tightness of the upper most problematic joint of the patch and slate. If you apply the third layer, then its area is recommended to be slightly increased.

Professionals advise covering the last layer of mastic with a thick cloth to protect the material from ultraviolet rays. This makes it possible to improve the operating conditions of the mastic and, accordingly, increase the operating time of the roofing.

Prices for bituminous mastic

Bituminous mastic

Cold welding cracks

This method is only suitable for sealing narrow cracks on the surface of the slate sheet. Large holes must be sealed with rolled materials. For sealing, cold welding on a bitumen basis is used. This modern innovative material is characterized by excellent performance. After solidification, it becomes moderately hard and plastic, which allows it to easily compensate for the thermal expansion of cracks and at the same time not lose its tightness.

Cold welding is easy to use, does not require special skills, has high adhesion with all building materials. The seam is not afraid of temperature changes, direct contact with water and ultraviolet radiation. As for the cost, it is available to all consumers. Moreover, the welding consumption is negligible, and the storage time is long. You can use welding at any time and not only for the repair of a slate roof. Professionals strongly recommend that you always have cold welding at home, it will help eliminate many construction errors.

Cold welding "Skol" produced by "Remplast"

How to repair slate by welding? As always, surfaces must be thoroughly cleaned. Only in the case of welding has its own characteristics. It is necessary to clean not only the surface of the sheets, but also the crack itself. It is very desirable to remove all the smallest fragments, dust and dirt. The cleaner the cracking plane, the more reliable the sealing of the leak will be.

Practical advice. Take a bottle of water with you to the rooftop. The fact is that in order to prepare welding for use, it is necessary to knead it and warm it up with your hands. If the palms are not moistened with water, then the bitumen will stick to them, which will make the work much more difficult. As soon as your hands dry out a little, immediately moisten them with a little water.

Step 1. Find the crack and clean it of dust. The main attention should be paid to the crack itself, but a clean strip about one centimeter wide should also be prepared around the perimeter.

Step 2 Knead the welding with your hands, it should become soft. Depending on the diligence, kneading will take 3-5 minutes.

Step 3 Roll a thin sausage out of welding. The diameter of the sausage should slightly exceed the width of the crack. Don't Prepare Right Away a large number of material, it should not cool down until the patch is applied.

Step 4 Press the sausage very firmly into the crack. If you have an assistant, great. Let him hold the welding emerging from the gap on the back of the roof, this will help to fill all the smallest pores with maximum density. The larger the area of contact of welding with the surface of the crack, the more reliable the sealing.

Step 5 As the gap fills with mastic, smear the excess with a thin layer along the edges of the crack. At the same time, form a small tubercle to divert the flow of water. The less water gets into the crack, the more reliable the roof. It is necessary to work with welding according to the principle of working with plasticine - do not rush and do not forget to periodically heat up the frozen material.

Practical advice. Choose dry and warm weather for repairs. If the slate is warm to the touch - excellent, the quality of adhesion will increase significantly.

The use of cold welding for the repair of a slate roof is the fastest, easiest and most reliable method. As practice shows, tightness is maintained for 5-6 years.

Repair of slate with foam plastic

Let's just say that it's not the best. The best way repair slate coating, but it can be used in cases where, for some reason, it is impossible or unprofitable to buy industrial materials. The material for sealing cracks is prepared independently from gasoline and foam.

Important. The glue dries very quickly, you need to work at a pace. Before making glue, it is advisable to find leaks and pre-clean them from dust and dirt. If there are a lot of them, then it is recommended to mark problem areas with chalk.

The payment is made in the following way.

Step 1. With a stick or small spatula, apply glue to the crack and press it as hard as possible into all the recesses.

Step 2 Align the layer of glue, pay attention that no dry surfaces remain around the perimeter of the hole.

Step 3 Place an appropriately sized piece of galvanized sheet steel on the adhesive and press it into the adhesive.

It is not necessary to close the gap with metal patches; other materials can be used. The main thing is that they are not afraid of moisture, do not dissolve in gasoline and are resistant to UV rays. But they must be used. The fact is that the foam plastic reacts very negatively to ultraviolet rays, without such protection the patches will crack the next year, and the roof will have to be repaired again. And this is a waste of time and nerves.

On a rigid patch, you can apply another layer of glue, due to this, the adhesion strength will further increase.

How to quickly repair a slate roof after hail

Situations are rare, but bring a lot of problems. The slate roof does not just leak, but flows like a sieve. Measures must be taken immediately, otherwise, all the interior premises will have to be repaired, and this increases the cost at times. Another problem is that hail falls in summer and autumn, and this is the time of rains. It is unrealistic to completely change the roof in the rain.

The repair we offer allows you to immediately eliminate a large number of holes in the slate and calmly wait for good weather for a major overhaul of the roof of buildings. If this is an inexpensive extension, then after repair it can wait for its turn for several years, patches will ensure tightness all this time. And one more plus of the method - the first stage of repair can be done from the attic.

Holes are sealed with silicone putty or sealant and corrugated cardboard. Corrugated cardboard bends well along the corrugation lines and holds the bending load across it well. In addition, this material is always at hand and costs almost nothing.

How to save a house after a hail?

Step 1. Climb up to the attic for a rough estimate of the amount of loss and revision of the condition of the slate sheets. As we already mentioned, when damaged by hail, the number of holes is in the tens. Prepare materials according to the volume.

Step 2 Cut out patches from corrugated board. There is no need to waste time trying on each hole, focus on the largest. Moreover, there is little time for repairs, everything must be completed as soon as possible. First, you should close up the holes only on the lower waves of the slate. The upper waves almost do not leak.

Step 3 Use any brush to remove dust from the slate. From the side of the attic, the sheets are much cleaner than from the outside; preparing the gluing site is much easier and faster. We recommend that you immediately prepare all the holes, it will be much faster than sealing and cleaning each individually.

Step 4 Squeeze out the silicone onto the patch, squeeze it out in a zigzag manner, and then spread it with your finger in an approximately even layer over the entire surface of the corrugated board. It must be borne in mind that silicone adheres strongly to the skin, work in disposable medical gloves or use other skin protection.

Extrusion on a patch of silicone

Important. Do not leave gaps, paper is afraid of moisture, silicone should reliably protect it.

Step 5 Immediately firmly glue the patch into place, making sure that it lies exactly along the profile of the bend of the sheet.

Sticking the patch in its place

Step 6 Once again, go over the perimeter of the patch with silicone, align the silicone with your finger, the fit should be tight.

Step 7 Protect the back of the corrugated board from moisture. Coat it with silicone in the manner described above.

This completes the first emergency repairs. In this state, the roof can be several months and expect a complete replacement. If it is impossible to quickly replace the sheets and the roof will remain in this state for the winter, then you need to take measures to strengthen the patches. Work is being done outside. How exactly?

Step 1. Scrub the area around the hole with a metal brush. Work carefully, do not damage the patch already installed below.

Cleaning the slate with a brush and brush

Step 2. Use a soft brush to remove dust, especially from the patch. The cleaner the surface, the more reliable the repair will be.

Step 3 Buy a bottle of solvent (you can use white spirit), put a spray bottle on it, wet the surface of the patch and the surface of the slate around it.

The solvent will not only degrease the slate, but also destroy all microorganisms growing on it. Due to this, the bonding strength is increased, the reliability of the slate repair is significantly increased. When working with solvents, follow the safety rules - the liquid is explosive, the fumes are poisonous. Protect your respiratory organs with personal protective equipment.

Step 4 Apply sealant over the entire area of the patch, especially carefully around the perimeter of the hole. It is desirable that the thickness of the sealant be slightly greater than the thickness of the slate, due to this method, water will not stagnate on the patch. But this is an optional condition, make a decision based on what period you are roughly counting on and how much sealant is.

Important. Be sure to have a certain amount of sealant on the surface of the slate around the perimeter of the hole. In the upper part, it is recommended to make a small tubercle, it will drain water along the sides of the patch.

Step 5 Align the surface of the sealant, check the quality of the putty. To prevent the sealant from sticking to your hands, periodically moisten them with soapy water. You can take some dishwashing detergent and dilute it with water.

If desired, the entire roof can be repaired in 4-5 hours. If everything is done correctly, then you can safely spend the winter, and next year make the final decision with the repair of the roof. Old damaged slate, of course, will have to be changed. And what roofing material to use instead of it is a personal matter for each owner of the building.

Prices for polyurethane sealant

Polyurethane sealant

Video - Slate roof repair

Among the popular roofing materials was and remains affordable and easy to install slate. It is resistant to weather and atmospheric loads, is not afraid of moisture, is durable and reliable. Its service life even in difficult conditions is at least 15 years. But even such a stable and reliable roofing material will require repair and maintenance over time. What should be done if the slate roof is leaking or has surface defects? How to properly repair, what to use, what technology to use? We will try to find detailed answers to these and other questions.

Service life of slate, or Why do leaks occur?

When covering the roof, smooth, and more often wavy, asbestos-cement sheet material is used. Modern technologies proposed an analogue of the classic slate - sheets based on jute and polyacrylic fibers. It is lighter and easier to install. Euroslate is also used - bitumen products. But no matter what kind of slate roof is used, it will need repairs in 7-10 years. Term capital works can be pushed back by 5-6 years if annual roof maintenance is performed.

But in any case, repair is inevitable. Reasons for this:

- physical aging of sheet products;

- incorrectly organized system drainage - leads to stagnation of water. The same problems will arise if the sheets are incorrectly installed. Therefore, when doing this procedure for the first time, it makes sense to ask how to fix the roof so that it does not leak if the roof is uneven - the slate structure in this case experiences additional stress;

- incorrect installation;

- incorrectly selected roofing material for operating conditions;

- accumulation of moisture;

- mechanical loads.

There are many more reasons why you have to figure out the question of how to fix a slate roof from leaking and restore its physical and technical data. Problems can be associated with non-compliance with the production technology of sheet products, and with their incorrect transportation, and with careless handling during installation. Therefore, choosing slate as a roofing material, you should initially familiarize yourself with its “weak points” and the technology of installation and maintenance. This will help reduce the risk of leaks in the future.

Can flaws be detected before they cause damage?

Yes, it is possible and even necessary. An annual inspection of the coating ensures timely detection of defects and their rapid elimination. Leaking roof - fungus and mold, high humidity, reproduction of microorganisms inside residential premises. All this will lead to rotting of the truss structure, damage to furniture and finishes, and will harm health. Therefore, having discovered that a slate roof is leaking, what needs to be repaired immediately. Then urgently carry out repairs.

What indicates a leak:

- raw construction rafters (may be in a certain place);

- high humidity in the attic;

- feeling and smell of dampness in the house, characteristic spots on the ceiling;

- raw thermal insulation material on the roof;

- mold zones on the elements of the roof structure, walls.

In order to repair the slate in time, not allowing leaks to spoil the microclimate in the interior, it is recommended to check the attic space after every rain, in the spring when the snow melts. If there are signs of leaks, there are also cracks, holes, chips, surface destruction. It is necessary to climb to the roof and assess the integrity of the coating. It is easier to work with smooth types of flooring - even small injuries are visible to the naked eye. It is more difficult to detect cracks and chips in corrugated slate, as well as repair them. Therefore, when choosing the type of roofing sheets, you should pay attention to this aspect.

In 8 out of 10 cases, the roof is organized using corrugated sheets. The type of cracks on them can be different. It is he who determines how difficult it will be to repair the slate, as well as what technologies to use. Varieties of cracks on the "waves":

There may be holes on a slate roof that has been used for a long time. They are sealed according to the same principle as the cracks going down the wave. Sealants, galvanized sheet iron and special patches are used.

Slate roof repair technologies

Having assessed the integrity of the surface, a decision should be made on how to cover up the slate so that the roof does not leak during snow and rain. Professionals offer a number of effective methods:

Method number 1: butyl rubber tape.

Used as a patch. You can buy it at any hardware store. The tape is ready to use. It is necessary to remove the protective film and stick the tape on the prepared area around the defect. The patch is made of non-woven material, and therefore resistant to stress and easy to color.

Method number 2: sickle tape.

Initially, the damaged area must be cleaned. Remove moss, dirt, loose parts of the covering. The next step: a layer of bitumen is applied to the crack with an area of 5-7 cm. A sickle is glued on top. Cheap and effective technology for the restoration of a slate roof - prevents the spread of a defect and leakage.

Method number 3: rubber bands.

This is a special patch for slate. Sold in hardware stores and is completely ready for use. Installed on a prepared surface - completely clean of dirt and moss, degrease with gasoline. Recommends capturing an area of 3-5 cm around the defect.

Method number 4: ordinary cement mortar.

Clean the damaged area of moss and dirt. Mix the solution. You need sand (pre-sift), water and cement. The mixture should be of a stiff consistency. Apply it to the crack. Let the patch dry.

Method number 5: waterproofing mastics or hot bitumen.

The first type of materials do not require additional heating. It is applied with a spatula on the prepared - cleaned, degreased and dry surface. When working with waterproofing mastics, a water-soluble coloring pigment is usually added to the composition. But this step can be skipped. Apply mastic, and then paint the surface.

Having chosen hot bitumen, slate repair will have to begin with melting a piece of material on a fire. Work is best done in the warm season. Bitumen must be applied to a surface free from dust and dirt. If the crack needs to be repaired in winter, mining is added to the molten bitumen.

Method number 6: putties.

They are purchased at hardware stores and are intended for work on slate. Sold in ready-made. But their use is associated with complex surface preparation. The damaged area is cleaned and degreased. Then a construction primer is applied to it. Only then, using a pistol, putty is distributed over the damaged area. Partial drying will be achieved in 6.5-7 hours.

Method number 7: moisture-resistant adhesives.

To complete the work, you will need to remove the slate sheet. Adhesive sealant is completely ready for use. But its use requires careful treatment of the damaged area. The first step is to scrub the damaged area with a stiff brush with clean water. After drying, a strong textile flap is glued onto the zone, capturing an area 3-5 cm from the edges of the crack. At this step, experts recommend saturating the flap well with moisture-resistant glue. After setting, the fabric is covered with glue again. Apply over the flap in an even and even layer. Let the glue set. The gap on the reverse side is concreted. As soon as the solution grabs onto its surface, another patch with moisture-resistant glue is placed.

Capital repairs must be carried out, adhering to technology. The slightest deviation from the instructions or a negligent attitude towards cleaning the damaged area will lead to the fact that during the next rain, water will certainly get inside the structure. After restoration work, you can check the quality of the patch by going up to the attic after another downpour. If everything is done correctly, there will be no moisture and dampness.

Slate is a fairly common material in the field of construction. Of course, now there are many more modern coatings that provide reliable protection buildings from rain and snow, but in many respects the choice of material is influenced by its cost. In addition, in the last century, slate was the most popular roofing material, so if the building is already many years old, a slate roof may need to be repaired. Do-it-yourself work is not difficult. The technology will allow to repair the coating and eliminate the cost of its replacement.

Types of slate and the benefits of using it

Diagram of types of slate with dimensionsThe material is made from asbestos. It is the raw materials for manufacturing that scare away many. It is important to know that asbestos dust, which is formed during production, is dangerous for humans. Ready-made roofing materials are not dangerous and can last for a long time without causing problems. This material is available in several types:

- rectangular slabs (VO brand);

- reinforced wavy for roofing (VU brand);

- wavy unified (UV brand).

In order to cover the roof with slate with your own hands, the last two types are used. The benefits include:

- good thermal insulation characteristics;

- reliable waterproofing;

- resistance to fire;

- ability to withstand high temperatures;

- ease of installation;

- low material cost;

- long service life.

All these characteristics allow slate to remain in the ranks of roofing materials, even in the presence of serious modern competitors.

Table with the characteristics of slate

Table with the characteristics of slate Roof damage

Over time, the roof covering is damaged or becomes unusable. The following adverse factors affecting the roof can lead to such phenomena:

- biological (various microorganisms, mold, fungus, moss, lichen);

- mechanical influences;

- weather conditions (rain, snow, strong wind).

Microorganism damage occurs due to the fact that the surface of the slate is not smooth. In autumn, fallen leaves fall on the roof and remain there, creating a favorable environment for the development of unwanted neighbors. In the process of life, such microorganisms secrete various substances, which are capable of destroying the roofing material.

Mechanical damage can be attributed to cracks from the fall of various objects. For example, in strong winds, tree branches can fall onto the roof, damaging it.

Weather phenomena adversely affect the slate, for example, in the case of sudden temperature changes. Severe frosts after a thaw lead to the fact that the water on the surface of the material freezes. Basic distinctive feature This liquid, which makes it completely unlike any other substance on the planet, is that when it freezes and turns into ice, water expands. At the same time, it exerts pressure on the material, causing cracks to open or a serious increase in existing damage.

Slate roof scheme

Slate roof scheme Apart from external factors destruction to the appearance of cracks and damage leads to a violation in the technology of installation of the roofing material. If the fasteners are not made correctly, over time, the slate around them will crumble and become unusable. In this case, the tightness of the structure is violated, and leaks appear.

Repair process

Repair of a slate roof largely depends on the cause of the damage. Depending on the scale, the events are divided into:

- redecorating;

- partial replacement of sheets;

- complete replacement roofing.

Redecorating

In the first case, cracks and chips are covered with mastic home cooking. There are several ways to prepare a composition for cosmetic repairs:

Bituminous resin for covering roof cracks

Bituminous resin for covering roof cracks - The cracks are covered with a composition made from chalk chips and drying oil. After the mixture has dried, the treated surface is covered with oil paint.

- A solution is prepared from grated asbestos, PVA glue and water. The composition is applied to the slate, leveled with a spatula and left to dry. When choosing this composition, it is important to remember what was said earlier: asbestos dust is dangerous to humans. Solution in without fail you need to prepare using a set of protective clothing: gloves, overalls, mask.

- The third option to sweep to cover cracks can be treating them with bituminous resin.

If it is possible to use a more modern repair composition, bitumen-based roofing sealants are purchased in the store. They are available in tubes and jars. The price of the composition in the bank is lower, but it is more convenient to work with the sealant in the tube.

Also cosmetic measures include painting the roof of slate and cleaning it from moss and lichen.

The latter is the prevention of biological damage and rather refers to preventive measures. There are two ways to remove moss from roofing:

- mechanical with a metal brush (the areas are cleaned, washed with water and treated with a primer);

- chemical using compounds based on acids or alkalis.

Partial replacement

Slate fastening scheme

Slate fastening scheme If carrying out only cosmetic measures is not enough, a partial replacement of severely damaged roof elements is performed. In this case, usually the need for repair is caused not only by cracks on the surface of the slate, but also by roof leaks. Work performance technology:

- remove the fasteners on the sheet to be replaced and loosen on the neighboring ones;

- carefully remove the damaged element;

- a new sheet is installed in its place;

- perform its fastening with the help of slate nails, return fasteners to the place on adjacent sheets of slate.

Before performing these works, it is also recommended to check the condition of the truss system. If wooden elements were exposed to water, they could develop mold and rot. In case of minor damage, it will be enough to treat the elements of the wooden truss system with antiseptic compounds. If load bearing capacity due to damage by microorganisms is reduced, reinforce or replace roof structures.

Partial repairs are carried out together. One person lifts the sheets adjacent to the damaged one, and the other makes a replacement.

Complete resurfacing

If the damage to structures has gone very far, patching holes is pointless. In this case, the least labor-intensive and effective way slate roof repair will be a complete replacement of the material. The owner of the house has two options:

- replacement of slate with slate;

- replacement with metal tiles, seam roofing or profiled sheet.

Only a profiled sheet can compare in price with slate, other materials can cost more. As in the previous case, before repair, they check the condition of the truss system: it may be necessary to replace not only the roofing, but the entire roof as a whole.

A person who is at least a little familiar with construction is capable of carrying out repair work on a slate roof. The main thing is to choose the right method of repair and observe safety precautions during roofing work.

Owners of slate roofs are often faced with the need for in-line repair work on roofing. The article describes the features of the repair of a slate roof. The material below will introduce you to the advantages and disadvantages of slate and the causes of surface defects. You will learn how to discover different kinds defects, what popular methods of slate roof restoration exist and how to prepare for roof repair.

Habitual landscape Source chebaki.ru

About slate

Despite the variety of modern roofing materials in the private sector are still familiar gable roofs covered with slate. This material is in constant demand in the construction of residential buildings, garden housing and outbuildings due to the following advantages:

budget cost. For the price, slate outperforms most roofing materials.

Long service life.

Easy installation and easy machining.

Low thermal conductivity. Unlike corrugated board or metal tiles, slate coating does not heat up very well on a sunny day.

Favorable physical properties. Slate is non-combustible, resistant to moisture, well absorbs noise during rain, hard enough to withstand the weight of a person.

Opponents of the use of slate coating point to the following disadvantages:

Compound. Slate sheets are made from a mixture of cement and asbestos fibers. Fibers increase the strength and fire resistance of the material, but at the same time, it has been proven to harm human health (if asbestos dust enters the respiratory tract).

Appearance. Over time, slate roofs tend to grow moss. The disadvantage is corrected by timely treatment with a primer; at the same time, the hydrostability is additionally increased, and, hence, the service life of the coating.

The weight. The slate sheet weighs about 20 kg. For installation, a strong truss system and sufficient physical strength of the performers will be required.

fragility. The material is damaged quite easily and requires careful handling during transportation, installation and operation.

Causes of defects

On roofs with gentle slopes, the service life of slate is estimated at 15 years, with steep slopes - up to a quarter of a century. But in practice, it turns out that slate roof repairs are required much earlier. The reason for most roofing defects is the low impact strength of the material. After the first ten years of operation, traces of time are visible on the asbestos-cement surface: chips, deformations and cracks, and sometimes holes. The inevitability of repair work is provided by the following reasons:

Poor quality material. This distinguishes handicraft slate, the manufacture of which was carried out with violations of the mixture formulation and technology.

carelesstransportation and storage. Microcracks are difficult to detect, but they will appear during installation work- the sheet will split at the first impact or when walking on it.

Impact loads. Mechanical impact is the most common cause of slate failure. A gap or crack in a leaf can occur due to the impact of a falling branch, stone or hail.

Roof parameters selection error. If the angle of inclination for the roof is not suitable for this material, the sheets will experience excess stress (until they crack).

Mounting errors. The sheet may break or crack if you try to fasten it too hard to the batten. Incorrect choice of fasteners (for example, using nails without rubber gaskets) or inaccurate hole making leads to cracks.

biothreat. The surface of the slate has a rough structure, on which any organic matter lingers well, and mosses, mold and lichens settle over time. These uninvited green guests not only reduce the aesthetics of the roofing, but also successfully destroy it, penetrating into the surface layer.

Weather and time. Slate withstands 25-30 freeze-thaw cycles without change performance characteristics. After that, the strength and water resistance begins to gradually decrease.

Types of defects and how to detect them

All these troubles will sooner or later lead to the need to repair the roof of slate. The main problem is the timely detection of defects (usually cracks), which is not difficult in the case of a smooth metal roof, but difficult on a rough, heterogeneous slate surface. Leaks not detected in time open the way for moisture to the under-roof space, the thermal insulation is saturated with water and ceases to perform its functions, the rafter system suffers, and serious repairs await you.

On our website you can find contacts construction companies who offer . You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

A slate roof (especially after a long service life) requires careful attention. Experts recommend inspecting the under-roof space after each shower. The presence of a problem at the very beginning may be indicated by the smell of dampness. The first visible sign is the appearance of a mold spot, which clearly indicates the location of the leak. If no cracks are visible from the inside, you can additionally inspect the joints of the sheets with slate nails through the light using a flashlight. Cracks in the surface of the slate need different repairs, damage can be classified as follows:

A small crack on the upper (protruding) wave. Such a defect often occurs after severe frosts. It is easiest to notice it during an external examination, since water does not stagnate under such minor damage, and a leak is observed only after heavy rain. This is the most harmless defect that can be easily corrected.

On our website you can find contacts of construction companies that offer. You can directly communicate with representatives by visiting the exhibition of houses "Low-Rise Country".

Crack in the bottom wave. A defect usually leads to leaks, since the low point is the place where moisture constantly stagnates. The main problem during the repair is to achieve the necessary tightness.

Crack across the wave. The most unpleasant option, difficult to repair and with long-term consequences - such cracks tend to expand, capturing neighboring waves.

Significant crack or break. The result of a missed small crack, severe mechanical damage or a careless walk. The older the roofing, the easier they occur.

Skol. The usual place for the occurrence of chips is the edge of the roof, the reason is icicles, a particularly snowy winter, or an unsuccessfully fallen branch.

Moss. Harmless, at first glance, the plant is able to turn a slate leaf into dust, which will result in overhaul with an appropriate budget. It is much more practical and cheaper to take care of the problem on time (as in other cases).

Video description

About sealing cracks on the roof of the garage in the following video:

Repair types

Despite the fact that slate roofing is characterized by low resistance to damage, most are easily fixed with local repairs and minor cash outlays. In general, the repair of a slate roof according to the degree of intervention is divided into three types:

Small. Successfully copes with small defects, cracks or minor holes. In such works, modern sealants and bituminous mastics have proven themselves well.

Partial. In some cases (large break, long transverse crack), the replacement of the damaged sheet is inevitable. It is not difficult to do this - a slate roof is a maintainable structure that allows the replacement of individual sheets. Along the way, you can check (and, if necessary, improve) the condition of the layers of hydro and thermal insulation.

Capital. It is carried out with extensive malfunctions, most often caused by the venerable age of the roof. Usually it is accompanied not only by the replacement of the slate coating, but also by the leveling of the base, the complete or partial replacement of the elements of the roof structure.

Preparation for repair

Before starting work, it is necessary to carry out preparation, which consists in the following activities:

Surface preparation. The roof is thoroughly cleaned of debris, earth and any organic matter; to treat areas with cracks, a brush with stiff bristles is additionally used. After mechanical cleaning, the slopes are doused with a stream of water from a hose and allowed to dry.

Work comfort. For support, a ladder, a board with bars stuffed across or a ladder are used to help evenly distribute the load. Put on feet rubber boots, which will help to conveniently and safely sit next to the problem sheet and not push through the neighboring ones.

Work safety. The specificity of slate makes you take care of the protection of the respiratory system. The best option there will be a respirator, in the absence of which you can use a gauze bandage (glasses will also be useful).

Video description

About slate repair bituminous mastic in the next video:

9 ways to repair

In practice, for the repair of slate coating are used various technologies and materials, the most common are the following techniques:

Using bituminous resin. Resin, heated to 150 °, fills the cracks; after drying, the resin forms a waterproof film. Such work requires a professional approach, given the toxicity of fumes and the temperature of the repair composition.

Using bituminous sealant. bituminous sealant forms a non-shrinking seam and provides long-term water-resistant sealing and crack sealing. The material has excellent adhesion (adhesion) even with a wet surface; available in jars and tubes (which is somewhat more expensive, but much more convenient).

Slate Roof Repair Tape. Self-adhesive bituminous tape is easy to use and provides an instant seal. One side of the material is covered with a bitumen layer protected by a film (removed before work), the other side is laminated with aluminum foil. The tape is resistant to changes in humidity and temperature and has a long (15-20 years) service life.

Cement based mixtures. cement mortar in composition it is close to asbestos-cement slate, which makes it possible to obtain a strong seal. cement mixtures prepared immediately before use, there are various recipes. Slate repair can be carried out with a mixture of cement and liquid glass, or cement and sand with the addition of tile adhesive (PVA). A common solution is a mixture of cement, tile adhesive and asbestos (in this case, you should worry about personal safety and stock up on a respirator). Initially, these methods were widespread, but, with the advent of modern and effective waterproofing agents, they are gradually becoming a thing of the past.

A mixture of drying oil and chalk. budgetary folk remedy- the crack is filled with the prepared mixture, and after drying, it is masked with oil paint. The method has a significant disadvantage - due to heating by sunlight, the plasticity of drying oil decreases, the seam may lose its tightness.

Finished putties. Mixtures with waterproofing additives in the composition are used. In order for the waterproofing to be of high quality, work is carried out in dry cloudy weather. The repair turns out to be multi-layered: a mixture is applied to the crack, after a certain time, fiberglass is laid on top, which is covered with a second layer of putty.

Roll roofing material. Bituminous coating, which is intended for arranging a soft roof, is quite suitable for repairing slate. A piece of membrane is applied to the cleaned and degreased place with a defect. right size with heated back. For heating, small cylinders with a roofing gas burner are used.

Video description

About washing slate under high pressure in the next video:

Latka. If the gap in the roof is too large to be sealed with mortar or tape, a slate sheet patch is used. It is applied to a sheet with a defect, previously treated with a sealant (glue or hot bitumen). The patch can be cut not only from an asbestos-cement sheet, but also from ondulin (polymer slate) or corrugated board (if the wave matches).

Moss removal. Fighting treacherous vegetation with a stiff broom is ineffective, and it increases the risk of damaging the roof to the point that major repairs are required. Manufacturers offer sprays for the destruction and prevention of the appearance of moss, lichen and mold. The liquid is sprayed on the infected surface, after a few hours all organic matter is removed with a brush with water. To prevent moss from reappearing, the roof is primed and covered with weather-resistant acrylic paint.

Sheet replacement. It is carried out if the previous methods are not able to cope with numerous damages. Sheet replacement will require a team of 2-3 people - the material is heavy and requires careful handling, which is difficult to provide alone.

Conclusion

If cracks appear simultaneously in different places on the roof, this almost certainly indicates that the installation was carried out without observing the technology. In this case, the destruction process caused by the internal stresses of the material will continue, and it will not be possible to stop it by conventional methods. To relieve the load, it is recommended to drill a hole in the crack, fix it with a self-tapping screw and treat the edges with a sealant. Periodic (once a season) inspection of the slate roof, careful care and preventive measures will help extend the life of this unpretentious roofing material.

Wave roofing is a popular solution for small houses, outbuildings and garden dwellings. Due to the low cost and ease of installation, asbestos cement roofing material does not lose its relevance and is in demand in low-budget construction. Despite its advantages, it has poor resistance to mechanical damage, and therefore it often needs repairs. This article will tell you how to repair a roof covering with your own hands, repair a crack or replace a whole sheet.

Experienced builders consider a slate roof to be durable, since the life of the asbestos cement coating lasts 15-20 years. It perfectly resists the penetration of moisture, does not corrode, rot and is a dielectric. However, even with time, traces of intensive use appear: cracks, chips, minor deformations, holes. Asbestos cement roof repair is inevitable due to the following reasons:

Important! Slate is a fragile material that should be transported and stored with care. When buying, pay attention to the integrity of the sheets. If there are small cracks on the surface, the material cannot be used, as it will crack from the first blow of the hammer.

The advantage of asbestos cement is that you can repair and even replace several damaged sheets with your own hands, without spending money on professional roofers. Most problems are solved by observing the installation technology and preventive measures roof protection.

Crack repair

Most often, damage to a slate roof manifests itself as small and medium-sized cracks. Homeowners do minor repairs with their own hands, sealing gaps in the roof with various putties that prevent moisture from penetrating. Cracks can be repaired in the following ways:

Note! Before starting work on replacing slate or repairing cracks, carefully study the condition of the roof. Sometimes it is more rational to perform a complete reconstruction, without wasting money and time on partial repairs that will not bring benefits. When rebuilding a house after purchase, it is better to completely open the roof in order to assess the "viability" of the truss frame.

Sheet replacement

If the roof has a lot of damage and cracks, the use of a variety of sealants, mastics or putties will not stop the destruction of the roofing. She will need a major overhaul, that is, the replacement of part of the slate sheets. To complete this task with your own hands, you need to get 1-2 assistants, because due to the large weight of asbestos cement, it is very difficult to do it alone. Replacement is carried out according to the following scheme:

Important! In order not to bring the matter to an expensive reconstruction, they carry out preventive maintenance and seasonal maintenance of the slate roof. The surface is cleaned of dirt, moss using a grinder with sanding attachment or a metal brush, treat with a primer and apply 1-2 coats of paint. This measure strengthens the asbestos cement hydro-barrier, strengthens the structure and prevents the spread of mosses and lichens.

Compliance right technology installation, seasonal inspection, preventive measures extend the life of slate roofs. With careful care, judging by the experience of builders, they can “survive” the service period guaranteed by the manufacturer twice.

Video instruction