Warm floor in the bathroom

Feedback from owners who use underfloor heating in the bathroom, kitchen or garage confirms its high efficiency in creating a favorable microclimate in the room. No wonder the well-known proverb says that you need to keep your feet warm and your head cold. Such a temperature distribution for the human body is most consistent with its physiology and does not cause discomfort over even a very long time of using these systems. Lower surface temperatures, even distribution of warm air, economical use of oxygen and many other advantages lead to the widespread use of heated floors in residential and public buildings.

Despite some difficulties that arise in the design and coordination, the installation of warm ones has become the most integral part of modern apartment renovation. A slight increase in the cost of work allows leveling the shortcomings of ventilation systems, floor cladding materials and creating an insurmountable barrier of dampness, which is fertile ground for the development of microorganisms harmful to humans. Floor heating in a bathroom, swimming pool or sauna implies a pleasant tactile sensation during the adoption of water procedures. As an example, consider the installation of a warm floor in the bathroom, where these works are most often performed.

Types of heated floors

When installing floor heating for residential and public buildings, several systems are used that differ from each other in the method of heating, the type of coolant and the materials used.

Heating system using a liquid heat carrier, the so-called water-heated floor

It is distinguished by the complexity of installation, a large number of preparatory work and high requirements for the materials used. Requires complex engineering calculations, a large number of valves and the use of circulation pumps. The large length of pipelines creates increased hydraulic resistance, which limits the use of the system in existing multi-apartment buildings.

Connected to a central heating system, water heated floors in the bathroom can cause a complete imbalance of the system and stop the circulation of the coolant. The high temperature in the centralized circuit, reaching 75-80 degrees, is unacceptable for floor heating, which makes it necessary to reduce the circulation rate or mix cold water into the coolant. Such actions cause a decrease in the temperature of the heating devices located after the connection point. At a minimum, this guarantees the dissatisfaction of neighbors who are forced to freeze in their apartments.

Important! Chapter 4 of the Housing Code of the Russian Federation and Decree of the Gosstroy of the Russian Federation No. 170 “On approval of the Rules and norms for the technical operation of the housing stock” legally prohibit such interference in the centralized life support systems of the housing stock at the federal level. The broad powers of the subjects of the Federation also make it possible to adopt local legislative acts in force in specific territories, take, for example, Decree of the Government of Moscow No. 73-PP.

The use of elevator nodes for balancing the house heating system (nodes for adjusting the pressure and flow of the coolant) allows the use of only copper pipes for the coolant in underfloor heating systems. This significantly increases the cost of the system and makes its installation economically unprofitable. Therefore, the water floor in the bathroom has become widespread in the individual construction and design of autonomous heating systems.

Autonomous heat generators, distribution systems and separate circuits of the system with their own circulation pumps make it possible to obtain the required temperature of the warm floor in any room, absolutely independent of the main heating circuit. Controlled electronic or mechanical control valves automatically maintain the set temperature. The low pressure in the system allows the use of cheaper polymer pipes, which reduce the cost of the system without compromising efficiency and durability.

Electric heating system using a heating wire

The electric heating system is widely used in apartment buildings due to the absence of the need for long-term coordination and can be installed with sufficient electrical power supplied. Relatively low energy consumption, the ability to install inexpensive automation and laying under any finishing coatings have brought deserved popularity to electric heating, and slightly increased energy costs cannot be compared with the resulting comfort.

Electric underfloor heating in the bathroom, the installation of which significantly improves the performance of the room, requires minimal additional costs for the purchase of equipment and materials. The installation of electric heating fits into the technological operations for the arrangement of a conventional floor. The cable is laid on a heat-insulating base and filled with a cement screed of the subfloor.

Temperature sensors installed during installation control floor heating to a predetermined temperature, which is maintained using an electronic thermostat that looks like an ordinary switch. The modern microprocessor element base allows you to program temperature controllers literally in minutes, which significantly reduces energy costs. Electric heating has low inertia and high efficiency, which makes operation cost-effective.

Difficulties with the installation of electrical cable that arose at an early stage of application are fully taken into account in the subsequent development of technology. The heating cable is placed on a heat-resistant grid using special fasteners. The resulting mats are completely ready for laying, easy to use and can significantly reduce the time to make a warm floor in the bathroom. .

In the production of the heating cable, a plastic heat-resistant insulation is used that can withstand a much higher temperature than the maximum heating temperature of the cable. All electrical connections are made at the point where the heater is connected to the thermostat, which guarantees the occurrence of a dangerous electrical potential on the floor surface, and the ability to connect through a differential switch will instantly de-energize the system at the slightest current leakage.

Please note: One of the advantages of electric floor heating is the insignificant thickness of the heating element, which, unlike water, can be mounted with minimal alterations to the existing floor. This advantage makes cable heating unrivaled in those rooms where it is impossible to make a screed of more than 3 cm.

Manufactured in compliance with all technological subtleties, electric cable heating does not require further maintenance during the entire service life. A high-quality heating cable has more than a ten-year warranty period only, and the maximum service life is not limited.

Electric heating system based on infrared film heaters

Recently widely advertised film heating elements are successfully used to create heating systems that emit infrared thermal radiation in the range of 10-15 microns. Infrared rays cause heating of surrounding objects, which transfer secondary heat to the air in the room. Without going into complex technical details, this type of heating can be compared with the action of sunlight, when even at low air temperatures a person feels comfortable and can even sunbathe when there is snow around.

The main element in the film heaters on the basis of which the infrared warm floor in the bathroom is made is a carbonaceous material, which, when an electric current passes, begins to emit heat rays, heating up to a temperature of no more than 70 degrees. The heater is enclosed in a durable polymer film with high thermal stability and is not subject to combustion. The polymer absolutely does not pass electric current and serves as a good insulator for current-carrying tires. The film heater has a very thin thickness compared to other systems that provide floor heating in the bathroom, and can be mounted directly under the finish coat.

Such an element consumes less electricity than traditional heaters and therefore reduces operating costs.

Important! However, when equipping a heated floor in the bathroom, it must be remembered that the film heater cannot be laid in a cement screed or tile adhesive, which narrows the types of finishes used. An infrared heater based on carbon rods connected by an electrical wire of increased security is free from this drawback. Such a heater can be safely poured with a cement screed 2-3 cm thick.

The choice of underfloor heating

After we have studied all the possible design options, it's time to consider the factors that affect the choice of underfloor heating in the bathroom. Having decided to install underfloor heating in the bathroom, it is necessary to choose the right heating system, based on the characteristics of the room and the nature of the coating:

- In a private house or cottage, despite the high initial costs, it would be best to install water floor heating in the bathroom, resulting in savings using the energy of the installed heating boiler;

- When using electric heating, take into account the existing restrictions on the use of heaters specified by the manufacturer;

- Accurately maintain the installation technology not only of heaters, but of the entire system as a whole, including, it would seem, minor elements;

- It is imperative to perform thermal and electrical calculations to obtain a balanced heating system that excludes the occurrence of critical overloads of heating equipment or the power supply system of a house or apartment;

- In case of lack of confidence in the correctness of the calculations performed or compliance with the installation technology, it is better to contact specialists to provide the necessary assistance. Trained, licensed professionals will perform quality work, and will incur some warranty obligations within the agreed time;

- Starting all work on the design and installation of underfloor heating, especially in apartment buildings, consult about the possible legal consequences of such work.

Installation of floor heating systems in the bathroom

Water heated floor

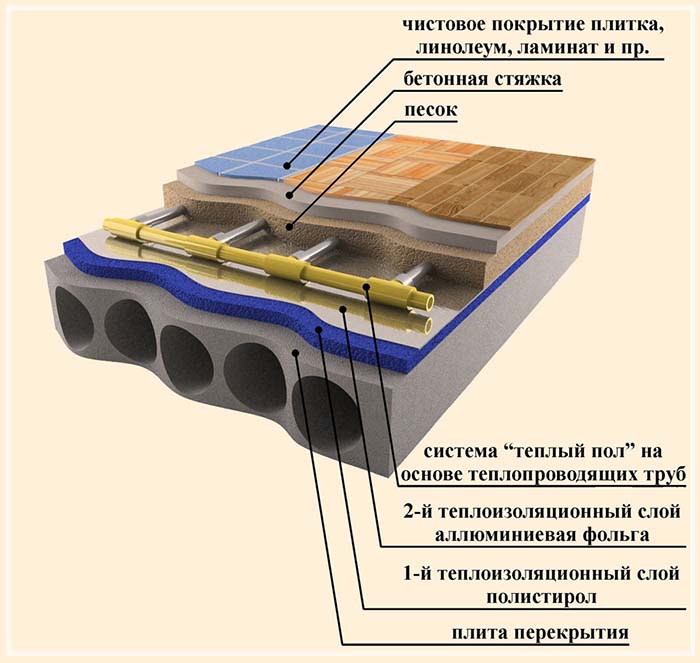

The laid water-heated floor in the bathroom shown in the photo gives a visual representation of the order of work:

- It is necessary to prepare the base by removing the old screed and leveling the surface. When laying a water floor, height differences are not allowed, which can serve as pockets for air released during heating of the coolant and which can significantly impede or completely block circulation in pipes of small diameter and considerable length;

- Run a layer of waterproofing and lay a heat-reflecting screen with applied markings;

- Lay a tape compensator for thermal expansion of the floor surface during heating along the perimeter of the room;

- To create a stronger screed operating in the thermal deformation mode, it is necessary to lay a reinforcing mesh with a mesh size of 50x50 mm and a wire diameter of 3-4 mm over the heat-insulating layer

- The metal-plastic heating pipe is laid either spirally or around the perimeter of the room, but with any laying method, the supply and return pipelines must run parallel to each other over the entire area of \u200b\u200bthe room for more uniform heating of the floor surface.

To facilitate this operation, it is necessary to draw up a large-scale sketch, lay the route and apply markings directly to the underlying surface. Only then is the pipe laid, and the remaining drawing must be saved in order to have an idea where the heating pipe passes after a while.

- depending on the thickness of the screed, which can be from 30 to 70 mm, it is necessary to install the pipe on supports of the appropriate height in order to ensure the flow of the mortar to be laid and prevent the formation of voids;

- when choosing a pipe for a warm floor, you do not need to make heat engineering calculations. The maximum length of a pipe with an internal diameter of 16 mm is 80 m, and a thicker pipe with an internal diameter of 20 mm can be laid no more than 100 m. The shorter the underfloor heating line, the lower the hydraulic resistance, the higher the temperature and the more economical the heating system.

- After the laying of the warm floor in the bathroom is completed, the screed of the required thickness is poured and carefully smoothed out to obtain a smooth surface. After pouring the screed, it is necessary to withstand the concrete until it has completely set and gained strength for at least seven days, and only then proceed with further work on the floor cladding;

- To put the floor into operation, it is necessary to connect the supply and return pipelines to a special distribution system, which is performed when piping the boiler.

Electric floor heating

- An electric underfloor heating based on a heating cable is laid similarly to a water floor, given the smaller diameter of the cable. All preparatory and waterproofing operations are similar;

- To facilitate the laying of such a floor, it is better to buy ready-made thermostats for the bathroom: with its small size, the rise in price will not be significant, and the quality of the installation will increase significantly;

- When laying an electric underfloor heating, one should not forget about the presence of a temperature sensor, which is mounted between the cable branches at a small distance from the wall, which increases the accuracy of measuring the floor temperature. The electronic temperature controller can be installed directly next to the light switch or in any place convenient for use. It is better if it is protected from excessive ingress of moisture, and even more so direct ingress of water, which can disable the electronic device;

- After checking all electrical connections for the absence of short circuits and contact of current-carrying with surrounding structures, you can make a trial inclusion of a warm floor, and then, disconnecting it from the electrical network, fill the screed and ensure complete drying of the solution.

Note! Turning on the heater is possible no earlier than 28 days after filling. This is due to the possibility of cracking the screed and damaging the floor heating cable.

Infrared warm floor

- when installing an infrared warm floor in a bathroom under linoleum or waterproof laminate, it is necessary to choose the right heating film power. What kind of film of a particular manufacturer is needed, they can tell you in the store when buying. The power value is indicated on the side surface of the film and is indicated by the value "W / m" (watt per 1 running meter);

- Before laying the film, a layer of thermal insulation with a foil layer is applied to the prepared floor surface to reflect the rays towards the room. This increases the heating capacity of the floor and prevents heat loss in the floor slabs;

- When laying infrared film in the bathroom, it is necessary to remember the high-quality insulation of electrical connections and connect the floor to the mains only through a differential switch.

- The film is laid in a continuous carpet, and given its excellent heating capacity, it is possible to reduce the laying area by 15% without compromising the heating capacity of the floor;

- The infrared floor in the bathroom based on carbon rods is installed similarly to the electric floor based on heating cable, but differs in the heating method, which is similar to the film heater. Such an infrared heater can be placed in a screed or directly in a thickened layer of tile adhesive;

- When installing underfloor heating film in the bathroom, you must follow the manufacturer's instructions exactly to ensure high quality installation and durability of the heater.

By installing an underfloor heating system, you can save some money and not lay a warm floor under the bathroom and toilet, where it will not perform its functions to the required extent.

Conclusion

A person's desire to improve living conditions encourages him to search for new means of improving comfort. The creation of new life support systems, the use of new technologies and materials make it possible to create highly intelligent computer-controlled robotic systems from ordinary living quarters. Everything depends only on the desires of homeowners in private development and the ability to coordinate the desired changes with current legislation if the housing is located in an apartment building with centralized life support systems. Not so long ago, heated floors were known only to residents of the northern regions, which are located beyond the Arctic Circle, and then only in a limited list of premises. And now, not a single autonomous system of a private house can do without installing underfloor heating in rooms for various purposes.

Installing underfloor heating in the bathroom at first glance is not difficult. And indeed, having some experience with the tool and modern materials, you can do this work yourself, but when we make a warm floor in the bathroom on our own, it is never too late to turn to specialists to clarify this or that detail. Considering the presented videos about the warm floor, it is necessary to write down the order of operations, incomprehensible moments, specifying which you can start working. You need to hurry, slowly, then you can achieve the desired result. If there is no self-confidence, or a complete understanding of the operations performed, it is necessary to entrust the work to competent specialists.