Drawing a picture on a knife with your own hands. Artistic metal etching - knife blade

Beautiful weapons are a special topic. Even a person who is quite far from a passion for everything related to weapons is not left indifferent to souvenir and collection samples, decorated with skillful carvings and paintings. For example, here is a knife with a pattern on the blade, which is quite possible to do it yourself.

Artistic etching of a knife blade

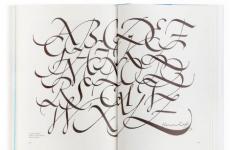

Step 1 SketchA floral ornament, a plot drawing about a hunt, an emblem or just initials - this is a small list of drawing ideas that can be imprinted on a blade. Decide what pattern you want to see on the blade and start sketching. You can draw it yourself or call for help

Next, transfer the drawing to the blade. To do this, you can place the blade in the scanner, and transfer the image to CorelDraw, where you can draw the outlines of the blade. Then apply a suitable ornament. The result is duplicated in a mirror image and sent to print.

Step 2. Varnishing the blade

Coat the blade with varnish in advance. You can use a matte varnish for plastic models-copies. Dilute the varnish with a nitro thinner (to dry faster) and apply with an airbrush (you can use a regular brush). The varnish is good because it retains plasticity during the day and does not crumble under the scrubber.

Step 3 Transferring the design to the blade

We cut out the sketch to make it more convenient to fit it to the blade, blacken the reverse side with a pencil, fix it on the blade with masking tape. Then we draw the ornament with a thin pen. As a result. we get a drawing on varnish.

Step 4 Scratching a pattern

We scratch the pattern on the surface of the varnish using scrubbers with different sharpening. In this case, the metal of the scrubber should not be harder than the metal of the blade, otherwise scratches are possible.

Step 5. Features of the drawing

Please note: in this example, the “field” is etched (this is a more complex option, since it is more difficult to scratch the pattern), although an easier option is also possible when only the outlines of the pattern are etched.

Step 6. The drawing is ready

So, the picture is completely scratched on the varnish.

Step 7. Electrocution

You can use a variable transformer, for example, from the children's railway. It will serve as an adapter for a mini drill, which is indispensable for fine work. The maximum voltage is 12 volts, which is quite enough.

Heat-shrinkable cambric serves as insulation.

Flannel

Brass / copper plate - approx. 100 mm / 7 mm

Step 8 Etching

So, we put the fabric on the plate and soak it all in a strong saline solution (do not spare the salt)! Then we begin to poison - with short touches, you should not hold it for a long time, since you can overheat the varnish.

You will need

- the knife itself, a liquid for degreasing the surface of the knife (gasoline, alcohol, cologne), a pattern for applying to the knife blade, adhesive tape, a sharp knife or scalpel, a 5 ... spoon for 50 grams of water).

Instruction

Drawing on the blade of a knife can be applied with the help of -chemical. It is a method of applying to all metals and alloys without the use of complex chemicals. It is based on the principle of electromechanical metal etching. However, this method is not suitable for silver and lead. Get to work.

Blade preparation. The surface of the blade must be degreased, because the quality of the applied pattern directly depends on this. Degrease the surface with any of the liquids at hand: gasoline, alcohol or cologne.

Pre-drawing. Stick a piece of tape on the blade in the right place. Use a sharp knife or scalpel to apply the pattern to the tape, being careful not to damage the tape.

Metal etching. At this stage, you will need a power supply, you can use a mobile charger. Prepare saline solution. Then proceed to the electrochemical cleaning of the metal surface. Attach "+" to the knife and "-" to the cotton-head nail, it will replace the electrode. After that, turn on the power supply, dip the electrode in saline solution and swipe over the surface of the pattern. Repeat this procedure 2-3 times for best results.

Then change the cotton head of the nail to a clean one and reverse the polarity: "+" to the electrode, and "-" to the knife. Dip the electrode in saline solution and start drawing a pattern that will appear before your eyes. To achieve the greatest effect, repeat the procedure 2-3 times.

End of work. Peel off the tape from the knife and remove sticky traces of it. The engraving on the knife blade is ready.

Sources:

- knife drawings

Engraving on steel has been around for a long time. Most often, the objects of engraving were edged weapons or cutlery. They engraved the name of the owner, his motto or coat of arms.

Instruction

Currently, engraving is common not only on weapons and utensils. It can be a gift inscription on a lighter, a token on a dog's collar or a sign on the gate. Electrochemical engraving on metal is not difficult, the finished pattern can only be cleaned off by grinding, and no special skills or items are required to work. You can start with a knife or spoon that you have at home.

In order to make an engraving on a kitchen knife or mark a personalized spoon of one of the family members, you can use several options. But you will definitely need a DC source, which, most often, use an old, unnecessary charger. The engraved surface is thoroughly cleaned and degreased: with alcohol, gasoline or cologne.

In order to make an engraving, you need to leave open only the surface of the drawing or letters, numbers that are intended to be engraved. To do this, use several methods. You can fill the surface with wax and clean () the place for engraving with a wooden stick. In the same way, nail polish is used, but in this case, you need to draw quickly until the varnish has hardened. And finally, you can seal the surface with adhesive tape, in which the future pattern is cut out. Which method to use depends on the type of drawing.

Exposed areas of steel will turn black under the influence of electrochemistry. To create it, you need a circuit, it will use a charger and a light bulb. From

The best gift for a man can be a weapon with a personal engraving. Most men love weapons as devotedly as a woman loves jewelry. Weapon engraving is an easy way to leave a commemorative inscription or ornament on any material such as wood, metal, plastic, etc.

Sabers, knives, daggers and daggers with engraving will make them a more attractive and desirable gift for any man. Engraving on edged weapons is a unique way to make a present truly elite and exclusive, it is an opportunity to make a gifted weapon a high quality souvenir. Such a gift indicates a special attitude towards the person to whom it is intended.

An engraved knife is a great keepsake!

Engraving is carried out in order to give special significance, it will help to emphasize your special attitude towards the one for whom the gift is intended. Engraving capabilities allow you to put on knives and other inscriptions and ornaments according to the templates and sketches of the customer.

It is possible to apply manual artistic or mechanical diamond engraving of your choice. The inscription created by engraving is not subject to erasure and is distinguished by clarity and accuracy of execution. A combat or decorative engraved knife will be an excellent decoration for any interior or a special “highlight” in the collection of connoisseurs. A less embossed engraving is suitable for a knife that is supposed to be used. Engraving will make any thing individual and emphasize its beauty, add sophistication, the product will become unique and unrepeatable.

What to engrave?

Emblems of various branches of the military, government organizations (FSB, FSO, Airborne Forces, etc.).

Mottoes (may complement the emblem, for example "No one but us").

Wishes, parting words.

Significant dates.

Winged phrases.

Company logos (if it is a corporate gift).

Just interesting patterns decorating the blade and handle.

You can choose not only the inscription ...

An inscription or image can be applied to various places of edged weapons:

On the blade. The engraving on the knife blade looks especially impressive. At the same time, it does not impair the quality of the blade, does not lead to its corrosion, loss of strength. If the butt of the knife is thick enough, then the pattern can be applied to it.

On the handle. You can engrave on the handle of a knife from any material. Our machine can process plastic, metal, wood, leather (including shark), etc.

Drawing a picture on with a laser allows you to get a very clear image of black on the blade. The color of the inscription on the handles will depend on the material from which it is made, but, as a rule, it is darker than the surrounding background. The picture does not fade, is not erased.

5 examples of chic engraving

Technique: Engraving, chasing, engraving, oxidation.

Materials: Damascus, yellow metal, white metal, walnut, marble, case covered with leather.

The master about his work: “An office knife on a stand can be used as a convenient functional item, while being a product of cultural and artistic value. The knife consists of three parts. This is a Damascus blade, turning into a guard, a walnut insert and a white metal handle. On the blade on both sides a bear is depicted in different angles. The plot is united by intertwining tree branches passing from the butt to the side parts of the blade. On the left side of the handle, we see a deer, frightened by a hungry beast, and on the right side, a deer is attentively listening to the sounds of the forest. The knife is decorated with elements of Russian ornament.

Hunting knife "Duck hunting" in sheath (1997).

Materials: Damascus steel, steel, cupronickel, walnut.

More delusional than the other senses. If you look at the knife traditionally, you can see only a cabinet knife on a stand, but try to look from the other side and you will see the skull of a prehistoric animal, where the lower jaw is a stand, and the upper jaw and the skull itself is a knife handle. You will see the eye sockets of the animal burning with fire. Knife "Artifact" (2011)

Technique: Engraving, embossing, electroplating, woodcarving.

Materials: Damascus, white metal, yellow metal, gilding, restored Karelian birch, African ebony, pearls, granite, leather-covered case.

The master about his work: “Creating this work, I wanted to play on the illusions of perception. Sometimes our senses let us down, as if deceiving us. Vision o, a ring is inserted into the nasal cavity, the front fangs act as a guard. A dragon is depicted on the right side of the blade. The left side has a pronounced Damascus steel structure. The warmth of wood is concisely combined with the cold mother-of-pearl of marble.”

Knife on a stand "Pre-Ice Age" (2008).

Materials: Damascus, white metal, mammoth bone, petrified wood of the preglacial period found near Nizhny Novgorod, blackwood, ebony, sipo.

Technique: Forging, engraving, cutting, chasing, oxidation.

A pair of hunting knives in a sheath (1995).

Materials: Damascus steel, cupronickel, walnut.

Technique: Forging, engraving, chasing, carving, oxidation.

Laser engraving - what is it?

There is laser engraving and laser marking. Both of these methods are in high demand. The reason for the popularity is simple - laser marking on weapons looks great. It has a noble black color and excellent detail. Laser engraving is a method of applying an image to any product (including a knife) using a focused laser beam. As a rule, this image has some depth (relief), and this is the main difference between laser engraving and laser marking.

Using a laser allows you to put on the knife not only text in various fonts in any language, but also images / logos - which is very much in demand for corporate clients.

Engraving can be done on most knives. Therefore, feel free to choose any knife with specific performance characteristics and a specific purpose. Adding engraving to the blade does not take much time, and if you do not know what to choose, then our online consultant will always help you. And do not forget, when ordering a knife in the Rognar store from 5000 rubles, engraving is a gift!

- Share with friends

How to make a drawing on a knife at home. How to draw on a knife. For starters, you need to have an idea! It is necessary to decide what exactly to poison on the blade - i.e. take into account its style, for example - an oriental ornament, the theme of hunting ... Then we look for suitable sketches on the net (however, you can come up with it yourself).

Further, as a person living in the 21st century, I corny stuff the blade into the scanner, and drag the image into CorelDraw, where I outline the contours of the blade (by the way, I design the handles the same way), apply a suitable ornament (or put it next to it), and, on it I draw my own basis.

You can, of course, “lick off” the finished one, but if you have to adjust the blade for it, it will not be entirely fair, and interest is lost.

After suffering with drawing and placing in the figure, I duplicate it in mirror image, and the result is printed.

During the development of the sketch on the blade, the varnish was drying ...

I use TESTORS polish. This is a varnish for plastic models-copies. Almost any store that sells models has it. I take a matte one, dilute it with a nitro thinner (to dry faster) and apply it with an airbrush, but you can also use a brush. The varnish is good because it retains plasticity during the day, and does not “crumble” under the scrubber.

The next task is to transfer the pattern to the blade. I do it this way - I cut out a sketch so that it is more convenient to fit it to the blade, I blacken the reverse side with a pencil, I fix it on the blade with masking tape

after which I translate and draw with a thin pen. As a result, we have a drawing on the varnish

To do this, I made several scrubbers (as they are, it turns out, "scientifically" called), with different sharpening. The metal must not be harder than the metal of the blade! For scratches are possible. There is one more nuance here - the drawing is possible of two types - the “field” is etched, as in this option, it is, IMHO, more complicated (it is more difficult to scratch the drawing), and - the drawing itself is etched

Well, like everything is ready - scratched!

Getting the unit ready!

I'm using a variable transformer from a Pico toy railroad. Ancient, and the main purpose is an adapter for a mini-drill, it is smaller and not as resourceful as the Drimel (which is also in the arsenal), but is indispensable for “fine” work. Max.voltage - 12 volts, this, IMHO, is enough! Schematic diagram of the unit -

So, they put a cloth on the plate, and soaked it all in a strong saline solution, do not spare the salt! And we begin to poison - with short touches, you should not hold it for a long time, because you can overheat the varnish.

What is good about this method, in contrast to etching in the vessel of the blade "whole" - it is easier to control the process. We went through the drawing several times (I recommend that you first practice on the “cats”, because ruining the blade ... is more offensive, and more expensive) and when we see what looks like readiness, we chop off the unit and wipe the blade with a solvent.

Well, that's all.

Artistic electrochemical metal etching- one of the methods for applying a pattern to metal products (amulets, knives, blades, etc.), compared to engraving, it is less painstaking and takes less time. In this article, you will learn how to decorate the blade of a knife.

Step 1

Let's start by creating a sketch, which we will transfer to the knife blade. You can choose any theme of the sketch - see what other blades have, come up with your own, transfer some drawing, etc. - it all depends on your fantasy and imagination.

After you have chosen a pattern, you need to transfer it to the blade. To do this, place the knife blade in the scanner, scan and open the scanned image in a graphical editor, outline the outlines of the blade; apply the selected pattern, image and edit it. The resulting sketch should be duplicated in a mirror image and printed.

Step 2

Take a knife blade and cover it with varnish, the varnish can be diluted with a nitro thinner, so the varnish dries faster and apply to the blade with an airbrush or brush. We use varnish, because. it retains plasticity during the day and does not crumble.

We cut out the sketch to make it easier to fit it to the blade, "blacken" the back side with a pencil and attach it to the blade with masking tape.

Step 3

We scratch the pattern on the surface of the varnish with the help of scrubbers with different sharpening. Important: do not damage the blade with a scrubber, otherwise it will be scratched.

Step 4

As a power source, you can use a variable transformer, for example, from a toy railway (maximum voltage - 12V). Heat-shrinkable cambric serves as insulation. Flannel: copper/brass plate - approx 100/7mm.

Metal etching begins with the fact that we put the fabric on the plate and soak it all in saline. After that, we begin to poison - with a quick touch, you should not hold it for a long time, because. varnish may overheat. When the drawing has a finished look, turn off the machine and wipe the blade with a solvent.

This method of metal etching is good because it is easier to control the process, unlike etching in the vessel as a whole, it is enough to go over the drawing several times.