Modular boiler ksv outdoor placement. Steel hot water heating boilers for external use Deaeration expansion tank

How long will you overpay for heat and water supply, when you can save on installation, maintenance and gas consumption by purchasing a modular boiler KSV!

Modular boiler KSV replaces old boilers and has capital costs up to 4 times lower than block and roof boilers.

Stop paying for heat!

Costs are reduced by 5 times for heat, and for hot water 8 times thanks to new design boiler.

Reduced equipment maintenance costs. Boiler control does not require specially trained personnel.

Reducing losses in the heating network to zero due to the absence of a pipeline outside the heated facility.

An economical blast burner of our own production is several times cheaper than foreign analogues.

Low cost of boilers KSV, compared with a stationary or block boiler.

Block boilers require more than 20 permits, and KSV boilers can be started with just one document.

Why the KSV modular boiler will solve your heating problems?

- All elements of the block boiler house are mounted in one outdoor boiler body.

- Energy savings through the use of energy-saving devices.

- Gas savings due to high efficiency.

- Burner automatics operate at extreme temperatures down to -45 °C

- Quick installation

- Easy start-up (burner has already been adjusted at the factory)

- Long service life (15 years)

- LLC NPO Vr KS produces spare parts for warranty and post-warranty service

- Reduced capital costs by 2-4 times (compared to block and rooftop boilers)

- Possibility of complete electrical independence

ECONOMIC EFFECT in just one heating season!

Technical specifications

modular boilers KSUV

Complete set of modular boiler KSV

The modular outdoor boiler of the KSV series is a 3-pass fire-tube boiler with a blast burner of the GDK series, located in a thermally waterproofed galvanized steel casing. An energy-automatic three-way thermostatic valve is mounted inside the boiler, in piping with a circulation pump of appropriate capacity.

- Blast burner

- THREE WAY CRANE

- DEAERATION EXPANSION TANK

- Water-water heater

Blast burner GDK - diffusion-kinetic burner

The use of diffusion-kinetic burners (HDK) makes it possible to obtain the same characteristics as when using imported blast burners of the same power, while the power consumption for the burner fan drive is reduced by 3 times, which allows the boiler to operate in a non-volatile mode, up to 72 hours, the noise level is reduced by 2 times. GDK burners can operate at outdoor air temperatures up to -45°C, which is unattainable for foreign-made blast burners. The latter circumstance is decisive when using these burners in boilers with external placement of SWR.

AUTOMATIC THERMOSTATIC 3-WAY VALVE

The formation of condensate inside the fire-tube part of the boiler leads to the build-up of soot, a decrease in efficiency and the failure of the boiler.

The use of an energy-dependent automatic three-way valve, with low hydraulic resistance, allows the use of conventional circulation pumps with a head of 6÷8 m and a drive power of up to 210 W for stand-alone DHW and heating systems with a power of up to 100 kW. This device eliminates the formation of condensate inside the boiler furnace during start-up and operation of the boiler in hot water supply systems.

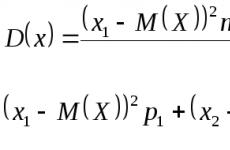

DEAERATION EXPANSION TANK

DRB is designed to remove gases and compensate for the thermal expansion of the coolant. A decrease in carbon dioxide content leads to the formation of a protective film from CaCO3 carbonates on metal pipes heating systems, heating devices, fire-tube parts of boilers. At permanent job thermal deaeration occurs in the expansion tank, which contributes to an increase in the durability of steel pipelines, heating appliances, and boiler equipment.

KSV 40 - KSV 100 - KSV150 - KSV 500

THE PASSPORT

STEEL hot water BOILER FOR OUTDOOR PLACEMENT

344009 Teplov LLC, Rostov-on-Don, Sholokhov Ave. 237

1.Purpose

Boilers steel universal outdoor placement type KSV are designed for heating and hot water supply of administrative buildings, residential buildings, social and cultural facilities, schools, hospitals facilities for various purposes.

2.General information about the product

- Boilers are equipped with an atmospheric or draft burner for low-pressure natural gas or liquid fuel, with an atmospheric burner they are non-volatile gas boilers and are intended for outdoor installation;

- KSV boilers can be used as a backup source of heat supply at facilities with an unstable power supply system;

- Boilers are used in heating systems with natural and forced circulation of the coolant;

- The boiler operates in automatic mode without the constant presence of service personnel;

- Climatic performance boilers Category 1. GOST 15150-69;

- Boilers automatically provide standby heating mode when the gas supply decreases;

- Outdoor KSV boilers automatically comply with safety requirements (clause 4.16 of SP 41-104-2000).

Boilers of the KSV type comply with TU 4931-007-10258780-97. The main parameters are given in the table.

|

No. p / p |

Options |

Boiler type |

||||

|

SWR 40 |

SWR 100 |

SWR 150 |

SWR 500 |

|||

|

1 |

Heat output, kW |

atmospheric burner |

36 |

95 |

- |

- |

|

Blast burner |

70 |

190 |

290 |

500 |

||

|

2 |

Rated heat output (at 80% load from max) |

atmospheric burner |

29 |

76 | ||

|

Blast burner |

56 |

152 |

240 |

400 |

||

|

3 |

Heated area (H=2.5-3 m) m² |

atmospheric burner |

360 |

1000 | ||

|

Blast burner |

700 |

2000 |

3000 |

5000 |

||

|

4 |

Efficiency, % not less than |

86 |

89 |

89 |

89 |

|

|

5 |

Nominal gas pressure in the network, kPa |

1,2 |

2,0 |

|||

|

6 |

Atmospheric burner type / blast / diesel |

atmospheric burner |

UGT |

|||

|

Blast burner |

Per resolution |

|||||

|

7 |

Maximum gas consumption, m³/h of fuel, kg |

atmospheric burner |

4,4 |

11,4 |

- |

- |

|

Blast burner |

8,5 |

22,8 |

32 |

61,1 |

||

|

8 |

Maximum coolant temperature, ° С |

95 |

||||

|

9 |

Emissions of carbon monoxide (СО) in dry undiluted combustion products at rated power, not more than mg/m³ |

|

Within acceptable standards |

Within acceptable standards |

Within acceptable standards |

|

|

10 |

The volume of the heat carrier in the boiler, l |

62 |

166 |

253 |

370 |

|

|

11 |

Diameter of inlet branch pipes of the heating system, mm |

57 |

76 |

89 |

108 |

|

|

12 |

Diameter of the supply gas pipeline, inch (DN) for an atmospheric burner |

1/2" (15) |

1"(25) |

- |

- |

|

13 |

dimensions, mm |

540x1200x1200 |

740x1460x1880 |

840x1710x2220 |

1080x2250x2220 |

|

14 |

Boiler weight (without chimney), kg |

170 |

470 |

850 |

1450 |

4. Completeness

The completeness of the boiler delivery is shown in the table.

|

No. p / p |

Name |

Quantity |

Note |

|

1 |

Boiler KSV assy |

1 | |

|

2 |

Burner * atmospheric |

1 | |

|

3 |

Automatic three-way valve |

1 | |

|

4 |

Chimney** with fixing brackets |

1 | |

|

5 |

The passport |

1 |

* Blast burner available as an option

** Supplied by separate order.

5. Boiler device.

The boiler is a combustion device with a water jacket. A bundle of vertical flame tubes is located in the upper part of the boiler. For more efficient heat transfer and increased efficiency, turbulators are placed in the flame tubes. A removable boiler cover is provided for cleaning the flame tubes and turbulators. At the back of the boiler there is an automatic flow regulator 2 (Fig. 1) (only for an atmospheric burner) and a cleaning hatch 6. The automatic flow regulator prevents the flame from breaking off due to excessive draft, and also increases efficiency and reduces gas consumption. The boiler is thermally insulated with mineral wool mats and thin sheet steel, which allows the boiler to be operated without the construction of boiler rooms and furnace rooms. On the front panel there is a thermometer 3, showing the temperature of the coolant at the outlet of the boiler 3, temperature sensors 9 and burner 4. The front panel is closed by a metal heat-insulated door with a screw lock.

6. Working principle

The boiler operates in automatic mode. Heat is transferred to the coolant through the walls of the boiler and the walls of the flame tubes. The heat outputs of the boiler and the heating system of the building must be coordinated. An automatic three-way valve 3 is placed in the boiler piping circuit (Fig. 2.3), which prevents the formation of condensate and tarry deposits in the furnace (even with excessive heating system power). For use in heating systems with forced circulation of the coolant, it is necessary to install circulation pumps of the appropriate power according to the scheme shown in fig. 3*. AT closed system heating, the deaeration process occurs by heating the coolant to 90º and removing air through the air outlet devices. Reheating and removal of released air completes the deaeration cycle heating system and serves to protect it from severe corrosion. The KSV boiler with a UGT burner has automatic gas flow control depending on the heat removal of the heating system and the outside air temperature. The KSVs boiler with a UGT burner, in the absence of draft and excess gas pressure in the furnace, switches to the ignition of the igniter, which indicates malfunctions in the gas duct or in the gas supply system.

The boiler is started in the following sequence:

- fill the system completely with water;

- open the gas cock on the gas pipeline to the boiler;

- start the boiler (according to the burner passport);

- when the temperature on the boiler reaches 60 ° C, turn on the network pump (with forced circulation of the coolant);

- Install the boiler on the site intended for installation. The chimney, which is an integral part of the boiler, is installed on the boiler. The height of the chimney must be at least 8 m (for boilers with an atmospheric burner).

- Installation to the heating system and gas pipeline is carried out in accordance with the "Model Rules fire safety for residential buildings, hotels, hostels, buildings of administrative institutions, individual garages” (PPB01-93).

- Install an automatic thermostatic three-way valve in the immediate vicinity of the boiler in the bypass line immediately behind the wall of the building,

- Thermally insulate the supply and return lines from the boiler to the building to be heated.

8. Indication of security measures

- Installation and operation of the boiler must comply with the requirements of the Rules for the Design and Safe Operation of Steam and Hot Water Boilers.

- start-up and adjustment of the boiler must be carried out by a specialized organization that has the appropriate license.

- when the boiler is stopped in winter for more than a day, it is necessary to completely drain the water from the boiler and the heating system.

- at the end heating season leave the boiler filled with water to avoid corrosion.

- it is not allowed to quickly fill the hot boiler with coolant.

- at a positive air temperature, the boiler must be operated with a load of no more than 80% of the maximum (for boilers with atmospheric burners).

9. Possible malfunctions and how to fix them

|

Malfunction |

Cause and remedy |

|

The smell of gas |

Gas pipeline leak. Check the gas pipes inside the boiler and outside. |

|

The smell is not complete burnt gas |

Clogging of the hot flue gas outlet. Make sure that the chimney height (for atmospheric burners) and its diameter correspond to the type of boiler. Check gas flow. Check combustion stability. |

|

Formation of condensate |

Return subcooling. Check if it works automatic three-way valve. |

|

Boiler fast product is contaminated tami combustion |

Adjust the combustion, check the composition of the exhaust gases. Check gas flow and chimney efficiency. |

10. Manufacturer's warranties

LLC "Teplov" guarantees the operability of the boiler and free replacement or repair of failed assembly units and parts of the boiler within 24 months from the date of commissioning but not more than 30 months from the date of shipment, provided that the consumer observes the conditions of transportation, storage and operation.

The manufacturer is not responsible in the following cases:

Mechanical damage to the boiler;

Incorrect connection to the heating system;

Incorrect operation of the boiler (heating the boiler without water, rapid filling of the hot boiler cold water, use of the boiler as an instantaneous water heater);

Lack of an automatic thermostatic three-way valve in the heating system;

Installation of the boiler by an organization that does not have the appropriate license;

Start-up and adjustment of the boiler by an organization that does not have the appropriate license;

Excess gas pressure over 5 kPa;

Lack of maintenance.

All of the above violations of the operating rules can cause cracks in the pipe structures of the boiler, which is not a manufacturing defect.

11. Acceptance certificate

1. Boiler SWR __________ factory number ____________________

complies with the specifications TU 4931-002-79248424-2006, TU 4931-001-79248424-2006 is manufactured in full compliance with GOST 10617-83 and GOST 20548-93 and is recognized as serviceable.

Pipe structures and pipe connections of the boiler were subjected to a hydraulic test with an excess pressure of 6 kg / cm 2 for 15 minutes.

2. Chimney: Diameter _________________ mm,

height _______________________________ m. (not less than 8 m for boilers with atmospheric burner.

Date of manufacture: _____________________________________

OTK representative _____________________________________

Director of operations __________________________________

12. Warranty card

Teplov LLC

Address: Rostov-on-Don, Sholokhov Ave., 237

13. Passport of the outdoor boiler KSV

The boiler is manufactured according to TU 4931-002-79248424-2006, TU 4931-001-79248424-2006

Factory number _______________________

Heat output, kW ______________

Heating medium working pressure 4.0 bar

Maximum coolant temperature, 95 º

The boiler is tested with a hydraulic test pressure of 6 bar

Date of manufacture ________________

OTK representative ________________

Head of production ______________ M.P.

|

BUT |

AT |

FROM |

D |

d |

To |

H |

H, |

|

|

KSV-40 |

540 |

1200 |

1200 |

178 |

57 |

150 |

115 |

1035 |

|

KSV-40 |

|

BUT |

AT |

FROM |

D |

d |

To |

H |

Hi |

diameter |

supply |

|

|

KSV-40 (W70 kW) |

540 |

1200 |

1200 |

178 |

57 |

150 |

115 |

1035 |

1/2 |

Left |

|

KSV-100 (W190 kW) |

740 |

1460 |

1880 |

178 |

76 |

200 |

130 |

1727 |

1 |

Left |

|

KSV-150 (W290 kW) |

840 |

1710 |

2220 |

219 |

89 |

250 |

160 |

2005 |

1.1/2 |

Left |

|

KSV-500 (W500 kW) |

1080 |

2250 |

2220 |

325 |

114 |

250 |

160 |

2005 |

2 |

On right |

|

1. Boiler body |

6. Gas flue cleaning hatch |

|

2. Natural air intake grille (winter, summer) |

7. Chimney pipe |

|

3. Thermometer |

8. Hot line connection |

|

4. Burner |

9. Thermostat |

|

5. Return connection |

10. Condensate outlet |

|

11. Gas pipeline branch pipe |

|

|

1. Chimney |

7. Pump |

|

2. Clamp |

8. Boiler circulation line |

|

|

9. Return line |

|

4. Boiler |

10. Vertical riser |

|

5. Deaerator |

11. Safety valve |

|

6. Heating appliance |

12. Ball valve |

|

13. Membrane expansion tank |

|

|

1. Chimney |

6. Heating appliance |

|

2. Clamp |

7. Boiler circulation line |

|

3. Automatic three-way valve |

8. Return line |

|

4. Boiler |

9. Vertical riser |

|

5. Expansion tank |

10. Water heater |

|

11. Shut-off valve

|

|

KSV 40 - KSV 100 - KSV150 - KSV 500

THE PASSPORT

STEEL BOILERhot waterOUTDOOR

344009 Teplov LLC, Rostov-on-Don, Sholokhov Ave. 237

1.Purpose

Boilers steel universal outdoor placement type KSV are designed for heating and hot water supply of administrative buildings, residential buildings, social and cultural facilities, schools, hospitals, structures for various purposes.

2. General information about the product

The boilers are equipped with an atmospheric or draft burner for low-pressure natural gas or liquid fuel, with an atmospheric burner they are non-volatile gas boilers and are designed for outdoor installation;

KSV boilers can be used as a backup source of heat supply at facilities with an unstable power supply system;

Boilers are used in heating systems with natural and forced circulation of the coolant;

The boiler operates in automatic mode without the constant presence of service personnel;

Climatic modification of boilers U category 1. GOST 15150-69;

The boilers automatically provide the standby heating mode when the gas supply decreases;

Outdoor KSV boilers automatically comply with safety requirements (clause 4.16 of SP 41-104-2000).

3. Technical data and characteristics of the boiler

Boilers of the KSV type comply with TU 4931-007-10258780-97. The main parameters are given in the table.

|

Options |

Boiler type |

|||||

|

Heat output, kW |

atmospheric burner |

|||||

|

Blast burner |

||||||

|

Rated heat output (at 80% load from max) |

atmospheric burner |

|||||

|

Blast burner |

||||||

|

Heated area (H=2.5-3 m) m² |

atmospheric burner |

|||||

|

Blast burner |

||||||

|

Efficiency, % not less than |

||||||

|

Nominal gas pressure in the network, kPa |

||||||

|

Atmospheric burner type / blast / diesel |

atmospheric burner |

|||||

|

Blast burner |

Per resolution |

|||||

|

Maximum gas consumption, m³/h of fuel, kg |

atmospheric burner |

|||||

|

Blast burner |

||||||

|

Maximum coolant temperature, ° С |

||||||

|

Emissions of carbon monoxide (СО) in dry undiluted combustion products at rated power, not more than mg/m³ |

Within acceptable standards |

Within acceptable standards |

Within acceptable standards |

|||

|

The volume of the heat carrier in the boiler, l |

||||||

|

Diameter of inlet branch pipes of the heating system, mm |

||||||

|

Diameter of the supply gas pipeline, inch (DN) for an atmospheric burner |

|||||

|

Overall dimensions, mm |

1080x2250x2220 |

||||

|

Boiler weight (without chimney), kg |

4. Completeness

The completeness of the boiler delivery is shown in the table.

|

Name |

Quantity |

Note |

|

|

Boiler KSV assy |

|||

|

Burner * atmospheric |

|||

|

Automatic three-way valve |

|||

|

Chimney** with fixing brackets |

|||

* Blast burner available as an option

** Supplied by separate order.

5. Boiler device.

The boiler is a combustion device with a water jacket. A bundle of vertical flame tubes is located in the upper part of the boiler. For more efficient heat transfer and increased efficiency, turbulators are placed in the flame tubes. A removable boiler cover is provided for cleaning the flame tubes and turbulators. At the back of the boiler there is an automatic flow regulator 2 (Fig. 1) (only for an atmospheric burner) and a cleaning hatch 6. The automatic flow regulator prevents the flame from breaking off due to excessive draft, and also increases efficiency and reduces gas consumption. The boiler is thermally insulated with mineral wool mats and thin sheet steel, which allows the boiler to be operated without the construction of boiler rooms and furnace rooms. On the front panel there is a thermometer 3, showing the temperature of the coolant at the outlet of the boiler 3, temperature sensors 9 and burner 4. The front panel is closed by a metal heat-insulated door with a screw lock.

6. Working principle

The boiler operates in automatic mode. Heat is transferred to the coolant through the walls of the boiler and the walls of the flame tubes. The heat outputs of the boiler and the heating system of the building must be coordinated. An automatic three-way valve 3 is placed in the boiler piping circuit (Fig. 2.3), which prevents the formation of condensate and tarry deposits in the furnace (even with excessive heating system power). For use in heating systems with forced circulation of the coolant, it is necessary to install circulation pumps of the appropriate power according to the scheme shown in fig. 3*. In a closed heating system, the deaeration process occurs by heating the coolant to 90º and removing air through air outlet devices. Reheating and removal of released air completes the deaeration cycle of the heating system and protects it from intense corrosion. The KSV boiler with a UGT burner has automatic gas flow control depending on the heat removal of the heating system and the outside air temperature. The KSVs boiler with a UGT burner, in the absence of draft and excess gas pressure in the furnace, switches to the ignition of the igniter, which indicates malfunctions in the gas duct or in the gas supply system.

The boiler is started in the following sequence:

Fill the system completely with water;

Open the gas cock on the gas pipeline to the boiler;

Start the boiler (according to the burner passport);

When the temperature on the boiler reaches 60 ° C, turn on the network pump (with forced circulation of the coolant);

7. Boiler installation

Install the boiler on the site intended for installation. The chimney, which is an integral part of the boiler, is installed on the boiler. The height of the chimney must be at least 8 m (for boilers with an atmospheric burner).

Installation to the heating system and gas pipeline is carried out in accordance with the "Model fire safety rules for residential buildings, hotels, hostels, buildings of administrative institutions, individual garages" (PPB01-93).

Install an automatic thermostatic three-way valve in the immediate vicinity of the boiler in the bypass line immediately behind the wall of the building,

Thermally insulate the supply and return lines from the boiler to the building to be heated.

After installing the boiler, carry out its hydraulic test, for which the system is filled with water, and the pressure in it is raised to 4.5 kg / cm 2 according to the pressure gauge. The boiler is considered to have passed the test if within 15 minutes. no signs of rupture, residual deformations, leaks, pressure drop were found.

8. Indication of security measures

Installation and operation of the boiler must comply with the requirements of the Rules for the Design and Safe Operation of Steam and Hot Water Boilers.

The start-up and adjustment of the boiler must be carried out by a specialized organization that has the appropriate license.

When the boiler is stopped in winter for more than a day, it is necessary to completely drain the water from the boiler and the heating system.

At the end of the heating season, leave the boiler filled with water to avoid corrosion.

It is not allowed to quickly fill the hot boiler with coolant.

At a positive air temperature, the boiler must be operated with a load of no more than 80% of the maximum (for boilers with atmospheric burners).

An increase in gas pressure above 5 kPa leads to failure of the gas burner device.

9. Possible malfunctions and ways to eliminate them

|

Malfunction |

Cause and remedy |

|

The smell of gas |

Gas pipeline leak. Check the gas pipes inside the boiler and outside. |

|

The smell is not complete burnt gas |

Clogging of the hot flue gas outlet. Make sure that the chimney height (for atmospheric burners) and its diameter correspond to the type of boiler. Check gas flow. Check combustion stability. |

|

Formation of condensate |

Return subcooling. Check if it works automatic three-way valve. |

|

Boiler fast product is contaminated tami combustion |

Adjust the combustion, check the composition of the exhaust gases. Check gas flow and chimney efficiency. |

10. Manufacturer's warranties

LLC "Teplov" guarantees the operability of the boiler and free replacement or repair of failed assembly units and parts of the boiler within 24 months from the date of commissioning but not more than 30 months from the date of shipment, provided that the consumer observes the conditions of transportation, storage and operation.

The manufacturer is not responsible in the following cases:

Mechanical damage to the boiler;

Incorrect connection to the heating system;

Incorrect operation of the boiler (heating the boiler with empty water, rapid filling of the hot boiler with cold water, using the boiler as an instantaneous water heater);

Lack of an automatic thermostatic three-way valve in the heating system;

Installation of the boiler by an organization that does not have the appropriate license;

Start-up and adjustment of the boiler by an organization that does not have the appropriate license;

Excess gas pressure over 5 kPa;

Lack of maintenance.

All of the above violations of the operating rules can cause cracks in the pipe structures of the boiler, which is not a manufacturing defect.

11. Acceptance certificate

1. Boiler SWR __________ factory number ____________________

complies with the specifications TU 4931-002-79248424-2006, TU 4931-001-79248424-2006 is manufactured in full compliance with GOST 10617-83 and GOST 20548-93 and is recognized as serviceable.

Pipe structures and pipe connections of the boiler were subjected to a hydraulic test with an excess pressure of 6 kg / cm 2 for 15 minutes.

2. Chimney: Diameter _________________ mm,

height _______________________________ m. (not less than 8 m for boilers with atmospheric burner.

Date of manufacture: _____________________________________

OTK representative _____________________________________

Director of operations __________________________________

12. Warranty card

Teplov LLC

Address: Rostov-on-Don, Sholokhov Ave., 237

13. Passport of the outdoor boiler KSV

The boiler is manufactured according to TU 4931-002-79248424-2006, TU 4931-001-79248424-2006

Factory number _______________________

Heat output, kW ______________

Heating medium working pressure 4.0 bar

Maximum coolant temperature, 95 º

The boiler is tested with a hydraulic test pressure of 6 bar

Date of manufacture ________________

OTK representative ________________

Head of production ______________ M.P.

|

1. Boiler body |

5. Return connection |

|

2. Air flow regulator |

6. Gas flue cleaning hatch |

|

3. Thermometer |

7. Chimney pipe |

|

4. Atmospheric burner |

8. Hot line connection |

|

9. Temperature sensor |

|

|

KSV-40 (W70 kW) |

||||||||||

|

KSV-100 (W190 kW) |

||||||||||

|

KSV-150 (W290 kW) |

||||||||||

|

KSV-500 (W500 kW) |

|

1. Boiler body |

6. Gas flue cleaning hatch |

|

2. Natural air intake grille (winter, summer) |

7. Chimney pipe |

|

3. Thermometer |

8. Hot line connection |

|

4. Burner |

9. Thermostat |

|

5. Return connection |

10. Condensate outlet |

|

11. Gas pipeline branch pipe |

|

|

1. Chimney |

|

|

8. Boiler circulation line |

|

|

9. Return line |

|

|

10. Vertical riser |

|

|

5. Deaerator |

11. Safety valve |

|

6. Heating appliance |

12. Ball valve |

|

13. Membrane expansion tank |

|

|

1. Chimney |

6. Heating appliance |

|

7. Boiler circulation line |

|

|

3. Automatic three-way valve |

8. Return line |

|

9. Vertical riser - |

|

|

5. Deaerator |

10. Ball valve |

|

11. Membrane expansion tank |

|

|

1. Chimney |

6. Heating appliance |

|

7. Boiler circulation line |

|

|

3. Automatic three-way valve |

8. Return line |

|

9. Vertical riser |

|

|

5. Expansion tank |

10. Water heater | Document

190 kW;

Combustion chamber type:

closed;

Producing country:

Russia;

Location:

floor;

Application:

for structures;

Contour:

single-circuit;

Brand:

Weishaupt;

The outdoor boiler KSV is designed for heating administrative and industrial buildings, residential buildings and structures for various purposes (schools, kindergartens, medical institutions, hostels, office buildings, car dealerships, shopping centers, warehouses, workshops, workshops industrial enterprises etc.).

Due to the design features, our outdoor boilers are installed near the building in open areas, without additional construction of specialized premises and do not require the installation of fire extinguishing systems and gas analyzers. Boilers for external use are equipped with a gas blast burner (Weishaupt - Germany, UNIGAS - Italy) or a liquid fuel burner (Weishaupt - Germany, UNIGAS - Italy). Boilers for external use operate in automatic mode without the constant presence and special training of maintenance personnel and are not subject to control by Rostekhnadzor during operation.

High efficiency (92%) in outdoor boilers KSV is achieved due to the placement of turbulators in the heat exchanger, which increase the time for the passage of exhaust gases, thereby providing more efficient heating of the coolant. Seamless steel pipes are used for the manufacture of the heat exchanger High Quality, which ensures a long service life reducing the risk of emergency shutdowns. Boiler body for external use is made of steel sheet with protective coating and insulated with modern heat-insulating foil materials. You can get acquainted with the prices for outdoor boilers produced by our company.

The production of outdoor boilers is carried out on modern equipment. At the request of the customer, they are produced in different versions. If necessary, our boilers for outdoor use are equipped with a double-walled "sandwich" type chimney system, which is a structure consisting of two pipes of different diameters (external and internal). The distance between them is filled with non-combustible heat-insulating material made from high quality basalt fiber. Thanks to this design, high-speed heating of the inner pipe is ensured, which, in turn, allows, in a short time, after the start of work, to raise the temperature in the chimney above the dew point and avoid the formation of condensate.

The product is certified.

Advantages:

- do not need a specially equipped room, they are located in an open area near the building.

- do not require the installation of fire extinguishing systems, gas analyzers, etc.

- work in automatic mode, without the constant presence of service personnel

- high efficiency - 92%.

- work on both natural gas and diesel fuel

Steel hot water heating boilers for external use

Powered by natural gas and light oil.

Heat output 0.036MW, 0.07MW, 0.095MW, 0.19MW, 0.29MW, 0.5MW.

Installation and operating instructions

KSV-00.12.-30 RE

The guide includes the following sections:

Introduction 3

1 Description and operation of the product 4

1.1 Purpose 4

1.2 General information 4

1.3 General requirements 4

1.4 Specifications 5

1.5 Composition 7

1.6 Device 7

1.7 How it works 7

1.8 Measuring instruments 12

1.9 Marking 12

2 Operation 12

2.1 Operating restrictions 12

2.2 Getting started 13

2.3 Operation 14

3 Maintenance 15

3.1 Safety precautions 15

3.2 Maintenance 15

4 Maintenance. 15

5 Storage 15

6 Transport 16

7 Disposal 16

8 Warranty 16

Introduction

This manual is an important and integral part of the delivery and is handed over to the consumer along with the product. Please read the entire manual carefully important information about the design of the boiler and its correct operation in order to ensure complete and correct use his technical capabilities. Steel hot water heating boilers for outdoor use of the KSV type (hereinafter referred to as boilers) with a heat output of 0.036 to 0.5 MW are designed in four standard sizes and can be operated on light liquid or gaseous fuels. The boiler must be serviced by an operator who has a certificate for the right to service boilers. Persons under the age of 18 are not allowed to work. Workers admitted to work with the boiler must be familiar with the device and the principle of its operation. Persons servicing the boiler must know and comply with general rules safety precautions when working with mechanisms that have an electric drive. When operating the boiler, in addition to this manual, the following regulatory and technical documents must be additionally used:

Rules for the design and safe operation of steam boilers with a steam pressure of not more than 0.07 MPa, hot water boilers and water heaters with a water heating temperature of not more than 115 ° C.

Safety rules for gas distribution and gas consumption systems. PB.

Passport and operation manual of the burner device (burner)

1. Description and operation of the product.

1.1 Purpose

KSV (steel hot water boiler) outdoor heating is designed for heating administrative and industrial buildings and facilities, residential buildings, structures for various purposes and hot water supply when using flow and high-speed boilers.

1.2. General information about the product

The boilers are equipped with an atmospheric or draft burner for low-pressure natural gas or liquid fuel, with an atmospheric burner they are non-volatile gas boilers and are designed for outdoor installation;

Boilers are used in heating systems with natural and forced circulation of the coolant;

The boiler operates in automatic mode without the constant presence of service personnel;

Climatic design of boilers U category 1. GOST;

1.3 General technical requirements

1.3.1. The boilers must use gaseous and liquid fuels of the type recommended by the Manufacturer. Depending on configuration additional equipment the boiler can operate on the following main types of fuel:

– gaseous fuel– natural gas GOST 5542-87;

– light liquid fuel- diesel fuel, (solar oil) GOST 305-88, TPB TU, viscosity at 20º C, 4 - 6x1 - 6); m2/S (cSt);

Attention!

1. The possibility of using other types of fuel must be agreed with the Manufacturers of the boiler and burner devices.

2. The fuel used must correspond in its characteristics to the fuel specified in the documentation for the burner.

1.3.2. Feed water quality indicators must comply with the requirements of the Rules for the Design and Safe Operation of Steam and Hot Water Boilers, PB 10-574–03”; GOST.

Attention!

Burners used with the boiler must have a valid certificate of conformity of the State Standard of the Russian Federation, a permit for the use of Rostekhnadzor of the Russian Federation

(Gosgortekhnadzor of the Russian Federation) and approval of the boiler manufacturer for use as part of a boiler unit.

1.4. Specifications, performance parameters and functional features outdoor boilers of the KSV series

Table 1

Technical characteristics of boilers for external use of the KSV series, operated with blow-type burners.

Model | KSV-40 | KSV-100 | KSV-150 | KSV-500 |

Power (heating capacity), kW | ||||

Rated power (heating capacity) at 80% of max power, kW | ||||

Efficiency, % not less than | ||||

Max gas consumption, m³/hour | ||||

Max gas pressure in the network, kPa | ||||

Max pressure in the heating system - atm | ||||

Max coolant temperature, °C | ||||

Volume of coolant in the boiler, liter | ||||

Diameter of branch pipes of the heating system, mm | ||||

Conductive gas pipeline diameter, inch/mm(not less than) | ||||

|

The method of chemical water treatment is chosen by a specialized organization designing the facility, taking into account the quality of the source water and the requirements for network water and make-up water. Before putting the boiler into operation, it is necessary to revise the heating networks. Eliminate leaks and flush the heating system. Methods and methods of flushing are established by a specialized design organization, depending on local conditions. Attention. It is strictly forbidden to put the boiler into operation without prepared (washed) heating networks and without ensuring the required quality indicators of network and make-up water, in order to avoid subsequent contamination of the boiler with sludge and scale. 2.2 Preparation for operation. Before putting the boiler into operation, make sure that the power supply system and all assembly units are in good condition, as well as that they are securely fastened. Boilers received for operation must be checked for the absence of mechanical damage associated with transportation and storage. Before installing and connecting the boilers to external mains, it is necessary to check its completeness in accordance with the boiler passport. During operation, the boilers must be kept in good condition and clean, periodically check the reliability of fastening of all its elements. The boiler is placed on outdoors, outdoors on a specially prepared foundation. The boiler installation project must be carried out by a specialized design organization, in accordance with the technical conditions and requirements for the installation and comply with the current SNiP P-35-75 "Boiler Installations" and "Safety Rules in the Gas Industry". Before starting installation work, it is necessary to remove all plugs and open the boiler for internal inspection of the furnace. Install, adjust and start up the boiler in accordance with the Installation and Operation Manual. Mounting, lining of the burner device should be carried out in accordance with the documentation supplied with the burner. Installation and commissioning of the burner protective shutdown device should be carried out in accordance with the instructions in the documentation for the device. Check the correct installation of all equipment, pipelines and fittings. Mount pressure gauges on the branch pipes of the water pipelines and install thermometers in the sleeves. Pour oil into the thermometer sleeves. Connect the boiler to all communications in accordance with the boiler installation project. Fill the boiler with water that has undergone chemical water treatment. Adjust the safety valves to open them when the water pressure in the boiler rises above the working one. Before putting the boiler into operation, commissioning work must be carried out by a specialized organization, in which it is necessary: - check the correct installation and all equipment, pipelines, fuel lines, shut-off and safety valves, instrumentation and instrumentation; − carry out verification tests for density. Eliminate all identified leaks. Before final commissioning, the following points must be fulfilled: 8. Warranty If these instructions are not followed, the requirements for the manufacturer to fulfill the warranty obligations are not valid. This product has passed a hydraulic test in accordance with the Rules for the Design and Safe Operation of Steam Boilers with a Steam Pressure of Not More Than 0.07 MPa, Hot Water Boilers and Water Heaters with a Water Heating Temperature of Not More Than 115 °C, meets the requirements of GOST and is a certified equipment. No changes should be made to the design of the boiler without the consent of the manufacturer. If such changes are made, the manufacturer is not responsible for the operation and safety of the boiler. The warranty period for the operation of the boiler is 2 years from the date of commissioning. But not more than 36 months from the date of sale. The average service life before decommissioning is 10 years. In the event of failure or breakdown of the boiler and/or its constituent elements, excluding third-party components (fittings, safety devices, instrumentation devices, etc.), during the warranty period, the consumer must notify the manufacturer. Consideration of all defects that have arisen during warranty period, is carried out in accordance with the contract for the supply of products and the legislation of the Russian Federation in force at the time of the defect. By agreement with the manufacturer, it is allowed to carry out repairs by a third-party specialized organization according to the recommendations and instructions of the manufacturer. The warranty does not cover damages and their consequences caused by: Inappropriate use. Improper installation or commissioning by the user or a third party. natural wear. Incorrect or negligent handling or poor maintenance. Unsuitable operating media, especially incorrect selection or adjustment of the burner, unintended fuels or impurities in the combustion air. Chemical, electrical or electronic influences not caused by the fault of the manufacturer. Not enough water. Failure to follow these installation and operating instructions. Incompetent measurements and repairs carried out by the buyer or a third party. |