Apparatus for breathing compressed air. Sooo "factory of modern fire fighting equipment"

Aerotecnica Coltri Spa is one of the world's largest compressor manufacturers high pressure breathing air and technical gases. http://www.coltri.com/

The core business of WISS is the production of technologically advanced special fire trucks, fire fighters and work lifts. http://www.wiss.com.pl/

MSA is a world leader in the development and production of personal protection(PPE) and ensuring safety at work. The priority areas of the company are self-contained breathing apparatus, stationary and portable gas and fire detection systems, PPE against falls from a height, head, eye, face and respiratory protection, gas analyzers. http://www.msasafety.com/

SAFER® innovations from Techplast Ltd. based on a 65% reduction in cylinder weight compared to a steel cylinder. The effect of lightness is achieved through the use of a PET liner and high-quality carbon and aramid (Kevlar) fibers. http://www.safercylinders.net/

STAKO is a world leader in the design and manufacture of pressure cylinders, which are widely used in many industries. Mission to become the world's best manufacturer of pressure cylinders for air, LPG and CNG. http://www.stako.pl/

Worthington is a global manufacturer of high pressure cylinders. Kienberg seamless steel cylinders are known for their unique quality in over 70 countries around the world. The latest innovation is the Longlife Powercoat powder coating technology, which has set a new standard for exterior coatings. http://worthingtonindustries.at/en/

CJSC Eliot was founded in 1998 in St. Petersburg. It is a developer and manufacturer of fire-resistant materials and personal protective equipment for firefighters. The organization supplies personal protective equipment for the needs of the Ministry of Emergency Situations, the Ministry of Internal Affairs, the Ministry of Defense, enterprises of the oil, gas and chemical industries. http://www.zaoeliot.com/

KZPT is engaged in the production of protective helmets and helmets for special purposes from hardened resins with glass mat. Дaннaя тeхнoлoгия в тeчeниe мнoгиx лeт пpoизвoдcтвa дaлa вoзмoжнocть cпeциaлизaции зaводa в пpoизвoдcтвe выcoкокaчecтвeнных и фyнкциoнaльных шлемов, котopыe пoлyчили пoлoжитeльнyю oцeнкy кaк пoльcких тaк и зapyбeжных пoльзoвaтeлeй. http://www.kzpt.pl/

LLC "BLIK" - 7 years of leadership in the production of professional flashlights for industrial and military purposes! The BLIK company develops and produces professional battery-type flashlights for search and rescue activities and general industrial purposes. The products of the enterprise are in demand in the bodies of the Ministry of Emergency Situations and the Ministry of Internal Affairs, for metro services, border guards, housing and communal services, etc. http://www.ooo-blik.ru/

LLC "Tierney and Henderson" is the exclusive distributor of the largest Russian manufacturer of hydraulic rescue tools (GASI) - the plant "Agregat". New Tool features a much more extensive range, improved performance, a more reliable and compact control unit, a more convenient type of connector that allows you to connect a tool without depressurizing. http://tierney-henderson.ru/

Fireco is a leader in the manufacture of special telescopic masts made of high quality aluminium. They are fitted with halogen or LED lamp, antennas, radars and cameras. Fireco also manufactures motor pumps and high pressure kits for first responder vehicles. The wide range of telescopic masts also includes the Aquamast series, which is equipped with a fire monitor for extinguishing fires in tall buildings. http://www.fireco.eu/

The F.M. "BUMAR-KOSZALIN" - has been supplying more than ten types of car lifts for more than seventy years, including: fire telescopic lifts designed for rescue operations, civil lifts. Many years of experience, knowledge and potential, together with a modern technological idea, as well as the company's design capabilities, allow us to expand the range of products offered, thereby strengthening the position of the WISS Group on the international market. http://www.bumar.pl/

VTI Ventil Technik GmbH has been designing and manufacturing valves for medium and high pressure cylinders since 1946. It is the largest supplier to all countries of the world. The company's products meet all applicable requirements, and even surpass them in some respects. http://www.vti.de/

JANKO DOLENC s.p. since 1979 has been manufacturing gloves and safety shoes. In 2000, they began to produce boots for firefighters and rescuers, and their certification was also carried out. Currently, the company has 32 employees on 1400 sq. m of production space. http://www.brandbull.si

The company “Latakva Fire Service” operates in the field of sales of fire equipment, firefighting maintenance and repair, as well as in the production of fire protective compositions throughout Latvia and the Baltic. https://www.latakva.com/en/

Since 1993, the company has been supplying equipment to the fire brigade and other emergency services, and has been manufacturing fire and rescue equipment.

Human beings need air to function. It contains vital oxygen and nitrogen. But sometimes a situation may arise when it is impossible to get access to the usual air. This problem is relevant for divers, firefighters and many others. And in these cases, breathing apparatus with compressed air comes to the rescue. What are they? What variety is there? How to look after them? These and a number of other questions will be answered in this article.

general information

And let's start with the terminology. So, breathing apparatus with compressed air (also known as SCBA) is an insulating reservoir device, which provides for the possibility of storing substances necessary for the functioning of the human body. As a rule, a balloon is selected for this. The air in it is stored in a compressed state. DAVS work according to an open breathing pattern. In other words, inhalation is carried out from the balloon, and exhalation is carried out into the surrounding atmosphere. What do compressed air breathing apparatuses look like in general terms? The scheme of their device usually assumes the presence of:

- Cylinder with valve.

- Hanging system.

- Reducer with safety valve.

- Lung machine with air hose.

- Sound signaling device.

- Exhalation valve.

- Devices for additional air supply.

- pressure gauge.

- Front part with intercom.

Also can be attached additionally:

- A fitting that is used for quick refueling of cylinders.

- Rescue device connected to a breathing apparatus.

- Quick connector for connecting a life-saving appliance or ventilator.

When trying to classify AHRS, the question immediately arises of what to choose as a reference point. So, if you look at the design, it will be one thing, the purpose is completely different. Questions about air consumption, its reserves and much more are also relevant. Therefore, in order not to get lost among the three pines in the future, let's deal with all the species diversity.

Classification of breathing apparatus

With compressed air, they do not need to be. If we consider the design, then they are created:

- Open circuit. It is to them that the considered breathing apparatus with compressed air belongs.

- Closed loop. They run on compressed, liquefied or generated oxygen. Rather uncommon due to complex Maintenance and high fire hazard.

In addition, the classification is still carried out on the basis of the principle of their action: non / autonomous. If we talk about the use in difficult conditions (for example, for firefighters), then such devices belong to the second type. And this is not surprising - who knows where you have to climb.

In addition, there are lung machines with excess air pressure under the front of the device and without it. These devices are more focused on people who have to work in conditions high temperatures. For example, firefighters. Excessive pressure in this case is necessary in order to protect a person from a smoky and toxic gas environment during fire extinguishing. After all, they perform their duties in extreme conditions, in which being without special breathing apparatus is guaranteed to cause health problems or even be fatal. Structurally, they are an insulated gas mask that does not involve the use of ambient air.

Interaction with the design: check

Respiratory protection in case of fire or deep sea diving is a priority. And in this case, it is extremely important that everything works without problems. Therefore, the design must be carefully and carefully checked. Previously, a list of what is included in it has already been presented. Now let's look at the intended purpose of each component and why you need to check the breathing apparatus with compressed air:

- The front part - allows you to protect human organs and provides the usual working conditions for the whole organism.

- One/two/three cylinders are needed for storage compressed air. To prevent it from getting lost, they are equipped with a shut-off valve.

- The flexible hose system provides air supply to the breathing zone.

- A manometer is needed to determine the residues.

- The alarm mechanism warns of the imminent stoppage of work and that you should leave the danger zone.

- The charging of the cylinder is carried out thanks to high-pressure compressors, which are equipped with a system for filtering and drying the surrounding air.

For operational preparation of equipment in the middle of the process of work and further activities, additional rescue devices can be used. Their purpose is to quickly restore air supplies. If everything is done correctly, then a person will be created comfortable conditions breath, in which stocks will be spent economically, and there will also be no third-party chemical components. When inspecting the structure, it is necessary to pay attention to the signaling mechanism - you need to make sure that it works without problems. All this will save your life from possible problems.

However, it should be noted that all these devices have a significant weight and dimensions, and the cylinders also need periodic recharging.

And a little about gas masks

For most people, this topic relates exclusively to civil defense. Well, it should be noted that gas masks have a much wider application than they are accustomed to attribute. And this is not surprising, because almost no attention is paid to other aspects. For example, it is difficult for many to imagine what an insulated gas mask is. It refers to a greater extent exclusively to firefighters. The insulating gas mask allows you to maintain high mobility, while protecting against harmful gases. After all, it is no secret that the vast majority of those killed in fires, before burning out, get carbon monoxide poisoning and lose consciousness.

The insulating gas mask works on the principle of scuba gear. It should be noted that in it the compressed air is under extremely high pressure. If the valve bursts, then if it hits a person, significant injuries will be inflicted on him, perhaps even incompatible with life. Since these devices are small, the operating time with them is 30-40 minutes. Usually this is more than enough. But still, firefighters often carry several spares with them.

By the way, gas masks can work not only with air, but also with oxygen. In this case, their shelf life can reach four hours. This advantage is used when working in mines, subways and other similar structures. But at the same time there is one significant minus - teeth deteriorate very quickly. If you constantly work in such an apparatus, then they will crumble as if they were made of plaster. Therefore, an oxygen insulating gas mask is used quite rarely. Again, only under adverse conditions when other devices are not suitable. That is, initially, the air supply can be calculated and the necessary actions can be assessed, and then the appropriate choice can be made.

The nuances of work

The pressure under which the air is in the cylinder is estimated at 300 atmospheres by default. In the future, this indicator is influenced by the frequency and depth of breaths. It is on this that the internal pressure and the time of activity with protection depend. Many may have a question: if work in breathing apparatus with compressed air takes place in such conditions, then how does a person not flatten inside the mask? This fact has a very simple explanation: the thing is that when he goes through the hoses, he has to go through a special gearbox. It sprays air with a thin (but powerful) stream, creating a pressure of two atmospheres in the mask. If the gearbox fails, then the air will not smear the person, but its supply will simply be stopped.

It should also be noted caution in working with rooms in which there are toxic and dangerous gas mixtures. Let's look at one important example. Movies often show how a lone firefighter rushes ahead to pull someone out. In reality, this is contrary to safety regulations. If firefighters enter a dangerous room, then their link should consist of at least three people (two, if more is not possible for certain reasons). Also, according to safety regulations, one person should always stand outside. He calculates the remaining time for the link, estimates when they should leave and the like.

It should be noted that this moment is often ignored, and in practice everyone who has respiratory protection equipment in case of fire goes inside the object.

What is the difference between different devices?

Since the main distribution was received by means of respiratory protection in case of fire or chemical accident for rescuers, we will consider this issue from already known positions. What is their difference? Suppose a firefighter needs to give an answer. So, if you try to dive under water with his respiratory protection kit, then the water will put pressure on the reducer valve. The deeper, the stronger.

It is considered safe to dive to three meters. Then there will be problems with the reducer valve - it will not open, which will prevent air from flowing.

But to stay in space, having only a cylinder of compressed air like firefighters, is quite possible. True, high-quality sealing is not ensured, moreover, the air supply is limited - therefore, it is not recommended for this purpose.

How are they similar?

Initially, the rather high price should be noted. A high-quality kit costs in the range from 40 to 80 thousand rubles, although relatively cheap devices are sold, the task of which is to give a small gain in time for people who do not take risks on an ongoing basis.

It is also common for the device itself to be assigned to several people. But the mask is for only one person. This is done for sanitary and hygienic reasons - in case someone has herpes.

It should also be noted that the weight is quite significant, which is measured in kilograms. After several hours of movement in them, back pain occurs.

The principle of operation in devices is the same. Numerical parameters vary, which can affect both the timing and the size of the apparatus. So, a cylinder with compressed air can be designed for 10-15 minutes, or for several hours.

We will devote time to the representative of these remedies

So far, we have considered conditionally generalized apparatuses. Now let's look at specific representatives.

You can start with AP-2000 (Breathing Apparatus). It is designed to protect eyesight and respiratory organs from exposure to hazardous smoky and toxic environments during fire fighting and emergency response. It can also be used to evacuate an injured person from a dangerous area in which an environment unsuitable for breathing is observed.

AP-2000 is an insulating tank apparatus. The air supply is stored in a compressed state in cylinders. In this case, the working pressure ranges from 1 MPa to 29.4 MPa, or, in other words, from 10 kgf/cm 2 to 300 kgf/cm 2 . A full-fledged panoramic mask of the device allows you to maintain excess pressure for pulmonary ventilation. This indicator can reach a value of 85 liters per minute.

Operating temperature range - from -40 to +60 degrees Celsius. Excessive pressure in the undermask space at zero air flow is maintained at 300±100 Pascals, which for clarity is equivalent to 30±10 millimeters of water column or 0.225 mercury.

The duration of the protective action is affected by the severity of the work performed, as well as temperature. So, for example, when spending 30 l / min and 25 degrees Celsius, you can perform actions in the device for 60-80 minutes (depending on the specific configuration). Whereas at minus 40 this figure will be only 45-60.

It should be noted that this is not the best copy that is on the market. For example, there is a breathing apparatus with compressed air AP "Omega", which was built taking into account the wishes of those people who operated the AP-2000. It has increased safety, comfort, as well as some additional features. Let's look at it in more detail.

What is the device of the breathing apparatus AP "Omega"?

It is made up of these parts:

- Suspension system and light panel. Made of composite materials, comfortable, have an ergonomic surface profile to ensure maximum comfort for the user. The suspension system provides for the presence of soft shoulder straps and a comfortable belt.

- Hoses. They have high frost, oil and petrol resistance, are characterized by high strength, and can also withstand the effects of surfactants. The hoses are designed in such a way as to exclude the possibility of breakage during operation, and also provide maximum safety during active work. The hoses have tees, which are equipped with two quick couplings. They are used for the main mask and also for the rescue device.

- Lung machine AP-98-7KM. This miniature servo-driven device is made of high-strength plastic. It has a bypass, as well as an overpressure off button. It is attached to the side of the mask, so it does not interfere with the tilt of the head. To enable / disable the bypass, you only need to turn the handwheel on the body, which allows you to quickly and practically without occupying your hands to perform manipulations.

- Lung machine AP-2000. Made from high strength polycarbonate. There is a multifunctional button on the case for turning on additional air supply / turning off excess pressure (aka bypass).

- Lung machine AP "Delta". A small design that does not interfere with the tilt and turn of the head. There are two options for bypass operation. Can work automatically or manually.

What else?

We have covered the first part of the list. The second one looks like this:

- Mask PM-2000. Designed specifically for breathing apparatus of the AP series. Among the advantages, one should recall the increased ergonomics and the quality of the material used.

- Delta mask. It was developed by order of the Ministry of Emergency Situations of the Russian Federation. Suitable for any type of breathing apparatus with compressed air, which has excess pressure in the mask space. It has low inhalation and exhalation resistance. The design allows the air flow to evenly blow over the sight glass, which eliminates its freezing and fogging. This allows you to use the mask for a wide range of temperatures - from -50 to +60 degrees Celsius. You can also install a communication device in it.

- Mask "PANA POWER". It is panoramic. Side connection of the lung machine is provided. It is possible to use it together with a welding shield.

- Alarm device with pressure gauge. It is on the shoulder strap and has a swivel joint.

- Reducer. A simple and reliable device for which a built-in valve is provided. It provides a stable reduced pressure for the entire service life of the device. Additional adjustments during operation are not required.

- High pressure cylinders and valves. As part of the device, two types of tanks are used: steel (Russia or Italy) and metal-composite (Russian Federation or USA). For valves, a vertical and horizontal arrangement of the flywheel is provided. There are several options for their execution: with a shut-off valve (prevents the occurrence of a jet stream when breaking off); with a membrane-type safety device (protects the cylinder from explosion when the pressure rises when the cylinder is heated, etc.); both variants.

Let's say a word about maintenance

This is practically considered breathing apparatus with compressed air. It remains only to pay attention to how to care for these devices. After all, timely maintenance of breathing apparatus with compressed air is a guarantee of their constant readiness and high reliability during operation. Which, accordingly, allows you to ensure safety for life and health. In order for the devices to function well, it is necessary to perform a certain set of organizational and technical measures and work. Depending on their purpose and nature, two groups are distinguished:

- Maintenance system. Includes work that is aimed at maintaining the device in a usable condition.

- Repair system. Includes work aimed at restoring the lost functional suitability of parts and assemblies.

A test is carried out to determine what is needed. There are several types of it:

- It is carried out in order to maintain the device in good condition.

- Scheduled inspection to make sure that all parts and mechanisms work as they should.

- Disinfection, replacement of oxygen cylinders and the like.

All these actions allow you to keep the compressed air apparatus ready for operation.

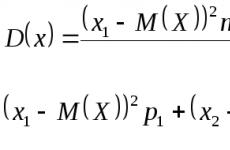

A compressed air breathing apparatus is a self-contained insulating reservoir apparatus in which the supply of air is stored in cylinders in a compressed state. The respiratory apparatus operates according to an open breathing scheme, in which air is taken from the cylinders for inhalation, and exhalation is made into the atmosphere (Fig. 3.4).

Compressed air breathing apparatus is designed to protect the respiratory organs and eyesight of firefighters from the harmful effects of an unbreathable environment when extinguishing fires and performing rescue operations.

The air supply system provides the person working in the device with a pulsed air supply. The volume of each portion of air depends on the frequency of breathing and the magnitude of the rarefaction during inspiration.

The air supply system of the apparatus consists of a lung machine and a reducer; it can be single-stage, gearless and two-stage. A two-stage air supply system can be made from one structural element, combining a gearbox and a lung machine, or two separate ones.

Breathing apparatus depending on climatic design subdivided into breathing apparatus general purpose, designed for use at ambient temperatures from -40 to +60 ° C, relative humidity up to 95%, and special

Rice. 3.4.

values, designed for use at ambient temperatures from -50 to +60 ° C and relative humidity up to 95%.

The respiratory apparatus must be able to work in breathing modes characterized by the performance of loads: from relative rest (pulmonary ventilation 12.5 dm 3 /min) to very hard work (pulmonary ventilation 100 dm 3 /min), at an ambient temperature of -40 to + 60 °C, as well as ensure operability after being in an environment with a temperature of 200 °C for 60 s. The breathing apparatus includes:

- - Breathe-helping machine;

- - rescue device (if any);

- - spare parts kit;

- - operational documentation for DAVS (operating manual and passport);

- - operational documentation for the cylinder (operating manual and passport);

- - instructions for use of the front part.

The generally accepted working pressure in domestic and foreign

DAWP is 29.4 MPa.

Form and dimensions breathing apparatus must correspond to the physique of a person, be combined with protective clothing, a helmet and equipment of a gas and smoke protector, provide convenience when performing all types of work on a fire (including when moving through narrow hatches and manholes with a diameter of 800 ± 50 mm, crawling, on all fours, etc. .d.).

The breathing apparatus must be designed in such a way that it is possible to put it on after turning it on, as well as to remove and move the breathing apparatus without turning it off when moving through tight spaces.

The reduced center of mass of the breathing apparatus should be no further than 30 mm from the sagittal plane of the person. The sagittal plane is a conditional line that symmetrically divides the human body longitudinally into the right and left halves.

The total capacity of the balloon (with pulmonary ventilation of 30 l/min) should provide a conditional time of protective action (PVZD) of at least 60 min, and the mass of DABP should be no more than 16.0 kg with PVZD equal to 60 min and not more than 18.0 kg at HPV equal to 120 min.

The main technical characteristics of breathing apparatus with compressed air are given in Table. 3.4.

The composition of DAVS (see Fig. 3.4) includes: a frame / or a back with a suspension system consisting of shoulder, end and waist belts with buckles for adjusting and fixing the breathing apparatus on the human body; balloon with valve 2 , reducer with safety valve 3 , collector 4, connector 5, lung machine 7 with air hose 6, front part with intercom and exhalation valve 8, capillary tube 9 with buzzer, pressure gauge with high pressure hose 10, rescue device 11, spacer 2.

In modern devices, in addition, the following are used: a shut-off device for the pressure gauge line; rescue device connected to a breathing apparatus; fitting for connecting a rescue device or an artificial lung ventilation device; fitting for quick refueling of cylinders with air; a safety device located on a valve or a cylinder to prevent an increase in pressure in the cylinder above 35.0 MPa; light and vibration signaling devices, emergency gear, computer.

Suspension system of the breathing apparatus - component apparatus, consisting of a back, a system of belts (shoulder and waist) with buckles for adjusting and fixing the breathing apparatus on the human body.

The suspension system prevents the firefighter from being exposed to the heated or cooled surface of the cylinder. It allows the firefighter to put on the breathing apparatus and adjust its fastening quickly, simply and without assistance. The system of breathing apparatus belts is supplied with devices for adjusting their length and degree of tension. All devices for adjusting the position

Rice. 3.5. Breathing apparatus PTS "Profi": a- general form; b- main parts

breathing apparatus (buckles, carabiners, fasteners, etc.) are made in such a way that the belts are firmly fixed after adjustment. The adjustment of the suspension system belts should not be disturbed during the apparatus change.

The suspension system of the breathing apparatus (Fig. 3.6) consists of a plastic back /; belt systems: shoulder (2), end (2), fastened to the back with buckles 4, belt (5) with a quick-release adjustable buckle.

Lodgements 6, 8 serve as a support for the balloon. The balloon is fixed with a balloon strap 7 with a special buckle.

|

Parameter |

AP-2000 (AP "Omega") |

||

|

Number of cylinders, pcs. |

|||

|

Cylinder capacity, l |

|||

|

Working pressure in the cylinder, MPa (kgf/cm2) |

|||

|

Reduced pressure at zero flow, MPa (kgf/cm2) |

0,55...0,75 (5,5...7,5) |

0,5...0,9 (5...9) |

0,5...0,9 (5...9) |

|

Activation pressure of the safety valve of the reducer, MPa (kgf/cm2) |

1,2...1,4 (12...14) |

1,1-1,8 (11... 18) |

1,1 .1,8 (11...18) |

|

The conditional time of the protective action of the apparatus during pulmonary ventilation is 30 dm3 / min, min, not less than |

At a temperature: 25 °С - 60 min, 50 °С - 42 min |

||

|

Actual inspiratory breathing resistance with pulmonary ventilation 30 dm3/min, min, Pa (mm water column), no more |

300...350 (30...35) |

350...450 (35...45) |

|

|

Excessive pressure in the submask space at zero air flow, Pa (mm w.c.) |

300...450 (30...45) |

200...400 (20...40) |

200...400 (20...40) |

|

Alarm device actuation pressure, MPa (kgf/cm2) |

5,3...6,7 (63...67) |

5,5...6,8 (55...68) |

4,9...6,3(49...63) |

|

Overall dimensions, mm, no more |

700 x 320 x 220 |

||

|

Weight of equipped vehicle (without rescue device), kg, no more |

Table 3.4

Main technical characteristics of domestic DAS

|

PST "Standard" |

PTS "Profi" |

|||

|

0,55...1,10 (5,5...11,0) |

0,7...0,85 (7...8,5) |

0,7...0,85 (7...8,5) |

0,6...0,9 (6...9) |

0,7...0,85 (7...8,5) |

|

1,2...2,2 (12...22) |

1,2...1,4 (12...14) |

1,2...2,0 (12...20) |

1,2...1,4 (12...14) |

|

|

350...450 (35...45) |

||||

|

150...350 (15...35) |

420...460 (42...46) |

300...450 (30...45) |

420...460 (42...46) |

|

|

5,0...6,0 (50...60) |

5,0...6,0 (50...60) |

5,0...6,2 (50...62) |

290...400 (29...40) |

5,0...6,0(50...60) |

Rice. 3.6.

The cylinder is designed to store the working supply of compressed air. Depending on the model of the apparatus, metal, metal-composite cylinders can be used (Table 3.5).

Cylinders have a cylindrical shape with hemispherical or semi-elliptical bottoms (shells).

A conical or metric thread is cut in the neck, along which a shut-off valve is screwed into the cylinder. On the cylindrical part of the cylinder, the inscription "AIR 29.4 MPa" is applied.

The valve (Fig. 3.7) consists of a body /, tube 2 , valve 3 with insert, breadcrumbs 4 , spindle 5, gland nuts 6, handwheel 7, springs 8, nuts 9 and plugs 10.

The cylinder valve is made in such a way that its spindle cannot be completely turned out, and the possibility of its accidental closing during operation is excluded. It must maintain tightness in both the "Open" and "Closed" positions. The valve-cylinder connection is sealed.

The cylinder valve withstands at least 3000 opening and closing cycles. The valve fitting for connection to the reducer uses a 5/8 internal pipe thread.

The tightness of the valve is ensured by washers 11 and 12. washers 12 and 13 reduce friction between the spindle shoulder, handwheel end and gland nut ends when the handwheel is rotated.

The tightness of the valve at the junction with the cylinder with a conical thread is ensured by a fluoroplastic sealing material (FUM-2), with a metric thread - by a rubber O-ring 14.

Specifications of Air Cylinders

|

Designation |

Cylinder capacity, l, not less than |

Mass of a cylinder with a valve, kg, no more |

Overall dimensions of a cylinder with a valve, mm (diameter x height) |

Balloon material |

|

Steel |

||||

|

TU 14-4-903-80 |

||||

|

metal composite; liner - stainless steel |

||||

|

Metal composite with aluminum liner |

||||

|

Metal o composite with steel liner |

||||

|

Lightweight metal composite with aluminum liner |

||||

|

BK-U-ZOOA-U |

||||

|

SUPER ULTRA |

||||

|

SUPER PREMIUM |

Rice. 3.7.

a - with tapered thread W19.2; b - with cylindrical thread M18 x 1.5

When the handwheel is rotated clockwise, the valve, moving along the thread in the valve body, is pressed by the insert against the seat and closes the channel through which air enters the breathing apparatus from the cylinder. When the handwheel is rotated counterclockwise, the valve moves away from the seat and opens the channel.

The collector (Fig. 3.8) is designed to connect two cylinders of the apparatus to the reducer. It consists of a body / in which fittings are mounted 2. The manifold is connected to the cylinder valves with couplings 3. The tightness of the joints is ensured by sealing rings 4 and 5.

Rice. 3.8.

The reducer in breathing apparatus performs two functions: it reduces the high air pressure to an intermediate set value

and provides a constant supply of air and pressure after the reducer within the specified limits with a significant change in pressure in the cylinder. The most widespread are three types of gearboxes: leverless direct and reverse action and lever direct action.

In direct acting gearboxes, high pressure air tends to open the reducer valve, in reverse acting gearboxes it closes it. A leverless gearbox is simpler in design, but a lever gearbox has a more stable outlet pressure adjustment.

AT last years piston reducers began to be used in breathing apparatus, i.e. gears with balanced piston. The advantage of such a gearbox is that it is highly reliable as it has only one moving part. The operation of the piston reducer is carried out in such a way that the pressure ratio at the outlet of the reducer is usually 10:1, i.e. if the pressure in the cylinder is from 20.0 to 2.0 MPa, then the reducer supplies air at a constant intermediate pressure of 2.0 MPa. When the cylinder pressure drops below this intermediate pressure, the valve remains open permanently and the breathing apparatus operates as a single stage until the air in the cylinder is depleted.

The first stage of the air supply device is a reducer. As shown by the comparative tests of the devices, the secondary pressure created by the reducer should be as constant as possible, independent of the pressure in the cylinder, and be 0.5 MPa. The throughput of the pressure reducing valve must fully and under any kind of load provide two working people with air without increasing breathing resistance during inhalation.

In the steady state of operation of the gearbox, its valve is in balance under the action of the elastic force of the control spring, which tends to open the valve, and the pressure of the reduced air on the membrane, the elastic force of the locking spring, and the air pressure from the cylinder, which tend to close the valve.

The reducer (Fig. 3.9) of a piston, balanced type is designed to convert high air pressure in the cylinder to a constant reduced pressure in the range of 0.7 ... 0.85 MPa. It consists of a body 7 with an eyelet 2 for attaching the gearbox to the apparatus frame, inserts 3 with sealing rings 4 and 5, pressure reducing valve seats including body 6 and insert 7, pressure reducing valve 8 , on which with a nut 9 and washers 10 fixed piston 77 with rubber o-ring 12, working springs 13 and 14, adjusting nuts 15, the position of which in the housing is fixed with a screw 76.

A lining 77 is put on the gearbox housing to prevent contamination. The gearbox housing has a fitting 18 s sealing ring 79 and screw 20 for connecting the capillary and fitting 21

for connecting a low pressure connector or hose. The fitting is screwed into the gearbox housing 22 with nut 23 for connection to the cylinder valve. A filter is installed in the nozzle 24, fixed by screw 25. The tightness of the connection of the fitting with the body is ensured by the sealing ring 26. The tightness of the connection of the cylinder valve with the reducer is ensured by the sealing ring 27.

The design of the gearbox provides a safety valve, which consists of a valve seat 28, valve 29, springs 30, guide 31 and lock nuts 32, fixing the position of the guide. The valve seat is screwed into the reducer piston. The tightness of the connection is ensured by the sealing ring 33.

The reducer works as follows. In the absence of air pressure in the reducer system, the piston 11 under the action of springs 13 and 14 moves with the pressure reducing valve 8, removing its conical part from insert 7.

When the cylinder valve is open, high pressure air enters through the filter 25 by fitting 22 into the cavity of the gearbox and creates a pressure under the piston, the value of which depends on the degree of compression of the springs. In this case, the piston, together with the reducing valve, is mixed, compressing the springs until a balance is established between the air pressure on the piston and the spring compression force and the gap between the insert and the conical part of the reducing valve is closed.

When you inhale, the pressure under the piston decreases, the piston with the pressure reducing valve will mix under the action of the springs, creating a gap

between the insert and the conical part of the pressure reducing valve, ensuring the flow of air under the piston and further into the lung machine. Nut rotation 15 it is possible to change the degree of compression of the springs, and, consequently, the pressure in the cavity of the gearbox, at which an equilibrium occurs between the compression force of the springs and the air pressure on the piston.

The safety valve of the reducer is designed to protect against the destruction of the low pressure line in case of failure of the reducer.

The safety valve works as follows. During normal operation of the reducer and reduced pressure within the specified limits, the valve insert 29 spring force 30 pressed against the valve seat 28. When the reduced pressure in the gearbox cavity increases as a result of its malfunction, the valve, overcoming the resistance of the spring, moves away from the seat, and the air from the gearbox cavity escapes into the atmosphere.

When rotating the guide 31 the degree of compression of the spring changes and, accordingly, the amount of pressure at which the safety valve operates. The gearbox adjusted by the manufacturer must be sealed to prevent unauthorized access to it.

The value of the reduced pressure must be maintained for at least three years from the date of adjustment and verification.

The safety valve must prevent the supply of high pressure air to parts operating at reduced pressure in the event of a gearbox failure.

The adapter (fig. 3.10) is intended for connection to the reducer of the lung governed demand valve and rescue device. It consists of a triple 1 and connector 2, interconnected by a hose 4, which is fixed on fittings with caps 5. The tightness of the connection between the adapter and the gearbox is ensured by a sealing ring 6. In connector housing 3 a bushing 7 is screwed in, on which the assembly for fixing the fitting of the rescue device is mounted, consisting of a clip 8, balls 9, bushings 10, springs 11, corps 12, sealing rings 13 and valve 14.

9 17 11 12 3 18 16 13 2 5 4 1

When connected to the connector, the end of the fitting of the rescue device, resting against the cuff 17 and overcoming the resistance of the spring 11, diverts valve 14 with sealing ring 13 from the saddle 15 and provides air supply from the reducer to the rescue device. The annular protrusion of the fitting at the same time displaces the sleeve inside the connector 10 ; while the balls 9, out of contact with the sleeve 10, enter the annular groove of the fitting of the rescue device. Released Clip 8 under the influence of a spring 19 is displaced and fixes the balls in the annular groove of the fitting of the rescue device, thus ensuring the necessary reliability of the connection between the fitting and the connector.

To disconnect the hose fitting of the rescue device, simultaneously press the hose union of the rescue device and move the clip. In this case, the fitting will be pushed out of the connector by the force of the spring. 11, and the valve will close.

The lung machine (Fig. 3.11) is the second stage of reduction of the respiratory apparatus. It is designed to automatically supply air for the user's breathing and maintain excess pressure in the undermask space. Lung machines can use valves of direct (air pressure under the valve) and reverse (air pressure on the valve) action.

Rice. 3.11.

The lung governed demand valve consists of a body / with a nut 2, valve seats with sealing ring 4 and locknut 5, shield 6, fixed with screw 7. Lever 9 with springs is installed in cover # 10, 11. Retainer 12 made as a single unit with the cover. Lid with valve body and membrane 13 hermetically connected with a clamp 14 with a screw 15 and nuts 16. The valve seat consists of a lever 17, fixed on the axis 18, flange 19, valve 20, springs 21 and washers 22, secured with a retaining ring 23.

The lung machine works as follows. valve in rest position 20 pinned to the saddle 3 spring 21, membrane 13 fixed with a lever 9 on the latch 12.

At the first breath, a vacuum is created in the submembrane cavity, under the action of which the membrane with the lever breaks off the latch and, bending, acts through the lever 17 on the valve 20, which leads to its distortion. Air from the reducer enters the resulting gap between the seat and the valve. Spring 10, acting through the lever on the membrane and the valve, it creates and maintains a predetermined excess pressure in the submembrane cavity. In this case, the pressure on the membrane of the air coming from the reducer increases until it balances the force of the overpressure spring. At this moment, the valve is pressed against the seat and blocks the air flow from the gearbox.

The lung machine and the additional air supply device are switched on by pressing the control lever in the “On” direction.

The lung machine is switched off by pressing the control lever in the "Off" direction.

The device may include a rescue device.

The rescue device consists of an approximately two-meter hose, at one end of which a bracket is attached for connection (for example, bayanette) with a T-shaped connector. A lung machine is connected to the other end of the hose. As the front part, a helmet-mask or an artificial lung ventilation device is used.

The breathing air for the firefighter and the victim comes from the same breathing apparatus.

When working in a breathing apparatus, the T-connector can be used to connect to external source compressed air, carrying out rescue operations, evacuating people from a smoky area and providing workers with air in hard-to-reach places. The rescue device uses a lung machine without excess pressure.

The connections for connecting the lung machine of the main front part (if any) and the rescue device must be quick-disconnect (of the “Euro-coupling” type), easily accessible, and not interfere with work. Spontaneous shutdown of the lung machine and rescue device must be excluded. Free connectors must have protective caps.

The front part (mask) (Fig. 3.12) is designed to protect the respiratory and vision organs from exposure to a toxic and smoky environment and compounds respiratory tract person with a lung machine.

Rice. 3.12.

The mask consists of 7 body with glass 2, fixed with half-rings 3 screws 4 with nuts 5, intercom 6, fixed with clamp 7, and valve box 8, into which the lung machine is screwed. The valve box is attached to the body with a clamp 9 with screw 10. The tightness of the connection between the lung machine and the valve box is provided by a sealing ring. An exhalation valve is installed in the valve box 13 with hard disk 14, overpressure spring 15, saddle 16 and lid 17.

The mask is attached to the head with a headband. 18, consisting of interconnected straps: frontal 19, two temporal 20 and two occipital 21, buckled to the body 22 and 23.

mask holder 24 with inhalation valves 25 attached to the mask body with the help of the intercom body and the bracket 26, and to the valve box - a cover 27.

The headband is used to fix the mask on the user's head. To ensure the fit of the mask to size, the headband straps have serrated protrusions that lock into the body buckles. Buckles 22, 23 allow quick adjustment of the mask directly on the head.

To wear the mask around the neck, a neck strap is attached to the lower buckles of the front part. 28.

When inhaling, air from the submembrane cavity of the lung machine enters the cavity under the mask and through the inhalation valves - into the mask. In this case, the panoramic glass of the mask is blown, which eliminates its fogging.

When exhaling, the inspiratory valves close, preventing exhaled air from reaching the mask glass. The exhaled air from the undermask space is released into the atmosphere through the exhalation valve. The spring compresses the exhalation valve to the seat with a force that allows maintaining a predetermined overpressure in the undermask space of the mask.

The intercom provides the transmission of the user's speech when the mask is worn on the face and consists of a body 29, pressure ring 30, membranes 31 and nuts 32.

The capillary tube is used to connect a signaling device with a pressure gauge to the reducer and consists of two fittings connected by a high-pressure spiral tube soldered into them.

An alarm device (Fig. 3.13) is a device designed to give a sound signal to a working person that the main air supply in the breathing apparatus has been used up and only a reserve reserve remains.

To control the consumption of compressed air when working in breathing apparatus, pressure gauges are used, both permanently located on cylinders (ASV-2) and remote, mounted on a shoulder strap.

Rice. 3.13.

To signal the decrease in air pressure in the cylinders of the apparatus to a predetermined value, minimum pressure indicators are used.

The principle of operation of indicators is based on the interaction of two forces - the air pressure force in the cylinders and the spring force opposing it. The pointer is triggered when the gas pressure force becomes less than the spring force. In breathing apparatus, three designs of indicators are used: rod, physiological and sound.

Stock pointer The device is installed directly on the gearbox housing, on the hose, on the shoulder strap. When controlling pressure, the position of the stem is felt by hand.

The pointer is cocked by pressing the button of the rod before opening the valve of the device. When the pressure in the cylinders drops to the set minimum, the rod returns to its original position.

The physiological indicator, or the reserve air supply valve, in various designs is a locking device with a movable locking part. The locking part has a spring to hold the valve against the seat. When the pressure in the cylinders is above the minimum, the spring is compressed and the valve is raised above the seat. At the same time, the air freely passes through the ma-

hystrals. When the pressure drops to the minimum, the valve, under the action of a spring, falls on the seat and closes the passage. A sharply occurring lack of air for breathing serves as a physiological signal about the consumption of air to the minimum (reserve) pressure.

buzzer most common in compressed air breathing apparatus. It is mounted in the reducer housing or combined with a pressure gauge on the high pressure line. The design principle of the work is similar to the stock indicator. When the air pressure in the cylinders drops, the rod moves, and the air supply to the whistle opens, which makes a characteristic sound.

The operation of the sound signal according to standards, both European and domestic, should be at the level of 5 MPa or 20-25% of the air supply in the equipped cylinder. The duration of the signal must be at least 60 s. The volume of the sound should be at least 10 dB higher than that of a fire. The sound must be easily distinguishable from other sounds without compromising other sensitive or important operating functions.

The signaling device (Fig. 3.13) consists of a housing /, pressure gauge 2 with cladding 3 and gasket 4, bushings 5, bushings 6 with sealing ring 7, whistle 8 with locknut 9, casing 10, sealing rings 11, shtochka 12, bushings 13 with sealing ring 14, nuts 15 with locknut 16, springs 17, plugs 18 with sealing ring 19, sealing rings 20 and nuts 21.

The signaling device works as follows. When the cylinder valve is open, high-pressure air enters through the capillary into the Aik cavity to the pressure gauge. The manometer shows the amount of air pressure in the cylinder. From cavity A, high-pressure air through a radial hole in the sleeve 13 enters the cavity B. The rod under the action of high air pressure moves to the stop in the sleeve 5, compressing the spring. In this case, both outlets of the oblique hole of the rod are located behind the sealing ring 7.

As the pressure in the cylinder decreases and, accordingly, the pressure on the stem shank, the spring will move the stem to the nut 15. When the exit of the oblique hole in the rod closest to the sealing ring 7 is mixed behind the sealing ring, air under reduced pressure through the channel in the housing 1, the oblique hole in the rod and the hole in the sleeve 5 enters the whistle, causing a steady sound signal. With a further drop in air pressure, both outlets of the oblique hole in the rod move beyond the sealing ring, and the air supply to the whistle stops.

Adjustment of the pressure of the alarm device is carried out by moving the whistle along the thread in the body. In this case, the sleeve 5 is moved with the sleeve 6 and O-ring 7.

Security questions for chapter 3

- 1. Name the device of the breathing apparatus with compressed air.

- 2. Tell us about the appointment and technical specifications domestic DAS.

- 3. Describe the principle of operation of AHSA.

- 4. Appointment of hose breathing apparatus.

Questions for self-study

Study the device and principle of operation of a breathing apparatus with compressed air.

- Complete with rescue device. Depending on modification. Cylinder capacity, overall dimensions and weight of the equipped apparatus are determined depending on the model.

Available in two sheets)

Methodology for certification of GDZ

Certification is carried out in the following sequence according to the significance:

1. Psychological examination;

2. Checking physical performance (PWC 170);

3. Acceptance of practical skills (GDZS standards, check No. 1 RPE, passing the performance characteristics of RPE);

4. Acceptance of theoretical tests.

I. Psychological examination (vocational selection) chapter IV of order 163/88

Carried out by a qualified psychologist legal entity(admissible psychologist GU) according to the tests. If the result of the tests is “Not recommended”, the candidate is not allowed for further tests.

II.Physical performance test (PWC 170) Appendix No. 9 of Order 163/88

It is carried out in the following order. Specify the subject's body weight and age. Within 3 min. 50 sec. subject in outerwear carries out an ascent to a step 25 cm high. Immediately after the end for 10 seconds. We measure the heart rate. We give 2 min. to rest. Further within 3 minutes. 50 sec. the subject makes an ascent to the upper step. Immediately upon completion within 10 seconds. We measure the heart rate. When performing exercises, we monitor the frequency of execution by the metronome, the time by the stopwatch. With a “Low” indicator, a commission decision is made on further tests.

III. Reception of practical skills

Compliance with GDZS standards

- No. 1 putting on and inclusion in the apparatus (for correctness within 60 seconds);

- No. 2 Fixing for the structure (6; 8; 9 sec.)

- No. 3 Knitting double rescue with putting on (32; 38; 45 sec.).

Check No. 1 PPE.

When checking No. 1, you need to check:

1. Preparing the device system for operation (connect the tube from the model to the device, stick a carrot, move the distributor handle to the "-" position, create a vacuum of 1000 Pa, the distributor handle to the "closed" position, note 1 minute with a stopwatch, press the button " reset "by equalizing the pressure between 1000 and 900 Pa and again we detect 1 minute if the pressure has not dropped, the system is tight).

2. Checking the tightness of the head with excess pressure (switch to the "inflate" position, 25-30 strokes with the pump, check the tightness of the connections with soapy water, detect 1 min.)

3. Serviceability of the mask.

4. Serviceability of the device as a whole.

5. The presence of excess pressure in the undermask space and the tightness of the high and reduced pressure system.

6. Alarm pressure.

7. Serviceability of the additional air supply device (bypass).

8. Air pressure in the cylinder.

Checking the health of the mask visually check the completeness of the mask and the absence of damage to its elements. For this:

Disconnect the mask from the lung machine;

turn out the chin cup;

Inspect the glass of the mask and its body, the body of the mask holder, the inhalation valve, the exhalation valve and the intercom;

· make sure that there are no damages to the panoramic glass, ruptures of the intercom membrane, punctures of the mask body and mask holder.

Checking the health of devices in general produced by external inspection, while:

Connect the lung machine to the mask, having previously checked the absence of damage to the sealing ring;

· check the reliability of fastening of the suspension system of the apparatus, the cylinder (cylinders), pressure gauge and make sure that there are no mechanical damage to the components and parts.

Checking for overpressure in the undermask space and tightness of the high and reduced pressure system:

· the model is connected by a hose to the device, the lung machine is turned off, the handle of the distributor of the installation is set to the (-) position, the panoramic mask is put on the headform, the neck straps are tightened (starting from the lower ones, to the upper ones) until the mask obturator fully adheres to the surface of the model;

Open the cylinder valve

the pump creates a vacuum until the valve of the lung machine is actuated (switched on) (a characteristic click is heard), the distributor knob is in the “closed” position;

· the pressure gauge on the device determines the parameter of overpressure under the mask (300±100 Pa);

close the cylinder valve, turn on the stopwatch and record its reading on the manometer of the tested apparatus, while the pressure drop should not exceed 1 MPa in 1 minute;

· if, as a result of checks, the air pressure drop in the system for 1 minute does not exceed 2 MPa (20 kg/cm2) with the rescue device disconnected, the device is considered to be airtight;

Checking the triggering pressure of the alarm device:

· when the cylinder valve is closed, release the pressure with the button of the lung machine until the sound signal sounds, while the parameters (50 - 60 kg s / cm2) are recorded on the manometer of the device.

Check of serviceability of the device of additional air supply(bypass) is produced as follows:

Open the cylinder valve

· by smooth pressing the button of the lung machine open additional air supply and make sure that the device is in good condition by the characteristic sound of the air supply.

Checking the air pressure in the cylinder:

· The cylinder valve opens and the reading is fixed on the pressure gauge, which must be at least 24.5 MPa (260 kg s/cm2).

TTX PPE:

The principle of operation of breathing apparatus with compressed air, their technical characteristics.

The breathing apparatus is made according to an open circuit with exhalation into the atmosphere and operates as follows: when valve 1 is opened, high-pressure air enters from cylinder 2, into the high-pressure cavity A of the reducer 5, and after reduction into the reduced pressure cavity B. The reducer maintains a constant reduced pressure in the cavity B regardless of the change in inlet pressure. In the event of a malfunction of the reducer and an increase in the reduced pressure, the safety valve 6 is activated. From the cavity B of the reducer, air enters through the hose 7 into the lung machine 8 of the apparatus and through the hose 9 into the lung machine of the rescue device. The lung machine maintains a predetermined excess pressure in the cavity D. When inhaling, air from the cavity D of the lung machine is supplied to the cavity B of the mask 11. The air, blowing the glass 12, prevents it from fogging. Further, through the inhalation valves 13, the air enters the cavity G for breathing. When exhaling, the inhalation valves close, preventing exhaled air from reaching the glass. To exhale air into the atmosphere, the exhalation valve 14, located in the valve box 15, opens. To control the air supply in the cylinder, air from the high-pressure cavity A flows through the high-pressure capillary tube 16 to the pressure gauge 17, and from the low-pressure cavity B through the hose 18 to the whistle 19 of the signaling device 20. When the working air supply in the cylinder is exhausted, the whistle is turned on, a warning sound signal about the need to immediately exit to a safe area.

High pressure - up to 300 atm;

Reduced pressure - 4.5 - 9.0 atm;

Pressure in the mask space - 0.3 - 0.4 atm;

Sound signal operation - 60 +/- 10 atm;

Operation of the excess valve - 11-18 atm;

Operating time after the sound signal is triggered - 9 - 13 minutes;

The mass of the device is 7 - 12.5 kg. (depending on tank type).

When assessing "2" for one of the types of practice, theory credit is not allowed.

Breathing apparatus with compressed air PTS "Profi""for firefighters is the basic model (instead of the apparatus AIR-98MI) and is designed for individual protection of the respiratory organs and eyesight of a firefighter from the harmful effects of an unbreathable, toxic and smoky gaseous environment when extinguishing fires in buildings and structures and at production facilities, as well as performing other types of emergency work in various sectors of the national economy at an ambient temperature of -50 o C to +60 o C. The device does not change its technical parameters after being in an environment with a temperature of 200 o C for 60 s and withstands exposure to an open flame with a temperature of 800 o C for 5 s.

It has:

fire safety certificate,

GOST R Certificate of Conformity,

Certificate Federal Service on Environmental, Technological and Nuclear Supervision, Sanitary and Epidemiological Conclusion.

Design advantages:

- an original suspension system with thermo-fire-resistant straps and a plastic ergonomically profiled back, equipped with a chest strap and soft shoulder pads, which significantly reduces the load on the user's back and provides comfort during work;

- universal fastening system suitable for all types of cylinders, characterized by simplicity and reliability of fixation;

- the lung machine maintains a uniform overpressure in the undermask space of the front part at various respiratory loads;

- The apparatus includes an adapter with a quick-disconnect connection that allows connection of a rescue device.

Distinctive features:

- Complete set with cylinders of various capacity (from 4 to 9 l).

- Completion of incoming units (panoramic mask, lung machine, valve) manufactured by OJSC "PTS" or by foreign manufacturers.

- Rescue device in two versions: panoramic mask or hood.

Basic performances:

| Machine version | Qty | Cylinder capacity, l. | Cylinder designation | Conditional PDM, *min, not less than | Weight, kg |

| -168A | 1 | 6.8 | R-EXTRA-5/PTS | 60 | 15.9 |

| -168E | 1 | 6.8 | BMK 6/8-139-300 | 60 | 10 |

| -190K | 1 | 9.0 | ALT 865 | 82 | 12.8 |

| -240M | 2 | 4.0 | BK-4-300S | 72 | 14 |

| -268E | 2 | 6,8 | VMK 6.8-139-300 | 120 | 16.8 |

* - conditional time of protective action at pulmonary ventilation 30 cubic dm/min and ambient temperature +25oС

Specifications:

Working pressure in the cylinder, MPa (kgf / cm 2) | |

Reduced pressure, MPa (kgf / cm 2) | 0,7…0,85 (7…8,5) |

Response pressure of the safety valve of the reducer, MPa (kgf / cm 2) | 1,2…2,0 (12…20) |

Excessive pressure in the submask space at zero air flow, Pa (mm w.c.) | 250…450 (25…45) |

Actual expiratory breathing resistance with pulmonary ventilation 30 dm 3 /min, Pa (mm of water column) | |

Rescue device weight, kg, no more | |

Service life, years |

Breathing apparatus with compressed air PTS "Profi"

AUTOLADDER (AL-50) Mobile control center for work in crisis situations and liquidation of large fires (MPU) Fire tanker ATs 2.0-40/2 on the chassis ISUZU HQR75P Installation of combined fire extinguishing UKTP "Blizzard-20" Thermally aggressive suit made of special polymer materials TASK (TU 8570-025-46840277-2003 with II 003-2008) Radiation-protective clothing set for firefighters, RZK (TU 8570-047-38996367-2004) Fire tank truck with ladder ACL 3-40/4-24 (43118 ) Breathing apparatus with compressed air PTS "Profi" Aerodrome fire truck АА-12/60 (63501) Fire tank truck АЦ-3,2-40/4 Fire truck multifunctional Smoke removal fire truck AD 90/22(3205)-01НН First aid car APP-0.4-90/300 (FIAT 244 CSMNG-RG) 035PV Pneumatic jumping rescue device (PPSU-20) Rescue sleeve devices (USR) Fire and rescue boat KS-110-39 Mobile robotic complex MRK-25 Universal fire carriage fire nozzles "LS-P20U", "LSD-P20U" Manual combined air-foam nozzle "SVPK-4" Manual combined fire nozzle RSKO-50 Mobile robotic complex MRK-27X -40/2 (530104) with elements of the rescue vehicle Fire tanker ATs 0.8-4/400 High-pressure portable fire motor pump MPV - 2/400-60 Heat-reflecting suit for firefighters (TOK-200) Fire fighting clothing of the 1st level ladder (AL-60) Fire first aid vehicle APP-0.3-2 (3302)PM-532A Articulated lift (AKP-50) Fire tanker ATs-3.0-40 (43206) High-pressure nozzle "SRVD" -2/300"