Barbecue from a small gas cylinder. We make a barbecue grill from a gas cylinder

Practical and reliable barbecue grills, as well as other grill options, are obtained from gas cylinders. After studying the instructions, you can easily make them yourself.

Pros and cons of homemade barbecues

The material and design of the cylinders determine the advantages of barbecues:

- thick walls made of high-quality metal are resistant to high temperatures;

- multifunctionality - the made design can also be used for smoking or frying foods, roasting vegetables;

- ease of use - after cooking, the brazier is closed with a lid, it is not necessary to extinguish the coals;

- savings - buying a cylinder is cheaper than buying sheets of metal, but often even this is not necessary, since many people already have unnecessary containers on the farm;

- speed and ease of manufacture - the dimensions and design of the cylinders are such that a minimum of actions is required to create a brazier, and special skills are not needed and all the work takes little time.

There are few shortcomings. Some do not like the large size, bulky design. Others consider the semicircular bottom of a homemade barbecue, which is inconvenient for lighting firewood, to be a minus.

The spherical design of the brazier is considered by some to be a plus (meat is evenly baked), and by others - a minus (the aroma of meat is not revealed)

Preparatory actions

At this stage, choose gas bottle prepare diagrams or drawings with dimensions, materials and tools.

This is a fairly simple building. To create it, complex drawings are not needed, but it is advisable to make a diagram with dimensions. This will help determine the amount of materials required and plan the order of actions.

You can also consider the drawings offered on the network: they will help to make useful changes to the proposed version of the brazier, improve it or simplify the manufacturing process

What will be required

In addition to the balloon itself, the following materials will be required:

- pieces of corners and pipes made of steel;

- door hinges;

- metal handles (they are needed for the lid);

- for a chimney: a pipe with a knee (at an angle of 90 degrees) - diameter 100 mm;

- bolts and nuts;

- materials for decorating and finishing the structure - primer, thinner, paint, selected decor, etc.

Of the tools you need:

- welding transformer;

- grinder (angle grinder), as well as cleaning and cutting discs for it;

- electrodes with a diameter of 3–4 mm;

- electric drill and drills for metal;

- clamps - necessary for fixing metal parts;

- long metal ruler;

- core;

- brushes for coloring the brazier (you can also use a brush attachment on a drill to simplify the painting process);

- gas, adjustable wrenches and a set of wrenches.

Cylinder selection

Fits a 50 liter tank. Its design allows you to use skewers at full length, and therefore cook faster for a large number of people.

If you need a mobile and light brazier, take a 27 l cylinder.

The wall thickness of such containers is at least three millimeters, so even those products that have been outside for a long time can most likely be used. The main thing is to check for corrosion. If it is, it is better not to take such a balloon.

Safety rules for working with cylinders

When working with gas cylinders, follow three simple safety rules:

Do-it-yourself brazier from a balloon: step by step instructions

It is better to assemble the structure on a flat area so that the brazier is stable. The work consists of the following stages:

- Dismantling the valve and marking the cylinder.

- Cutting the container.

- Leg making and assembly.

- Finishing - painting and other works.

Dismantling the valve and marking

If the valve has not been untwisted before, this must be done to make sure that there is no gas in the cylinder (perform the actions described above with water) and its further safe use. To work, you need an adjustable or gas wrench.

The cylinder valve is unscrewed, and a chimney pipe is welded to the place where it was located

If the valves cannot be unscrewed in any way, the crane is cut off with a grinder. The resulting hole is used to install the chimney, that is, a pipe is welded to it.

As a chimney, you can use a piece of any thick-walled pipe with a knee

- Each container has a welding seam along the length - this is the first marking line. From it, at a distance of 24 cm in both directions, you need to draw the second and third marking lines with chalk: they divide the balloon in half (its diameter is 96 cm). It is convenient to do this with a tape measure and a ruler.

- From the first line, mark 10 cm to the right and left, draw two more in parallel (3rd and 4th marking lines). They will have holes for air.

- On the top side of the brazier, make marks for the lid. Add 10 cm to the 3rd line and draw the fifth.

- Step back from the circular welds at the bottom and top of the cylinder 3 cm inward (i.e. towards each other) and draw lines. In these places there is a tape reinforcing the seams, which cannot be damaged while cutting the brazier. Therefore, put marks at a distance from it.

- Divide the 2nd and 3rd lines into equal parts (8–10 cm each). These are marks for drilling holes for skewers.

A pre-compiled diagram of the cylinder will help to correctly mark up the container for opening

Opening the cylinder and making the cap

According to the markup made with an angle grinder, cut out the cover:

To subsequently reduce the inconvenience when installing the cover on the body, immediately weld the hinges along the line of the first cut.

Limiters are welded along the circular edges of the structure. They can be made in different ways, for example, from a chain with large rings or steel corners. The distance to which the lid will open is chosen so that the structure does not close itself and at the same time the lid can be conveniently opened by the handle.

It is convenient to use ready-made metal loops

Instructions for making legs

The resulting brazier must be installed on the legs. There are several ways to do this:

- Weld four corners or pieces of steel pipe to the body. The attachment points of the legs must be marked so that the structure is stable. The recommended height of the brazier is no more than one meter from the ground to the level of the holes for the skewers.

- Make a frame out of metal pipe(side posts) and semi-circular steel bar elements welded to the posts. The two parts of the structure are connected according to the type of underframe, using a metal profile for this. Next, the brazier body is installed on semicircular parts and welded for reliability.

If metal wheels are attached to the legs of the brazier, the design will be more mobile.

Racks with a metal bed are more reliable and practical than legs made of steel pipe cuts

Barbecue finishing

The final stage of work is painting. best material for this - heat-resistant paint, which is usually used for painting mufflers. Silicone paint is also suitable for finishing barbecues, fireplaces, metal stoves. But these materials are expensive and difficult to apply.

More affordable option- mineral bitumen resins. Such coatings are practical and durable, but dry for a long time and have an unpleasant odor. To get rid of it, as well as to strengthen the coating, you need to wait until the composition is baked, that is, just use the barbecue for the first two or three times, without cooking kebabs. Apply the material in 3-4 layers. It is important that the previous layer is completely dry.

You can decorate a home-made design in an unusual way, add decorative details and get, for example, a brazier in the form of a steam locomotive, a piglet, etc.

Photo gallery: unusual options for homemade barbecues

Brazier with a cauldron is easy to decorate in the form of a steam locomotive

Brazier with a cauldron is easy to decorate in the form of a steam locomotive  One of the most simple options unusual design brazier - make it in the form of a pig

One of the most simple options unusual design brazier - make it in the form of a pig  If the legs of the barbecue pig are made of thin pipes, for the stability of the structure it is better to strengthen them with transverse inserts

If the legs of the barbecue pig are made of thin pipes, for the stability of the structure it is better to strengthen them with transverse inserts  The body of the brazier can be decorated, for example, with metal leaves

The body of the brazier can be decorated, for example, with metal leaves

Other types of grill from cylinders

From such containers they also make:

Features of the use of barbecues made by hand

To cook always delicious barbecue on a new home-made barbecue and increase the life of the structure, do not forget about simple rules use of this useful facility:

- watch the heat - properly heated coals are red with a gray coating;

- do not turn the skewer often - for uniform roasting of the meat, this only needs to be done twice;

- in the zone with maximum heat, cook meat, and in others - vegetables or fish;

- do not bring the brazier into the room, for example, when it started to rain - this will worsen the draft, which means it will increase the amount of carbon monoxide in the air;

- do not place the structure close to flammable objects;

- do not throw away the ashes immediately after use to prevent fire: it smolders for up to a day.

Video: how to make a brazier yourself

Creating a brazier from a gas cylinder is not an easy task, although it is doable. Even the minimum skill of using the tools required for this job will be enough. And even if they don't, it's never too late to learn something new. The main thing is to carefully read the instructions, follow the recommendations of experts and always follow the safety rules.

Holidays outside the city, whether it is a summer cottage or a picturesque glade in the forest or near a pond, very often involves cooking barbecue. Of course, for this you can get by with a few bricks and a couple of metal crossbars, but the real pleasure of cooking meat on skewers can only be obtained next to a convenient and practical barbecue. A solid construction can be made from thick sheet metal. If there is no such thing on the farm, then you should not rush to the construction market. An excellent device for cooking meat can be built with your own hands from an ordinary gas cylinder.

Features of a brazier made on the basis of a tank for liquefied gas

The city gas cylinder is an excellent base for many improvised designs. Good solid metal, almost finished shape and several standard sizes allow you to get a potbelly stove, boiler with minimal effort indirect heating, autoclave and other necessary equipment in the household. The thick walls of the liquefied gas container can withstand high temperatures, so it is the best suited for making a smokehouse, barbecue or barbecue. Other advantages of the design are also known:

A brazier built from a tank for household gas has practically no drawbacks. Some consider large dimensions to be a minus, but what prevents them from taking a smaller cylinder, for example, 27 liters? The negative aspects include perhaps the semicircular shape of the bottom, which is not very convenient during the ignition of firewood. On the other hand, with this configuration, the coals will be closer to the edges of the skewers. Due to this, the outer pieces of meat will be better baked, which, when cooked on a traditional rectangular roaster, often remain raw. Experts believe that the spherical walls of the brazier are not entirely suitable for cooking barbecue, as they interfere with processes that help the rich aroma of baked meat “open up”. In the future, we will touch on this issue, revealing the secret of how to avoid the disadvantages associated with the round shape of the bottom.

Preparatory activities

Before you pick up welding machine, you need to pick up a gas cylinder and prepare it for work, draw up a rough sketch of the future barbecue and stock up on the necessary tools and materials.

Which bottle can be used

For the manufacture of brazier, any gas cylinders of a cylindrical shape are suitable. The best option is quite capacious and the most common 50-liter container for household propane-butane. If you want to get more mobile and lightweight construction, which can be transported in the trunk passenger car, you can take a standard cylinder of 27 liters. It should be borne in mind that the width of the working space of a portable barbecue may not be enough due to the spherical shape of the sidewalls.

Gas cylinders are made of high-alloy low-carbon steels 30XMA, 45, 34CrMo4, 30XGSA. The high content of ligatures and the reduction in the amount of ligatures in the metal makes the alloy more durable and improves anti-corrosion properties.

An ideal option for a stationary barbecue would be a car gas cylinder of 50–80 liters. It has an increased diameter, so it will be much more convenient to kindle firewood. In addition, such a vessel has a high capacity. Its width makes it possible to use the entire length of a standard skewer, and this will allow you to cook dinner for a large company. The only caveat is that finding an unnecessary car gas tank will not be easy, and buying a new one will not be financially feasible.

Gas cylinders are made of high-quality alloy steel with a thickness of 3 or more millimeters, so even if the container has been standing in the open for a long time, it is likely to be usable. If the vessel is very rusty, then you should not waste time on it - it will not be difficult to find a workpiece in good condition.

How to protect yourself from an explosion

Even if the valve of the used container is completely unscrewed and the gas does not come out of it, do not rush to take on the grinder. Despite the fact that inside the cylinder the pressure was equal to atmospheric pressure, most likely, unsafe substances remained in it - propane-butane and condensate. The latter is drained by turning the vessel upside down, and in order to completely remove the explosive contents, the cylinder is filled to the top with water and left for several hours. Only after this requirement is met and the liquid is drained, you can start cutting and welding metal.

Schemes and drawings

The brazier from a gas cylinder is such a simple structure that it does not require careful design. Nevertheless, at the preparatory stage, it is recommended to draw up a small drawing or sketch of the future structure, indicating the dimensions of all its elements. This will make it possible to determine how much and what kind of rolled metal will be required, and will also allow you to properly plan individual processes. Perhaps the drawings and diagrams presented in our gallery will help you in working on the barbecue.

Gallery of drawings and diagrams

Scheme of a brazier with a supporting structure

Scheme of a brazier with a supporting structure  Drawing of a brazier from a 50-liter gas cylinder

Drawing of a brazier from a 50-liter gas cylinder  The design of the brazier from a gas cylinder

The design of the brazier from a gas cylinder  Scheme of the movement of heated air

Scheme of the movement of heated air

Materials and tools necessary for work

In addition to the gas cylinder itself, you will need:

- pieces of steel pipes and corners;

- metal handles for the lid of the barbecue;

- door or furniture hinges;

- pipe with a diameter of 100 mm with a 90-degree elbow, if you plan to install a chimney;

- grill, which will be needed for barbecue;

- bolts with nuts or rivets.

In addition, you should prepare decorative elements designed to refine the structure, as well as the primer, paint and solvent that will be needed to paint it.

If we talk about tools, then we are sure that everyone who is interested in the issue of building a home-made barbecue will find them:

- welding transformer or inverter;

- angle grinder - angle grinder (colloquially "Bulgarian");

- electrodes Ø3–4 mm;

- cutting and cleaning disc for angle grinder;

- electric drill;

- a set of drills for metal work;

- clamps for fixing metal parts;

- long metal ruler;

- scriber;

- core;

- adjustable and gas key;

- set of wrenches.

If, after manufacturing, the brazier will be painted, then additionally prepare a brush attachment for a drill or grinder, as well as brushes or a spray gun with a compressor.

Making a brazier with your own hands from a household gas cylinder of 50 liters

Installation work is best carried out in a well-ventilated area or on outdoors. The place where the assembly will be performed must be fairly even, otherwise it will not be possible to ensure the correct geometry of the structure and the brazier will be unstable.

When carrying out locksmith work, it is important not to forget about the safety rules, be sure to use protective equipment and overalls.

Step-by-step instruction

- Unscrew the valve. To do this, use a gas or adjustable wrench. Sometimes the shut-off valves turn sour so much that there is no way to unscrew it. In this case, the tap can be cut off with an angle grinder. Using the same tool, they cut off the lower support rim - with it the design will look unaesthetic.

- Mark the cutting points. The diameter of the 50-liter propane-butane tank is 960 mm, which allows it to be accurately divided into four parts. It is convenient to take a longitudinal seam as a reference point. Putting the balloon on flat surface, from the welding line in both directions, measure a quarter of the diameter - 240 mm and apply horizontal markings that will divide the cylinder in half. An indent of at least 30 mm is made from the attachment line of the upper and lower parts of the vessel, after which circular lines are drawn. The distance between them is divided into equal intervals of 80-100 mm, on which the skewers will be laid. After that, mark the lid of the barbecue. Its length should be less than half the diameter, so 100 mm are measured from one of the longitudinal lines towards the horizontal weld. A parallel drawn strip will indicate the place of the cut.

- Having installed a cutting disc on the "grinder", they cut a line that divides the diameter of the cylinder in two. After that, the slot is marked into equal parts and the loops are welded. Their number can be from two to four (depending on size). After that, the cover is cut out along the circular marks, as well as the longitudinal line, which is located at a distance of 140 mm from the horizontal seam.

Do not rush to cut the entire cover at once. Subsequently, this will entail a lot of inconvenience associated with its correct orientation, setting gaps, etc. It will be problematic to do this without an assistant. If the loops are immediately welded along the line of the first cut, then in the future it will be possible to save a lot of time and nerves.

- In order for the upper door to be held in the desired position and not to break the hinges when tilted, limiters must be welded along the cut line. You can make them from 20–30 mm pieces of a steel corner with a shelf width of 40–50 mm. Fixing stops are mounted on both sides - this will avoid distortion of the cover.

The distance at which the door will recline can be changed by unbending the latches to the desired angle. At the same time, a position is chosen in which it will be possible to easily reach the handles of the lid, without leaning forward much, and at the same time will not allow the structure to spontaneously slam shut.

- In order to prevent the door from falling inward when closing, a limiter must be welded around the perimeter of the circular cutouts. To do this, a strip 30–40 mm wide is cut out of sheet steel with a thickness of 1–3 mm. It is attached from the inside of the balloon with an interrupted seam.

Instead of limiters, you can use a piece of chain of the desired length, welding it with one end to the barbecue, and the other to the lid.

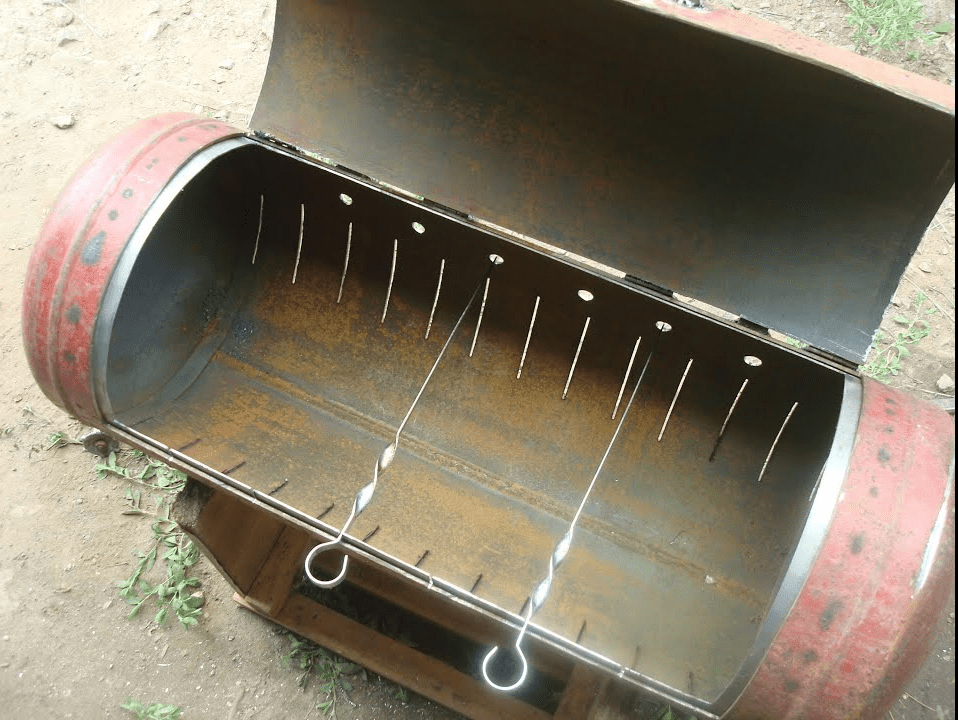

- Below the loops, a series of drillings Ø12–14 mm are made for skewers. Previously, these places were marked along the dividing line of the diameter. Slots or triangular cutouts are made on the front wall opposite each hole, on which skewers will be placed.

- Mount handles for opening the lid. For this, factory products with overlays made of wood or refractory composites are best suited - they will not allow you to get burned. In extreme cases, the handle can be made by bending a piece of metal bar or reinforcement in the form of the letter “P”.

- At the next stage, holes are cut in the bottom of the brazier for air to enter the combustion zone. To do this, the structure is turned over with the lid down, measured from the longitudinal seam 100-120 mm in each direction and horizontal lines are drawn. Setting aside 100 mm from these marks, strips are obtained, in which cuts are made every 50 mm. Drilling can be done instead of slots. In this case, holes with a diameter of 10–12 mm are made in a checkerboard pattern.

Cutting through the bottom for air supply is impractical for a number of reasons. Firstly, this will weaken the weld, which makes the structure more rigid, and secondly, the holes will quickly become clogged with fatty deposits mixed with ash and ash, and will cease to fulfill their functions.

- The hole for the valve must be welded. If the brazier is also planned to be used as a smokehouse, then the opening is expanded to the diameter of the chimney. After that, a chimney is welded to the cylinder.

On this, the main part of the work is considered completed. It remains to install the brazier on the legs and ennoble interesting decor or just paint the structure with heat-resistant paint.

Installation of supports for barbecue

There are several options for installing the brazier on legs, which is facilitated by the rather thick metal of its body. The first and easiest method is to weld four pieces of steel pipe or angle directly to the hull. Of course, the attachment points must be carefully verified, and in the process, use a square and building level, otherwise the design will look askew and untidy. Everyone makes the height of the brazier for themselves, but there is also a standard recommendation - the distance from the ground to the plane of laying the skewers should be no more than 1 m.

It is worth noting that the method described above cannot add presentability and convenience. If you want to get a stylish, practical structure, then for this you need to make a frame-type support. To do this, a pair of side racks is made from a profile metal pipe 20x20x2 mm. In its upper part, a semicircular bed is welded from a metal tire, curved in the shape of a cylinder. Between themselves, both parts of the structure are fixed with the same metal profile so that a kind of underframe is obtained. The balloon is placed on the prepared bed and tacked by welding. In order to make the brazier more mobile, metal wheels can be attached to the legs.

A brazier made from a household gas cylinder can be taken with you when outing into nature. In order for it not to take up much space in the trunk of a car, the supporting structure is made collapsible. All that is needed for this is a 40-centimeter piece of pipe with an internal diameter of 18-30 mm and a 3-meter pipe with a diameter of 16-28 mm. The main requirement is that when they are paired, the gap should be small, otherwise the brazier will be unstable.

By cutting a short piece into four equal parts, couplings are obtained, which are welded to the cylinder at the installation sites of the supports. After that, the brazier is installed on the legs and through drilling is performed to fix them inside the couplings. Pins inserted into these holes make it easy to carry assembled structure- tubes will not fall out. In addition to the sides of the portable brazier, carrying handles can be welded. By the way, during the transportation of the structure, all legs, firewood (or a package of coals) and ignition fluid can be placed inside. Such optimization will save a lot of space in the trunk.

Gallery of ready-made homemade barbecues

The side walls of the structure can be designed in the form of a funny pig

The side walls of the structure can be designed in the form of a funny pig  Steam locomotive styling

Steam locomotive styling  support structure can be made from old sewing machine

support structure can be made from old sewing machine  Barbecue with bottom shelf and firewood box

Barbecue with bottom shelf and firewood box  Styling the brazier under a submarine

Styling the brazier under a submarine  Shelf, located under the grill, will be very handy during cooking

Shelf, located under the grill, will be very handy during cooking  Universal building with barbecue, smokehouse and barbecue

Universal building with barbecue, smokehouse and barbecue  Additional work surfaces make the design more practical

Additional work surfaces make the design more practical  Is it still a brazier or already a steam locomotive?

Is it still a brazier or already a steam locomotive?

How to bring the design to perfection

The ease of manufacture and other advantages of a barbecue grill from a cylinder are somewhat overshadowed by the conclusions of barbecue experts that the meat in them is not as tasty as in traditional braziers. Careful examination of the problem revealed several failures.

- Due to the rounded bottom, the layer of coals in the center and along the edges differs in height. This heterogeneity leads to the fact that the firewood that is on the periphery burns out much longer than in the middle of the bookmark - the heat in the center settles much faster.

- The spherical walls emit infrared rays not towards the kebab, but towards the coals, which further enhances the effect described above.

- Unlike a flat-bottomed structure, the supply of oxygen to the brazier made from a round container is uneven.

It turned out to be quite simple to eliminate the shortcoming that did not allow to get the “right” barbecue. Refinement of the brazier requires the arrangement of a longitudinal duct along the entire length of its bottom. To do this, you need a steel corner with dimensions of 80 × 80 mm and a length of 900 mm. In both of its shelves, holes with a diameter of 12–15 mm are made in increments of 50 mm. The air duct is welded into the bottom so that both of its edges remain outside. The essence of the improvement is more clear from the presented figure.

How to paint to "cheap and forever"

A metal structure must be painted for both aesthetic and practical reasons. Unprotected steel will quickly rust, which will add neither beauty nor durability to the structure. Any heat-resistant paint intended for automobile mufflers is best suited for painting the brazier, however, its high price and complex application technology do not allow us to call this option ideal. The same disadvantages have silicone-based paints, specially created for painting. metal furnaces, fireplaces, barbecues and barbecues.

A cheap and practical material is Kuzbass varnish and similar mineral compounds based on bituminous resins.

The coating should be carried out in 3-4 layers, with a complete intermediate drying after each application. Of course, there is no need to paint the inner surface of the brazier - a soot coating, on the contrary, will contribute to obtaining an ideal product.

The disadvantages of this method are a long drying time and unpleasant, toxic fumes. In addition, the paint remains fragile for a long time, therefore it requires careful handling. The first 2-3 fires are best done "idle". This will eliminate the smell, make the coating more durable and safe. When mineral composition sintered, it will be very difficult to damage it. Practice shows that such a composition does not require updating for decades.

Video: how to build a brazier from a gas cylinder in three hours

Many options for barbecues built on the basis of a gas cylinder allow you to build a practical, functional and original design. It can be placed under a canopy or in a gazebo, installed in the open air or made completely mobile. A properly built brazier gives a soft and even heat, which makes the kebab soft and juicy. Therefore, all that remains to be desired is good company and bon appetit!

Those who often fry kebabs and barbecues in the country know how unreliable and fragile store barbecues are. The heat turns out to be small, the structure bends and creaks, the dimensions are somehow non-standard, and contrary to the assurances of the sellers, the structure quickly rusts. Maybe stop wasting money on unnecessary things? If your country house has an old gas cylinder, it is quite possible to make not only a brazier, but also a chic smokehouse from it. How to make a brazier from a balloon correctly? Our article is about just that.

Instrument preparation

To build a gas barbecue with your own hands, you will need the cylinder itself with a capacity of 50 liters and a height of 120 centimeters. In our opinion, these are the most successful sizes, allowing you to cook a sufficient amount of food at a time.

Having taken out the old cylinder from the barn, carefully inspect it. The product is considered suitable if there is no corrosion on it. Otherwise, rusty places will burn out, and instead of a high-quality brazier from a gas cylinder, you will get an obscene sieve.

Naturally, in addition to the barbecue, you will need a certain set of tools. Now we will list it: a drill and a grinder, a chisel, a hammer, a screwdriver and an adjustable wrench, two loops, a metal pipe, a corner. Since the main range of work will fall on metal cutting, it is the grinder that will be your main tool in the manufacture of cylinder structures.

You can't do without a grinder

You can't do without a grinder What will we do from the balloon

Before starting work, we will consider in detail what types of barbecues can really be built from a metal gas cylinder.

There are four main varieties:

- do-it-yourself classic barbecue from a gas cylinder without a lid;

- smokehouse;

- smoker;

- barbecue.

With the first classical type, everything is clear, and it does not need extra advertising. But what exactly is the difference between the other three types, now we will figure it out.

B-B-Q represents enough simple design not only externally, but also internally. In short, you cut off part of the side, attach it to the hinges, use it instead of the door. A grid is placed inside. It is on it that you will fry mushrooms and meat.

B-B-Q

B-B-Q Do-it-yourself barbecue grill from a gas cylinder is good because you can fry almost everything on it. The preparation will be quick and easy.

What is the feature smokehouses? It turns out that she has her own firebox, and the design itself is surprisingly airtight. To make a smokehouse, as in the photo, a strip of metal is cut out at the bottom, part of the bottom is also sawn off. The firebox, which is made of strong iron or a second cylinder, is welded. For unhindered removal of smoke, a pipe is welded. As soon as the smokehouse is ready, it is thoroughly ignited with firewood 2-3 times.

Smokehouse

Smokehouse And what is this steam locomotive? Don't be surprised, but smoker people actually call it that. Assembly is more difficult, but the design is many times more functional. It combines absolutely everything: a grill, a smokehouse, a barbecue from gas cylinders. To build a super unit, you will definitely need 2-3 cylinder pipes. Each will have its own option.

All in one - smoker

All in one - smoker We open the bottle correctly

It doesn’t take a great physicist to understand that when working with equipment that is somehow related to gas under pressure, safety should always come first. So it’s definitely not worth throwing yourself at a balloon with a grinder. There must have been some propane left inside, and any spark could backfire.

armed wrench, carefully unscrew the valve and wait until the gas has completely evaporated. Then turn the structure upside down and drain any condensate that has formed. By the way, it is easy to monitor the output of propane. To do this, a little soapy foam is applied to the valve. As soon as it stops bubbling, work continues.

The design is laid on its side, the valve is sawn off. The place of sawing is constantly watered. The last step is to attach a hose to the cut and fill the container with water to the very top. From time to time the cylinder is shaken so that the inner surface can be washed from the remaining gas.

From cutting to installing legs

Many users are interested in what video instructions and drawings you need to use when you plan to make a brazier from a gas cylinder without outside help. We explain - the process itself is so simple and understandable that you can easily do without a drawing. The end result and procedure depends entirely on your personal preferences.

And here is a good example. The owner of the house wants to make a barbecue, but plans to use only a grill and ready-made coals. In this case, the distance between them must be made small. Our advice is to cut the balloon exactly in the middle. If every time you plan to burn real firewood and use skewers from time to time, the lid is made smaller than the base.

When the metal container is completely washed and dried well, all you have to do is cut it lengthwise. The result is two open classic barbecues. One will be the basis for coals, the second can be scrapped, used to create a cover or given to a neighbor - also for making a barbecue.

From the balloon you can make two braziers at once

From the balloon you can make two braziers at once But those who make a barbecue from a gas cylinder with their own hands will have to go the other way. You will need a “pattern” of a rectangle that will become a lid. We leave the second part as a basis.

To do this, draw a rectangle from the cut lines on the surface. Make sure that the horizontal lines pass strictly in the middle of the balloon, and the transverse lines - 20 centimeters from the edge.

How to cut a barbecue container with a lid

How to cut a barbecue container with a lid How to properly cut?

Your business is really simple - pick up a grinder and cut the balloon. In order to outline the boundaries of the lid, you will need to step back from the weld that connects the bottom and base, mark the cut line.

Even if you follow all the rules, force majeure situations during the cutting process are also likely. When the cylinder has sufficiently thick walls, and the work is done intensively, by the end of the cutting, the grinder disk may simply burn out. To avoid this, we advise you to either stock up on a few discs in reserve, or do not cut each cut to the end. Subsequently, you can easily complete the work with a chisel.

Having carefully estimated what size of the brazier will be optimal for you, start attaching the legs. For the convenience of welding the roof, the structure is installed on the ground.

In the photo you can see how to make a barbecue with legs from a sewing machine. If your grandmother did not leave you such antiques, it does not matter. It may well be replaced by the underframe of a school desk. Pipes are bolted to the bottom. It is enough to make four holes, and then insert the bolts. They are either fixed with nuts or welded - you choose.

Legs for barbecue from a sewing machine

Legs for barbecue from a sewing machine The subtleties of mounting the handle

Your lid will be hinged. Therefore, care must be taken to ensure that holes are made for them. Each hinge is fixed with a rivet and securely welded. How it looks in reality, you can see in the photo.

Welding hinges to the lid of the barbecue

Welding hinges to the lid of the barbecue Welding is required because rivets may not withstand constant exposure to high temperatures and easily fall off. Some craftsmen install a removable version of the lid without hinges. In this case, metal strips are attached to the transverse edges of the structure. So the lid will never fall inside.

The fastener of the handle for the lid of the barbecue is carried out with the help of loops. Drill holes, fix - and you can safely open and close the lid. Ask your hardware store if they have handles that won't burn or heat up. Buy these. The limiter on the lid is made from a part of the pipe or corner, the lid itself is fixed with chains.

From assembly to painting - the brazier is almost ready!

Many users ask: I did everything according to the instructions, but after cooking, the brazier began to deform. What to do in this situation? To avoid this, we advise you to weld the corners to the inner edges of the base, and put a skewer or grate on the ledge. You can make the high legs of the barbecue more durable and stable if you weld a corner around the perimeter.

Why are there holes in the bottom? It's simple - they simplify the extraction of coal and the drainage of rainwater. However, something else is important - 10-15 holes will provide excellent traction from below.

The flue pipe is always installed where the valve used to be. By the way, this is a desirable but not mandatory measure, and you can do without it. This is especially true for situations where you plan to cook food exclusively with the lid open.

The pipe is usually installed in place of the valve

The pipe is usually installed in place of the valve Remember, we wrote about installing a corner for more convenient turning of skewers and protection against deformation? Not everyone attaches such a corner, and here's why. There is a completely working, alternative way - to make slots in the sides for installing each skewer.

In principle, the brazier is ready - it remains only to paint it with good paint. First of all, such a procedure is important from an aesthetic point of view. It is better to buy heat-resistant paint. It is not afraid of high temperatures and does not decompose, so the food will always smell delicious.

On sale you can find a great variety of paints and varnishes designed to work at temperatures from 600 to 800 degrees. And buy them. First, the brazier is opened with a primer, after which environmentally friendly paint is applied.

Barbecue painting (video)

Conclusion

If you have read the article to the conclusion, congratulations - you are completely ready to create a barbecue or grill from a gas cylinder. Do not forget to load a decent amount of meat, vegetables into the brazier made by yourself, and invite people close to you to visit. Let the gas grill become a symbol of hospitality and a place that will gather relatives and friends all year round!

Do-it-yourself barbecue workshop (video)

Brazier and barbecue are simply necessary for summer residents and lovers of outdoor recreation. Factory designs do not always meet all requests. Therefore, it is not necessary to buy a device for frying barbecue and meat, you can make it yourself. Homemade brazier and barbecue will not differ in any way from the factory product.

AT recent times barbecues and barbecues from a gas cylinder are very popular. Many people think that the product will turn out to be ugly and too bulky, but if you dream up a little, you can get an unusual design that will decorate your dacha.

To independently make a barbecue and a barbecue from a gas cylinder, you need to have at least some idea of \u200b\u200bthe design and its operation. Use the ready-made drawings and you will get a beautiful device for frying meat.

What are mangas?

The brazier has been used for a very long time not only by cooks for cooking meat and vegetables on coals, but also by amateurs.

Types of barbecues:

- Portable or foldable. These models are the most popular. They are convenient to take with you on nature and long trips. It takes up little space and is easy to assemble;

- Portable. These braziers are not designed for transportation, but they can be easily moved and moved to another place. Often, these are overall structures.

- Stationary (professional). These barbecues are installed in restaurants and cafes, but you can use them at home. They are very big. They put them in a certain place where there is already a special foundation stand and a chimney.

You can make a brazier from the most various materials. A conventional gas cylinder would be the ideal solution. For example, a barbecue grill. Detailed drawings and instructions will help you create this device from a conventional gas cylinder. But remember that you must provide a firebox and make your smoker airtight.

The bottom of the cylinder is cut, and you will get a hole - this will be the firebox. Usually, thick iron sheets are welded on so that the smokehouse will serve you. long years. As a result, you will get a one-piece structure, with a door and a small stove. Be sure to attach the pipe. It can be bought at a specialized store or on the construction market. It should be of medium size. Many craftsmen install a special motor with which the meat will rotate on a spit. But you can hang pieces of meat or carcasses on small hooks.

The finished brazier is worth painting. For this, non-toxic and heat-resistant paint is perfect.

Before you start cooking in a new grill, it should be properly washed and pierced. Not always once is enough. The gas may not erode for a long time.

Another type of barbecue that you should pay attention to is a brazier steam locomotive. It is not so easy to make and you will have to spend more than one day to get the finished design.

Outwardly, the brazier really resembles a steam locomotive. It can be considered a universal product, because it consists of: an ordinary barbecue, grill, smokehouse and barbecue. Masters with the help of several large gas cylinders are able to create a real masterpiece.

The basis of the brazier-steam locomotive is a gas cylinder with a volume of 50 liters. The remaining parts can be made from pipes and small barrels. If you make wheels, then you can buy ready-made ones at any store. The finished product must be painted with heat-resistant paint. In order for the brazier to serve you for a long time, it is worth taking care of it and updating the coating.

With the help of forged patterns, you can decorate the finished product. Small tables, retractable grills and various functional elements can be attached to the gas cylinder.

Brazier steam locomotive can decorate country cottage area, but with the help of it you can cook various dishes in a short time.

It is very difficult to make a brazier on your own. You need to have various skills, for example, to skillfully use welding and a grinder. These tools are very dangerous for humans. Failure to comply with safety regulations can lead to disastrous results.

How to make a brazier from a gas cylinder with your own hands?

For the barbecue, a gas cylinder with a volume of 50 liters is suitable. Small cylinders can also be used, but the design will be miniature and not suitable for big family and hospitable hosts.

Before you start work, you need to prepare a gas cylinder: completely pump out the gas and rinse it. It must be remembered that the cylinder may explode or catch fire. Observe safety precautions while working.

Preparation of tools and materials for work

It is worth starting work prepared in advance. Spontaneous work, without necessary tools and materials will drag on for a long time and will not bring the expected result.

Gas cylinder cutting tools

To make something unusual and beautiful barbecue at home, you need to have on hand:

- Bulgarian (preferably large and small);

- Welding machine;

- Electric drill;

- Clamp;

- Medium sized pipe;

- Sheets of iron (of course dense);

- Loops. They are needed for the cover;

- Rivets;

- The gas cylinder is the basis of the barbecue! It is desirable that the volume was not less than 50 liters.

How to safely disassemble a gas cylinder?

Working with a gas cylinder is very dangerous. Therefore, before making a brazier from a gas cylinder, pump out all the gas from it. It is not difficult to do this. To protect yourself and others, the empty container must be filled with cold water.

Safe disassembly of the gas cylinder

Carefully turn off the faucet and connect the water hose. The water pressure should be small. The container should be filled to the brim. After that, you can start working as a grinder.

How to pump out gas?

Pumping gas from a full gas cylinder is a fairly simple procedure. It must be turned upside down and unscrew the valve. In the inverted position of the balloon, it will come out much faster than in the normal position.

If you want to see if gas has come out or not, then lather the valve hole with laundry soap. If the gas has not yet escaped, then you will notice small bubbles. As soon as they disappear, then there is no more gas in the cylinder.

Then remove the faucet. You will need a wrench. If there are studs on the valve, then use pliers. Removing the tap, you will see the outlet. Through this hole, it is worth filling an empty bottle with water. In addition to gas, there is also an odorant in the cylinder. It gives the gas such a pungent odor. You should also get rid of it. An empty container should be washed with soapy water and filled with a solution of bleach or ammonia.

The smell disappears for a long time. Leave the disinfectant container for 3-4 days. But even such cleaning products do not always help get rid of bad smell. After the brazier is ready, kindle a fire in it, but do not fry anything. At high temperatures the smell burns out.

The balloon is usually cut along with water. You should not be afraid, there is no more gas in the tank. It is desirable to cut from the longitudinal section of the cylinder, the grinder is led tangentially.

A brazier from a large gas cylinder turns out to be standard. It can accommodate 6-8 kebab skewers.

Marks should be made along the longitudinal seam of the cylinder. If he puts marks relative to him, then everything will turn out smoothly, without crooked corners and distortions.

The outer diameter of the balloon is 96 centimeters. On both sides, from the bottom of the seam, measure 24 centimeters. Be sure to draw lines. You can use chalk or black marker.

For convenient operation, the balloon should be placed on the ground. Immediately calculate the distance for skewers, measure 8-10 centimeters. You should get 6-8 marks. Using an electric drill, drill small holes at each mark.

From the main line, where the markup begins, we count up 10-12 centimeters. From the middle of the seam is approximately 34 centimeters. There will be a brazier cover in this area.

Now you can start marking the cover. It will be located between the first line and the last. It is worth retreating from the welds about 4-5 centimeters and draw two lines. Thus, you will draw a lid on the balloon itself, which will close the brazier. It is relatively small.

We make a cover for the barbecue

The walls of the balloon are not too thick, about 4 millimeters. It is not worth cutting at the place of the seams, because the iron is much thicker here. Therefore, step back from the walls and seams by about 3 centimeters.

The lid can be made oval or square. It all depends on your idea. The lid needs to be tight. To do this, additional strips are welded to the attachment point. It is also desirable to weld the hinges. You can weld the loop to the brazier, and screw the other sash to the lid of the brazier using self-tapping screws or large screws.

Brazier with a lid, it's pretty complex structure. It will be difficult for beginners in this business to immediately make a quality product.

It will be easier to take a gas cylinder and just cut it in half. Make small indentations for skewers. Be sure to drill holes on the sides. They are needed in order for air to flow.

The last step is the legs. You can use thick reinforcement. Cut the rods of the required length and weld to the cylinder. Mangal is ready!

You can also attach a lid to it. The second half of the gas cylinder is welded to the usual loops. To prevent the lid from falling and pulling the brazier back, you can make a stopper. An armature or a chain can act as a stopper.

We make legs for the barbecue

The legs are the most important part of the brazier. If you plan to transport the barbecue, then you need to make folding legs. And if the brazier will constantly stand in one place, then there is no need for removable legs.

You can make legs from rebar or pipes of medium diameter. If the legs are non-removable, then they can be welded. Removable is better to bolt.

Making holes for skewers

Holes are created for convenience so that the skewers stand in their place without touching each other. If you decide to make holes for skewers, then measure a distance of 8-10 centimeters from the front side of the barbecue. Cut out small indentations at the base of the brazier.

We decorate the brazier

At home, making a brazier from a gas cylinder is quite within the power of an adult man. It will cost you much less than the factory version, but will not be inferior in anything. You can decorate your product with various forged elements. If your brazier has a lid, then you can install a handle on it. It is needed not only as a decoration, but also for convenience. Various patterns can be welded onto the walls of the brazier. You can make them yourself, or you can buy ready-made ones.

If you are good at drawing, you can draw beautiful drawing paints. If the brazier is dark in color, then the pattern can be light or, conversely, bright. Before decorating, it is necessary to grind all the burrs and level the metal.

From the inside, the barbecue must be painted with heat-resistant paint. It will protect your product from corrosion. Of course the paint will come off. But by this time the brazier will be covered with soot and soot, and rust will no longer be terrible for him.

What paint to paint the brazier?

A do-it-yourself brazier made from a balloon can be painted:

- Powder thermal paint. But at home you cannot cover the barbecue. It needs to be fired in special furnaces at a high temperature;

- Heat-resistant organosilicon enamel. It can withstand temperatures up to 600 degrees;

- Oxidation. great way for processing homemade barbecue. First of all, the body of the product is treated with sulfuric acid. Then the brazier must be boiled in a solution laundry soap. After that, hold for 30-40 minutes in a solution of caustic sodium. After carrying out all these procedures, your brazier will not rust and will delight you for many years.

Be sure to heed the advice of experienced craftsmen and clean the iron from old paint, rust and dirt. It is also necessary to degrease the surface.

In the end, I want to say - it is quite possible to make a brazier from a gas cylinder at home. Of course, you will have to work hard, but the result will please you. Every time you cook barbecue and fry vegetables, you will rejoice and praise your product. Before work, carefully study the drawings, make calculations, buy everything necessary materials and watch the video tutorials. Don't forget to follow safety precautions.

On the Internet you can find various technologies and step-by-step instructions that tell in detail and show how to make a brazier from a gas cylinder yourself. It may seem that this is simply unrealistic and in the end nothing will work out. But this is far from the case, our craftsmen are able to make the most unusual products from simple things. Do not be afraid to experiment and add something of your own to the finished drawings. Perhaps your design will be the most unique and beautiful.

Brazier - a necessary design for every summer resident and lovers active rest. Of course, you can buy it in any specialized store, but a hand-made brazier will warm your heart for many years. Food on it will be much tastier. and your family and friends will admire your success and praise the "golden hands" of the craftsman. Experiment and you will definitely get a masterpiece!

Reading time ≈ 10 minutes

Many people like to relax in nature with family or friends, have picnics and outdoor gatherings. And, of course, leaving the city is often accompanied by cooking barbecue or grilled vegetables. In order for the rest to be pleasant and memorable, a solid one is needed for the surroundings. It can be made independently, using improvised materials, for example, an unnecessary gas cylinder.

Varieties of barbecues

Today in stores you can find a huge assortment of country barbecues and smokehouses for every taste. But buying such a product is not at all necessary, because you can make it from a gas cylinder, barrels and other materials with your own hands. Before you understand which design is right for you, you need to know what kind of barbecues there are:

The material for a homemade barbecue should be:

- Durable and reliable.

- Fire resistant.

- Keep warm.

An excellent option is a standard brazier from an old gas cylinder, it is easy to make it using drawings and the necessary tools. What configurations can be made:

As a decor, you can use metal knitting needles, figured handles, rods or other details. The design of the case depends on your imagination, the main thing is that the brazier fits into the landscape of the summer cottage. The video master class shows the manufacture of a barbecue container with step by step instructions and according to drawings.

Features and Benefits

You can buy a ready-made brazier in the store, or you can make a design of any configuration and size from a gas cylinder with your own hands. Is it worth using just such a container, and is it safe? According to the advice of experienced craftsmen, an old 50-liter cylinder is suitable for manufacturing. In this case, the optimal length is considered to be about 85 centimeters, and the diameter - from 30 centimeters.

Consider the advantages of models of such homemade barbecues:

A do-it-yourself brazier from a gas cylinder can also have several disadvantages:

How to safely disassemble a cylinder

The preparatory stage for creating a homemade brazier is dismantling the old metal cylinder and acquiring all the necessary tools. Before you start cutting the body of the future barbecue, you need to make sure that there is no gas and gasoline left inside. Gasoline is a special mixture of hydrocarbons in liquid form that remains in the tank. How to do this job safely:

What tools and materials do we need:

- Door hinges for attaching the cover.

- Adjustable wrench.

- Metal pipe for chimney.

- Hammer with a screwdriver.

- Clamps.

- Electric drill.

- Apparatus for welding.

- Bulgarian.

Mastery Secrets

The whole process of building a homemade brazier can be divided into several stages, in each of which instructions should be followed:

Roaster with lid

You can make a barbecue grill with your own hands from a propane tank without spending a lot of time and resources. old gas burner you can not throw it away, but make a homemade brazier using the drawings.

Following the advice of the masters and clear instructions, we proceed to manufacture:

Following the advice of the masters and clear instructions, we proceed to manufacture:

Barbecue on low legs

To bring to life your idea of creating your own mini brazier for a summer residence, you can use an old metal container, for example, a gas cylinder. First, pay attention to the marking indicating the volume and dimensions.

Let's get started:

- We cut out the cover in the case, leaving the sides intact, as in the photo. So the coals will not scatter in the wind.

- Make sure that the rings are exactly at the seams.

- Now we have the body and lid of the future mini-smoker ready, two separate parts.

- We connect the cover to the body with two metal loops. They must then be well welded so that they do not fly off during operation.

- Fastening is first done with aluminum rivets, as in the photo.

- On the cover we apply markings for the location of the handles. They must not be made of flammable material.

- In order to avoid deformation of the cylinder inside the body, we fasten the corner. It should also be well welded and serve as a support for skewers and a grate for arranging grilled products.

- We make the legs shortened so that you can transport the barbecue in the trunk of a car.

- It's time to weld the lid to the hinges.

- The handles are welded to the outer surface of the lid, which we put on the hinges.

- We mount the limiters on the cover to fix it in the open state.

- In the bottom, you need to drill several holes for the passage of burnt coal and for better traction. On the opposite side of the holes, we cut out slots for fixing the skewers inside.

- The design is ready to use!

The whole process of creation can be seen on the video master class.

There are many options for the manufacture of barbecues, smokehouses and barbecue ovens of various configurations. However, the most universal way Consider using an old propane tank. Instructions and advice from experienced craftsmen will tell you how best to make such a design, and help you avoid common mistakes.