Making plastic windows with your own hands. Do-it-yourself assembly of modern plastic windows Installation of plastic windows

PVC profile welding is one of the main operations in the production of PVC windows. The quality of the welding process ensures operational properties finished window, its aesthetic appearance and technical

PVC window profile welding is one of the main operations in the PVC window production process. The quality of the welding process ensures the operational properties of the finished window, its aesthetic appearance and technical characteristics.

In the window unit, frame and sash profiles are welded at the corners. The profiles must fit snugly against the collets, which completely repeat the configuration of the profile. The clamping pressure must be such as to exclude the possibility of their displacement and deformation during welding. Skewed plates are not allowed. To provide High Quality seam, and therefore its durability, it is necessary to withstand the welding conditions that are determined by the manufacturer of this PVC profile.

Welding machines

Welding machines are distinguished by the number of welded heads. The most popular welding machines are considered one-, two-, and four-headed. Multi-head in-line welding machines are used for simultaneous welding of contours and welding of mullions in one working cycle. This technology is not popular in the manufacture of PVC windows in our country.

On a single-head machine, one window contour is welded in four cycles, on a two-head welding machine, two cycles are required, on a four-head machine, all four corners are welded in one cycle in automatic mode. The most productive is a machine with four welding heads.

Single Head Welding Machine

The single-head welding machine has the ability to weld profiles at a non-standard angle, that is, not at 90 degrees. The same possibility is provided on some two-head welders where one of the weld heads has a similar mechanism. The four-head welding machine is designed to weld standard corners and is used for large volume production of standard PVC windows.

Four-head welding

There are two types of four-headed machines - vertical and horizontal. Vertical welding machines are more compact, but cannot be integrated into automatic welding and cleaning lines. In such lines, horizontal four-head welding machines are used. These lines occupy large areas in PVC window production, have a high productivity and require a smaller number of labor involved.

Welding process

The process of PVC profile welding in window production provides for strict adherence to the prescribed standards of welding technology, namely: heating of the PVC profile surfaces to be welded, duration of surface melting, welding temperature, sufficient cooling time of the welded profiles. It is also necessary to maintain cleanliness working area, timely clean the melting elements of the machine and the PVC profile itself for the correct and reliable welding of the profile. The technical conditions for welding PVC profiles require strict adherence to the quality control rules for the welded window contour, since the quality of the weld depends on the further strength of the finished product, that is, PVC windows, its operational longevity and safety.

During the welding process, it is necessary to strictly adhere to the necessary conditions welding:

The temperature of the welded knife is 230 - 250 °C.

The surface of the knife must be clean.

The Teflon coating of the knife is wiped with clean cotton or a paper towel every hour, on a “hot” basis, without the use of solvents.

Seam heating time - 25 - 40 sec.

Seam welding time - 25 - 40 sec.

Before installing the PVC profile on the welding machine, it is necessary to make sure that the surfaces to be welded are clean, since grease, dust, PVC profile or metal shavings drastically worsen the quality of corner welding. After the end of the welding process, a visual quality control of the welded seam of the metal-plastic window is carried out:

the seam should be white (darkening is not permissible, as it indicates that the heating temperature of the welding knife was too high or its warm-up time was too high).

the seam should be uniform along the entire length.

The blanks must be welded over the entire area of the surface to be welded. Compliance control overall dimensions products according to the order form. Teflon film is changed after 300-400 welding operations. Heating temperature, heating time and exposure under pressure are specified for each batch of profiles.

When welding PVC profile, pay attention to the following

moments (causes of possible welding errors)

The strength in the corners is significantly reduced if the temperature of the welded profiles does not reach 17 ° Celsius, or there are

large drafts;

From the correctness of sawing the profile on the mustache, if the inaccuracy of the angle exceeds even 1 degree.

The temperature according to the indicators of the device does not correspond to the temperature of the welded plate;

The welded plate is cooled on one side by a draft;

The temperature, time and pressure of the melt do not correspond sufficiently to each other;

Weld stoppers set too narrow;

Insufficient pressure of pressure plates;

Correspondence of the dimensions of the clamp to the dimensions and configuration of the welded profile;

Welding surfaces are located due to incorrect fixing (adjustment of the welding machine) or cutting not

parallel to the heating plate.

Temperature in industrial premises should not fall below 17 ° C, relative humidity - not higher than 70%. The area of the fillet weld, as well as its quality, along with the nature of the fastening of the impost, are decisive for the spatial operation of the window block under the action of operational and installation loads.

A bright weld bead near the weld indicates that the welding was carried out correctly. The blanks must be welded over the entire area of the surface to be welded. The seam must be uniform and free of cracks.

If a weld bead forms when welding a white profile Brown color with a rough surface, this means that the material has been burned due to too much high temperature welding or too long melting time. At low temperatures, the seam bubbles.

Windows with such defects are not accepted for installation in openings, and are definitely subject to alteration.

During welding, temperature, pressure, cycle time, surface cleanliness for welding, as well as the size of the profiles along the length before and after welding, the welding angle, the diagonals of frames and sashes, are controlled on a scale of instruments,

dimensions in width and height.

After welding the frames, the strength of the welded corner joints is checked. For this, corners of 250x250 mm in size are cut from PVC profile at least 10 pcs. and carry out their tests in accordance with GOST 30674-99 "Window blocks from

PVC profiles\".

Welded profiles must cool down for about 5-10 minutes before they can be processed further. Do not cool the weld in an accelerated way with compressed air and avoid contact with a cold floor, which leads to the formation of uncontrolled stresses in the material and the possibility of rupture of the welded parts.

Automation of the welding process

Automation of the welding process is carried out using the so-called welding process controller.

The controller provides semi-automatic control of the welding process and maintenance of the set heating temperature.

Its main functions:

- measurement and indication in digital form of the temperature of the plate (knife);

- start and stop of the machine according to the given program;

- automatic temperature control of the plate;

- indication in digital form of the algorithm of the machine;

- operational setting of the required plate temperature;

- operational setting of the required duration of heating and welding.

The average power consumption of the controller is about 20 watts. The average service life is at least 10 years.

According to the Center modern technologies"Universal", STK companies

| Brand " Different brands» in the Equipment Catalog >>> Brand "Different brands" on the Equipment Exchange >>> Suppliers of the brand "Different brands" in the Catalog of Companies >>> |

|

During the construction of his mansion, one acquaintance decided to buy windows, while it was impossible to ignore the graph with the cost of the material.

The builder was in a slight shock! The price was almost two times lower than the cost of the entire order. It was then that it was decided to purchase a profile and other materials at cost, and that PVC plastic windows would be made from them with their own hands.

The equipment necessary for the work was also assembled by hand. To obtain the desired welding fixture used hand tool, which was at hand - in the form of drills, electric jigsaws, punchers, and other necessary tools.

The cutter for trimming the impost was purchased - in the same place where the profile was taken.

Since the profile is available today in a wide variety of shapes and designs, it is recommended to look through the product catalog before ordering.

Before buying, you should also make sure that there is a steel frame inside the profile, which enhances rigidity. window frame and prevents breakage.

Profile processing steps

First of all, you need to make a measurement. After measuring and marking, the ends of the profile should be milled, providing them with transverse compatibility. To cut corner joints, a "corner cutter" is used - a device that cuts at a certain angle. Each profile joint must be adjusted to the nearest degree. All angles must be respectively 45 degrees.window frame soldering

To fasten the workpieces for welding, peculiar shoulders are used - one such shoulder can move along the guide skids. For the manufacture of heating element two burners were taken from an electric stove, and covered with teflon fabric. Heating can be adjusted.

After heating, the workpieces must be pressed against one another using a pneumatic cylinder from a jack. Thanks to the stop system, the melted edges of the workpieces are not pressed into each other by more than 3–4 mm. Compressed air is injected into the receiver, made from an old gas cylinder, due to car compressor(up to 4 kg/s).

When the seam has cooled, the procedure is repeated with the next pair. Thanks to the clamping system, almost all types of profiles can be fastened.

To clean the weld in the plane, we take a wide chisel, from the ends - a knife.

Before windows are installed, make sure that all corners are glued and fastened at a 90 degree angle. If at least one corner does not meet this indicator, the window must be considered defective.

Double-glazed windows for PVC windows

We finished with the frame, then we need to insert a double-glazed window inside. It is several layers of glass connected in a certain way. There can be a different number of them - for example, 2 or 4. The glasses that the glass cutter measures and cuts must be placed one on top of the other and a special metallic profile, and fill it with small balls that will absorb excess moisture. When the metal profile is ready, we put it between the glasses and cover it with a special polymer, similar to a rubber compound. In this way, an airtight space is obtained between the glasses, which acts on the principle of a thermos.

Glasses are simple and energy-saving. The second type of windows is different in that it reflects heat and keeps it indoors. Such PVC windows are correspondingly more expensive.

Before ordering, you need to decide on the type of double-glazed window. If winters are mild enough in your area, single glazing will suffice. But where severe frosts are commonplace, it is better to install a window with two or three glasses.

Double-glazed windows should dry well, then you can proceed to their installation. They are simply inserted into the window frames that are pre-made. Usually there are so-called bonnets with a rubber edging in the profiles - this design does not let air in from the outside. We also cut these bonnets with a corner cutter to fit the window frame, and then insert them into the frame profile.

accessories

The choice of accessories - handles, mechanisms, etc. should be approached with special attention. Keep in mind that the room where the plastic windows are located must be constantly ventilated. That is, you will often open and close the window, which means you will use fittings. The life of the windows directly depends on the quality of the mechanisms. Therefore, it is worth choosing more expensive, but reliable fittings, so that later you do not bother with window repairs.

Installation of plastic windows

should be trusted exclusively to professionals in this matter. It is also not worth saving here, it is better to do it once and with high quality. After the windows are installed, it is recommended to check them several times - open, close. The design should work clearly, flawlessly, and easily enough. Mounting foam should be applied evenly and in the right amount to ensure proper sealing. The result is user-friendly windows, energy savings, soundproofing, and stylish interior rooms and the exterior of your home.

Nowadays, you will not surprise anyone with plastic windows, presented in a large assortment on the market. Not so long ago, for many it was a novelty, but now it is commonplace. If suddenly you are faced with a choice of which PVC windows to choose, then you need to know that there is simply no 100 percent standard. In this article we will look at the technology of manufacturing windows, with all the little things that will be useful to you when choosing this product.

Everyone agrees that coziness and comfort in every home certainly depends on heat, which means that plastic windows are the detail that contributes to its formation. What is the secret? Why plastic windows retain much more heat than traditional ones? And why have they become so popular in our time?

A highly conductive polymer is the material from which the windows are made, in everyday life it is simply called "profile". This product is highly resistant not only to moisture ingress, it is also not afraid of temperature changes, as well as exposure to sunlight. That is why you do not have to paint the windows every year because they dry out, lay cotton wool for the winter, as our parents did, all these problems are left behind.

"Profile" can be of various shapes and designs, usually, before ordering windows, it is best to look through the catalog of profile shapes. The firm and quality of the profile may not always match the original appearance.

Before ordering PVC windows, make sure that a steel frame is laid inside the profile, which prevents brittleness and adds rigidity to the window frame.

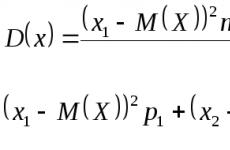

The profile goes through several stages of processing before you can see the resulting frame from it.

The first stage is freezing. After measuring and marking desired size the ends of the profile are milled for their transverse compatibility. Corner joints are cut off with a "angle cutter" device that cuts at a certain angle. All profile joints must be fitted to the nearest degree, in all corners there must be a correspondence of 45 degrees.

The second stage is soldering and fastening. Different parts of the profile are interconnected in two ways: soldering and mechanical fasteners. The edges of the frame (previously sawn off at 45 degrees) are placed on a special device - an iron, which presses two profiles and solders them together. Well, here, the corner joints are ready. The internal connections of the profile are fastened with fittings (angular plate) using special screws.

Before your windows are installed, make sure all corners are glued and stapled at 90 degrees. Otherwise, if one of the corners does not meet this requirement, the window can be considered a defect.

The frame is ready, now it's worth inserting a double-glazed window inside. A double-glazed window is an unusual combination of several sheets of glass. From how many sheets of glass - 2.3 or 4, double-glazed windows are called double or triple, etc. Glasses pre-measured and cut with a glass cutter are placed together on top of each other, a special metal profile is laid between them, into which small balls are poured - ... These balls suck out excess moisture. After the metal profile is prepared, it is placed between the glasses and coated with a special polymer (something similar to a rubber compound). Thus, a space is formed between the panes, while being absolutely hermetic. This can be compared to a thermos system.

The glasses themselves are divided into categories: simple and energy-saving. Energy-saving windows reflect heat, keeping it inside the house. The price of energy-saving glass is, of course, higher.

Before placing an order, decide which double-glazed window you want to install. If you live in countries where the winter is not so fierce, then a single one is quite enough, but if the winters are very cold, then opt for a double or triple glazing.

After the double-glazed windows dry, they will become usable. They are simply inserted into pre-made window frames. As a rule, the profile has “bonnets” with a rubber edging, this allows you to not let air in from the outside. The "bonnets" themselves are also cut with an angle cutter to fit the window frame, and then simply inserted into the frame profile.

It should be borne in mind that the choice of accessories: handles, mechanisms, etc. is a very important part that deserves special attention. It should be borne in mind that the room where plastic windows are installed constantly needs to be ventilated. Therefore, you will very often open and close windows, which means using mechanisms. Their service life depends on how high-quality fittings are installed on PVC windows. It is better to spend a little more, but be sure that your windows will not give you unnecessary problems with their repair.

Installing windows is another item that should not slip out of your sight. A team of professionals should know their business well. Check all windows after installation, open, close them several times, nothing should cling or interfere with opening. Mounting foam should be applied evenly around the entire perimeter of the slots. After all, sealing is the key to heat in the house.

The quality of the window sill can affect the entire work. Choose leading manufacturers so that after all the work, after a while you have problems with the window sill, which will require its replacement.

It is not easy to make plastic windows on your own, but, as practice shows, it is possible. Eurowindows have a number of advantages, but the price of a finished structure is often quite high. This is especially noticeable if you plan to install plastic windows in a house with non-standard window openings. In this regard, many are thinking about how to make plastic windows with their own hands.

Self-manufacturing of plastic windows

Firstly, for the manufacture of windows you need a room. With "home" production plastic windows with their own hands, this room will be used for cutting blanks, assembling window structures and storing materials. The floor area must be at least 35 sq. m., with a long side of at least 7 meters, because the finished PVC profile for eurowindows is sold in lengths of 6.5 meters. To make plastic windows with your own hands, you will need a steel reinforcing profile, sealant, fittings and double-glazed windows. All blanks must be stored on special racks. For cutting blanks, a working workbench is needed; the euro-window structure will also be assembled on it.

Secondly, in order for you to be able to assemble reliable plastic windows with your own hands, you need special equipment. The minimum required set includes profile cutting tools, a milling machine and welding machine. You will also need a drill, a grinder, a hammer, a square, a tape measure and much more from the carpentry and metalwork arsenal.

If there are no difficulties with the presence of a conventional tool, then the selection special equipment for the production of plastic windows becomes a separate task. For cutting reinforcing parts and PVC profile, you should purchase a pendulum saw, because. You will have to perform this operation several times. A special tool will allow you to cut workpieces quickly and safely.

A welding machine is often in the arsenal of those who are used to doing everything themselves. Do-it-yourself plastic windows are unlikely to justify its purchase in terms of financial costs. It is better to rent a welding machine for a while. You will also need a workbench with fixtures for holding workpieces and guide rails. This will allow you to perform high-quality welds.

When making plastic windows, you will periodically need a milling machine. With its help, the impost is trimmed. Unlike welding, this can be done at a third-party site where the equipment is available. Drainage holes and handle holes can be drilled with a conventional electric drill.

After assembling the frame and installing fittings, the installation of a double-glazed window follows. Glass is installed on the adjusting plates, which are set in advance. When the double-glazed window stands exactly in the frame, it is fixed with glazing beads. Plastic windows must be airtight. To do this, a sealing contour is installed around the perimeter of the frame.

After assembling the frame and installing fittings, the installation of a double-glazed window follows. Glass is installed on the adjusting plates, which are set in advance. When the double-glazed window stands exactly in the frame, it is fixed with glazing beads. Plastic windows must be airtight. To do this, a sealing contour is installed around the perimeter of the frame.

Having decomposed the process of production of plastic windows into separate components, you will understand that this is quite a feasible task for those who are used to relying on their own strength.