Power plant with diesel gear transmission. Power plant with diesel gear transmission Rtm a atlantic stern trawling

45 years ago, on February 28, 1967, the Soviet trawler Tukan sank in the North Sea. According to one of the many versions of the disaster, the ship was destroyed by his secret cargo. Browser "Authority" Evgeny Zhirnov found in the archives of the Central Committee of the CPSU the solution to this mystery.

"Hull shaking was felt on the ship"

Much of what happened during the last trip of the Toucan looked strange, and sometimes inexplicable.

This type of RTM (freezing fishing trawler) was designed in the GDR on a Soviet order and was called "Tropic": trawlers were intended for fishing in southern latitudes. The ships of this series were built in the same place, in the German socialist state, and received names depending on the place of their future base. Those heading for the Black Sea were named after the Black Sea cities - "Alupka", "Yalta", etc. And the trawlers intended for the Baltic were named after the southern constellations. That is why the RTM, built in 1962 at the shipyard in Stralsund for Kaliningrad fishermen, received the name "Toucan".

One of the most famous specialists in the history of the Russian fishing fleet, the captain of the Kaliningrad Sea Fishing Port, Vyacheslav Morozov, wrote about the further work of the Tukan:

"Since the acceptance of the Kaliningrad base of the trawling fleet in September 1962, the vessel has made five fishing trips (two of them are double), and from June 1966 to February 1967 it was under scheduled maintenance."

Repair, however, as Captain Morozov wrote, did not go quite smoothly:

“Due to the lack of necessary spare parts in the warehouses of Tralflot, the defective active rudder was dismantled from the vessel. According to the USSR Register Rules, the absence of an active rudder did not affect the seaworthiness of the vessel, and therefore the trawler team had no reason to demand its restoration.”

Vyacheslav Morozov restored the entire subsequent history of the Tukan and its crew on the basis of an investigation conducted by a commission of the USSR Ministry of Fisheries:

"The RTM Tukan left its 6th fishing voyage on February 25, 1967 at 17.30. The voyage across the Baltic and the Danish Straits to Cape Skagen took place under normal navigational conditions. The crew came to their senses after the coastal waste turmoil. During February 25 and 26 the boatswain handed out life jackets to the crew members. A characteristic nuance for Tropic-type vessels: 10 people refused to receive them, citing the lack of space in the cabin to store life-saving equipment. This practice took place on more than one Toucan, I can confirm this as a person , who worked on the "tropics" for four years ... On February 27, at about 18 o'clock, in relatively good weather, they entered the Skagerrak Strait. But they were preparing for the upcoming storm. At about 23 o'clock, one of the mining masters arrived on the bridge and reported that on the stern on the deck, all hatches and necks were battened down, and the cargo was secured "in a storm" ... By 23.30 the wind increased noticeably, the pitching intensified. At 23.50 we received a weather forecast on the radio. A storm was expected from the southwest with a force of 10 points.

The tragic events began two and a half hours later:

"On February 28, at about 02.30, a hull shaking was felt on the ship (as some rescued crew members suggest, from hard hit waves). At about the same time, the engine watch discovered water entering the propeller shaft tunnel ... It turned out that it was coming from the reinforcement room. Through the wide slots intended for receiving fish, sea water poured into the vessel in a stormy stream.

On the vessels of the "Tropic" series, the German workmanship was fully compensated by design flaws

"Did not answer either the radio or the lightgram"

“At about 3 o’clock,” Vyacheslav Morozov continued the description, “the ship noticed a list to port. At 03.20, the captain gave the order to the engine room to pump fuel from the port side tanks to the starboard side tanks to reduce the list. But the ship continued to list to the port side. .. At about 4 o'clock Captain Khramtsov ordered to pump fuel from tank N23 on the port side overboard By this time the wind had reached force 9 from the south-west, the sea was 7 points... Captain Khramtsov went into the cabin of the head of the radio station Efimov, woke him ...

At 04.10 the sailor on duty reported that he saw an oncoming ship right on the course. The captain gave the command to disperse on the left sides. After that, Captain Khramtsov, Senior Officer Safonov, and First Officer Mayevsky went into the pilothouse for a short while to discuss the situation.

At 04.20, after passing with an oncoming ship (it was the mother ship "Vilis Latsis" of the Riga Baltic Fleet), the captain, senior and first mate again entered the chart house. After a short meeting, the senior assistant gave the order over the broadcast: "Everyone get up, put on life jackets and go to the upper deck" ... To the captain of the Latsis, L. Onuchin, who suspected something was wrong, the Tukan did not answer either the radio or the lightgram. Subsequently, none of the surviving members of the Tukan team could unequivocally explain the logic of this act.

Ten minutes later, when the crew members gathered at the boats, the captain gave the command to turn to the shore. But the roll increased sharply.

“At 04.35,” wrote Morozov, “senior assistant Safonov on the broadcast gave the command: “To the entire crew in the boat on the port side.” Chief engineer Kuzub ordered everyone in the engine room to go to the upper deck. The senior engineer himself remained in the engine room, and with since then, none of the surviving members of the crew saw him again.After the command "everyone into the boat", the head of the radio station, Efimov, stopped the first mate, who was running past the door of the radio room, and asked him to give the coordinates of the ship for dialing a distress signal. Safonov shouted on the run that he was now in the radio room the captain will come. Without waiting for captain Efimov, he began to give the signal "SOS", but at that time the captain came in and brought a note with the coordinates of the ship's location. The signal "SOS" was broadcast at 04 hours 42-43 minutes ... Captain Khramtsov of the bridge did not left. After that, none of the surviving crew members saw him again."

Many members of the team failed to escape:

Unlike other fishing bases (pictured), in Kaliningrad, drinking on vacation was not only not prohibited, but also encouraged.

“An attempt to lower the boat on the left side,” wrote Captain Morozov, “failed ... It was impossible to lower the boat on the starboard side because of the large roll to the port side. it was approaching a well-lit vessel. It was impossible to give distress signals with rockets, the wheelhouse, where all the pyrotechnics were stored, was already at the mercy of the waves. They shouted, waved their hands, but all to no avail - they were not paid attention. The vessel, without stopping, proceeded past. Stern the trawler began to sink quickly, and the bow part of the ship went out of the water.Many crew members began to jump into the water, those who remained on the deck were washed away by the waves.Electrician Artemyev with several crew members rushed to the upper bridge, where the life rafts were, but the emergency bars fell off their regular places almost all the sailors were knocked down and washed overboard by the waves. of them. Immediately after that, all the rafts were also washed overboard, and three of them were in working order, and two did not open. Around this time, the starboard boat was torn off the ship and capsized, and the port side boat was broken and also torn off, but kept afloat in an inverted state. The ship continued to sink astern into the water. At about 04.50, the bow of the trawler also disappeared under water. The sailors who found themselves in the water were scattered over a large area. Those who were close to the life-saving equipment still managed to use them with great effort. At first, there were about 20 people on the bottom of the capsized starboard boat, but soon half were washed away by the waves. Eleven people in the water were able to climb into one of the three rafts. No one else was able to use the raft on which Artemiev was. The third opened raft floated empty.

The crew of the "Toucan" was lucky in only one way. The Soviet floating base did not have time to go far.

"At 05.10, after receiving a distress signal and analyzing the situation, the floating base Vilis Latsis turned to the area of the accident. At 05.40, flickering lights were found on the water. These were the lights on the life rafts and life jackets of the Tukanovites. At 06.00, they started rescuing people At about 7 o'clock, 10 people were removed from the bottom of the capsized lifeboat. By 8 o'clock, 11 people were lifted aboard the mother ship from the life raft. The last person was lifted (from the second life raft) at 09.06 ".

Of the 79 crew members, only 22 were saved.

"Drinking on ships should not be encouraged!"

The commission appointed by the USSR Ministry of Fisheries conducted a detailed investigation of all the circumstances of the tragedy and found out a lot of interesting things. For example, "Stability information for the master of Tropic-type ships", which should have been guided by emergency situations, had many obscurely written places, which was the result of an inaccurate translation of it from German language. In addition, the designers ensured that if one sealed compartment was flooded, the vessel would remain afloat and not capsize. But in fact, the design was made in such a way that when water entered the fish shop, the adjacent compartment was also flooded. So the firm guarantee of unsinkability was worth nothing.

The commission also investigated how water got inside the ship's hull. The version of the hole did not match the description of the disaster, compiled after interviewing the surviving crew members. The path of water inflow, as Captain Morozov wrote, they tried to find out by calculation:

"Kaliningrad scientists from the Department of Ship Theory KTIRPiKh (Kaliningrad Technical Institute of the Fishing Industry and Economy) investigated and calculated six options for water penetration into the hull. The following penetration routes were recognized as the most probable of them: through open hatches in the coamings of the 1st or 4th fish bunkers; through loose closing of hatches of the 2nd or 3rd fish bunkers.

It was calculated that in both cases, through any of these holes, within 2-2.5 hours, the amount of water sufficient to lose the vessel's buoyancy could enter. This happens even if permanent job sewage bilge pump".

Deputy Prosecutor General of the USSR Mikhail Malyarov (pictured on the podium) did not publish the conclusion that those responsible for the death of the trawler died with him

Theoretical calculations confirmed by the testimony of a witness:

"From the testimony of the fish master Myasishchev, it follows that during the repair, a rubber sealing gasket was not installed on the cover of the 3rd fish bunker, without which a large gap formed around the perimeter of the cover. The ship's service mechanic had to install the gasket at the transition to the fishing area."

Only one thing remained unclear:

“Based on the requirements of normal maritime practice,” wrote Vyacheslav Morozov, “the captain, having received information about the ingress of water into the ship, was obliged, first of all, to announce a water alarm and make every effort to discover the causes and place of water ingress, and then take measures to eliminate it But the crew was not prepared for damage control, and the alarm was not announced ... The commission did not find an explanation for the reasons why Captain Khramtsov, in violation of the instructions of the Charter of the service, did not give a distress signal in time. The captain also did not give an order to prepare all rescue equipment for immediate use when the ship has actually been lost."

The commission suggested that the reason for this behavior of the ship's command could be the abuse of alcohol. Moreover, the direct superiors not only did not prohibit drinking on ships, but, on the contrary, encouraged it in every possible way. For example, sea captain Leonid Tatarin, who sailed for many years on the ships of the Kaliningrad base of the trawl fleet, recalled:

"One of the clearest examples is the former head of the Kaliningrad "Tralflot" Vasily Dmitrievich Albanov. No one will argue that he was a wonderful person. The tug in the port, named after him, is a well-deserved memory of him. But everyone was embarrassed to tell him the truth - you can’t Encourage drunkenness on ships! In 1965, the Fisherman's Day holiday was officially introduced in our country. Then I was the third navigator on the RTM "Pallada" in the South-East Atlantic, just north of Walvisbay. Exactly on the day when the holiday was celebrated, on "Tralflot" chief himself arrived at the Priboy TR. Our captain was the Hero of Socialist Labor A.F. Tsygankov. Of course, Albanov decided to celebrate the holiday on board. In the morning, our captain moored to the side of the "Priboy" - beautifully, even elegantly. The chief immediately switched to the Pallada. We were reloaded with a sling of vodka, then a sling of cognac, a sling of champagne - to the loud cries of the crew "Hurrah!"

But some of the surviving members of the Tukan crew, instead of an alcoholic one, put forward a completely different version of the death of the ship, which Vyacheslav Morozov recorded from their words:

“Mechanic Zolotarev claims that there can be no talk of any general drunkenness. If only because the ship had just left the repair, the crew was hastily recruited from the reserve, and few people in this “hodgepodge” knew each other. But the mechanic has a different answer to the questions.

- Shortly before sailing, four containers were loaded on board the RTM - as they said, with equipment intended for secret Soviet facility in Cuba,” Zolotarev recalls.

During a storm in the Skagerrak, one of the containers broke off its mounts and hit the slipway, which brought it into the open position. Obviously, at this time on the "Tucan" they felt the shaking of the hull, which became fatal for the ship. Another crew member, V. Mezentsev, also recalled the mysterious containers.

The version that the opening of the slipway (a platform for lifting the trawl with the catch to the deck) was the reason for the flooding of the "Tukan" had every right to life. Just as the version discussed in Kaliningrad that the cause of the death of the trawler was the Soviet submarine that accompanied it and the secret cargo was not without meaning. It was said that it was she who hit the "Toucan", after which he sank. In confirmation of these mysterious versions, then and much later, it was pointed out that the Toucan was never raised, although it sank at a shallow depth: it is more convenient to hide the truth.

However, in 1967, none of the officials began to either confirm or deny these versions. And not only because the party and the government only in the rarest cases reported on catastrophes with the death of so many people, and even more so about their causes. The silence was also explained by the fact that the USSR Prosecutor General's Office did not complete the investigation.

"Investigation closed"

The Acting Prosecutor General of the USSR Mikhail Malyarov reported on the results of the investigation into the circumstances of the death of the "Tukan" to the Central Committee of the CPSU only in the following year, 1968:

"The investigation into the causes of the loss of the fishing trawler Tukan, which occurred on February 28, 1967, when the ship left the Skagerrak Strait for the North Sea, established the following:

February 25, 1967, after the end of the planned current repair and obtaining the class of the Register of the USSR, the trawler "Tukan" left Kaliningrad to fish in the North-West Atlantic. On February 28, while sailing to the North Sea, the trawler "Tukan" got into a severe storm and, as a result of water penetration into the compartments of the ship's hull, sank at a depth of 37 meters. During the shipwreck, 57 crew members died.

The expedition, which intended to raise the "Toucan", did not have the necessary skills, healthy divers, and most importantly, as evil tongues claimed, the desire to work

In contrast to the conclusions of the departmental commission, the investigators of the Prosecutor General's Office came to more definite conclusions:

"The death of the trawler" Tukan ", according to experts, occurred due to the flooding of two adjacent compartments - the fish shop and the fish-meal plant (reinforcing compartment), from where the water quickly spread to other areas of the ship's hull. The shipwreck and the death of a significant part of the trawler's crew were the result of low labor and production discipline on the ship, blunting vigilance and neglect of danger in storm conditions, as well as the result of clearly incorrect actions and gross violations of the Charter of Service on the Vessels of the Fishing Industry Fleet, the Rules technical operation and provisions regulating the safety of navigation, on the part of the ship's command staff.

Upon receiving a storm warning on February 27, the senior assistant captain Safonov did not take the necessary measures to ensure the hermetic closure of all hatches on the aft deck, and the watch navigator Gutsulyak did not organize monitoring of their condition, as a result of which the flow of water into the production premises of the hull was noticed very late. The captain of the trawler Khramtsov did not declare a water alarm and did not take urgent measures to find out and eliminate the causes of leakage, did not inform the Kaliningrad trawl fleet base about the emergency state of the trawler. Khramtsov and his subordinate commanders Safonov, Gutsulyak, Kuzub did not take appropriate measures to effective fight for the survivability of the vessel and the rescue of the crew, who, moreover, through their fault, was not prepared and trained for organized and decisive actions. It was established that on February 26-27, individual members of the ship's crew, including Khramtsov, Safonov, Kuzub and Yeresko, drank alcohol and at the time of the emergency situation showed obvious inactivity and passivity.

Despite the opportunity, Khramtsov did not turn to the Soviet ship Vilis Latsis for help, which he parted with twenty minutes before the shipwreck.

In the presence of a real threat of the death of the ship and crew, the distress signal was given very late, and the orders for the ship's crew to prepare for rescue were given at the moment when the trawler began to sink into the water. The command to the crew to "leave the ship" was not given at all, and no one was in charge of rescuing people during the shipwreck.

The situation that had developed by this time was aggravated by the fact that most of the crew members did not know how to properly use the collective life rafts.

The conclusions of the Prosecutor General's Office also contained information about the design flaws of the vessel:

"The flooding of the trawler was facilitated by certain design flaws of the vessel (the location below the waterline of two communicating with each other through the drainage system industrial premises, unreliable fastening of the slip cover and inconvenient closing of hatch covers in the aft deck coamings)".

And about. The Prosecutor General unequivocally pointed to the perpetrators of the tragedy:

“Considering that Khramtsov, Safonov, Kuzub, Gutsulyak, who were responsible for the shipwreck, died, the investigation of the case was terminated. Officials of the Kaliningrad base of the trawl fleet and the Kaliningrad production department of the USSR Ministry of Fisheries, who made official omissions in the preparation of the Tukan trawler for flight, punished in the party and disciplinary order".

But not only the conclusions were interesting in the note. It didn't say a word about any secret cargo. It is doubtful that and about. Prosecutor General, if the "Toucan" was transporting something secret, bypassed this circumstance in a report to the Central Committee. Moreover, the document itself did not have a secrecy stamp, which clearly indicated that it did not talk about any military or state secrets.

True, the note stated that "final conclusions about the causes of the flooding of the trawler could be made only after the rise and thorough examination of the sunken ship." But, as it turned out, the trawler had not yet been lifted. And a new detective story is unfolding around the ship-lifting works.

"Get more currency and dress up"

In February 1968, an anonymous letter was sent to the Central Committee of the CPSU about how the Tukan was organized and carried out:

"At the beginning of 1967, the Soviet fishing vessel Tukan of the Ministry of Fisheries was lost off the coast of Denmark. The reasons for the death of the vessel were not exactly clarified. According to the agreement, the work to raise the vessel was taken over by the ASPTR (rescue and underwater technical work team. — "Power") of the Baltic Shipping Company with an obligation to complete in 1967. However, they worked for about 6 months. Composition of about 160 people. A floating base with a displacement of 14,000 tons, rescue vessels, diving boats, equipment, machinery, etc. But ASPTR did not succeed. They spent more than 1.5 million rubles, more than 28 thousand gold. rub. in currency.

Reasons for failure: illiteracy, lack of any practice in this type of work. Lack of desire to work. The presence of a desire to get more currency and dress up abroad. The selection of the team, in essence, was not proper. In pursuit of the currency went, who managed. We issued 3 diving specialists, and none of them has the right to dive. What did they do underwater for 6 months? What did they do there? It is unknown and lies on the conscience of divers. The Danes offered to officially lift the ship in 1.5 months, but ours? It's a shame, they have disgraced themselves and still say: they will work in 1968 and spend the same amount of foreign currency, and it will cost at least 4 million rubles. That's what they call it. This is a feeder: you can earn extra money, and without any guarantee for the end of the ascent in 1968. The indignation of the fishermen is understandable ... It's time to stop all this farming and waste money, because you can build three new ships.

Usually, anonymous letters were not paid much attention. However, this one was transferred to the transport department of the Central Committee of the CPSU with instructions to immediately look into the matter. The department sent inquiries to the Ministry of the Navy of the USSR and the Ministry of Fisheries of the USSR, and, as it turned out from their answers, the facts given in the anonymous letter were fully confirmed.

The Ministry of the Navy, however, tried to justify itself. The reply of Deputy Minister Timofey Guzhenko to the request of the Central Committee, sent on March 12, 1968, stated:

"Due to limited technical means for similar works in the Ministry of the Navy, a number of items of material and technical equipment for the recovery expedition were provided with the involvement of other specialized organizations and the owner of the vessel. These positions include the allocation of the Tungus floating base, a keel-boat, ship-lifting pontoons, the missing number of cables, cables and hoses, and the installation of offshore equipment in the sea at the work site.

The total duration of the work provided for by the vessel lifting project was 109 days. In conditions of unstable weather during the period May-October 1967, which differed sharply from the long-term average, it was possible to use only 65.5 days, including 12 days in August, 14 days in September and 5 days in October. In the same period, there were strong storms lasting 8-9 days, breaking not only the rhythm, but causing serious damage to the work already done (storms in August and September 1967). The floating base, the keelector and rescue vessels were repeatedly forced to leave the place of work for shelter.

Deputy Minister of Fisheries Vladimir Kamentsev submitted to the Central Committee a calculation indicating that the Tukan is not worth the cost of raising it

Taking into account the severe weather conditions and the loss of time for repeated rearrangement of watercraft, measures were taken to speed up the work: the composition of divers and other specialists increased, an operating mode was introduced using overtime hours, and lifting technology was changed. In early September, the status of the work was reviewed by the Ministries of the Marine Fleet and Fisheries. At the suggestion of the Ministry of Fisheries, the work was continued in the autumn period, and measures were taken to speed it up by a joint decision. However, continued adverse weather prevented the work from moving forward. Involvement of the Danish firm Crower to joint work, according to the conditions of the actually developing weather, turned out to be impractical. In connection with the onset of the autumn-winter period on November 14, with the consent of the owner of the ship, it was decided to temporarily stop ship-raising work until the spring of 1968.

For the entire period from June to October 1967, 70-75% of the total volume of ship-lifting work was completed, for which the customers paid the ASPTR detachment about 900 thousand rubles. All payments for the work performed, including the payment of foreign currency to personnel, were made with the execution of relevant documents with confirmation of the customer's representative, who was constantly at the work site.

In December 1967, the Baltic Shipping Company analyzed the operation to lift the trawler. It was noted that in addition to unfavorable weather, there were significant shortcomings in the preparation and production of the expedition. The main shortcomings include: a delay in the start of work at the lifting site for one month due to the late arrival of a keel ship belonging to the DKBF to equip the raid; discrepancy between the actual state of the soil at the site of the sunken ship and the characteristic presented on the basis of a survey carried out by a third-party organization commissioned by the owner of the trawler (the soil turned out to be much harder, which was not taken into account by the lifting project); insufficient attention to the logistical support of the expedition and the organization of ship-raising operations on site; lack of diving specialists capable of descending to a sunken ship to depths of up to 40 meters for health reasons.

Probably, if some super-secret cargo existed and was raised, the position of the Ministry of the Navy would look much better and Guzhenko would definitely mention this. But the penitential note further said only that the ministry was going to raise the "Toucan" in the coming 1968.

"The ship broke off and fell to the ground"

However, the Ministry of Fisheries of the USSR had a completely different opinion on the issue of lifting the Tukan. The report of Deputy Minister Vladimir Kamentsev, sent to the Central Committee on April 19, 1968, stated:

"Given that the Ministry of the Navy has a special organization for ship-lifting, it was decided to raise the vessel by the rescue team of the Baltic Shipping Company and refuse the proposals of foreign firms that undertook to perform this work. On April 27, 1967, the Kaliningrad Production Administration of the Fishing Industry a contract agreement with a detachment for lifting the trawler "Tukan" in 1967 with the cost of lifting the ship approximately 610 thousand rubles ...

According to the information of the Ministry of the Navy, in 1967, a detachment washed 4 tunnels and brought ship-lifting slings into them, sharpened 4 lag 400-ton ship-lifting pontoons and 1 suspended 400-ton pontoon, completed preparatory work to raise the stern of the "Tucan" from the ground in order to establish slings for the midship 400-ton pontoons.

After these works, two attempts were made to raise the stern of the ship, but in both cases, for various reasons, the ship broke off and fell to the ground.

In the second half of September, the detachment made new attempts to raise the bow of the Tukan, however, in this case, the lifting equipment was damaged, and the work was unsuccessful.

Taking into account these circumstances and the beginning of the storm period, the Ministry of the Navy raised the issue of recalling the detachment and postponing ship-raising work to 1968.

According to the reporting data, in 1967 the Kaliningrad Production Directorate of the Fishing Industry spent 2,146,000 rubles on ship-lifting work on the Tukan, including 900,000 rubles (instead of 610,000 rubles) on paying the rescue team (instead of 610,000 rubles) and, in addition, 22,086 foreign currency rubles to pay the currency part of the salary to engineering and technical personnel, divers, sailors and other participants in the work.

In the first quarter, the rescue team submitted to the Kaliningrad Fishing Industry Production Administration a draft contract for the lifting of the Tukan trawler in 1968 for 150 days.

There was not a single word about a secret cargo here either. However, a calculation was further cited, the correctness of which was not challenged by the Central Committee:

“According to the calculations made by the detachment, the cost of the work planned for 1968 will be about 850 thousand rubles for the work of the detachment, 750 thousand rubles for the maintenance of the Tungus base, for paying for the services of a lifeboat, renting pontoons, services of a rescue ship and etc. about 400 thousand rubles, and only about 2 million rubles and 32 thousand rubles in foreign currency.Thus, the total cost of lifting the trawler was determined in the amount of at least 4.2 million rubles.

However, the contract does not provide any guarantees for the lifting of the vessel and does not provide for liability for costs in case of non-performance of work.

During the long stay of the vessel at the bottom, it received additional damage and wear from the effects of bad weather and from corrosion, and especially from impacts when falling on the ground during unsuccessful attempts to raise the stern in 1967, in connection with this, the restoration of the trawler will require high costs, which are determined settlements of 1.3 million rubles.

Consequently, the total cost of lifting and repairing the trawler "Tukan" will be about 6 million rubles, with a residual value of the vessel of 1.4 million rubles. In connection with the above, and also due to the lack of guarantees for the unconditional lifting of the Tukan trawler, the USSR Ministry of Fisheries decided not to continue these works in 1968.

So the secret of why the ship was not raised turned out to be not military, but financial. The importance of the cargo that was sent to Cuba with the Toucan is apparently also greatly exaggerated. And the whole story turned out not to be about secrets, but about the human factor. In all its variety of manifestations.

In 1964, a new stern trawler "Bonn" http://www.shipspotting.com/gallery/photo.php?lid=424751 was handed over to the West German customer in Germany, which was the next generation of the trawler after English project"Fairtry" which included a BMRT of the "Pushkin" type, also built in Germany.

Having adopted the concept of the "Bonn" trawler, commissioned by the MRP / MRKh of the USSR and in cooperation with specialists from the Soviet department, a project was developed in the GDR for a fishing trawler that received the code "Atlantik", which compensates for a number of shortcomings of the first generation BMRT that had been in operation by that time for almost a decade, and exactly:

* applied combined navigation and commercial cutting

* a diesel gear unit with 2 main engines and a power take-off was used, which significantly increased the reliability and survivability of the vessel, and also expanded the possibilities of working in the field. It should be noted separately that the power plant of the trawler had a 3-fold survivability due to the installed electric shaft, which after 40 years became almost mandatory for tankers with one main engine.

* the longest fishing deck is provided

* applied a number of automated control and management processes that made the trawler one of the most modern automated ships of that time.

A total of 171 ships were built in Stralsund (147) and Wismar (24) from 1966 to 1976. The first fifty trawlers belonged to the Atlantic I project.

The next 121 ships built between 1968 and 1976 belonged to the upgraded Atlantic II project.

Also, on the basis of this project, in 1971-72, seven Scientific Research Vessels (RV) of the Evrika type were built, and in 1973, seven fishing training vessels (UPS) of the Kursograph type.

The bulk of this type of trawlers left the stocks of the Stralsund shipyard, and only 24 units. were built in Wismar.

In addition, 24 ships were built for Bulgaria, 8 for Romania, and 5 for Cuba.

Purpose of the vessel:

- fishing with bottom and mid-depth trawls;

- processing of fish into frozen products;

- processing of non-edible by-catch and fish processing waste into fodder meal and industrial fat;

- storage and transfer of manufactured products to transport refrigerators or transportation to the port.

Overall length, m: 82.20

Overall width, m: 13.62

Board height to the upper deck, m: 9.55

Draft average loaded, m: 5.16

Maximum displacement, t: 3362

Deadweight, t: 1150

Registered tonnage gross / net, reg. t: 2657/1139

Main engines:

Quantity and power, piece*hp: 2*1160

Make: 8NVD 48A-2U

Productivity of technological lines:

Frozen fish, t/day: 45

Fishmeal and technical fat, t/day: 35

Refrigerated holds, quantity and total volume, pcs * cub. m: 3*1095

The volume of premises for the storage of fishmeal, cu. m: 163

Volume of fat tanks, m3: 9

Temperature in holds, degrees C: -25

Coolant: Ammonia

Cargo booms, number and load capacity, pcs*t: 4*3.0 (2*3.0; 2*5.0)

Diesel fuel, t: 602

Heavy fuel, t: 69

Fresh water, t: 133

Speed, knots: 13.8

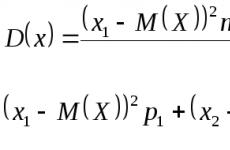

This installation has, as a rule, two main engines, from which power is transmitted to one propeller through a gearbox.

Gear ratio of reducers 1:2; 1:4 allows the use of motors with increased speed. Gearboxes in such installations only reduce the speed of the crankshaft; reverse is provided by reversing the engine or with the help of CPP.

The diagram of the diesel gear transmission is shown in Figure 2.5. The crankshafts of the two main engines 5 are connected through couplings 4 to the primary shafts of the gearbox. The gearbox is a single-stage gear transmission. Gears 3 and 6 rotate a large gear wheel connected to shafting 2 and propeller 1. A shafting thrust bearing is mounted in the gearbox. Due to the presence of a reduction gear, the rotational speed of the propeller shaft can be reduced to a value that ensures high efficiency of the propeller.

Figure 2.5 - Scheme of diesel gear transmission

Sliding induction or hydraulic clutches are used as clutches, which ensures quick disconnection of the shaft line from the crankshafts, shutdown of one of the engines in case of malfunctions, and also protects the gears of the gearbox from sharp shocks when the gear is engaged.

Diesel gear transmission is currently widely used in installations with two medium-speed main engines of the French company Semt-Pilstick. These engines are four-stroke, tube, V-shaped, turbocharged, with 12 to 16 cylinders. All engines of this type (PC-2V-400) have the same cylinder and stroke dimensions. Their cylinder power is 342 kW (465 hp) at a speed of 500 rpm.

Figure 2.4 - Location of mechanisms in the engine room of the PPR "Rembrant"

1 - fresh and sea water pumps of the main engine; 2 - evaporators; 3 - distillate pumps; 4 - distiller; 5 - pumps of ship systems; 5 - diesel generator; 7 - warm box; 8 - boiler feed pumps; 9.10 - hydrophores outboard and fresh water; 11 - steam boiler; 12 - desk; 13 - oil and fuel separators; 14 - pumps serving main engine; 15 - cylinders of compressed air; 16 - fresh and outboard water pumps of the main engine; 17 - bilge water separator; 18 - cooling water pumps of the refrigeration unit; 19 - fresh water coolers of auxiliary engines; 20 - diesel generators; 21 - oil coolers of the main engine; 22 - fresh water refrigerators of the main engine; 23 - main engine

Reduction gears with such engines are installed on transport refrigerators of the Sea of Okhotsk, Amur Bay, Russky Island types.

Installations similar in type were used on RTM "Tropic", "Atlantic". They consist of two main single-row NVD SKL engines of 490 kW (670 hp) for the Tropic RTM, and 850 kW (1160 hp) for the Atlantic RTM, connected to the gearbox by means of induction couplings.

A feature of these units is the use of reversible electric shaft generators in their composition (shown in Fig. b by a dashed line), which makes it possible either to take power from the main engines to supply electricity to ship consumers, or to use the power of the ship's power plant to propel the ship. Shaft generators are driven from the driven gear of the gearbox through a gear that increases the speed. Such installations make it possible, when performing fishing operations (lowering, lifting fishing gear), to use the power reserve of the main engines to power the fishing mechanisms through a shaft generator.

During transitions, the shaft generator can be used as a shaft motor to increase the speed of the vessel.

RTM type "Atlantic"

Fishing freezing trawlers of the "Atlantic" type were built by the folk enterprise "Volksverf" in Stralsund (GDR) by order Soviet Union. The trawler is designed to operate in the areas of the Middle and South Atlantic, equipped with a stern trawling device, a facility for freezing the catch and storing fish products in refrigerated holds.

The vessel is single-rotor, double-deck, with an excess freeboard and the location of the power plant in the middle part. On the main deck there is a three-tiered superstructure. The stem is inclined, the stern is transom with a flat transom, having a slope towards the bow. The main characteristics of the ship type "Atlantic":

Trawlers of the "Atlantic" type are built to the class of the Register of the USSR

Propulsion plant - diesel-reduced, two-machine, with CPP and power take-off for shaft generators.

Two main engines type 8NVD-48. 2AU through induction clutches and a gearbox transmit power to the CPP. Part of the power through the same gearbox can be taken by a three-phase alternating current shaft generator operating on the ship's network, and a generator direct current working on fishing mechanisms. The ship's alternating current power plant consists of four diesel generators with a capacity of 320 kVA each, an emergency diesel generator with a capacity of 50 kVA, switchgear, equipment and electricity sewerage networks.

The basis of the auxiliary boiler plant is a water-tube boiler of the Wagner-Hochdruck system with a steam output of 2.5 t/h at a pressure of 785 kPa (8 kgf/cm2).

Evaporative installation vacuum, direct evaporation. All auxiliary mechanisms serving the power plant are electrically driven.

The plan of the engine room of the trawler is shown in Figure 2.6.

Propulsion plant. As the main ones on the RTM of the "Atlantic" type, SKL engines manufactured by the plant named after. K. Liebknecht (GDR). Engines four-stroke "single action, trunk-type, reversible, with gas turbine pressurization. The main characteristics of the engines are given below.

Engine type 8NVD-482AU

Number of cylinders z 8

Cylinder diameter Du, mm 320

Piston stroke Sp, mm 480

Cylinder volume Vc, dm3 38.6

Compression ratio 13.25

Speed n, rpm 375

Continuous power Ne, kW (e.l. s)... 852(1160)

Starting speed n START, rpm. 80

Minimum sustained frequency

rotation n min , rpm 200

Forbidden zone speed n kr,

rpm 250-300

Average piston speed s t, m/s 6.0

Compression end pressure MPa (kgf / cm 2) .. 4, 12-4.1 (44-43)

Maximum cycle pressure p G, MPa

(kgf/cm2) 6.67-7.705 (68-72)

Average effective pressure p e, kPa

(kgf/cm*) 883 (9)

The degree of pressure increase in the turbocharger 1.27-1.33

Maximum backpressure at the exhaust

R V.G. , kPa (mm water column) 1.962 (200)

Exhaust outlet temperature

from cylinders t C VG, °C 375-425

Exhaust temperature before turbo

blower t* H,°C 435-85

Specific fuel consumption g E g/kWh

(g/e.l. s h) 218+ 5%(160+5%)

Figure 2.6 - General arrangement of mechanisms in the engine room RTM type

"Atlantic"

1 - main engines 8NVD-48A2U; 2 - induction couplings; 3 - reducer; 4 - AC shaft machine; 5 - DC shaft machine; 6 - condenser of the boiler plant; 7 - auxiliary steam boiler; 8 - oil pump; 9 - lubricating oil pump; 10 - feed water pump; 11 - drainage pumps; 12 - bilge water separator; 13 - bilge pump; 14 - outboard water pump for diesel generators; 15 - outboard water pump of the main engines; 16 - auxiliary diesel generators; 17- starting cylinder of a diesel generator; 18 - fuel pumps; 19 - reserve oil pump of the main engines; 20 - air cylinder of the control system; 21 - starting cylinders of the main engine; 22 - fuel separator; 23 - electric compressor; 24 - fresh cooling water pump for diesel generators; 25 - reserve fresh cooling water pump for main engines; 26- Vacuum pump evaporation plant; 27 - desalination plant condenser; 28 - evaporator condenser cooling pump; 29 - fire pump; 30 - evaporator brine pump, 31 - oil separator; 32 - cooling water pump for oil coolers of the gearbox; 33 - oil heater; 34 - refrigerator for gear oil; 35 - gear oil pump

The design of the engine is similar to the design of the 8NVD-48AU diesel engine installed on the Mayak-type SRTM. The increase in power is achieved by increasing the speed to 375 rpm and increasing the degree of boost.

The transmission of power from the main engines to the gearbox is carried out through two induction clutches. Couplings have the following main characteristics:

Type 1K2000-16/3

Rated torque, MN m (kgf m) 218(2220)

» excitation current, A 85

Rated excitation voltage, V 120

Forced arousal:

voltage, V 170

Limit torque at rated excitation

MN-m (kgf-m) 245(2500)

Limit torque with forced

excitation MN m (kgf m) 275(2800)

Nominal slip, % 2.5

The excitation voltage of the induction couplings is supplied from two converters, consisting of three-phase current transformers and silicon rectifiers. The clutches are switched on from the CPU. The clutch activation system has a locking device that operates in the following cases:

If the shafts of the main engines rotate in different directions;

if the pressure of oil in the gearbox and cooling water in the stern tube is below the minimum allowable;

When the barring device is on;

When shifting the rudder blade at an angle exceeding 40 °.

The gearbox is designed to transfer the power of the main engines to one propeller shaft and power take-off shaft, as well as to change the speed. Reducer characteristic:

Input shaft speed, rpm 375

» » propeller shaft, rpm 175

» » power take-off shaft, rpm. 1000

Power transmitted to the propeller shaft, kW (e. hp) 1705 (2320)

» » » selection shaft, kW 556

Maximum transmitted power, kW (e. hp) 1935 (2633)

Reducer gears are cylindrical, helical. All gearbox shafts, except for the power take-off shaft, are placed in plain bearings filled with babbitt. The power take-off shaft rotates in rolling bearings. A barring device is mounted on the free end of the power take-off shaft. A segmental thrust bearing is built into the gearbox, designed for a maximum thrust of 265 kN (27 tf).

As a propeller, the trawler is equipped with an adjustable pitch propeller manufactured by the plant. K. Gottwald (GDR). Characteristics of VRSh:

Screw diameter, mm. 3400

» hubs, mm 1000

Structural pitch ratio 0.852

Speed, rpm 175

Maximum angle of rotation of the blades forward / backward, ° 25/20

The hydraulic pitch change mechanism is located outside the hub.

The propulsion unit is controlled from the central control room in the engine room, and the propeller pitch is controlled from control stations located in the wheelhouse and in the central control room. The plant control system has load indicators for the main engines, which provide control over its distribution between diesel engines.

The rotational speed of engines and CPPs is not regulated.

Consider the characteristics of the propulsion plant.

Due to the fact that power is taken from the main engines to the AC shaft generator, the engines operate at a constant speed. Changing the speed of the vessel is carried out by changing the pitch of the propeller.

As tests have shown, the maximum freewheel speed when working on the propeller of one engine in the nominal mode is 10.4 knots. The turning angle of the CPP blades is 16°.

When the AC shaft machine is operating in the shaft motor mode together with two main engines, the freewheel speed increases by 0.2 knots, which is practically of no significant importance.

Tests of RTM "Aviator" were carried out during the operation of the vessel with a bottom 31-meter and a mid-depth 25-meter trawl.

Wind and excitement during the test period did not exceed three points.

Tests of the propulsion system on trawling showed that at towing speeds of the bottom trawl of 4.5 knots and of the mid-water trawl of 4.7 knots, the power consumed from the main engines is 0.65-0.67 of the nominal power at a blade turning angle of 15°.

The maximum trawling speed in calm weather, when the two main engines are operating at a mode close to the nominal one, and the blades turn angles within 16-16, 5 ° is about 5 knots.

When one main engine is operating with a load of 80-4-85% of the nominal (a \u003d 11, 5-f-12 °), the trawling speed is 3.5-3.9 knots.

Trawling against the wind with waves up to 6 points is possible at a speed of up to 4 knots without overloading the main engines. During the transition to the fishing site, the vessel's motion is provided by the operation of two main engines. The angle of rotation of the propeller blades is set within 19-21° depending on the weather.

When moving from a fishery to a port, due to an increase in vessel loading, the angle of rotation of the propeller blades decreases to 17-20°. The average daily fuel consumption for the main engines at crossings is 8.7 t/day, and in the field - 5.1 t/day.

A diesel-gear unit with power take-off through AC and DC shafts is called a “father and son” unit.

A diesel-reducer unit similar to the SEU RTM "Atlantika" with a power take-off is installed on the UPS "Khersones", as well as on ships of the RTM-K-S "Moozund" type.

Power plants with diesel-electric transmission. Such installations have been used mainly on ships with powerful fish processing equipment on board (production refrigerators, canning trawlers), where flexible redistribution of energy generated by the power plant is required: at crossings - maximum use generated energy for the needs of the movement of the vessel, and in the fishery - ensuring the operation of fishing and fish processing mechanisms. This possibility is provided by a power plant with electric transmission. The electrical transmission diagram is shown in Figure 2.7.

Figure 2.7 - Electrical transmission diagram

In the engine rooms of ships with diesel-electric transmission, units are installed consisting of diesel engines 5 and generators 4 of electric current driven by them. The propeller 1 in this gear is driven by an electric motor 2, which receives energy through a switchboard 3. The mechanical work of the main engines 4 in this gear is converted into electrical energy, which is then converted into mechanical work in the propulsion motor 2 to drive the propeller. This double conversion of energy naturally reduces the transmission efficiency.

Electric transmission has become popular on a number of industrial refrigerated trucks and canning trawlers due to the following advantages:

Ability to maneuver the number of operating diesel operators, which allows them to be used in whole or in part, depending on energy needs;

Easy reverse operation using electric switches or CPPs, which allows the propulsion unit to be controlled from the bridge;

Possibilities of placing the power plant regardless of the propeller shafts (no intermediate shafts and their tunnels);

The possibility of using the main generators to obtain current that feeds the auxiliary mechanisms.

The disadvantages of the electric drive include low efficiency, the complexity of the equipment and the need to increase the number of maintenance personnel (in addition to mechanics, electromechanics are also needed); high initial cost.

The installation depicted in Figure 2.7 is an installation with a single electric power system. Diesel generators in this case are not divided into main and auxiliary. The energy generated by them, depending on the mode of operation of the vessel, is distributed through the switchboard between the propulsion electrical installation and other consumers. According to this scheme, the power plants of trawlers of the Sever type, field and production refrigerators of the Altai type and canning fishing trawlers of the Natalia Kovshova type operate.

There are diesel-electric ships that have main and auxiliary diesel generators, i.e. propeller electrical installation and ship auxiliary, power plant in this case are autonomous.

Depending on the type of current, power plants with diesel-electric transmission can be of direct current (commercial refrigerator of the Druzhba type) and alternating current (commercial refrigerators of the Altai and Zelenodolsk types). The increased use of alternating current in modern diesel-electric installations is due to the compactness, simplicity of design and maintenance of generators, electric motors and other AC equipment compared to DC equipment.

Power plants with reverse gear transmission to the propeller from a non-reversible engine.

This type of installation is used on small-tonnage fishing vessels: medium and small seiners, small trawlers and receiving-transport vessels with a main engine power of 60-140 kW (80-200 hp). The scheme of the engine room with such an energy plant of the middle Black Sea seiner is shown in Figure 2.8

Figure 2.8 - Schematic plan of the engine room of a marine fishing vessel

The main engine 8 (diesel power 110 kW) rotates the propeller 1. Power is transferred from the engine to the propeller by shafting. It consists of separate shafts: intermediate 24 and stern tube, or propeller, 26, interconnected by flanges 3. The intermediate shaft is located in support bearings 4, and the stern shaft is in stern tube bearings 2, which are installed in the stern tube 25. At the end of the stern shaft the propeller 1 is fixed. The crankshaft of the engine is connected to the shaft line through the reverse gear 21, with the help of which the direction of rotation of the shaft line and the propeller is changed. A thrust bearing is located in the reverse gear housing. It perceives the pressure created by the propeller.

To provide energy to the ship's auxiliary and fishing mechanisms - pumps, winches, net-lifting machines - an auxiliary engine 17 (diesel power 14 kW) is located in the engine room at the starboard side, which drives an electric generator. A fire pump 9 driven by an electric motor is installed on the left side. In the bow there is a drainage pump 12, which pumps out water from the hold and is driven directly from the main engine. The main engine is started by an electric starter.

To power the electric starter and to illuminate the premises, batteries are provided, located in cabinet 22 on the starboard side. In the event of failure of the electric starter, the main engine can be started up with compressed air, which is stored in cylinders 20. Compressed air used for other purposes as well. Its stock can be replenished with a compressor 19. At the aft bulkhead there is a switchboard 23 of the ship's electrical facilities, a water heating boiler 6 and a coal bunker 5. Tanks are located on the sides: the main fuel supply 7 and 18, oil 14 and consumable fuel 16. At the bow bulkhead is installed consumable oil tank 11. Hand pumps are placed next to the tanks: 10 for water, 13 for oil, 15 for fuel.

For the implementation of maneuvers and reverse of the main engine, small size vessels are manufactured together with reverse gears, with the help of which it is possible to change the direction of rotation of the propeller shaft and reduce its speed. The design of the reverse gear also includes a disconnecting device.

Shafts 13 and 9 have disks 3 and 15. A third disk 4 is placed between them, which rotates together with housing 2, connected by flange 1 to the engine crankshaft.

Figure 2.10 shows a longitudinal section of the reverse gear of the 2ChSP 10.5 / 13 engine, operating according to the above scheme with a gear ratio of 1:1.35 in reverse and 1:1.25 in forward. Position numbers in figure 2.9 are the same as in figure 2.10.

Figure 2.9 - Scheme of a two-disk reverse gear

When moving to the right, disk 4 enters into engagement with disk 15 and causes it to rotate, and with it through gear 12 and shaft 11 (forward). When moving to the left, disk 4 engages with disk 3 and together with it drives shaft 9 into rotation. The rotation of shaft 9 is transmitted to the driven shaft 11 through gears 8 and 10. The direction of rotation will be the same as that of shaft 9, i. reverse direction of rotation of gear 12 (reverse). The "stop" position corresponds to the middle position of the disk 4. In the "stop" position, the engine crankshaft continues to rotate, and the propeller shaft will be stopped. The movement of the pressure plate 4 is carried out by the switching lever 5 using the switching clutch 6 of the lever mechanism 14. The advantage of the reverse gears of this scheme is the possibility of their long-term operation in reverse.

The disadvantages include the limited amount of transmitted torque, as well as the need for a very precise mounting of disks in the case. The slightest misalignment of discs can cause them to overheat and seize.

To transmit high torques, reverse gears with hydraulic or pneumatic control are used. Maneuvering of such installations can be carried out from remote automated consoles.

Figure 2.10 - Longitudinal section of a two-disk reverse gear