How to make a high pressure car wash with your own hands. How to make a high pressure washer with your own hands? Selection of electrical components - motor, pump and gearbox

The cleanliness of the car is not only an aesthetic indicator, but also protects the product from negative environmental factors. After all, adhering and dried dirt may contain aggressive elements that damage the paintwork. Also, long-term and regular pollution of the body can lead to irreversible damage to the metal, up to through corrosion on individual elements.

In this case it saves regular visit car wash or home water treatments. But in the second case, you need to buy a washing device or a car wash must be made with your own hands from improvised means. Prices in stores generally start at 5 thousand rubles. The upper threshold may not stop at 20 thousand. Therefore, we will do it ourselves.

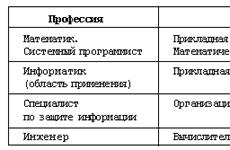

Pump and electrical part

The main part of any water supply unit is the pump. For our product, it will need a sufficiently powerful one, capable of developing a pressure of at least up to 150 atmospheres. When choosing a finished pump, it is necessary to take into account the materials from which the working units are made.

Preference should be given to products with a high-strength metal or ceramic piston.

It is desirable to select an electric motor with a voltage of 220 V. Reliable start is provided by an additional capacitor unit. A higher RPM will provide more performance.

You need to be aware that a pump that is too fast with a high number of revolutions can lose power at maximum operating speed and is subject to intense wear.

Consumers of 2-3 kW and rotation up to 2000 rpm are considered optimal.

Rotation transmission

Designed sink high pressure with their own hands must have in the chain the necessary safety elements to preserve important nodes. This link is the coupling connecting the pump and the engine.

It is desirable to install a coupling that can compensate for small axial misalignments between the shafts.

You can also install a belt drive with one stage. Such a gearbox will balance the speed and load between the engine and the pump. The gear ratio is selected based on their required output parameters in terms of rotation frequency.

Reservoir and performance regulator

The mini sink must be equipped with a sufficient water tank. A tank is suitable, which can be additionally powered from a constant source of water: faucet, deep water well or small water tower.

What to make a sink

It is advisable to install coarse and medium filters at the inlet to the tank. So, unnecessary rubbish will not get into the pump and will not interfere with the operation of the entire system.

Car shampoo or other approved car cosmetics can be added to the main water tank. The process will run more efficiently.

The performance regulator is usually combined with an unloading autovalve, which redirects unused pressure back to the tank, reducing the load on the pump.

External elements

All units are mounted on a frame made of shaped or round curved pipes. Often, a pair of wheels are attached to the down pipes to help transport the unit. Stops for fixing and a handle are also installed so that the entire structure can be moved.

The appearance of a do-it-yourself car wash

For a high pressure hose, you can use a plastic or rubberized reinforced hose. Be sure to ensure the tightness of the connections using high-quality clamps or hydraulic seals.

The design must be collapsible and maintainable. Therefore, it is desirable to use threaded connections where possible.

Also, in places of contact with water (fittings, valves), low-corrosion alloys should be used: brass and bronze.

Car wash scheme

Direct water supply is carried out through a gun with a nozzle installed in it. It bears a visual resemblance to a pistol at a gas station. A jet of water is formed only after pressing the key. This method helps to save the prepared working fluid with consumable additives. You can simply buy a gun at any hardware store.

Operation of a do-it-yourself sink

Details for assembling the sink

When using, you need to follow a few tips:

- periodically it is necessary to inspect the connecting nodes and tighten wrench threaded connections;

- the filters installed in the device need to be inspected before each connection so that the throughput does not decrease;

- the electrical part must be grounded to avoid accidents during operation, for this a cable with three copper cores is used, and the plug must have a ground terminal;

- during the washing process, it is not necessary to fix the jet at one point on the machine body for a long time, so as not to damage the paintwork with strong pressure.

Foam generators for car wash

A device for high-quality contactless washing is called a foam generator. With it, you can completely envelop the machine with small bubbles of washing suspension and carry out high-quality cleaning of the surface from dust, dirt and adhering small particles.

The process of foaming with a home foam generator

Do-it-yourself foam generator for washing can be made even in the garage. It is necessary to be patient and prepare all the nodes and elements.

The principle of operation of the foam generator

The device performs two main functions in the car wash process:

- the formation of fine-meshed foam from prepared reagents;

- uniform application of foam on the desired surface of the vehicle.

Homemade foam generator

To perform such a process, a jet of water mixed with car cosmetics (shampoo or other specialized preparations) is sprayed using an air stream passing through installed channels, and together form a coarse foam.

The mixture is then passed through a blowing tablet block. Now such a mass can be applied to the surface.

The flow control plates provide a fine atomizing spray to distribute the working foam to all the irregularities in the exterior of the body.

The difference between homemade equipment and professional

The quality of professional washing with a foam generator can be higher than when using a device made by yourself. For this, there are several criteria that determine the final result.

The main parameter is the size of the formed foam. An important characteristic is the homogeneous structure and the minimum bubble diameter.

When using professional sinks, specialized industrial shampoos are used.

Also, professional equipment allows you to pump a significantly higher fluid pressure than that which can be achieved in garage conditions. This reduces the consumption of detergents.

But with all these factors, the result of self-washing turns out to be quite worthy, especially since the final price for one session speaks in favor of a home-made device.

Self-made foam generator

Making a foam generator will require the creators to stock up on a set of keys, a grinder, a pre-purchased repair kit with spare parts for a professional installation, consisting of a nozzle, gun, compressor, flushing hose.

How a car wash works

In addition to the listed elements, it is necessary to take an inch pipe about 70 cm long. From it you need to make a filter. To do this, fill the cavity with pieces of fishing line. It is advisable to use it different diameter, so it will be more efficient to form foam.

After stuffing, you will need to install metal filters on both sides to prevent pieces of fishing line from falling into the shampoo container.

The principle of operation of the foam generator

Next, threaded plugs are placed on both ends of the pipe. Now a T-junction is screwed to one of the plugs. A compressor is screwed to such an adapter, and a hose from the liquid reservoir is screwed onto the second thread. The free end of the line tube will be the outlet for the foam. A hose is attached to it through a fitting for spraying the finished foam.

You need to know that the quality of the resulting foam depends on the quality of the stuffing in the tube with the fishing line.

achieve desired result You can change the stuffing in the tube with fishing line. It is also allowed to empirically select the required length of such a pipe and the texture of the stuffed fishing line.

Often there are situations when the car is very dirty as a result of driving through polluted areas, but there are no facilities nearby to wash it well. For example, you went to the forest for mushrooms or berries, to the lake. Running into a pond with a bucket to douse the car, simultaneously rubbing the dirt with an old rag, is not an option. For such purposes, you can make a small mini-sink from the simplest tools at hand. It will be very compact and will easily fit in the trunk of any car without eating up extra space.

To understand how to make such a device, watch this video:

Necessary materials for the manufacture of a mini-sink:

- foot pump;

- capacity;

- union;

- quick disconnect valve;

- lid;

- fungus from a tubeless wheel;

- hose;

- watering head;

- rubber gasket;

- glue;

- adapter sleeve;

- sealant.

To get started, we take a container prepared in advance. It can be an ordinary plastic canister with a volume of at least 10 liters. Ideally, you need to use a large capacity container made of thick plastic or metal.

A fungus from a tubeless wheel is built into the container lid, sealed with a rubber gasket on glue. The gasket can be omitted if the hole for the fungus is made very accurately, which allows it to hold tight and tight.

A hole is made at the bottom of the container, into which, with the help of an adapter and silicone sealant fitting is attached.

The watering head is equipped with a quick-release valve that allows you to connect a hose. Also, such a valve connects the hose to the tank.

It is best to use a watering head equipped with five modes of operation: 3 rain and 2 simple jets. This will make its use more functional.

Principle of operation.

Using a foot pump, we pump air into the container so that the pressure is no more than 0.1-0.2 atmospheres, this will be more than enough. This creates excess pressure inside the plastic canister, the air presses on the water in the container. Now it will be enough to open the valve of the watering head for the water to flow out. Just do not overdo it with pressure so that your container does not burst.

High pressure washers are widely used among residents of the private sector and car owners. This phenomenon is caused by the fact that the devices are used for various purposes: for cleaning paths in the backyard, when cleaning terraces, and even for washing cars and houses. To become the owner of the unit in question, it is not necessary to send it to a specialized store and spend a large amount of money. You can make an apparatus from a compressor and some other components.

Advantages of homemade equipment

If there is no financial opportunity to purchase a device, or there is a desire to assemble equipment for a high-pressure washer with your own hands, the instructions below will be of interest to you. Before you make a pressure washer, you should know about the advantages of technology:

- low financial waste;

- the possibility of modernization;

- functionality at the level of production equipment;

- fast production;

- operational simplicity;

- high efficiency;

- no spare parts needed and no extra costs.

With the help of the equipment, it is possible to effectively, quickly and efficiently wash off pollution of any degree of complexity. You will be able to clean various surfaces car body. A home-made high-pressure washer, made and operated with your own hands, eliminates damage to the treated surfaces. This quality favorably characterizes the cleaning technique in the eyes of the user.

We make our own equipment

First of all, you need to choose a suitable pump for washing. It is planned to operate the equipment for commercial purposes - make a choice in favor of industrial equipment. The basic principle remains the choice of a plunger pump equipped with ceramic pistons. The crank mechanism increases the service life. The main parts of a pressure washer are:

- washing filter;

- hoses;

- additional nozzles;

- water containers;

- detergents;

- sandblaster for washing;

- durable wear-resistant housing;

- High pressure pump;

- engine (petrol or electric).

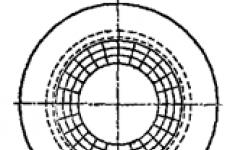

The schematic diagram of the operation of a home-made high-pressure washer is as follows: water is transported to a container from a special container or water pipe, after which it is pumped through a pump. The maximum load provides pressure up to 160 bar. Water is supplied through a hose to a gun with a nozzle. Consider the main steps in the manufacture of a pressure washer:

The schematic diagram of the operation of a home-made high-pressure washer is as follows: water is transported to a container from a special container or water pipe, after which it is pumped through a pump. The maximum load provides pressure up to 160 bar. Water is supplied through a hose to a gun with a nozzle. Consider the main steps in the manufacture of a pressure washer:

- The tank is equipped with a pump, and the connections must be completely tight and durable. Fixation involves the use of couplings.

- On the other side of the tank, you will need to fix the hose with which water will be supplied.

- The hose is equipped with a tip that directs the water jet.

An autoloading valve, produced in two variations, will need to be connected to the pump. The first type is represented by a closed valve. The system depressurizes after the gun is closed and then the water is pumped from the outlet to the inlet. It is recommended not to operate the device longer than 3 minutes. The valve with a supply differs in convenience. The liquid is transported through the collector to the tank or to the sewer immediately after the pressure is released (depending on the connection option of the sink).

There are two ways to connect the motor to the pump. In the presence of a motor with a full shaft, docking with the pump directly is possible. The motor shaft is placed on the front bearing, which creates an additional load. This technique shows the most economical results. If you make a sink with such an engine with your own hands, then it will have a significant overhaul period of operation. This is caused by high starting loads. It happens that it is not possible to remove the pump shaft from the engine. In this regard, it is advisable to install the device soft start.

Another method of coupling the motor to the pump is envisaged, which uses a clutch. It is used as a cushion, which softens the impact during the start-up of the equipment. The coupling serves as a protection that prevents the violation of the bearing of the shafts. In order to reduce the load during start-up, a soft start is allowed. Thanks to given element it is possible to gradually increase the power in the system.

The sink is mounted on a frame. The installation of the electrical component, the gun with the nozzle, and the high-pressure hose is carried out sequentially. It is important that the equipment in question be installed according to the recommendations of the part manufacturers.

The sink is mounted on a frame. The installation of the electrical component, the gun with the nozzle, and the high-pressure hose is carried out sequentially. It is important that the equipment in question be installed according to the recommendations of the part manufacturers.

Follow the established algorithm for assembling the device, take into account the load present during the tightening of the bolts. Also use anaerobic fixatives.

The sink must be connected to the water supply system with a hose. The connecting hose must be at least 7 meters long. The length of the hose allows you to smooth out pressure drops in the water supply. Consider a sink filter. It is recommended to use a hose with a non-return valve, which increases the working pressure.

- Debris accumulating in the filter element of the tank must be removed in a timely manner.

- It is advisable to inspect the connections in time, tighten if necessary.

- Each electrical element of a homemade sink must be grounded, for which use a flexible three-wire wire in double insulation. Also use a grounding plug for this purpose.

- Connect the power outlet to earth ground securely.

- The strong pressure of the jet produced by the apparatus is not needed. Otherwise, the pressure pump will be overloaded, which is then likely to adversely affect the paintwork of the equipment. These actions will cause moisture to enter the electrical equipment, damage to equipment and additional waste.

- Choose a water pressure that is suitable for removing basic dirt from the surface to be treated.

The product must be comfortable during operation, and therefore you should not resort to the use of large parts. If you live in an area where power is often cut off, it is advisable to provide an alternative power source: equip the equipment with a rechargeable battery.

The product must be comfortable during operation, and therefore you should not resort to the use of large parts. If you live in an area where power is often cut off, it is advisable to provide an alternative power source: equip the equipment with a rechargeable battery.

The device of its own production is able to wash off pollution of varying complexity from any surface, from any object. Even the most stubborn stains of dirt will be removed without any streaks or residual dirt. Big advantage installation, it remains impossible to damage the surface to be treated during the cleaning process. Listen to the advice of experienced professionals - save time and money by creating useful Appliances with your own hands.

Very high popularity recent times got pressure washers(AVD), most often they are used in car washes. With the help of AVD, you can quickly and efficiently wash the car body, engine compartment, such hard-to-reach places as the bottom and fender liner. But the use of such units is not limited to the car: they are successfully used in agriculture, metallurgy, public utilities, etc.

The basic principle of cleaning is a directed jet of high pressure water. Coming out of a special nozzle (nozzle), it is able to effectively clean the most severe contaminants and eliminate complex blockages in pipelines.

Therefore, the "heart" of the AED- (or pump) high pressure.

After carefully studying this article, you can easily collect enough professional apparatus high pressure by purchasing components for assembly and on our website.

Consider how you can assemble a medium-sized high-pressure apparatus for washing cars, cleaning pipelines with a diameter of up to 150-200mm, pumping sludge from wells and settling tanks, washing facades, and hydrosandblasting.

Price pressure washers consists of two main components: a pump (pump) and a drive (, an internal combustion engine, a hydraulic drive). This is the most expensive part in creating an AED.

It is necessary to rely on three main parameters: working pressure, productivity (water consumption) and shaft rotation speed. In order to cope with the above tasks, we need with a capacity of 900 to 1250 liters per hour and an operating pressure of 180 to 250 bar. Low speeds on the pump shaft have priority over high ones, as this increases the life of the pump. An important role is played by the width of the connecting rods on the shaft, however, with proper operation (sufficient level and timely oil change, prevention of overheating), this parameter can be neglected.

electric motor. It is necessary to determine the power of the electric motor (or other drive). Many manufacturers of high pressure pumps are willing to publish information about this in the characteristics of their products. For example, let's take a capacity of 900 liters per hour and a working pressure of 200 bar. An approximate calculation, without delving into exact formulas, will be as follows: the product of productivity (l / min) and pressure (in bar) is divided by 550. We get the power value. Connecting the electric motor to the network is necessary through a contactor or a special starter. All equipment must be grounded.

electric motor. It is necessary to determine the power of the electric motor (or other drive). Many manufacturers of high pressure pumps are willing to publish information about this in the characteristics of their products. For example, let's take a capacity of 900 liters per hour and a working pressure of 200 bar. An approximate calculation, without delving into exact formulas, will be as follows: the product of productivity (l / min) and pressure (in bar) is divided by 550. We get the power value. Connecting the electric motor to the network is necessary through a contactor or a special starter. All equipment must be grounded.

On the resulting "monoblock", at will and possibilities, you can "hang" pressure, switches "", thermal valve, damper, pressure gauge, cleaning filter and much more.

On the resulting "monoblock", at will and possibilities, you can "hang" pressure, switches "", thermal valve, damper, pressure gauge, cleaning filter and much more.

If the device is to be used permanently, then there is no need for a frame. But then you will need to find a reliable place to mount the electric motor.

If a AVD is supposed to be moved from place to place, then it will be required frame from metal pipes or profile, for mobility it can be equipped with wheels and an emphasis, as well as handles for easy transportation.

The quantity and quality of the water supplied to the high pressure pump is important.

Storage capacity. The best way to solve this issue is a storage tank that has auto-fill from water supply network using a conventional float valve. It is necessary that the container is not completely sealed, but excludes the possibility of dirt or particles getting into it, so as not to damage the seals or the ceramic inserts of the pistons (plungers). To do this, a filter is installed at the inlet to the tank and the necessary valve is arranged from above. It is not recommended to add the washing solution directly to the container. For this, it is best to use sprayers, foam injectors.

Storage capacity. The best way to solve this issue is a storage tank that has auto-fill from water supply network using a conventional float valve. It is necessary that the container is not completely sealed, but excludes the possibility of dirt or particles getting into it, so as not to damage the seals or the ceramic inserts of the pistons (plungers). To do this, a filter is installed at the inlet to the tank and the necessary valve is arranged from above. It is not recommended to add the washing solution directly to the container. For this, it is best to use sprayers, foam injectors.

Most high pressure pumps are capable of self-priming (self-priming), but you should not place the pump above 0.5 meters and use a regular garden hose to supply it. For these purposes, you need to purchase a rigid hose (pressure-suction). The inner diameter of the hose for a pump with a capacity of 900 liters per hour must be at least 15 mm with a length of 3-5 meters.

Ordinary "soft" hoses are only suitable for use directly from a pressurized water supply network. But do not forget that in such networks there are problems with the water supply necessary for the pump. This can adversely affect the operation of the pump and shorten the life of the internal seals ().

Regulator. When installing a pressure regulator the best way connection will use a bypass channel with its circuit in a storage tank. In this case, when the gun is closed, the water will circulate through the container, and not inside the pump.

Regulator. When installing a pressure regulator the best way connection will use a bypass channel with its circuit in a storage tank. In this case, when the gun is closed, the water will circulate through the container, and not inside the pump.

High pressure hose or - the length is selected as needed, several short hoses and a special connector can be used. So that the hose does not wear out prematurely, because. usually uncoated concrete floors in washing rooms, it is worth using a special spiral protection made of polypropylene.

High pressure hose or - the length is selected as needed, several short hoses and a special connector can be used. So that the hose does not wear out prematurely, because. usually uncoated concrete floors in washing rooms, it is worth using a special spiral protection made of polypropylene.

For sewer cleaning hoses and (nozzles) are used.

, nozzles, nozzles- everything can be purchased for specific tasks that you set to perform current tasks.

Important Tips:

Watch the threaded connections - they should not leak and be securely fastened.

Do not try to unscrew the hose, if it is under pressure - turn off AVD and take the pressure off!

Clean the filter regularly, even if it is "visually clean".

Do not use gun on-off switch unnecessarily - frequent operation wears out the gun regulator and valve!

Basically, for proper use AVD just read the instruction manual! Your device will serve you for a long time and will require regular replacement of wear parts in the pump - cuffs, valves, pressure regulator and scheduled oil changes.

The household goods market is replenished every day with new products that are designed to make life easier for a person. And here, far from the last place is occupied by a high-pressure washer, which makes it possible to significantly facilitate the process of washing a car, paths, shop windows and much more. A powerful jet of water is able to clean dirt even in the most inaccessible places, to cope with old dirt on any surface.

But at the same time, it is worth noting the fact that, due to the high cost, not everyone can purchase a device of this type, and therefore some craftsmen make it on their own. But how can you do a high-pressure washer with your own hands, we'll talk in this article.

| The content of the article: |

How to make your own pressure washer

pump and electrical network . For any water supply device, the pump is the basis. And in our case, it should also be powerful enough (from 150 atmospheres).

When choosing a pump, special attention should be paid to the working units, that is, the material from which these products were made.

If possible, we choose a product with a high-strength metal or ceramic piston. In this case, the block head is recommended to be selected from brass or bronze alloys. This design can last much longer. The resource between repairs is quite high.

A speed of 15 l/min will be sufficient for the pump.

It is recommended to choose an electric motor with a voltage of 220 V. An additional capacitor unit can provide a reliable start. Higher speeds also ensure greater productivity. But at the same time, a pump that is too fast at maximum operating speed is subject to intense wear.

The best option is a consumer of 2-3 kW and rotation up to 2000 rpm.

A home-made high-pressure washer, in order to preserve important nodes in the chain, must also have safety elements. This link is the coupling connecting the pump to the engine.

If possible, we install such a coupling that could compensate for small axial misalignments between the shafts.

You can also install a single stage belt drive, which will balance the speed and load between the motor and the pump.

The subordinate number is selected based on the required parameters for the frequency of rotation.

Reservoir and performance regulator. The minisink also needs a water tank. In this case, you can use a simple tank, which, if necessary, can also be powered from a permanent source of water (well or water tap).

To exclude the possibility of various debris entering, it is recommended to install coarse and medium filters at the inlet to the tank.

We also add shampoo or other approved auto cosmetics to the main water tank. In this case, the washing process will be more efficient.

As a rule, the pump has a capacity regulator combined with an unloading autovalve that redirects unused pressure back to the tank, reducing the load on the pump.

External elements. We mount all elements on a frame, which can be made of profile or round curved pipes. For the convenience of transporting the unit, a pair of wheels can also be attached to the down pipes. In addition, we also install stops for fixing and a handle.

How such a mini sink will look like can be seen in the photo.

For a high pressure hose, you can use a plastic or rubberized reinforced hose. Be sure to ensure the tightness of the connections using high-quality clamps or hydraulic seals.

The fittings and valves used must be made of low-corrosion alloys: brass or bronze.

Water will be supplied through the gun from the nozzle installed in it. Visually, it looks like a pistol from a gas station. A jet of water will be formed after pressing the key, which in turn will also save the working fluid with consumable additives. You can buy a pistol of this type in almost any hardware store.

- Periodically inspect the connecting units, and, if necessary, tighten the threaded connections with a wrench.

- In order not to reduce the throughput of a home-made mini sink, before each connection we inspect the filters installed in the device.

- To avoid accidents during operation, without fail we make electrical grounding. Therefore, the plug used must be with a grounding terminal, and the cable must be copper, three-core.

How to make a foam generator with your own hands?

You can make a foam generator at home. Of course, in terms of functionality, such a device will lag behind its counterpart, but in everyday life it is difficult to overestimate its benefits.

Of the tools we need:

- Set of wrenches;

- Roulette;

- Bulgarian;

- pliers;

1) .We use an inch pipe with a length of about a meter. We hammer the front part of the product with a plastic washcloth, the purpose of which will be the formation of foam.

2) . For one of the edges of the pipe we make a plug, we also screw a special tee here. After that, we connect a tap to the foam generator to the inlet hole.

3) . On the other side of the pipe, we install a tap, through which it will be supplied compressed air from a car compressor.

4) . We combine the second pipe outlet through a special fitting with a foam hose. To prevent the washcloth from getting into the tube, we also install a special filter. In this case, the filter element may have large sections.

A diagram of a foam generator of this type is presented below.

Please note that the density of the produced foam depends on the length of the tube and the density of its stuffing with a washcloth.

Any container that can withstand the pressure of the compressor is suitable as a liquid tank.

How to properly wash a car with a car wash?

Hand washing is the so-called easy option car cleaning from pollution. But as practice shows, in this way it is possible to partially clean the surface of dirt. Another thing is the use of special technical means– car washes that supply detergent and water under high pressure.

Thus, it is possible not only to clean the dirt, but also a layer of oxides and synthetic resins, which, while driving, are deeply “rubbed” into the paintwork.

- From the car wash sprayer, use a jet of water in different directions to knock off the dirt.

- Under low pressure, apply a weak foam concentrate to the surface of the body, which will effectively wash off the first two layers of dirt.

- Rinse the car surface with plenty of water.

- Apply the main detergent under high pressure, and this must be done from the bottom up. Leave the applied product for 3-5 minutes. At this time, you can wash the rims, suspension elements, bottom.

- Rinse the surface of the car with plenty of water. Remove its remnants with a squeegee and special napkins. Wipe the car dry, without ignoring the internal surfaces (thresholds, doorways).

- It is not recommended to wash the car until its body has cooled down. . The consequence of the contact of water with a hot body may be the occurrence of a corrosion process.

- If the surface of the car has ever been repaired using putty, do not wash the car with too high pressure.

- It is recommended to wash the car with special detergents no more than 1-2 times a month, as such products contain substances that can adversely affect the paintwork.

- If possible, use the manufacturer's recommended cleaners, as they will work best on the vehicle's paintwork.